Numerical simulation and test of AlN ceramic jet vane

-

摘要:

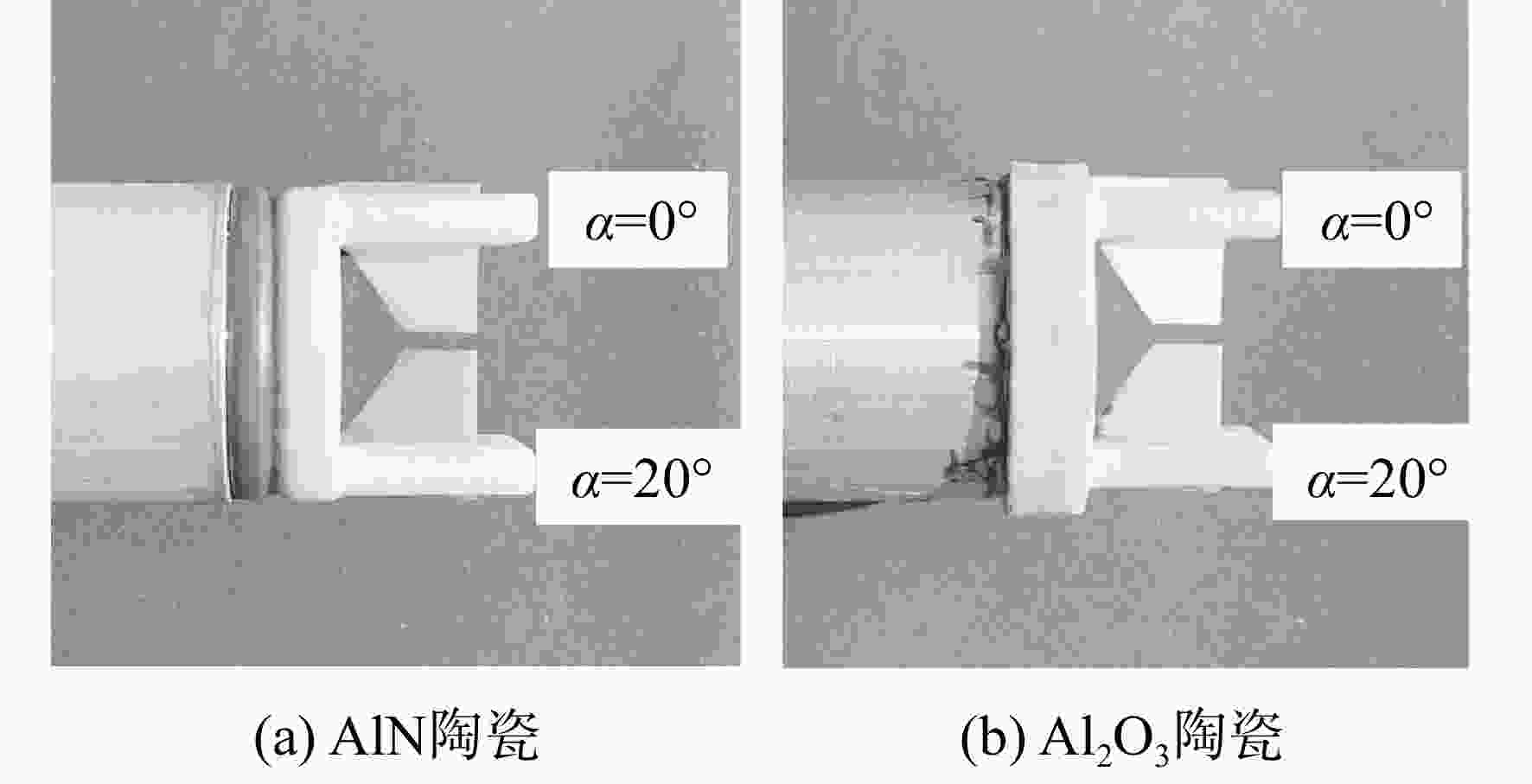

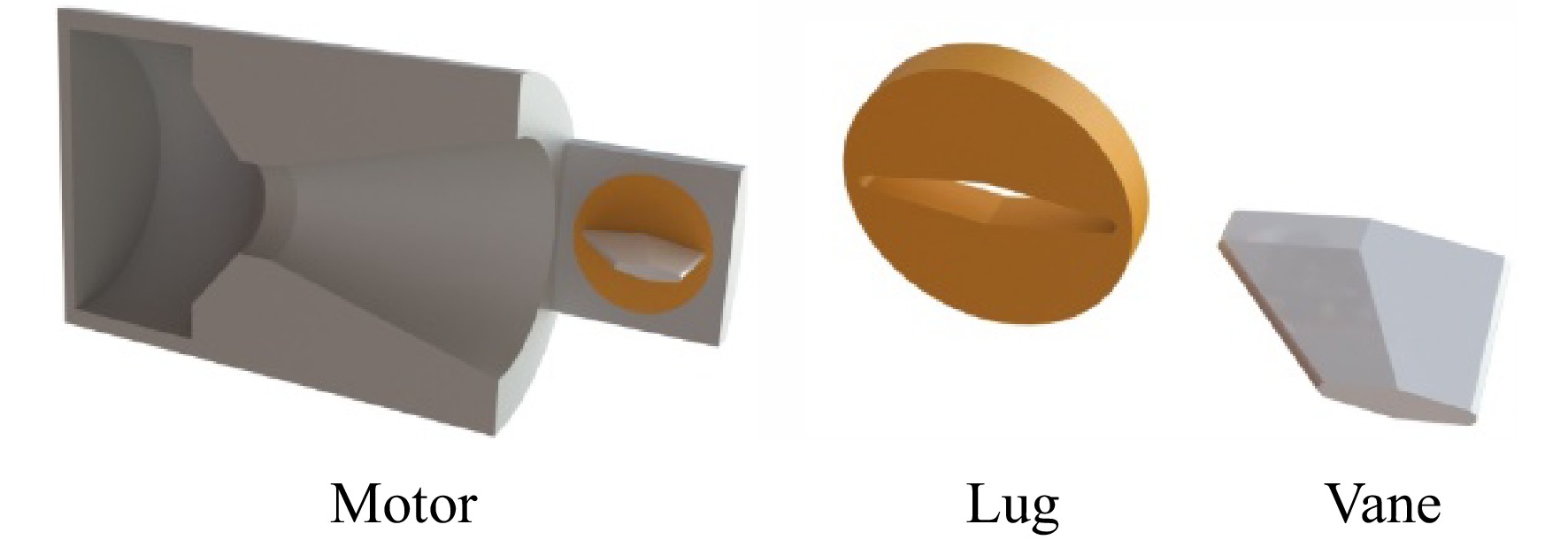

针对弹箭燃气舵轻量化问题,设计了基于高热导率氮化铝(AlN)陶瓷材料的新型燃气舵。为考察其可行性,建立了基于流固热耦合的非定常数值模拟方法,研究了氮化铝陶瓷燃气舵在不同舵偏角下的工作过程,并基于高温下陶瓷强度预测模型分析了燃气舵的抗热震能力。加工了氮化铝陶瓷燃气舵,开展了固体火箭发动机地面静态射流试验,并通过扫描电镜分析了试验结果。研究结果表明:数值仿真与试验结果基本一致,验证了数值模拟方法的有效性;对燃烧室总温为2284 K的固体火箭发动机,氮化铝陶瓷燃气舵可承受其燃气1 s内造成的最大机械冲击和热冲击;氮化铝陶瓷由于较高的热导率(理论达320 W/(m∙K)),有远优于常规结构陶瓷的抗热震性能,是一种良好的小型燃气舵选材。

Abstract:To solve the lightweight problem of rocket jet vanes, a new jet vane based on high thermal conductivity aluminum nitride (AlN) ceramic was designed. In order to investigate its feasibility, the unsteady numerical simulation method based on fluid-solid thermal coupling was established to research the working process of aluminum nitride ceramics jet vanes under different angles, and their thermal shock resistance was analyzed based on the ceramic strength prediction model in high temperature environment. AlN ceramic jet vanes were processed for the ground static jet test of solid rocket motor at different angles, and the test results were analyzed by SEM. The research showed that, the numerical simulation results were basically consistent with the test results, which verified the effectiveness of the numerical simulation method. For the solid rocket motor with the total temperature of 2284 K, AlN ceramic jet vanes can withstand the maximum mechanical shock and thermal shock caused by the engine gas in 1 s. AlN ceramic had much better high thermal conductivity (320 W/(m∙K) theoretical) and thermal shock resistance than other structural ceramics. AlN ceramic is a good alternative material for small jet vane.

-

Key words:

- AlN ceramic /

- jet vane /

- thermal coupling /

- thermal shock /

- solid rocket

-

表 1 计算用陶瓷材料参数

Table 1. Parameters of ceramic materials for calculation

材料参数 高导热氮化铝AlN 高纯氧化铝Al2O3 E/GPa $ E=E_0-BT'{\mathrm{e}}^{- (T\mathrm{_{_m}}-273.15\; \mathrm{K}) /T'}+B_1[T'-B_2 (T_{\mathrm{m}}-273.15\; \mathrm{K}) +|T'-B_2 (T_{\mathrm{m}}-273.15\; \mathrm{K}) |]{\mathrm{e}}^{- (T_{\mathrm{m}}-273.15\; \mathrm{K}) /T'} $ ρ/(g/cm3) 3.26 3.98 ν, B, B1, B2 0.23, 2.05, 0.975, 0.0129 0.22, 2.1441, 0.9278, 0.0352 E0/GPa 314 400.3 Tm/K 2785 (升华分解) 2323 k/(W/(m∙K)) 6.812×10−5T 2−2.446T+386.22 27.5−0.0289T (298~1 200 K)

1.5 (1 200~2 327 K)cp/(J/(kg∙K))

(A1、A2、A3)A1+A2×10−3T+A3×10−5T−2

(787.00, 553.32, −192.78) (298~600 K)

(1224.78, 28.585, −635.46) (600~1000 K)

(1222.95, 9.49, −424.32) (1000~2000 K)A1+A2×10−3T+A3×10−5T−2

(1018.15, 257.52, 285.20)(298~800 K)

(1181.53, 97.18, −474.22) (800~2327 K)α1/10−6 K−1 1.68ln T − 6.3239 1.93ln T − 5.3167 表 2 陶瓷材料温度性强度参数

Table 2. Temperature-dependent strength parameters of ceramic materials

材料参数 高导热氮化铝 高纯氧化铝

σth/MPa${\sigma _{{\mathrm{th}}}} = \sigma _{{\mathrm{th}}}^0{\left\{ {\displaystyle\frac{{E (T') }}{{{E_0}}}\left[ {1 - \displaystyle\frac{{\displaystyle\int_0^{T'} {{c_p} (T) {\text{d}}T} }}{{\displaystyle\int_0^{{T_{\mathrm{m}}}} {{c_p} (T) {\text{d}}T} }}} \right]} \right\}^{{1/2}}}$ ${\sigma ^0_{{\mathrm{th}}}} $/MPa 350 350 表 3 受力峰值点处的静力学求解数据

Table 3. Static solution data at peak stress point

材料 偏角/(°) 最大主应力/MPa 最大位移/μm 安全系数 AlN 0 4.813 1.271 83.108 20 34.687 25.62 11.532 Al2O3 0 4.952 1.262 70.679 20 35.103 24.81 8.468 表 4 常温下试验用陶瓷材料参数

Table 4. Parameters of ceramic materials for test at normal temperature

材料参数 高导热氮化铝AlN 高纯氧化铝Al2O3 E/GPa 320 300 ρ/(g/cm3) 3.3 3.7 ν 0.23 0.22 k/(W/(m∙K)) 200 24 α1/10−6 (1/K) 4.6 7.5 σth/MPa 320 300 -

[1] 刘钧圣,曾望,汤江河,等. 垂直发射多用途导弹发展现状与研究方向[J]. 弹箭与制导学报,2019,39(5): 172-177. LIU Junsheng,ZENG Wang,TANG Jianghe,et al. Development status and research trend of vertical launching multi-purpose missile[J]. Journal of Projectiles,Rockets,Missiles and Guidance,2019,39(5): 172-177. (in ChineseLIU Junsheng, ZENG Wang, TANG Jianghe, et al. Development status and research trend of vertical launching multi-purpose missile[J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2019, 39(5): 172-177. (in Chinese) [2] 谢玲玲,陈文亮,牛亚然,等. 燃气舵的绕流场及气动特性数值研究[J]. 航空计算技术,2015,45(6): 79-82,86. XIE Lingling,CHEN Wenliang,NIU Yaran,et al. Numerical study on flow field and aerodynamic characteristics of jet vane[J]. Aeronautical Computing Technique,2015,45(6): 79-82,86. (in ChineseXIE Lingling, CHEN Wenliang, NIU Yaran, et al. Numerical study on flow field and aerodynamic characteristics of jet vane[J]. Aeronautical Computing Technique, 2015, 45(6): 79-82, 86. (in Chinese) [3] 郑兴宇,杨涛,张青斌. 钨渗铜燃气舵化学烧蚀计算[J]. 兵器装备工程学报,2016,37(9): 166-170. ZHENG Xingyu,YANG Tao,ZHANG Qingbin. Calculation of chemical ablation of jet vane made of CIT (copper infiltrated tungsten)[J]. Journal of Ordnance Equipment Engineering,2016,37(9): 166-170. (in ChineseZHENG Xingyu, YANG Tao, ZHANG Qingbin. Calculation of chemical ablation of jet vane made of CIT (copper infiltrated tungsten)[J]. Journal of Ordnance Equipment Engineering, 2016, 37(9): 166-170. (in Chinese) [4] 薛海峰. 碳/酚醛燃气舵传热烧蚀数值仿真与试验研究[D]. 南京: 南京理工大学,2018. XUE Haifeng. Numerical simulation and experimental studies on heat transfer and ablation of carbon-phenolic jet vanes[D]. Nanjing: Nanjing University of Science and Technology,2018. (in ChineseXUE Haifeng. Numerical simulation and experimental studies on heat transfer and ablation of carbon-phenolic jet vanes[D]. Nanjing: Nanjing University of Science and Technology, 2018. (in Chinese) [5] 董晓芳. 固体火箭发动机燃气舵热分析研究[D]. 西安: 西北工业大学,2005. DONG Xiaofang. Thermal analysis of gas rudder of solid rocket motor[D]. Xi’an: Northwestern Polytechnical University,2005. (in ChineseDONG Xiaofang. Thermal analysis of gas rudder of solid rocket motor[D]. Xi’an: Northwestern Polytechnical University, 2005. (in Chinese) [6] CHEN Bo,ZHANG Litong,CHENG Laifei,et al. Erosion resistance of needled carbon/carbon composites exposed to solid rocket motor plumes[J]. Carbon,2009,47(6): 1474-1479. doi: 10.1016/j.carbon.2009.01.040 [7] BANSARD S,PLOUVIER S,VARDELLE M,et al. Experimental simulation of thermo-mechanical ablation of carbon/phenolic composite under the impact of liquid alumina particles[J]. High Temperature Material Processes (an International Quarterly of High-Technology Plasma Processes),2005,9(3): 431-441. doi: 10.1615/HighTempMatProc.v9.i3.90 [8] 薛海峰,陈雄,郑健,等. 基于热解动力学炭/酚醛燃气舵流热耦合数值研究[J]. 固体火箭技术,2015,38(4): 503-509. XUE Haifeng,CHEN Xiong,ZHENG Jian,et al. Numerical research on flow-thermal coupling of carbon-phenolic jet-vane based on pyrolysis kinetics[J]. Journal of Solid Rocket Technology,2015,38(4): 503-509. (in ChineseXUE Haifeng, CHEN Xiong, ZHENG Jian, et al. Numerical research on flow-thermal coupling of carbon-phenolic jet-vane based on pyrolysis kinetics[J]. Journal of Solid Rocket Technology, 2015, 38(4): 503-509. (in Chinese) [9] 薛海峰,陈雄,郑健,等. 炭/酚醛燃气舵烧蚀性能[J]. 固体火箭技术,2017,40(6): 706-713. XUE Haifeng,CHEN Xiong,ZHENG Jian,et al. Ablation performance of carbon-phenolic jet vanes[J]. Journal of Solid Rocket Technology,2017,40(6): 706-713. (in ChineseXUE Haifeng, CHEN Xiong, ZHENG Jian, et al. Ablation performance of carbon-phenolic jet vanes[J]. Journal of Solid Rocket Technology, 2017, 40(6): 706-713. (in Chinese) [10] 韩世纬. 舰载垂直发射导弹燃气舵材料的选择[J]. 上海航天,1986,3(4): 46-55. HAN Shiwei. Selection of gas rudder material for ship-borne vertical launch missile[J]. Aerospace Shanghai,1986,3(4): 46-55. (in ChineseHAN Shiwei. Selection of gas rudder material for ship-borne vertical launch missile[J]. Aerospace Shanghai, 1986, 3(4): 46-55. (in Chinese) [11] 严光能,邓先友,林金堵. 高导热氮化铝基板在航空工业的应用研究[J]. 印制电路信息,2017,25(10): 32-37. YAN Guangneng,DENG Xianyou,LIN Jindu. The research of high-thermal-conductive aluminum nitride substrate in airport power electronics[J]. Printed Circuit Information,2017,25(10): 32-37. (in ChineseYAN Guangneng, DENG Xianyou, LIN Jindu. The research of high-thermal-conductive aluminum nitride substrate in airport power electronics[J]. Printed Circuit Information, 2017, 25(10): 32-37. (in Chinese) [12] UPADHYA K,YANG J,HOFFMAN W. Materials for ultrahigh temperature structural applications[J]. American Ceramic Society Bulletin,1997,76: 51-56. [13] 刘志珩. 固体火箭燃气舵气动设计研究[J]. 导弹与航天运载技术,1995(4): 9-17. LIU Zhiheng. Study on aerodynamic design of solid rocket gas rudder[J]. Missiles and Space Vehicles,1995(4): 9-17. (in ChineseLIU Zhiheng. Study on aerodynamic design of solid rocket gas rudder[J]. Missiles and Space Vehicles, 1995(4): 9-17. (in Chinese) [14] 石仲仑,白澔烔,马天任. 一种环氧基复合推进剂、制备方法及其应用: CN112694372A[P]. 2021-04-23. SHI Zhonglun,BAI Haotong,MA Tianren. Epoxy composite propellant,preparation method and application thereof: CN112694372A[P]. 2021-04-23. (in ChineseSHI Zhonglun, BAI Haotong, MA Tianren. Epoxy composite propellant, preparation method and application thereof: CN112694372A[P]. 2021-04-23. (in Chinese) [15] ANDERSON J D. Computational fluid dynamics: the basics with applications[M]. New York: McGraw-Hill,1995. [16] 陈浩. 气动热弹性建模及分析方法研究[D]. 西安: 西北工业大学,2019. CHEN Hao. Research on aerothermoelastic modeling and analysis method[D]. Xi’an: Northwestern Polytechnical University,2019. (in ChineseCHEN Hao. Research on aerothermoelastic modeling and analysis method[D]. Xi’an: Northwestern Polytechnical University, 2019. (in Chinese) [17] LI Weiguo,WANG Ruzhuan,LI Dingyu,et al. A model of temperature-dependent Young’s modulus for ultrahigh temperature ceramics[J]. Physics Research International,2011,2011: 791545. [18] 李云凯,周张健. 陶瓷及其复合材料[M]. 北京: 北京理工大学出版社,2007. LI Yunkai,ZHOU Zhangjian. Ceramics and composites of ceramic materials[M]. Beijing: Beijing Insititute of Technology Press,2007. (in ChineseLI Yunkai, ZHOU Zhangjian. Ceramics and composites of ceramic materials[M]. Beijing: Beijing Insititute of Technology Press, 2007. (in Chinese) [19] PABST W,GREGOROVÁ E,ČERNÝ M. Isothermal and adiabatic Young’s moduli of alumina and zirconia ceramics at elevated temperatures[J]. Journal of the European Ceramic Society,2013,33(15/16): 3085-3093. [20] 钦征骑. 新型陶瓷材料手册[M]. 南京: 江苏科学技术出版社,1996. QIN Zhengqi. Handbook of new ceramic materials[M]. Nanjing: Phoenix Science Press,1996. (in ChineseQIN Zhengqi. Handbook of new ceramic materials[M]. Nanjing: Phoenix Science Press, 1996. (in Chinese) [21] 叶大伦,胡建华. 实用无机物热力学数据手册[M]. 2版. 北京: 冶金工业出版社,2002. YE Dalun,HU Jianhua. Handbook of practical inorganic thermodynamic data[M]. 2nd ed. Beijing: Metallurgical Industry Press,2002. (in ChineseYE Dalun, HU Jianhua. Handbook of practical inorganic thermodynamic data[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2002. (in Chinese) [22] 寇海波. 金属材料温度相关性弹性模量、屈服强度及单相陶瓷抗热冲击性能研究[D]. 重庆: 重庆大学,2019. KOU Haibo. Study on temperature-dependent elastic modulus and yield strength of metallic materials and thermal shock resistance of single-phase ceramics[D]. Chongqing: Chongqing University,2019. (in ChineseKOU Haibo. Study on temperature-dependent elastic modulus and yield strength of metallic materials and thermal shock resistance of single-phase ceramics[D]. Chongqing: Chongqing University, 2019. (in Chinese) [23] LI Weiguo,YANG Fan,FANG Daining. The temperature-dependent fracture strength model for ultra-high temperature ceramics[J]. Acta Mechanica Sinica,2010,26(2): 235-239. doi: 10.1007/s10409-009-0326-7 [24] DECHAUMPHAI P,WIETING A,THORNTON E. Flow-thermal-structural study of aerodynamically heated leading edges: AIAA 1988-2245[R]. Reston,Virigina: AIAA,1988. [25] 耿湘人,张涵信,沈清,等. 高速飞行器流场和固体结构温度场一体化计算新方法的初步研究[J]. 空气动力学学报,2002,20(4): 422-427. GENG Xiangren,ZHANG Hanxin,SHEN Qing,et al. Study on an integrated algorithm for the flowfields of high speed vehicles and the heat transfer in solid structures[J]. Acta Aerodynamica Sinica,2002,20(4): 422-427. (in ChineseGENG Xiangren, ZHANG Hanxin, SHEN Qing, et al. Study on an integrated algorithm for the flowfields of high speed vehicles and the heat transfer in solid structures[J]. Acta Aerodynamica Sinica, 2002, 20(4): 422-427. (in Chinese) -

下载:

下载: