Numerical calculation and experimental test of heat radiation⁃ convection coupling heat transfer characteristics of turbine casing

-

摘要:

开展了整环机匣的热辐射⁃对流耦合计算,获得了综合传热系数拟合关系式,并进行了实验测试验证。研究发现:封闭腔内,热辐射的存在大幅强化了壁面换热,辐射热流占总换热量比值可达90%以上。在3层机匣结构中,当发射率在0.3~0.8变化时,机匣沿径向方向上的温度梯度减小,主流区域的对流换热得到加强,半封闭区域对流强度降低。发射率为0.8时,外机匣流体侧壁面的辐射热流占总换热量的33.3%。

Abstract:The heat radiation⁃convection coupling calculation of the entire ring casing was carried out,the comprehensive heat transfer coefficient fitting relationship was obtained,and the experimental test was verified.The study found that the existence of heat radiation in the enclosed cavity greatly strengthened the wall heat transfer.The ratio of radiant heat flow to the total heat transfer can reach more than 90%.In the three⁃layer receiver structure,when the emissivity changed from 0.3 to 0.8,the temperature gradient in the radial direction of the receiver decreased,the convective heat transfer in the mainstream area was strengthened,and the convective intensity in the semi⁃enclosed area decreased.When the emissivity was 0.8,the radiant heat flow on the fluid sidewall of the outer casing accounted for 33.3% of the total heat transfer.

-

Key words:

- turbine casing /

- casing experiment /

- natural convection /

- fluid⁃solid coupling /

- radiation heat transfer

-

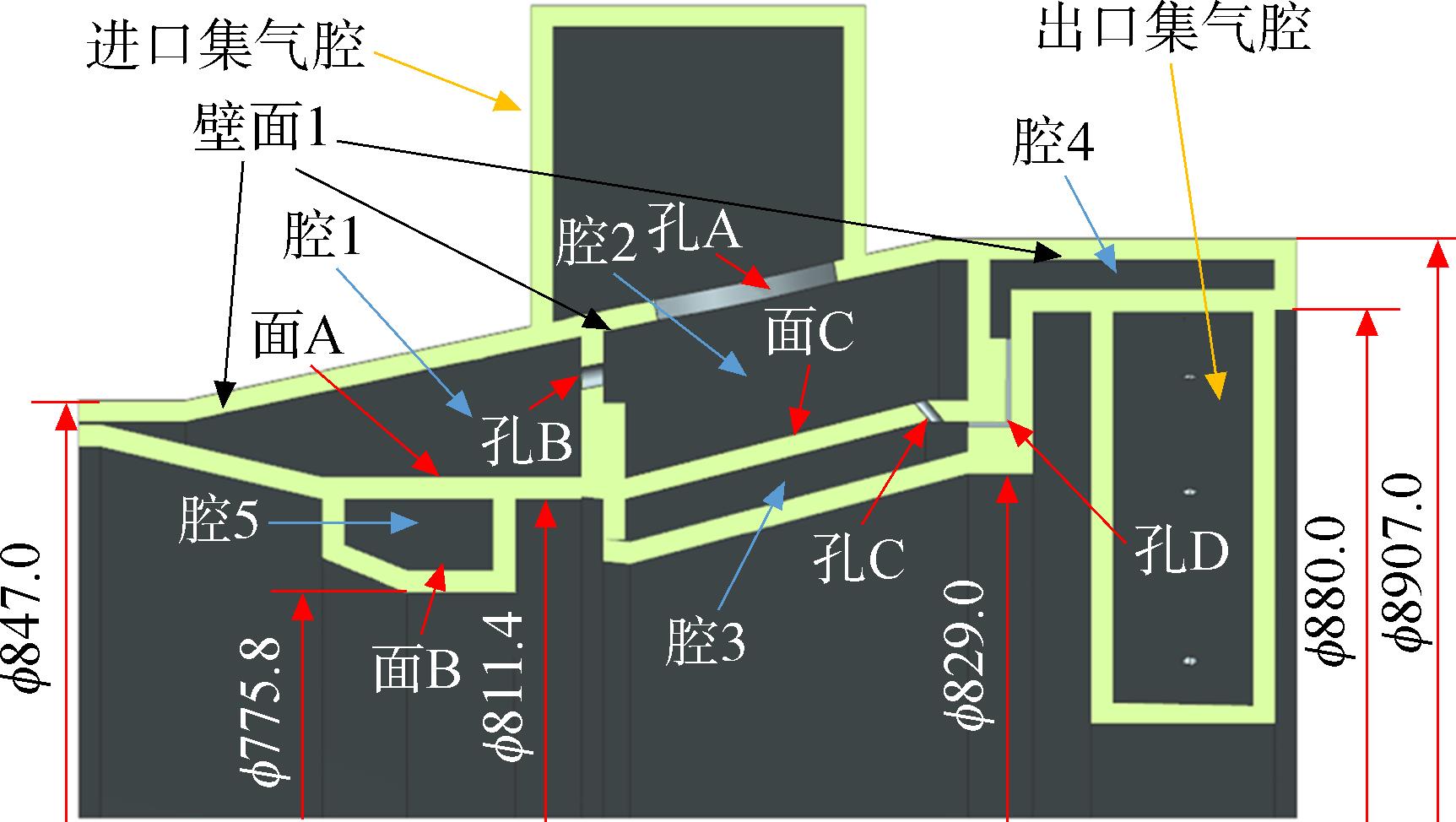

表 1 机匣内部通孔尺寸

Table 1. Through hole size inside the casing

孔道名称 尺寸/mm 个数 孔A 34(直径) 10 孔B 4(直径) 20 孔C (直径) 20 孔D 7 1(长×宽) 20 表 2 实验测量工况

Table 2. Experimental measurement condition

工况编号 进口流量/(kg/s) 内壁面加热温度/K 进口平均温度/K 1 0.07 600 285.7 2 0.07 700 287.4 3 0.1 600 285.6 4 0.1 700 287.8 表 3 不确定度分量汇总表

Table 3. Summary of uncertainty components

不确定度 不确定度来源 不确定度评定方式 标准不确定度/K 标准不确定度 热电偶 B类 数据采集系统 B类 合成不确定度 表 4 强迫对流区域的相关参数随发射率的变化

Table 4. Variation of relative parameters with emissivity in the forced convection region

发射率 /( ) ) 0.3 619.0 478.4 2 976.6 21.2 0.4 621.8 483.7 3 055.8 22.1 0.5 624.8 489.4 3 141.0 23.2 0.6 627.7 495.1 3 225.8 24.3 0.7 631.0 501.2 3 317.8 25.6 0.8 634.4 507.5 3 413.1 26.9 -

[1] 曾军,王鹏飞.民用航空发动机涡轮叶尖间隙主动控制技术分析[J].航空科学技术,2012(2):1⁃6.ZENG Jun,WANG Pengfei.Analysis of active control technology of turbine tip clearance of civil aviation engine[J].Aeronautical Science and Technology,2012(2):1⁃6.(in Chinese) [2] 胡嘉麟,高金海,柳光,等.基于主动间隙控制系统的高压涡轮机匣试验[J].推进技术,2018,39(4):740⁃750.HU Jialin,GAO Jinhai,LIU Guang,et al.High⁃pressure turbine casing test based on active clearance control system[J].Journal of Propulsion Technology,2018,39(4):740⁃750.(in Chinese) [3] COLLINS M,CHANA K,POVEY T.Application of film cooling to an unshrouded high‑pressure turbine casing[J].Journal of Turbomachinery,2017,139(6):61010.1⁃61010.12. [4] 张书华,张丽,朱惠人,等.涡轮机匣换热实验[J].航空动力学报,2011,26(5):1011⁃1016.ZHANG Shuhua,ZHANG Li,ZHU Huiren,et al.Heat transfer experiment of turbine casing[J].Journal of Aerospace Power,2011,26(5):1011⁃1016.(in Chinese) [5] STORZ J,MCKERCHER D G.International developments in heat transfer[M].New York:American Society of Mechanical Engineers,1962:454⁃460. [6] 单文娟,毛军逵,李毅,等.斜向冲击强化换热特性试验[J].航空动力学报,2013,28(3):701⁃708.SHAN Wenjuan,MAO Junkui,LI Yi,et al.Experimental study on enhanced heat transfer characteristics of oblique impact[J].Journal of Aerospace Power,2013,28(3):701⁃708.(in Chinese) [7] 许全宏,林宇震,刘高恩.封闭空间内单孔冲击局部换热特性研究[J].航空动力学报,2002,17(3):341⁃343.XU Quanhong,LIN Yuzhen,LIU Gaoen.Research on local heat transfer characteristics of single hole impact in enclosed space[J].Journal of Aerospace Power,2002,17(3):341⁃343.(in Chinese) [8] O'DONOVAN T S,MURRAY D B.Fluctuating fluid flow and heat transfer of an obliquely impinging air jet[J].International Journal of heat and mass transfer,2008,51(25/26):6169⁃6179. [9] KOSEOGLU M F,BASKAYA S.The role of jet inlet geometry in impinging jet heat transfer,modeling and experiments[J].International Journal of Thermal Sciences,2010,49(8):1417⁃1426. [10] XING Y,SPRING S,WEIGAND B.Experimental and numerical investigation of heat transfer characteristics of inline and staggered arrays of impinging jets[J].Journal of Heat Transfer,2010,132(9):092201.1⁃092201.11. [11] WANG X L,MOTALA D,LU T J,et al.Heat transfer of a circular impinging jet on a circular cylinder in crossflow[J].International Journal of Thermal Sciences,2014,78:1⁃8. [12] 毛军逵,刘震雄,郭文.小间距冲击凹柱面靶板换热特性实验[J].推进技术,2008,29(2):143⁃148.MAO Junkui,LIU Zhenxiong,GUO Wen.Experiments on heat transfer characteristics of small pitch impact concave cylindrical target plate[J].Journal of Propulsion Technology,2008,29(2):143⁃148.(in Chinese) [13] 刘维.涡轮机匣换热实验与流固耦合数值研究[D].辽宁 大连:大连理工大学,2015.LIU Wei.Experiment of turbine casing heat exchange and numerical study of fluid⁃structure coupling[D].Dalian,Liaoning:Dalian University of Technology,2015.(in Chinese) [14] 刘军涛,杨毅成,李承阳,等.涡轮机匣动力段流道流动换热特性与影响参数研究[R].南京:第5届空天动力联合会议暨中国航天第三专业信息网第 41 届技术交流会,2020. [15] BALLAND M,VERSEUX O,ESTEVE M.Aero⁃thermal computations with experimental comparison applied to aircraft engine nacelle compartment[R].Reno,US:Turbo Expo:Power for Land,Sea,and Air,2005. [16] MAO J,YAO T,HAN X,et al.Numerical study of the radiation effect on the jet array impinging heat transfer in a feeding pipe[J].Numerical Heat Transfer:Part A Applications,2018,73(2):125⁃142. [17] TIAN Y S,KARAYIANNIS T G.Low turbulence natural convection in an air filled square cavity:Part Ⅰ the thermal and fluid flow fields[J].International Journal of Heat and Mass Transfer,2000,43(6):849⁃866. [18] TIAN Y S,KARAYIANNIS T G.Low turbulence natural convection in an air filled square cavity:Part Ⅱ the turbulence quantities[J].International Journal of Heat and Mass Transfer,2000,43(6):867⁃884. [19] YUAN X,TAVAKKOLI F,VAFAI K.Analysis of natural convection in horizontal concentric annuli of varying inner shape[J].Numerical Heat Transfer:Part A Applications,2015,68(11):1155⁃1174. [20] SAID B O,MEDEBBER M A,RETIEL N.Effect of surface radiation on free convection in vertical cylinders partially annular[J].Defect and Diffusion Forum,2018,389:36⁃49. [21] 李云单,柴军生,沈毅.航空发动机涡轮机匣表面换热规律研究[R].贵阳:第15届中国科协年会:航空发动机设计、制造与应用技术研讨会,2013. [22] 葛纪全,刘盼盼.热电偶使用方法研究[J].计量与测试技术,2013,40(12):34⁃35.GE Jiquan,LIU Panpan.Research on the use of thermocouple[J].Metrology and Measurement,2013,40(12):34⁃35.(in Chinese) [23] 李杰.涡轮机匣流动换热特性研究[D].南京:南京航空航天大学,2019.LI Jie.Research on flow and heat transfer characteristics of turbine casing[D].Nanjing:Nanjing University of Aeronautics and Astronautics,2019.(in Chinese) [24] COLOMER G,COSTA M,CONSUL R,et al.Three⁃dimensional numerical simulation of convection and radiation in a differentially heated cavity using the discrete ordinates method[J].International Journal of Heat and Mass Transfer,2004,47(2):257⁃269. [25] 胡轶嵩,姜葳,罗发,等.高温氧化对304不锈钢红外发射率影响研究[J].西北工业大学学报,2020,38(1):225⁃229.HU Yisong,JIANG Wei,LUO Fa,et al.Effect of high temperature oxidation on infrared irradiation of stainless steel 304[J].Journal of Northwestern Polytechnical University,2020,38(1):225⁃229.(in Chinese) -

下载:

下载: