Transient dynamic response analysis of rotor during shutdown after blade loss

-

摘要:

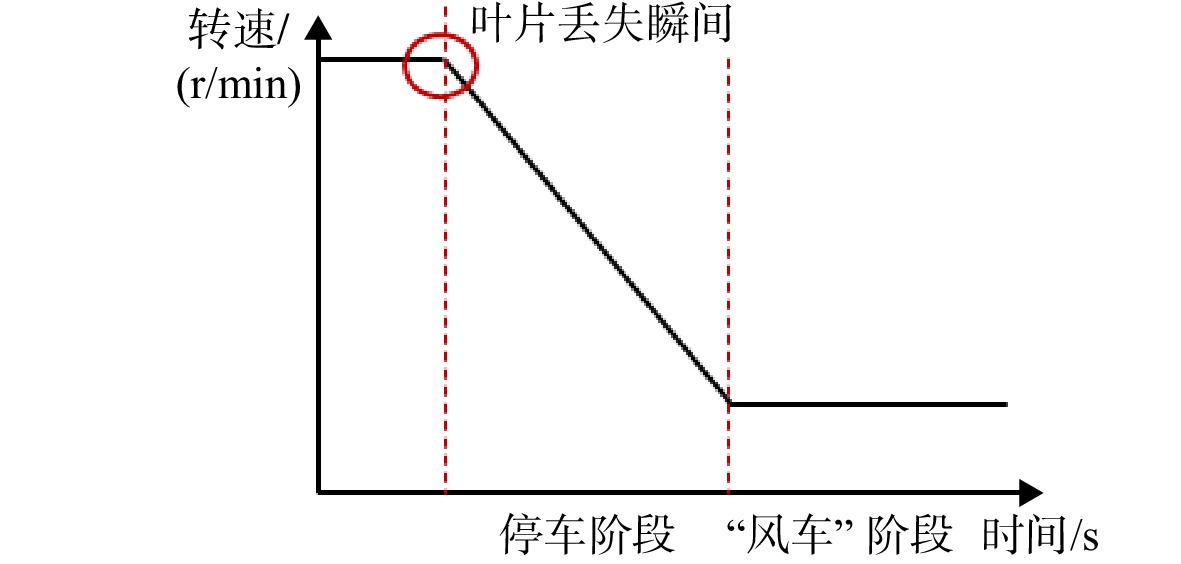

为揭示叶片丢失后转子系统停车过程动力响应特征,研究了叶片丢失后叶盘转动惯量非对称性及停车过程变转速特征,建立了非对称变速转子瞬态动力响应分析模型,对叶片丢失后转子系统停车过程瞬态响应进行了分析。结果表明:叶片丢失瞬间及转子过共振区,转子系统的瞬态振动响应加剧,并伴有横向固有振动。当转动惯量非对称比例为0.2时,转子系统响应峰值与不考虑轮盘非对称性相差58%。因此,对于大质量叶片或多叶片丢失情况,轮盘转动惯量非对称性就不能忽略,表明所建转子动力学模型可以有效分析大非对称转子停车过程复杂振动响应特征。

Abstract:In order to reveal the dynamic response characteristics of the rotor system during shutdown after aero-engine blade loss, considering the blade disk moment of inertia asymmetry and the characteristics of variable speed during shutdown, the transient dynamic response analysis model of asymmetric variable speed rotor was established to analyze the transient response of rotor system during shutdown after blade loss. The results showed that when the blade was lost and the rotor passed through the resonance zone, the transient vibration response of the rotor system was intensified, accompanied by transverse natural vibration. When the asymmetric ratio of moment of inertia was 0.2, the peak response of the rotor system differed by 58% without considering the asymmetry of the disk. Therefore, for the loss of large mass blades or multiple blades, the moment of inertia asymmetry can’t be ignored, showing that the established rotor dynamics model can effectively analyze the complex vibration response characteristics of large asymmetric rotor during shutdown.

-

Key words:

- asymmetric rotor /

- variable speed /

- shock effect /

- blade loss /

- dynamic response

-

表 1 多支撑悬臂转子结构参数

Table 1. Multi-support cantilever rotor structure parameters

参数 数值 叶盘质量(Md)/kg 120 叶盘极转动惯量(Jp)/(kg·m2) 8 轴段长度(l1, l2, l3)/mm 300,300,1400 轴段外径(D1, D2, D3)/mm 160,160,80 轴段内径(d1, d2, d3)/mm 140,140,70 支撑刚度(K1, K2, K3)/107 (N/m) 4,4,4 支撑阻尼(C1, C2, C3)/(N·s/m) 25,25,25 弹性模量E/GPa 210 泊松比μ 0.3 密度ρ/(kg/m3) 7850 阻尼比γ 0.02 不平衡量/(kg·m) 0.01 表 2 不同加速度下转子瞬态响应峰值

Table 2. Transient response peak value of rotor under different accelerations

参数 加速度/(rad/s2) −75 −188 −377 最大响应峰值/mm 1.53 1.24 1 最大响应峰值对应转速/(r/min) 2534 2447 2313 表 3 不同非对称比例下转子瞬态响应结果

Table 3. Transient response results of rotor under different asymmetric ratios

非对称比例 冲击响应峰值/mm 共振响应峰值/mm 0 0.39 1.18 0.05 0.40 1.24 0.1 0.41 1.37 0.2 0.43 1.87 -

[1] COSME N,CHEVROLET D,BONINI J,et al. Prediction of engine loads and damages due to fan blade off event[R]. AIAA-2002-1666,2002. [2] 陈伟,刘璐璐,宣海军,等. 突加高能载荷作用下航空发动机结构动态响应及安全性综述[J]. 推进技术,2020,41(9): 2099-2119. CHEN Wei,LIU Lulu,XUAN Haijun,et al. Review on dynamic response and safety of engine structure under sudden high energy load[J]. Journal of Propulsion Technology,2020,41(9): 2099-2119. (in ChineseCHEN Wei, LIU Lulu, XUAN Haijun, et al. Review on dynamic response and safety of engine structure under sudden high energy load[J]. Journal of Propulsion Technology, 2020, 41(9): 2099-2119. (in Chinese) [3] Federal Aviation Regulations. 14 CFR part 33 airworthiness standards: aircraft engines[S]. Washington DC: Federal Aviation Administration,1993: 81-99. [4] 中国民用航空总局. CCAR-33-R2 航空发动机适航规定[S]. 北京: 中国民用航空总局,2011: 38-78. [5] 马艳红,梁智超,王桂华,等. 航空发动机叶片丢失问题研究综述[J]. 航空动力学报,2016,31(3): 513-526. MA Yanhong,LIANG Zhichao,WANG Guihua,et al. Review on the blade loss of aero-engine[J]. Journal of Aerospace Power,2016,31(3): 513-526. (in ChineseMA Yanhong, LIANG Zhichao, WANG Guihua, et al. Review on the blade loss of aero-engine[J]. Journal of Aerospace Power, 2016, 31(3): 513-526. (in Chinese) [6] YU Pingchao,ZHANG Dayi,MA Yanhong,et al. Dynamic modeling and vibration characteristics analysis of the aero-engine dual-rotor system with Fan blade out[J]. Mechanical Systems and Signal Processing,2018,106: 158-175. doi: 10.1016/j.ymssp.2017.12.012 [7] LAWRENCE C,CARNEY K,GALLARDO V. Simulation of aircraft engine blade-out structural dynamics. revised[R]. NASA/TM2001-210957/REV1,2001. [8] 王宗勇,龚斌,闻邦椿. 质量及激励幅值突变转子系统动力学研究[J]. 振动与冲击,2008,27(8): 48-51,176. WANG Zongyong,GONG Bin,WEN Bangchun. Research on rotor dynamics with sudden change of mass and excitation magnitude[J]. Journal of Vibration and Shock,2008,27(8): 48-51,176. (in ChineseWANG Zongyong, GONG Bin, WEN Bangchun. Research on rotor dynamics with sudden change of mass and excitation magnitude[J]. Journal of Vibration and Shock, 2008, 27(8): 48-51, 176. (in Chinese) [9] KALINOWSKI P,BARGEN O,LIEBICH R. Vibrations of rotating machinery due to sudden mass loss[C]//the 8th IFToMM International Conference on Rotating Machinery. Seoul: IFToMM,2010: 584-590. [10] SINHA S K. Rotordynamic analysis of asymmetric turbofan rotor due to fan blade-loss event with contact-impact rub loads[J]. Journal of Sound and Vibration,2013,332(9): 2253-2283. doi: 10.1016/j.jsv.2012.11.033 [11] 侯理臻,廖明夫,王卫国,等. 叶片飞脱下转子动力学响应实验[J]. 航空动力学报,2019,34(5): 1010-1019. HOU Lizhen,LIAO Mingfu,WANG Weiguo,et al. Experiment of rotor dynamics under fan blade off[J]. Journal of Aerospace Power,2019,34(5): 1010-1019. (in ChineseHOU Lizhen, LIAO Mingfu, WANG Weiguo, et al. Experiment of rotor dynamics under fan blade off[J]. Journal of Aerospace Power, 2019, 34(5): 1010-1019. (in Chinese) [12] WANG Cun,ZHANG Dayi,MA Yanhong,et al. Theoretical and experimental investigation on the sudden unbalance and rub-impact in rotor system caused by blade off[J]. Mechanical Systems and Signal Processing,2016,76/77: 111-135. doi: 10.1016/j.ymssp.2016.02.054 [13] 王美令,温保岗,韩清凯. 弹支-刚性转子系统过共振瞬态响应特性研究[J]. 动力学与控制学报,2018,16(6): 533-538. WANG Meiling,WEN Baogang,HAN Qingkai. Transient response characteristic of a rigid rotor system with flexible supports across resonance[J]. Journal of Dynamics and Control,2018,16(6): 533-538. (in ChineseWANG Meiling, WEN Baogang, HAN Qingkai. Transient response characteristic of a rigid rotor system with flexible supports across resonance[J]. Journal of Dynamics and Control, 2018, 16(6): 533-538. (in Chinese) [14] 李超,刘棣,马艳红,等. 叶片飞失转子动力特性及支承结构安全性设计[J]. 航空动力学报,2020,35(11): 2263-2274. LI Chao,LIU Di,MA Yanhong,et al. Dynamic characteristics of rotor and safety design of support structure with fan blade off[J]. Journal of Aerospace Power,2020,35(11): 2263-2274. (in ChineseLI Chao, LIU Di, MA Yanhong, et al. Dynamic characteristics of rotor and safety design of support structure with fan blade off[J]. Journal of Aerospace Power, 2020, 35(11): 2263-2274. (in Chinese) [15] LIU Di,LI Chao,MA Yanhong,et al. Stability and frequency analysis for inertia asymmetry rotor based on hill method[C]//International Conference on Maintenance Engineering. Cham: Springer,2021: 773-783. [16] WANG Nanfei,LIU Chao,JIANG Dongxiang. Prediction of transient vibration response of dual-rotor-blade-casing system with blade off[J]. Proceedings of the Institution of Mechanical Engineers,Part G: Journal of Aerospace Engineering,2019,233(14): 5164-5176. [17] WENG Y,ZHENG L. An explicit-implicit time integration approach for finite element evaluation of engine load following an FBO event[R]. ASME Paper GT2017-64636,2017. [18] 廖明夫. 航空发动机转子动力学[M]. 西安: 西北工业大学出版社,2015. -

下载:

下载: