Numerical simulations on effect of equivalence ratio on flow field in aluminum power/air rotating detonation engines

-

摘要:

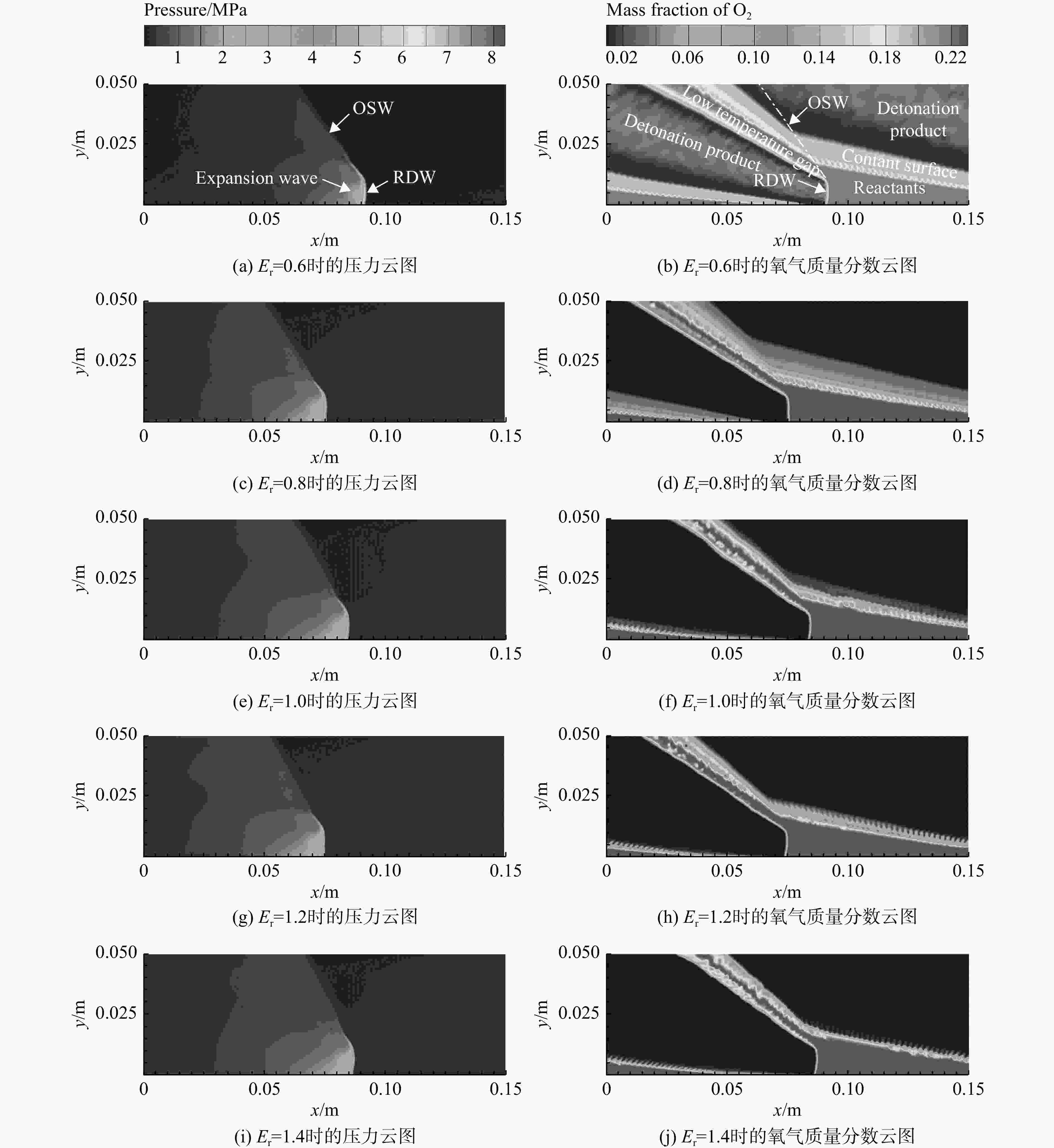

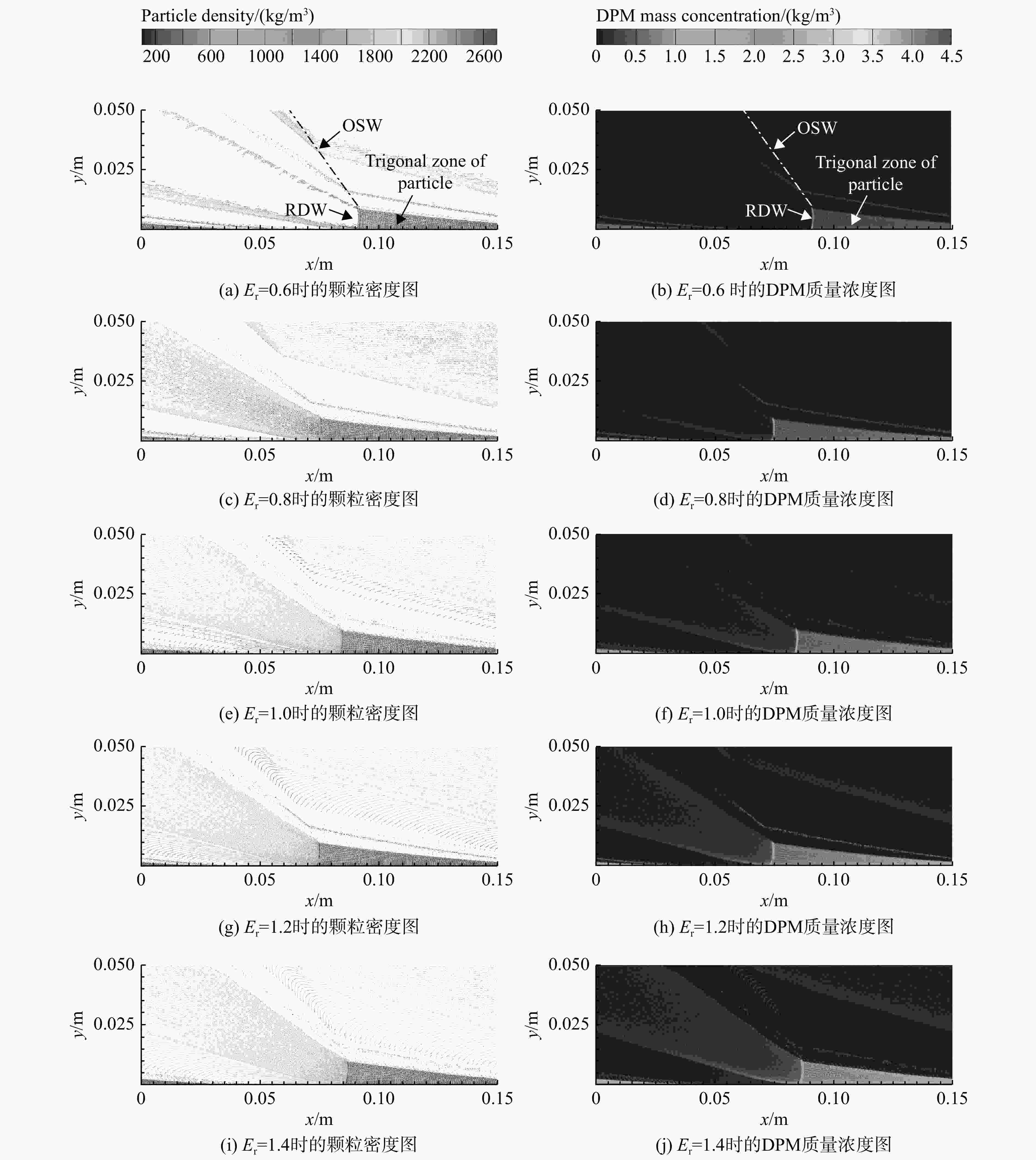

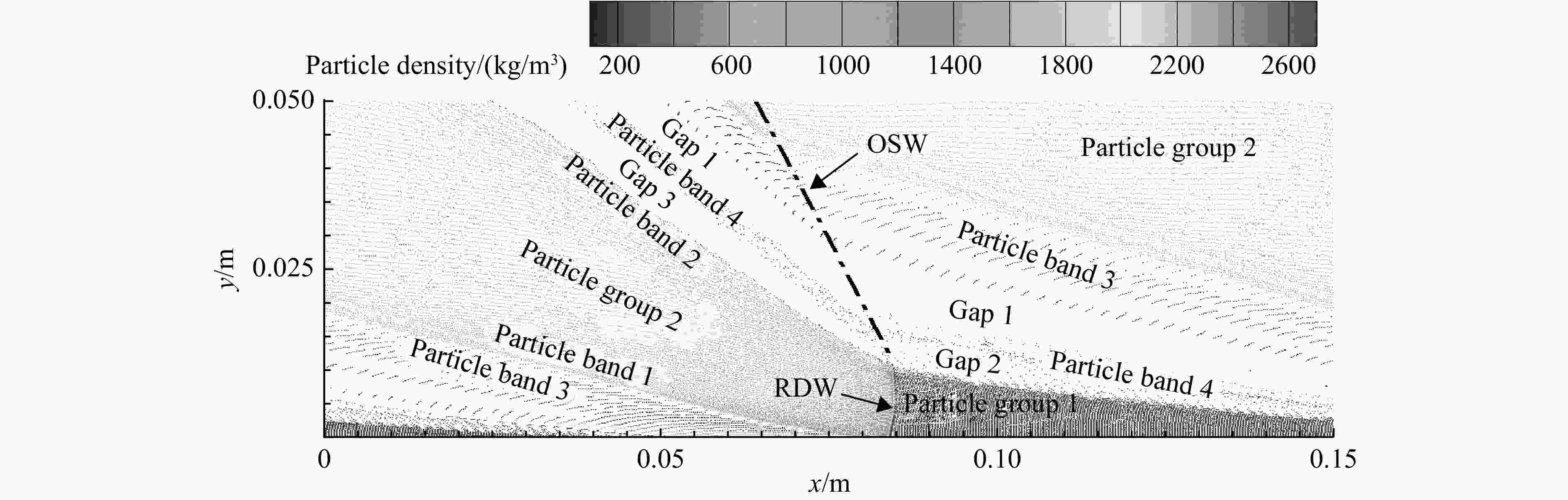

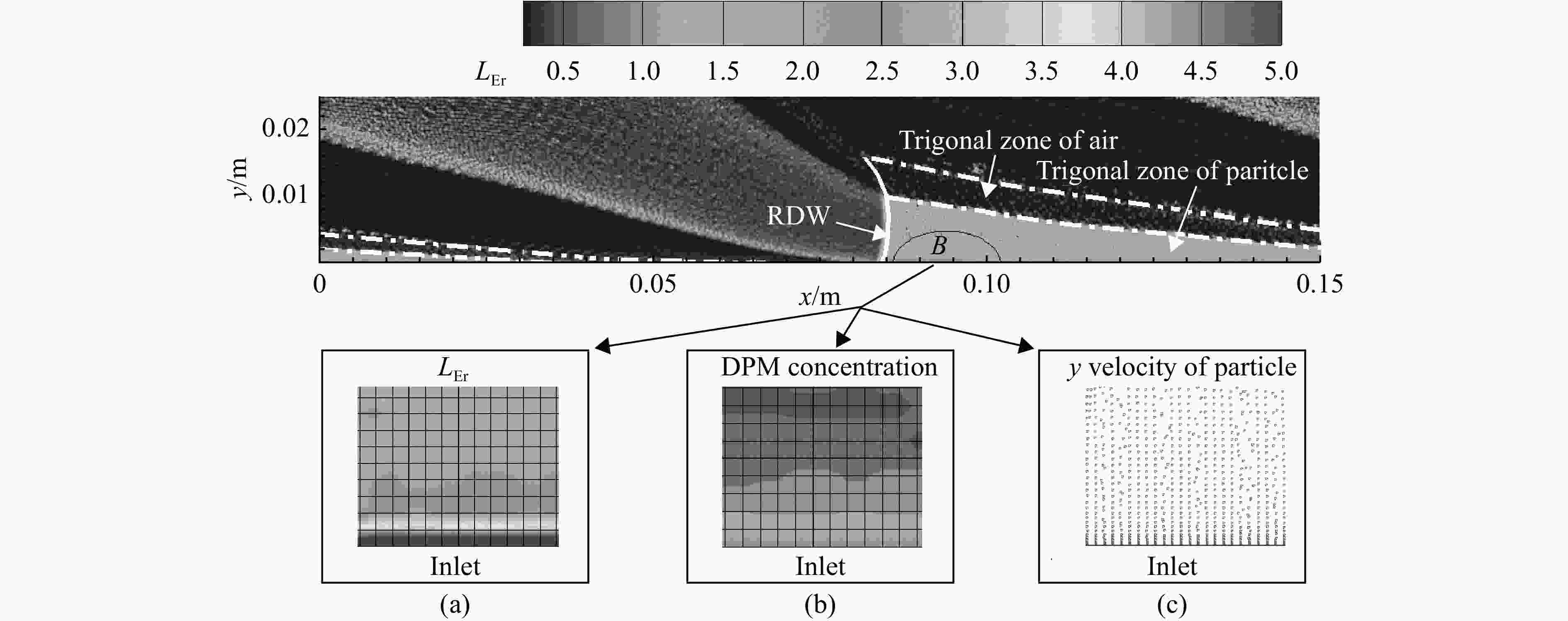

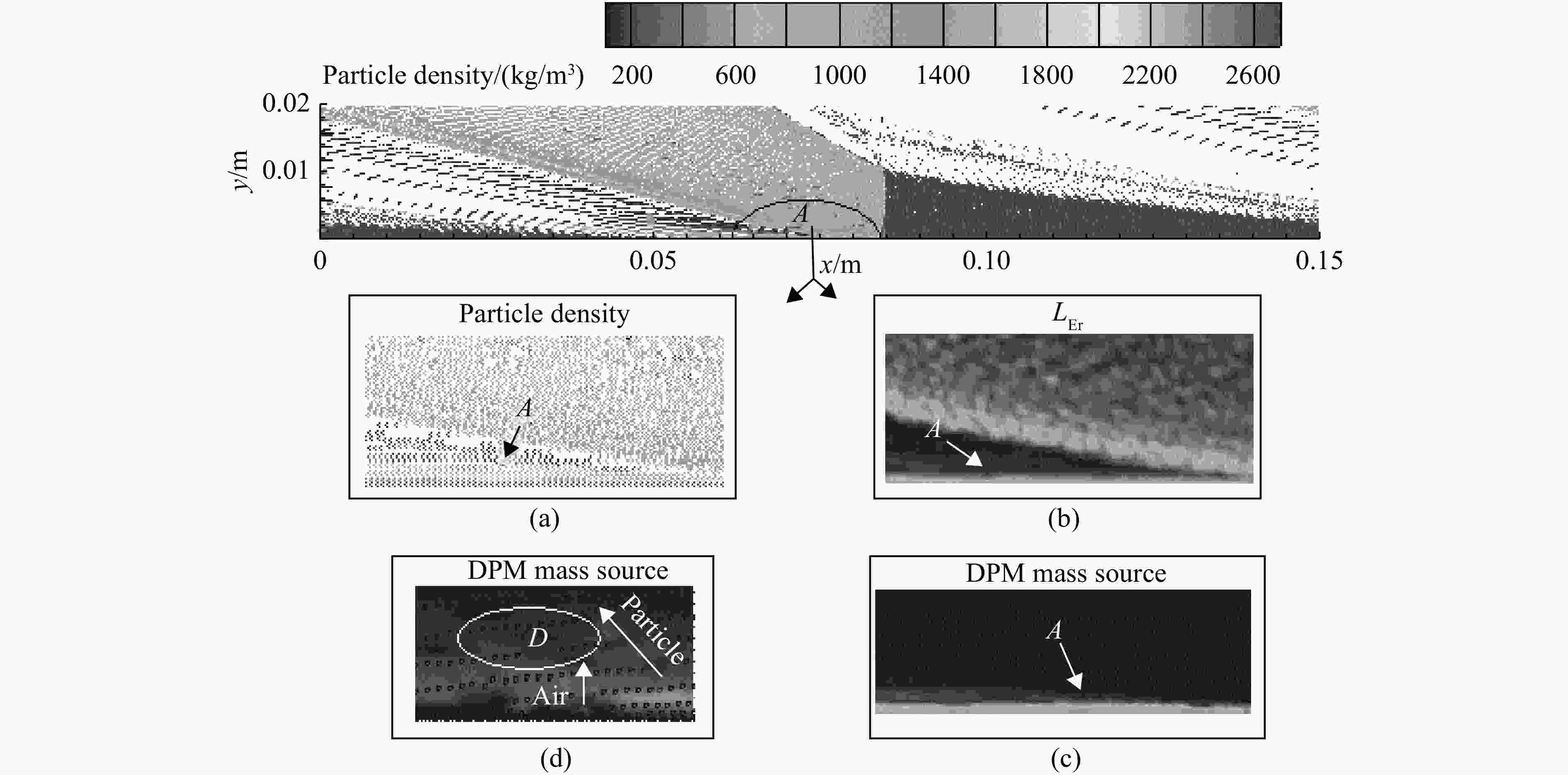

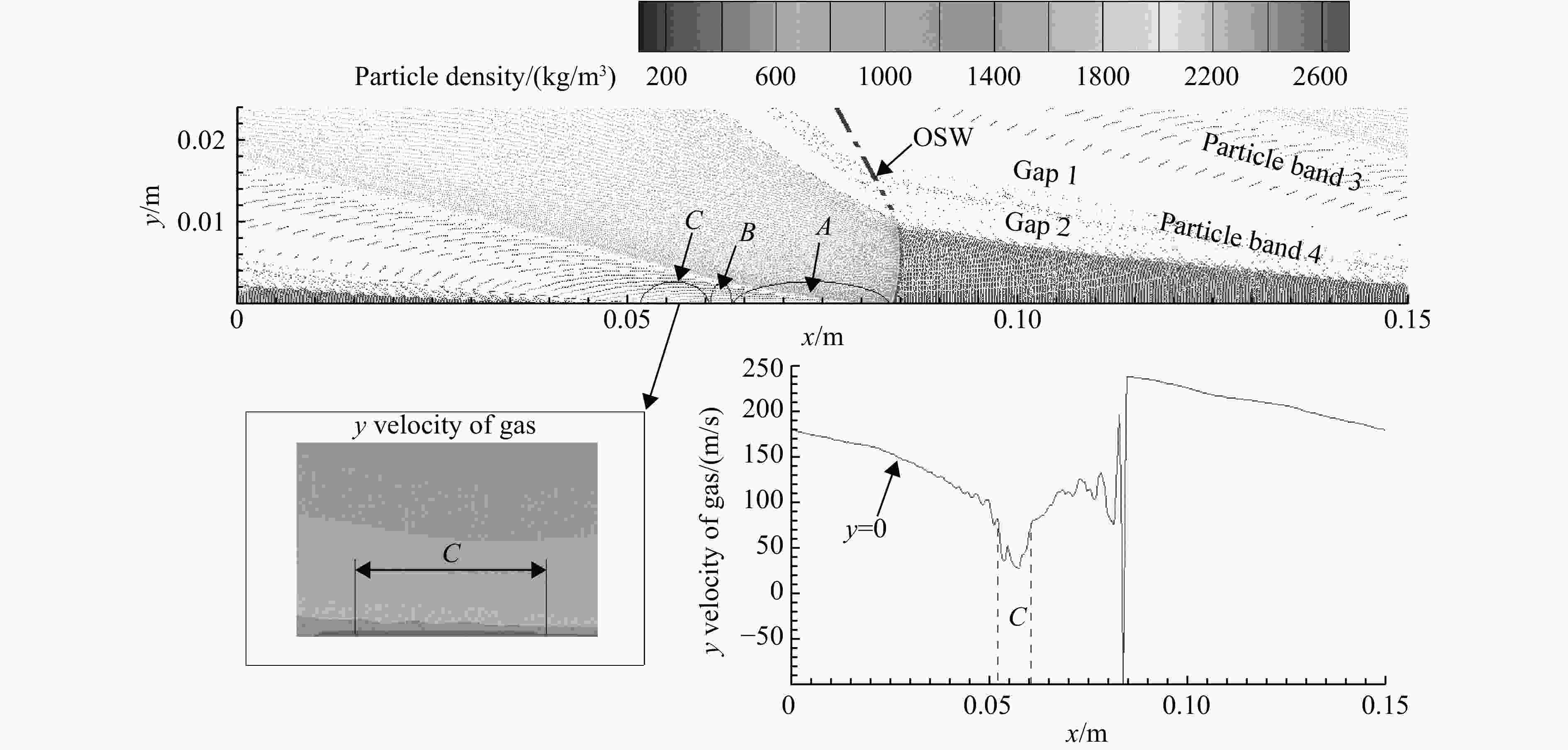

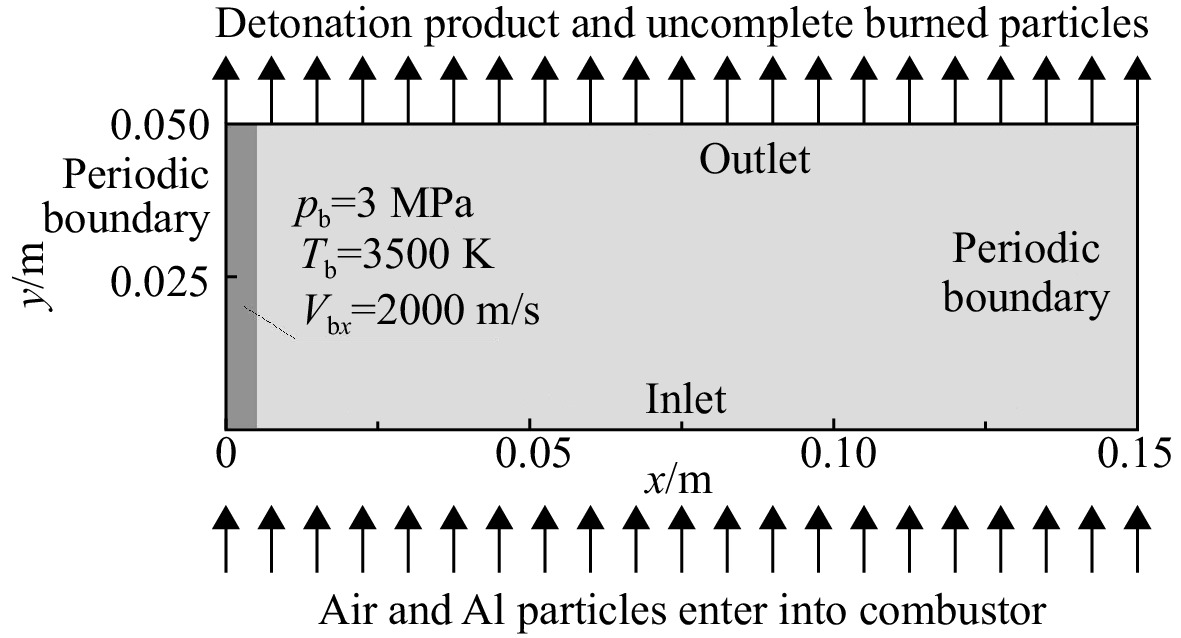

以铝粉为燃料,空气为氧化剂,通过一步反应机理,对不同当量比下气固两相旋转爆轰发动机的流场进行二维数值模拟研究。结果表明:由于颗粒注入速度和空气注入速度存在差异,导致反应物区中的颗粒三角区和空气三角区不完全重叠,使得当量比从0.6增加到1.4时,爆轰波前的平均局部当量比从0.929增加到2.093,爆轰波速度从2070 m/s降低到1690 m/s,爆轰波压力从5.67 MPa降低到4.87 MPa。燃烧室内基本的流场与气相旋转爆轰发动机相似,但气固两相之间的相互作用使得颗粒呈现出特有的分布特性,包括2个颗粒群和4条颗粒带以及它们之间的间隙。

Abstract:The flow field of a gas-solid two-phase rotating detonation engine taking aluminum powder as fuel and air as oxidant with one step reaction was investigated by two-dimensional numerical simulations at different equivalence ratios. Results showed that the velocity of the detonation wave decreased from 2070 m/s to 1690 m/s and detonation pressure decreased from 5.67 MPa to 4.87 MPa when the equivalence ratio increased from 0.6 to 1.4, because the average local equivalence ratio increased from 0.929 to 2.093, which was caused by incomplete overlapping of trigonal zones between air and particles because of the injection velocity difference between air and particles. The flow field was similar to that in gas phase rotating detonation engines. However, unique distribution characteristics, including two particle groups, four particle bands and gaps among them due to the interaction between gas phase and solid phase, were obtained.

-

表 1 不同当量比下的铝颗粒的质量流量

Table 1. Mass flow rate of aluminum particle at different equivalence ratios

当量比 铝颗粒质量流量/(kg/s) 0.6 7.86 0.8 10.49 1.0 13.11 1.2 15.73 1.4 18.35 计算参数 数值 铝的密度/(kg/m3) 2719 铝的燃烧热/107 (J/kg) 3.1 铝的比定压热容/(J/(kg·K)) 871 表面反应指前因子/(kg/(m2·s)) 200 表面反应活化能/107 (J/kmol) 9.55 有限速率质量扩散常数/10−12 (kg/(m2·s·Pa)) 5.0 表 3 Er=1.0时不同网格尺寸下的爆轰波参数

Table 3. Parameters of RDW for different cell sizes at Er=1.0

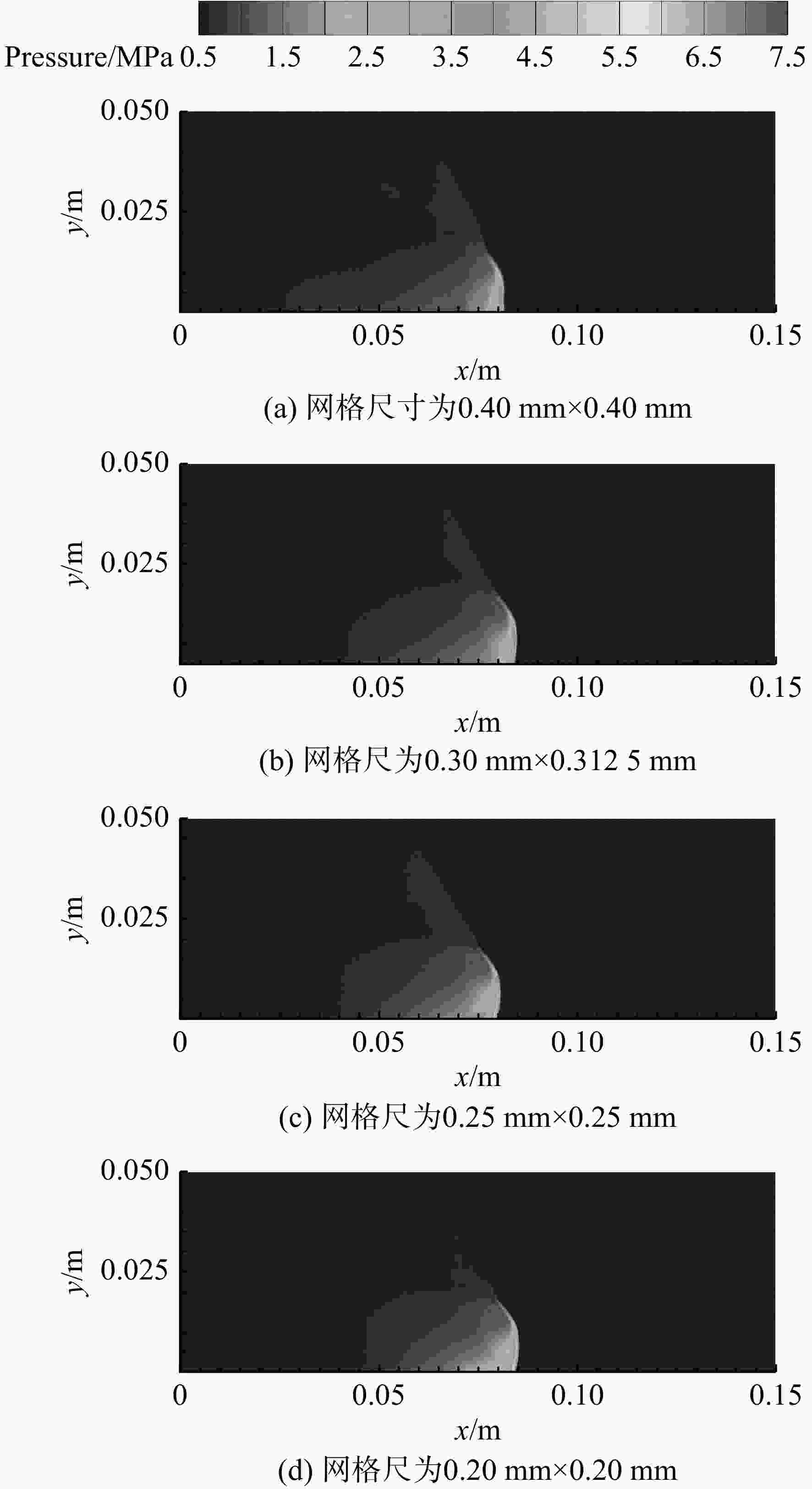

网格尺寸/

mm网格数量 爆轰波速度/

(m/s)爆轰波高度/

mm0.40×0.40 46875 1710 8.1 0.30×0.3125 80000 1760 9.5 0.25×0.25 120000 1790 9.8 0.20×0.20 187500 1 810 10.2 表 4 不同当量比下的爆轰波参数

Table 4. Parameters of RDW at different equivalence ratios

Er ALEr 爆轰波压力/

MPa爆轰波速度/

(m/s)爆轰波高度/

mm0.6 0.929 5.67 2060 9.3 0.8 1.196 5.37 1 900 9.8 1.0 1.510 5.03 1 810 10.2 1.2 1.793 5.02 1740 10.0 1.4 2.093 4.87 1690 10.1 表 5 不同当量比下颗粒三角区和空气三角区下游边界的斜率

Table 5. Slope of downstream boundary for trigonal zone of air and particle at different equivalence ratios

Er 0.6 0.8 1.0 1.2 1.4 tan $\alpha $ 0.113 0.113 0.105 0.109 0.115 tan $\beta $ 0.156 0.155 0.169 0.167 0.173 -

[1] FALEMPIN F,LE NAOUR B. R&T effort on pulsed and continuous detonation wave engines[R]. AIAA 2009-7284,2009. [2] 王兵,谢峤峰,闻浩诚,等. 爆震发动机研究进展[J]. 推进技术,2021,42(4): 721-737,716. WANG Bing,XIE Qiaofeng,WEN Haocheng,et al. Research progress of detonation engines[J]. Journal of Propulsion Technology,2021,42(4): 721-737,716. (in ChineseWANG Bing, XIE Qiaofeng, WEN Haocheng, et al. Research progress of detonation engines[J]. Journal of Propulsion Technology, 2021, 42(4): 721-737, 716. (in Chinese) [3] VOITSEKHOVSKII B V. Stationary spin detonation[J]. Journal of Applied Mechanics and Technical Physics,1960,3: 157-164. [4] FOTIA M,KAEMMING T A,HOKE J,et al. Study of the experimental performance of a rotating detonation engine with nozzled exhaust flow[R]. AIAA 2015-0631,2015. [5] FOTIA M,SCHAUER F,HOKE J. Experimental study of performance scaling in rotating detonation engines operated on hydrogen and gaseous hydrocarbon fuel[R]. AIAA 2015-3626,2015. [6] SONWANE C,CLAFLIN S,LYNCH E,et al. Recent advances in power cycles using rotating detonation engines with subcritical and supercritical CO2[R]. Pittsburgh,US: The 4th International Symposium-Supercritical CO2 Power Cycles,2014. [7] CLAFLIN S. Recent progress in continuous detonation engine development at pratt & whitney rocketdyne[R]. Tsukuba,Japan: International Workshop on Detonation for Propulsion,2012. [8] ANDERSON W,HEISTER S D,HARTSFIELD C. Experimental study of a hypergolically ignited liquid bipropellant rotating detonation rocket engine[R]. AIAA 2019-0474,2019. [9] ZHU Yiyuan,WANG Ke,WANG Zhicheng,et al. Study on the performance of a rotating detonation chamber with different aerospike nozzles[J]. Aerospace Science and Technology,2020,107: 106338. doi: 10.1016/j.ast.2020.106338 [10] 刘倩,郑洪涛,李智明,等. 连续旋转爆轰燃烧室的性能[J]. 航空动力学报,2015,30(6): 1328-1336. LIU Qian,ZHENG Hongtao,LI Zhiming,et al. Performance of continuously rotating detonation combustor[J]. Journal of Aerospace Power,2015,30(6): 1328-1336. (in ChineseLIU Qian, ZHENG Hongtao, LI Zhiming, et al. Performance of continuously rotating detonation combustor[J]. Journal of Aerospace Power, 2015, 30(6): 1328-1336. (in Chinese) [11] 徐雪阳,卓长飞,武晓松,等. 非预混喷注对旋转爆震发动机影响的数值研究[J]. 航空学报,2016,37(4): 1184-1195. XU Xueyang,ZHUO Changfei,WU Xiaosong,et al. Numerical simulation of injection schemes with separate supply of fuel and oxidizer effects on rotating detonation engine[J]. Acta Aeronautica et Astronautica Sinica,2016,37(4): 1184-1195. (in ChineseXU Xueyang, ZHUO Changfei, WU Xiaosong, et al. Numerical simulation of injection schemes with separate supply of fuel and oxidizer effects on rotating detonation engine[J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(4): 1184-1195. (in Chinese) [12] LIN Wei,ZHOU Jin,LIU Shijie,et al. Experimental study on propagation mode of H2/Air continuously rotating detonation wave[J]. International Journal of Hydrogen Energy,2015,40(4): 1980-1993. doi: 10.1016/j.ijhydene.2014.11.119 [13] FUGGER C A,LOPEZ J G,REIN K D,et al. The dynamics of a non-premixed rotating detonation engine from time-resolved temperature measurements[J]. Proceedings of the Combustion Institute,2021,38(3): 3787-3795. doi: 10.1016/j.proci.2020.06.373 [14] 赵明皓,王可,王致程,等. 燃烧室构型对旋转爆震波传播特性的影响[J]. 航空学报,2022,43(5): 243-254. ZHAO Minghao,WANG Ke,WANG Zhicheng,et al. Effect of combustor configurations on propagation characteristics of rotating detonation waves[J]. Acta Aeronautica et Astronautica Sinica,2022,43(5): 243-254. (in ChineseZHAO Minghao, WANG Ke, WANG Zhicheng, et al. Effect of combustor configurations on propagation characteristics of rotating detonation waves[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(5): 243-254. (in Chinese) [15] WIGGINS R,GAETANO A,PRITSCHAU T,et al. Rotating detonations through hydrogen-air and ethylene-air mixtures in hollow and flow-through combustors[R]. AIAA 2021-0420,2021. [16] YAO Songbai,WANG Jianping. Multiple ignitions and the stability of rotating detonation waves[J]. Applied Thermal Engineering,2016,108: 927-936. doi: 10.1016/j.applthermaleng.2016.07.166 [17] WANG Chao,LIU Weidong,LIU Shijie,et al. Experimental investigation on detonation combustion patterns of hydrogen/vitiated air within annular combustor[J]. Experimental Thermal and Fluid Science,2015,66: 269-278. doi: 10.1016/j.expthermflusci.2015.02.024 [18] WANG Yuhui,WANG Jianping. Rotating detonation instabilities in hydrogen-oxygen mixture[J]. Applied Mechanics and Materials,2015,709: 56-62. [19] ANAND V,ST GEORGE A,DRISCOLL R,et al. Longitudinal pulsed detonation instability in a rotating detonation combustor[J]. Experimental Thermal and Fluid Science,2016,77: 212-225. doi: 10.1016/j.expthermflusci.2016.04.025 [20] HUMBLE J,HEISTER S D. Heterogeneous detonation physics as applied to high pressure rotating detonation engines[R]. AIAA 2021-1027,2021. [21] DUNN I B,MALIK V,AHMED K A,et al. Evidence of carbon driven detonation waves within a rotating detonation engine[R]. AIAA 2021-1026,2021. [22] 李宝星,许桂阳,舒慧明,等. 燃烧室轴向和周向长度对气液两相旋转爆轰特性的影响[J]. 航空动力学报,2020,35(8): 1601-1611. LI Baoxing,XU Guiyang,SHU Huiming,et al. Influence of axial and circumferential lengths of combustion chamber on gas-liquid two-phase rotating detonation characteristics[J]. Journal of Aerospace Power,2020,35(8): 1601-1611. (in ChineseLI Baoxing, XU Guiyang, SHU Huiming, et al. Influence of axial and circumferential lengths of combustion chamber on gas-liquid two-phase rotating detonation characteristics[J]. Journal of Aerospace Power, 2020, 35(8): 1601-1611. (in Chinese) [23] BRZUSTOWSKI T A,GLASSMAN I. Spectroscopic investigation of metal combustion[J]. Heterogeneous Combustion,1964,15: 41-73. [24] BECKSTEAD M W. A summary of aluminum combustion[R]. Rhode-Saint-Genèse,Belgium: Internal Aerodynamics in Solid Rocket Propulsion,2002. [25] BECKSTEAD M W,LIANG Y,PUDDUPPAKKAM K V. Numerical simulation of single aluminum particle combustion (review)[J]. Combustion,Explosion and Shock Waves,2005,41(6): 622-638. doi: 10.1007/s10573-005-0077-0 [26] BAZYN T,KRIER H,GLUMAC N. Evidence for the transition from the diffusion-limit in aluminum particle combustion[J]. Proceedings of the Combustion Institute,2007,31(2): 2021-2028. doi: 10.1016/j.proci.2006.07.161 [27] HISHIDA M,FUJIWARA T,WOLANSKI P. Fundamentals of rotating detonations[J]. Shock Waves,2009,19(1): 1-10. doi: 10.1007/s00193-008-0178-2 [28] WANG Yuhui. Rotating detonation in a combustor of trapezoidal cross section for the hydrogen-air mixture[J]. International Journal of Hydrogen Energy,2016,41(12): 5605-5616. doi: 10.1016/j.ijhydene.2016.02.028 [29] ZHANG Fan,GERRARD K,RIPLEY R C. Reaction mechanism of aluminum-particle-air detonation[J]. Journal of Propulsion and Power,2009,25(4): 845-858. doi: 10.2514/1.41707 [30] BAUM M M,STREET P J. Predicting the combustion behaviour of coal particles[J]. Combustion Science and Technology,1971,3(5): 231-243. doi: 10.1080/00102207108952290 [31] HOSODA H,HAYASHI A K,YAMADA E. Numerical analysis on combustion characteristics of nano aluiminum particle-oxygen two-phase detonation[J]. Science and Technology of Energetic Materials,2013,74(1/2): 34-40. [32] TENG Honghui,JIANG Zonglin. Effects of different product phases in aluminum dust detonation modeling[J]. Science China Physics,Mechanics and Astronomy,2013,56(11): 2178-2185. doi: 10.1007/s11433-013-5268-1 [33] TANGUAY V,GOROSHIN S,HIGGINS A J,et al. Aluminum particle combustion in high-speed detonation products[J]. Combustion Science and Technology,2009,181(4): 670-693. doi: 10.1080/00102200802643430 [34] LYNCH P,KRIER H,GLUMAC N. A correlation for burn time of aluminum particles in the transition regime[J]. Proceedings of the Combustion Institute,2009,32(2): 1887-1893. doi: 10.1016/j.proci.2008.06.205 [35] TAO H. Shock wave ignition of aluminum particles[J]. Journal De Physique Ⅳ (Proceedings),2002,12(7): 105-112. doi: 10.1051/jp4:20020272 [36] SALVADORI M,DUNN I B,SOSA J,et al. Numerical investigation of shock-induced combustion of coal-H2-air mixtures in a unwrapped non-premixed detonation channel[R]. AIAA 2020-2159,2020. -

下载:

下载: