Calculation and test verification of gas-solid coupling pneumatic transport of hail continuous ejection

-

摘要:

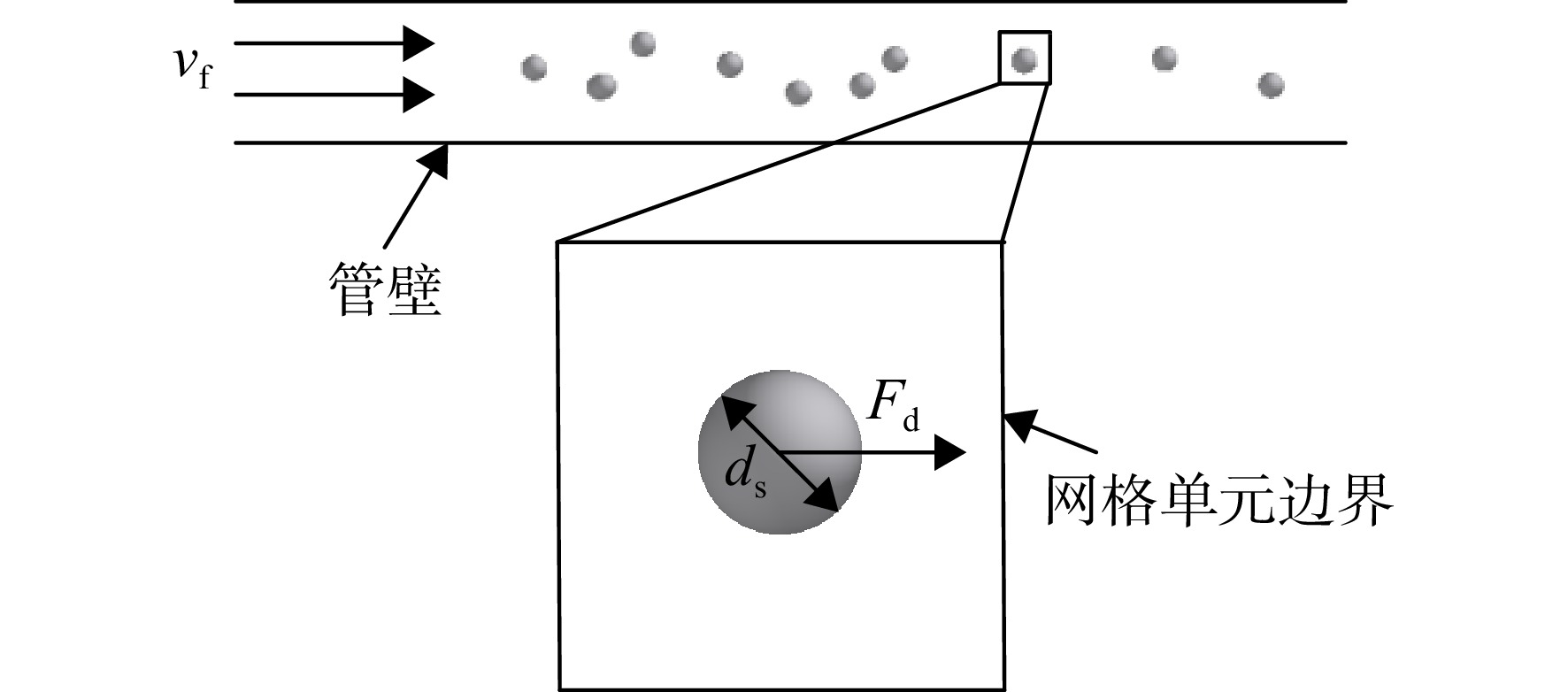

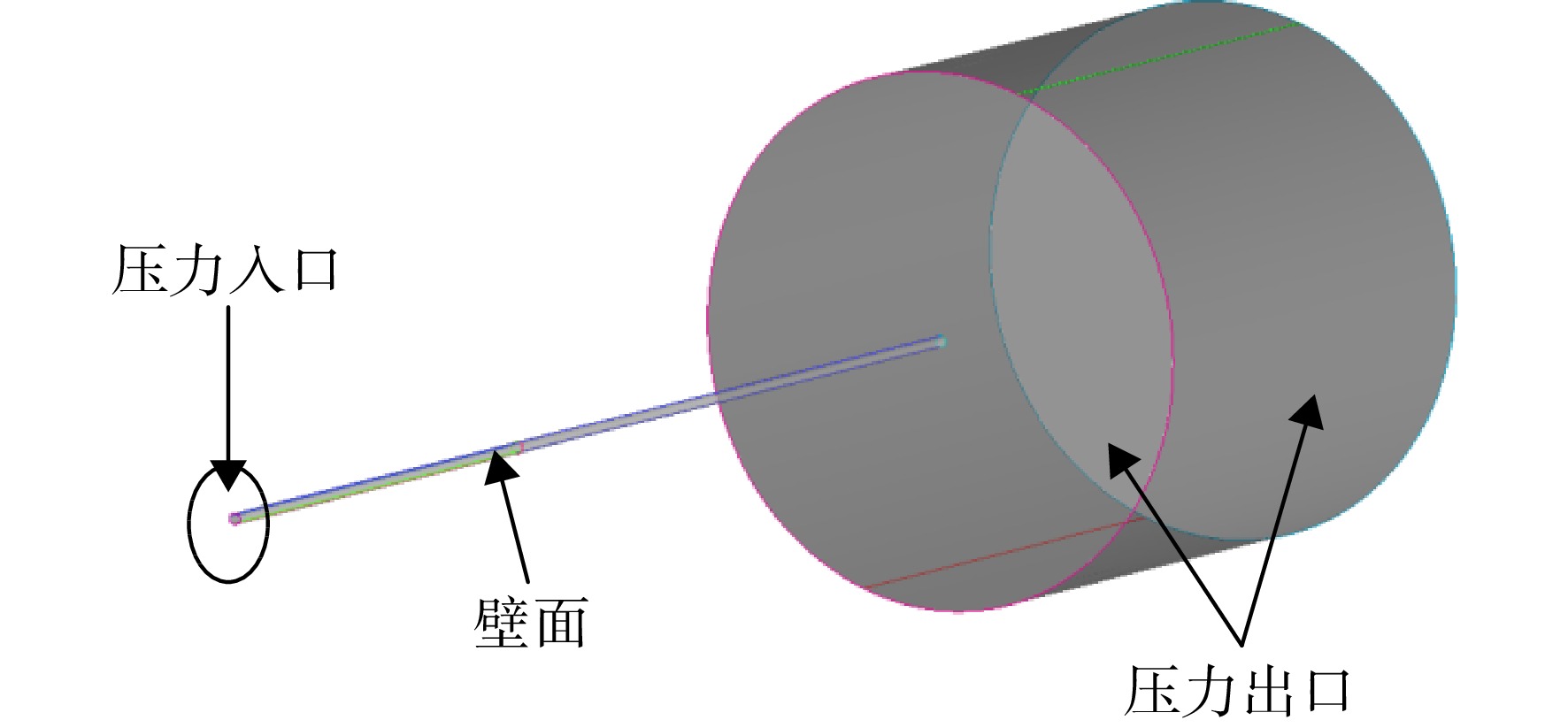

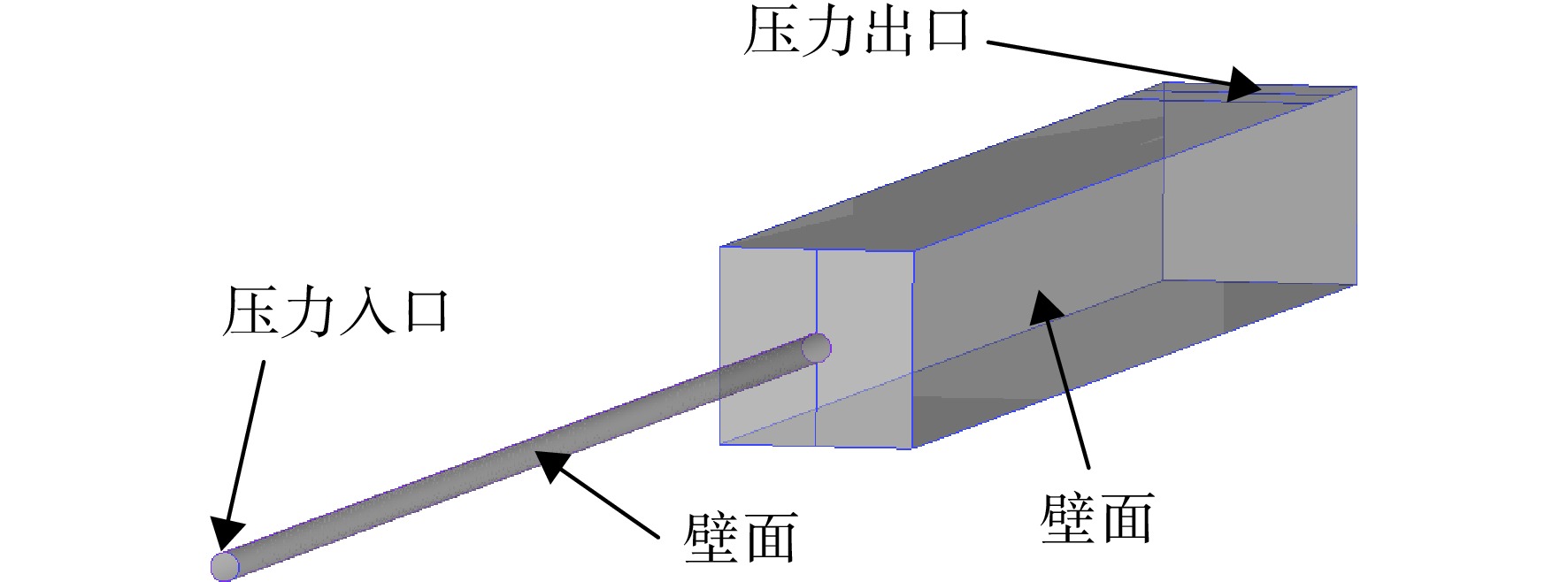

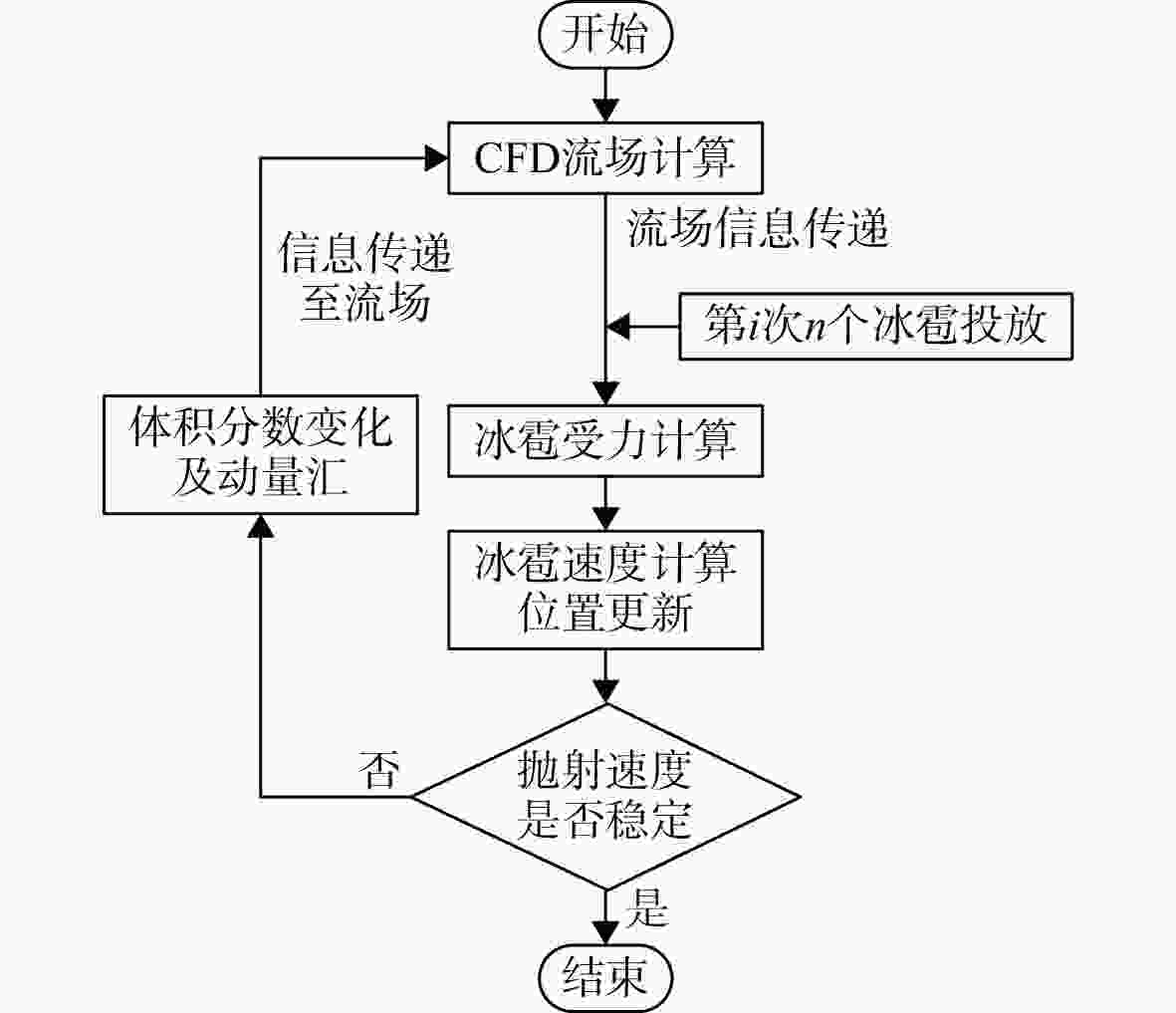

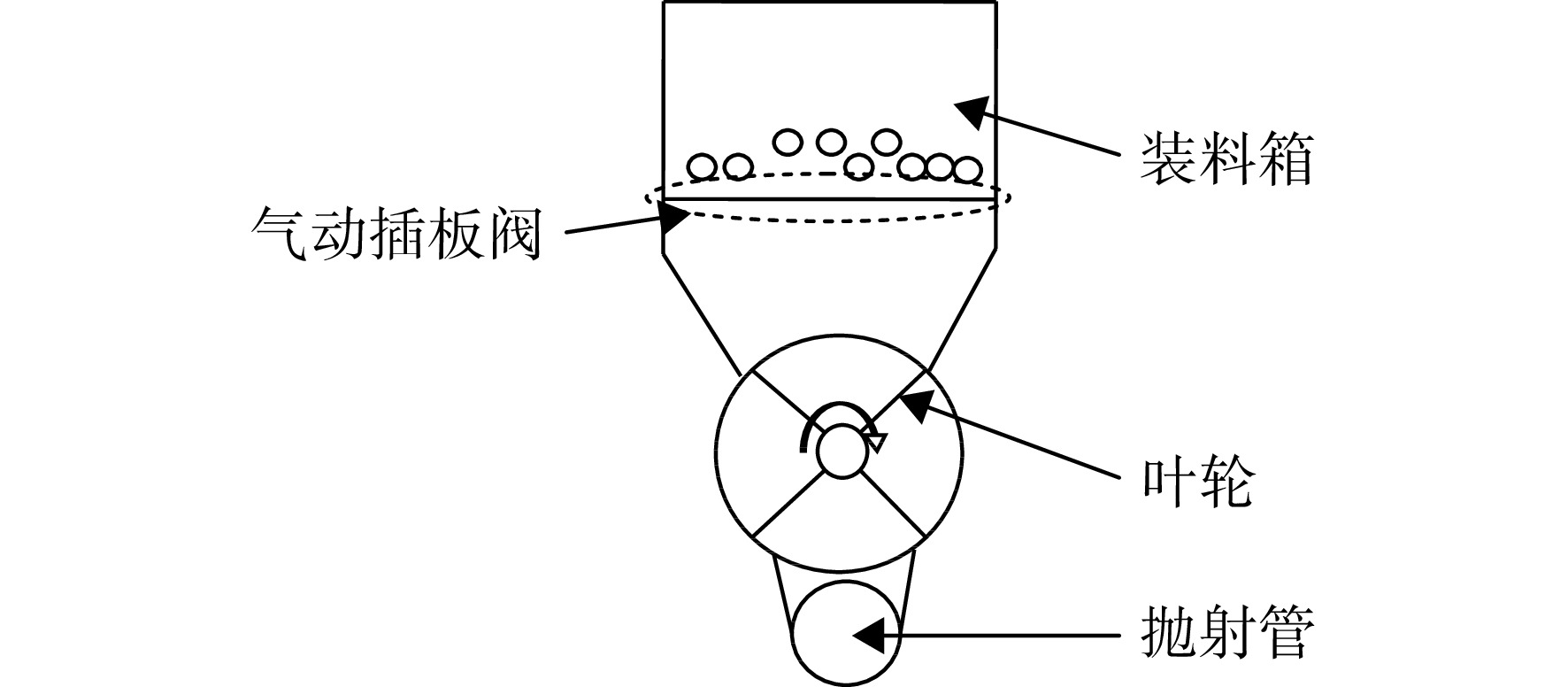

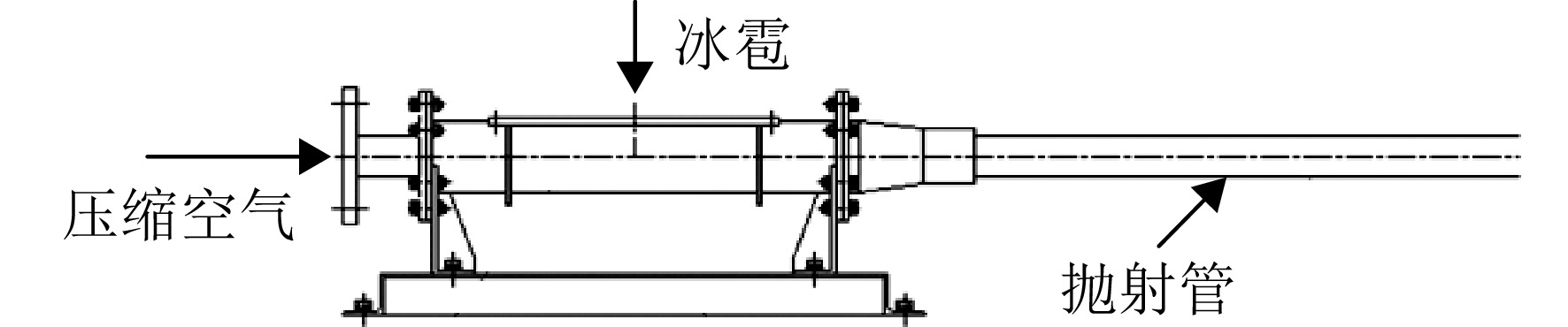

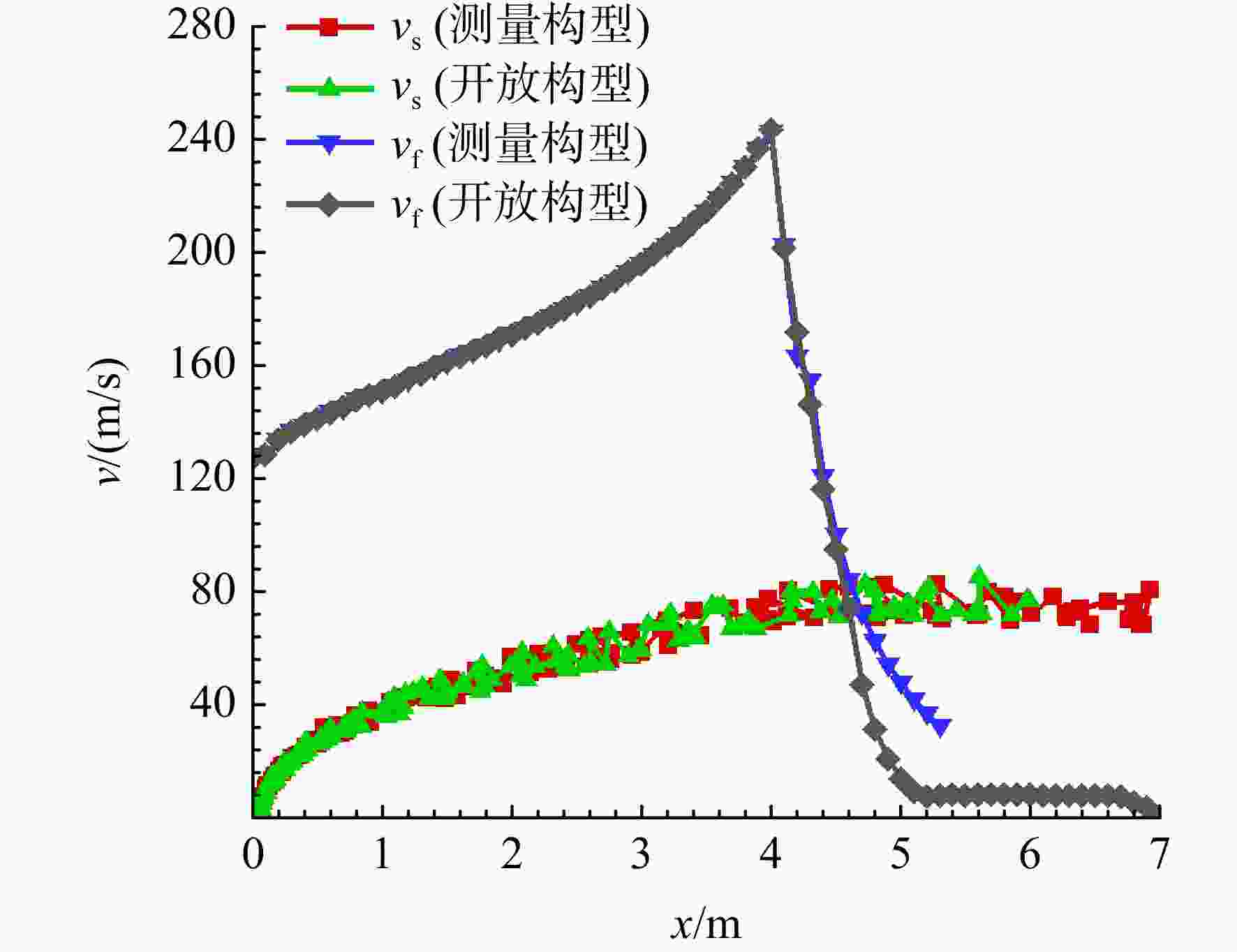

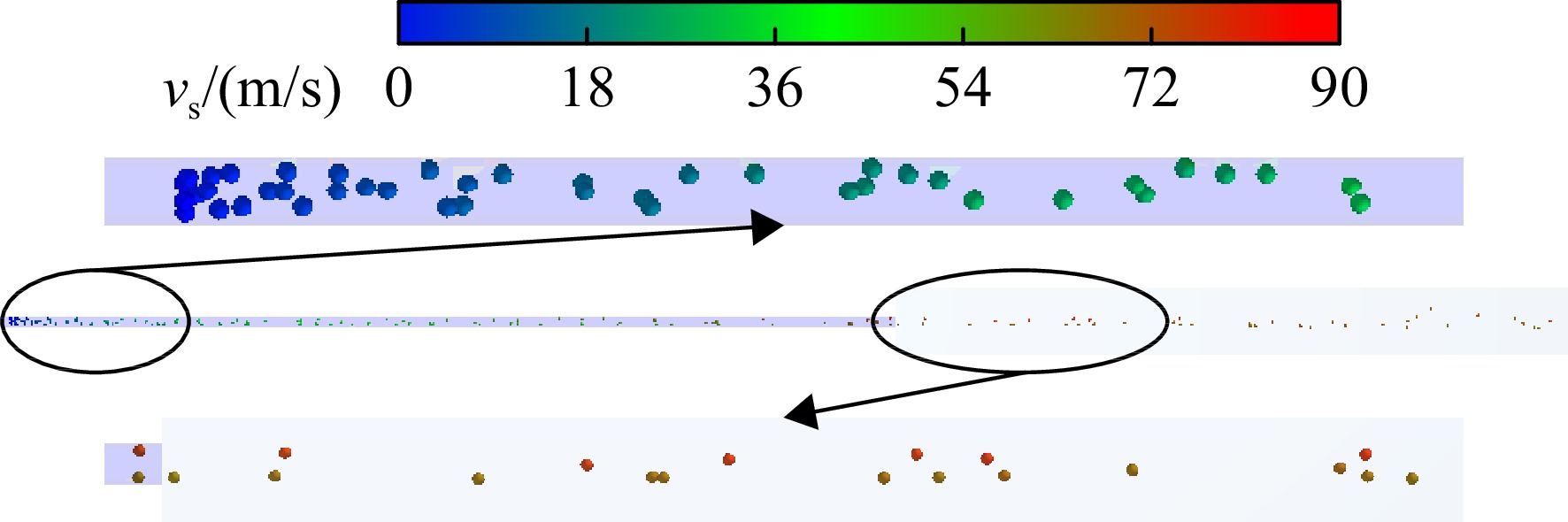

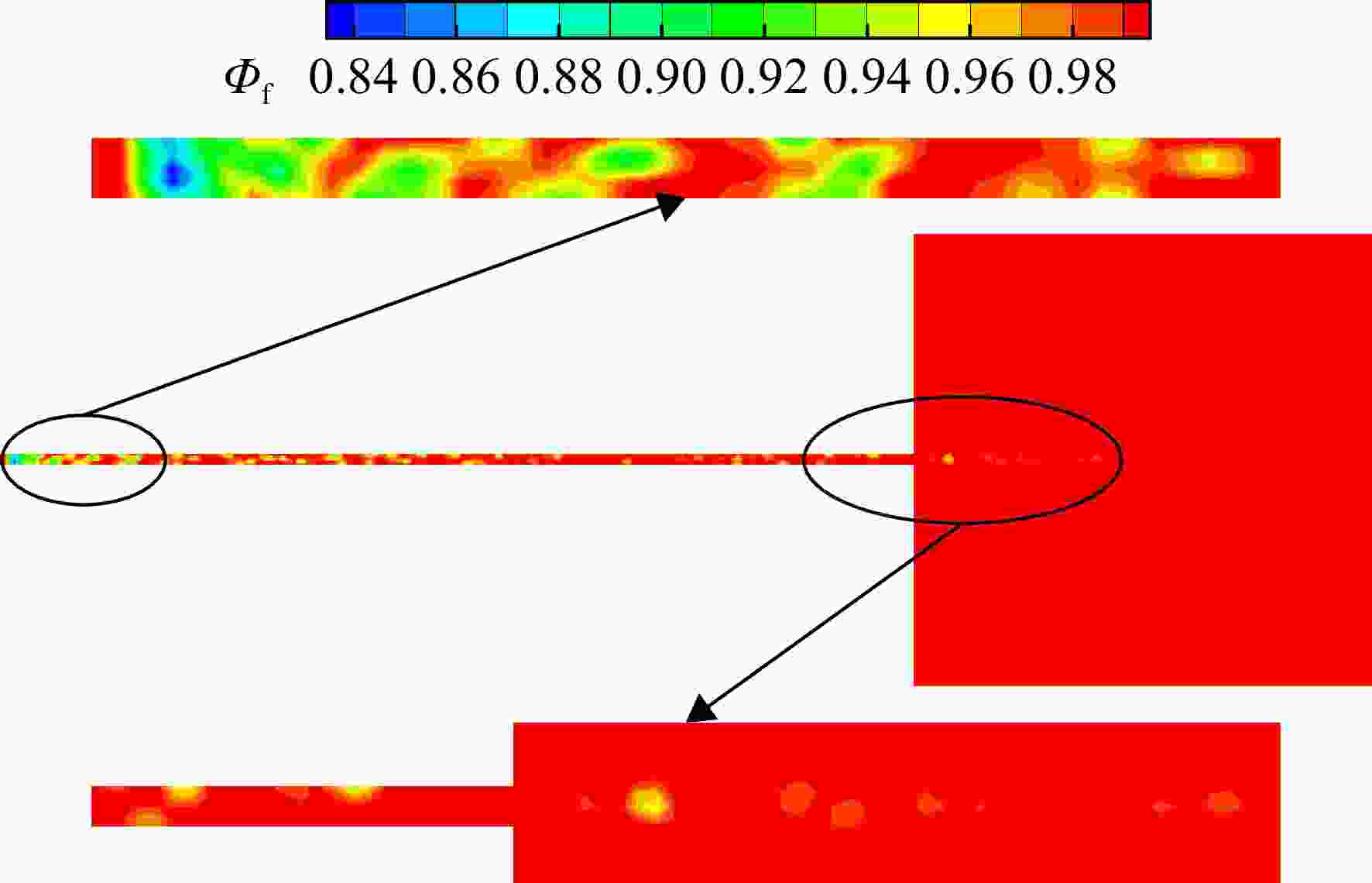

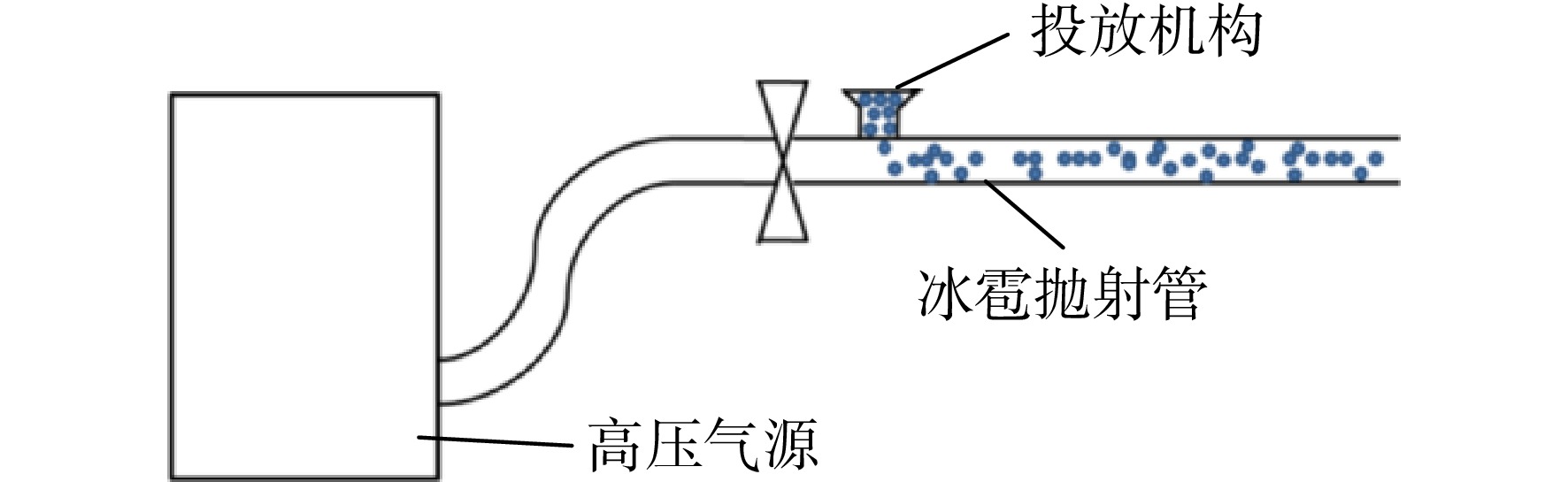

针对可压缩流气力输运大尺寸颗粒的气固两相流动问题,建立了计算流体力学(CFD)与离散单元法(DEM)耦合的计算方法,通过计算流体力学计算得到抛射管内气流流场分布,离散单元法根据气动参数计算得到冰雹受力及运动情况。进行冰雹速度测量时,需在抛射管出口处加装专用测量段,对测量构型与开放构型进行对比,结果显示测量构型与开放构型下的计算结果基本一致,因此测量构型下的计算与试验可支撑连续抛雹装置设计。通过3种颗粒阻力模型下的对比计算,Ergun模型与Di模型得到的冰雹速度计算结果较大,自由流阻力模型计算得到的冰雹速度与试验测量结果最接近,其计算得到的冰雹速度与试验结果相差8.9%,对冰雹连续抛射装置设计有一定的指导作用。

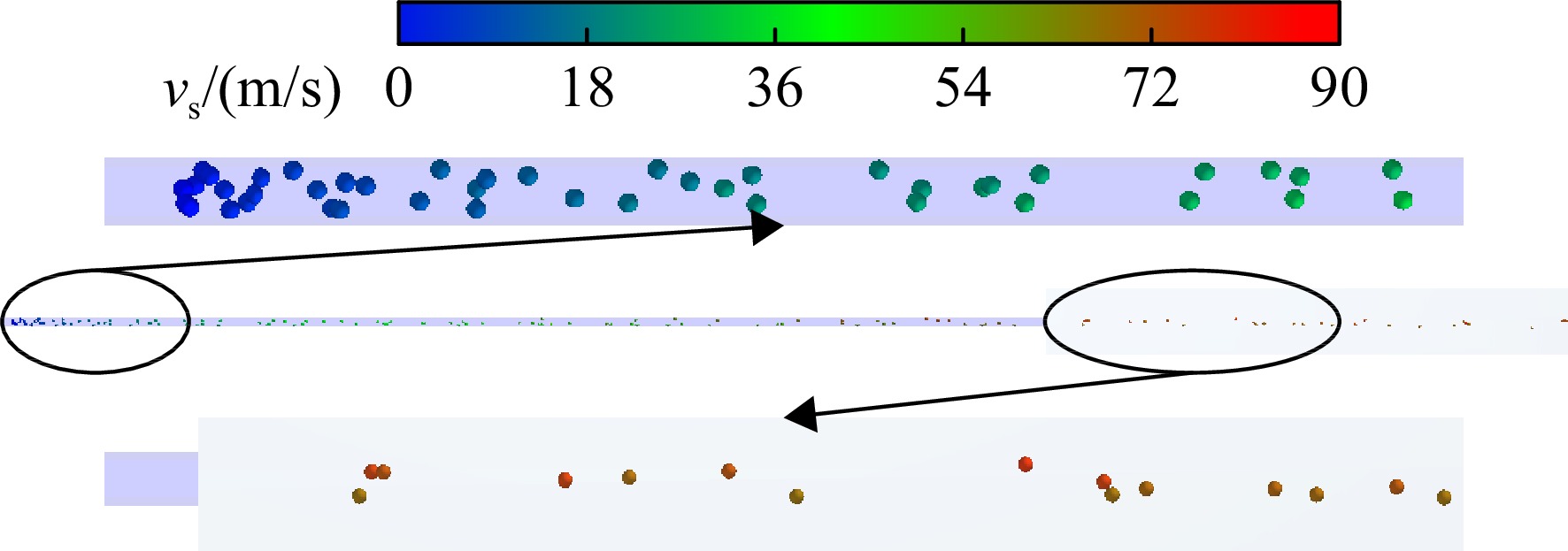

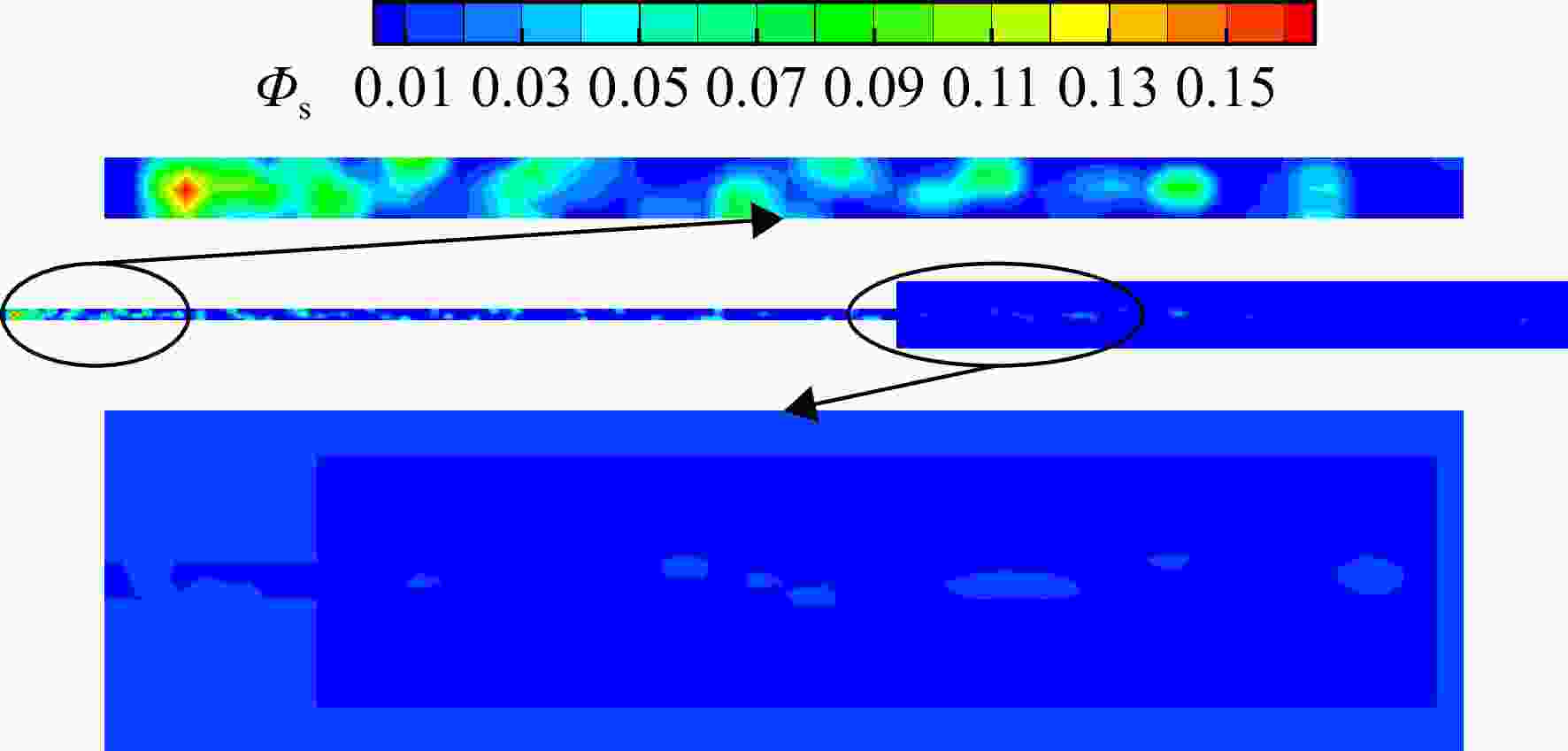

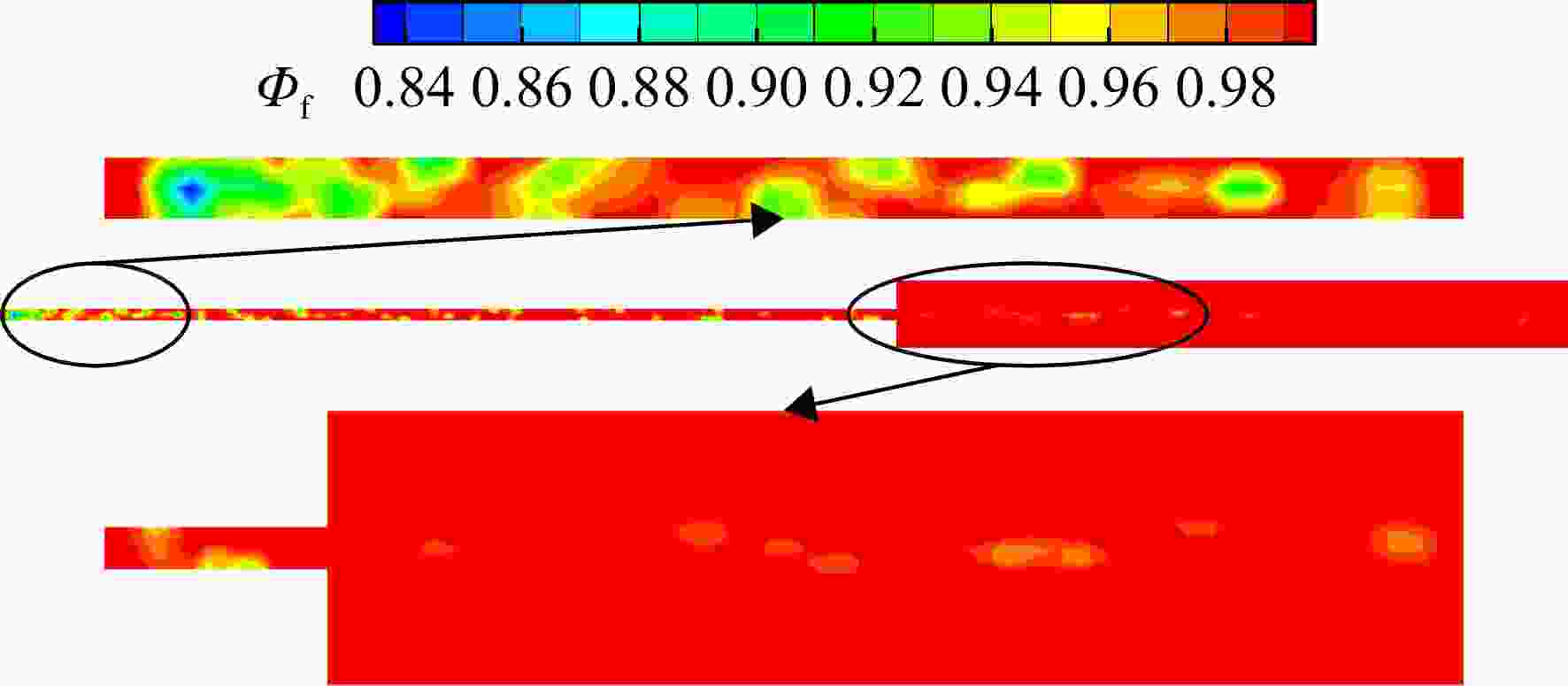

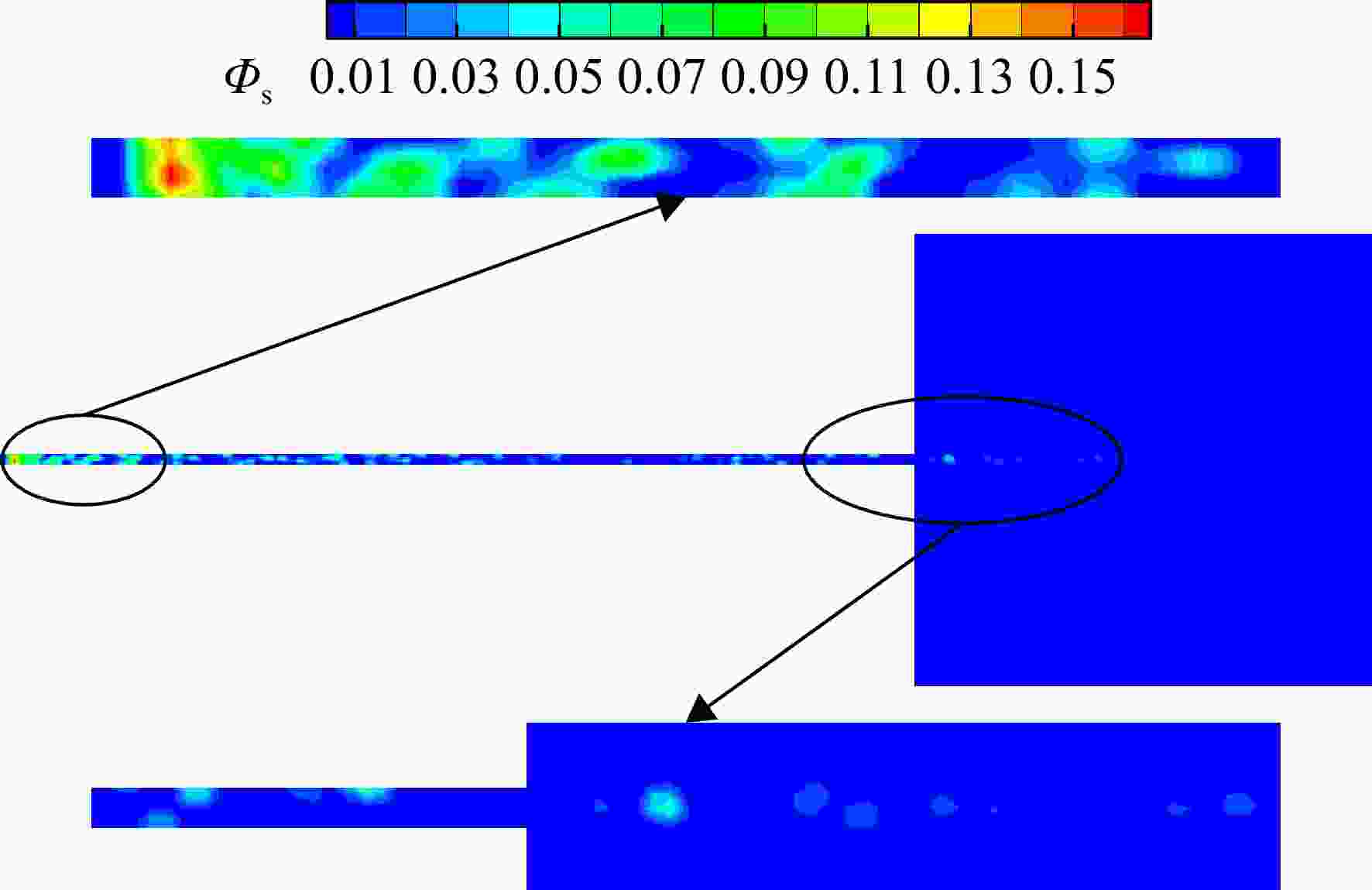

Abstract:Considering the gas-solid two-phase flow problem of compressible pneumatic transport of large particles, the coupling calculation method of computational fluid dynamics (CFD) and discrete element method (DEM) was established. The flow field distribution in the hail ejection pipe was calculated by computational fluid dynamics, while the force and motion of hail were calculated by discrete element method according to aerodynamic parameters. When measuring hail velocity, a special measurement section was required to be installed at the outlet of the ejection tube. The difference between the measurement configuration and the open configuration was then compared and calculated. The results showed that the calculation results under the measured configuration were basically consistent with those under the open configuration, so the calculation and test under the measured configuration can support the design of continuous hail throwing device. Through the comparative calculation and test verification under three particle resistance models, the hail velocity calculated by Ergun model and di model was larger, and the hail velocity calculated by free flow resistance model was closest to the test measurement results. The calculated hail velocity differs by 8.9% from the test results, playing a guiding role in the design of hail continuous ejection device.

-

表 1 不同阻力模型计算结果对比

Table 1. Comparison of calculation results of different resistance models

对比参数 构型 模型1 模型2 模型3 流量/(kg/s) 测量构型 0.4062 0.3878 0.3936 开放构型 0.4068 0.3875 0.3918 速度/(m/s) 测量构型 74.36 83.66 83.09 开放构型 75.56 82.63 83.25 表 2 颗粒速度测量结果

Table 2. Particle velocity measurement results

序号 冰雹速度/(m/s) 序号 冰雹速度/(m/s) 1 75.03 5 66.09 2 63.88 6 69.12 3 67.75 7 66.43 4 64.76 8 73.37 -

[1] Federal Aviation Administration. Airworthiness standards: aircraft engines: FAA FAR Part 33[S]. Washington DC: Federal Aviation Administration,1998: 41-43. [2] European Aviation Safety Agency. Certification specifications and acceptable means of compliance for engines: CS-E amendment5[S]. Cologne: European Aviation Safety Agency,2020: 162-179. [3] 中国民用航空局. 中国民用航空规章第33部: CCAR 33R2[S]. 北京: 中国民用航空局,2011: 55-56. [4] 李好婷,朱玉颖,孔德旭,等. 多孔介质内颗粒流动特性及其对传热影响的模拟研究[J]. 工程热物理学报,2021,42(8): 2017-2026. LI Haoting,ZHU Yuying,KONG Dexu,et al. Simulation study on flow and heat transfer characteristics of particles in porous media[J]. Journal of Engineering Thermophysics,2021,42(8): 2017-2026. (in ChineseLI Haoting, ZHU Yuying, KONG Dexu, et al. Simulation study on flow and heat transfer characteristics of particles in porous media[J]. Journal of Engineering Thermophysics, 2021, 42(8): 2017-2026. (in Chinese) [5] 刘岩,秦攀,洪文鹏. 基于计算流体力学-离散单元法耦合的粗糙壁面颗粒趋壁沉积过程的数值模拟[J]. 科学技术与工程,2021,21(13): 5216-5222. LIU Yan,QIN Pan,HONG Wenpeng. Numerical simulation on process of particle deposition on a rib-roughened surface using CFD-DEM[J]. Science Technology and Engineering,2021,21(13): 5216-5222. (in Chinese doi: 10.3969/j.issn.1671-1815.2021.13.007LIU Yan, QIN Pan, HONG Wenpeng. Numerical simulation on process of particle deposition on a rib-roughened surface using CFD-DEM[J]. Science Technology and Engineering, 2021, 21(13): 5216-5222. (in Chinese) doi: 10.3969/j.issn.1671-1815.2021.13.007 [6] 祝先胜. 气力输送管内气固两相流动的数值模拟[D]. 上海: 华东理工大学,2015. ZHU Xiansheng. Numerical simulation of gas-solid two phase flow in pneumatic conveying pipeline[D]. Shanghai: East China University of Science and Technology,2015. (in ChineseZHU Xiansheng. Numerical simulation of gas-solid two phase flow in pneumatic conveying pipeline[D]. Shanghai: East China University of Science and Technology, 2015. (in Chinese) [7] 张春燕,马超,晏飞. 基于CFD-DEM方法的不同弯径比弯管中气固两相流动特性[J]. 江苏科技大学学报(自然科学版),2018,32(6): 803-808. ZHANG Chunyan,MA Chao,YAN Fei. Gas solid two phase flow characteristics of elbow pipe with different bending radius ratio based on the CFD-DEM method[J]. Journal of Jiangsu University of Science and Technology (Natural Science Edition),2018,32(6): 803-808. (in ChineseZHANG Chunyan, MA Chao, YAN Fei. Gas solid two phase flow characteristics of elbow pipe with different bending radius ratio based on the CFD-DEM method[J]. Journal of Jiangsu University of Science and Technology (Natural Science Edition), 2018, 32(6): 803-808. (in Chinese) [8] 杨春彬. 气力输送系统中弯管磨损的数值模拟[D]. 长春: 吉林大学,2018: 25-28. YANG Chunbin. Numerical simulation of elbow wear in pneumatic conveying system[D]. Changchun: Jilin University,2018: 25-28. (in ChineseYANG Chunbin. Numerical simulation of elbow wear in pneumatic conveying system[D]. Changchun: Jilin University, 2018: 25-28. (in Chinese) [9] 谢楠. 基于CFD-DEM的膨胀石墨气固两相流动特性研究[D]. 秦皇岛: 燕山大学,2018: 27-30. XIE Nan. Research on the gas-solid flow characteristic of expanded graphite based on CFD-DEM[D]. Qinhuangdao: Yanshan University,2018: 27-30. (in ChineseXIE Nan. Research on the gas-solid flow characteristic of expanded graphite based on CFD-DEM[D]. Qinhuangdao: Yanshan University, 2018: 27-30. (in Chinese) [10] 李俊杰. 基于CFD-DEM方法的管道带电颗粒流气力输送模拟[D]. 兰州: 兰州大学,2021: 27-33. LI Junjie. Simulation of pneumatic conveying of charged particle flow in pipe based on CFD-DEM method[D]. Lanzhou: Lanzhou University,2021: 27-33. (in ChineseLI Junjie. Simulation of pneumatic conveying of charged particle flow in pipe based on CFD-DEM method[D]. Lanzhou: Lanzhou University, 2021: 27-33. (in Chinese) [11] 陈奇飞,刘士杰,陈树伟,等. 气固两相流对燃气-蒸汽弹射动力系统弯管结构影响的流热固耦合数值研究[J]. 航空动力学报,2022,37(11): 2668-2679. CHEN Qifei,LIU Shijie,CHEN Shuwei,et al. Fluid-heat-solid coupling numerical study on influence of gas-solid two-phase flow on elbow tube of gas-steam ejection power system[J]. Journal of Aerospace Power,2022,37(11): 2668-2679. (in ChineseCHEN Qifei, LIU Shijie, CHEN Shuwei, et al. Fluid-heat-solid coupling numerical study on influence of gas-solid two-phase flow on elbow tube of gas-steam ejection power system[J]. Journal of Aerospace Power, 2022, 37(11): 2668-2679. (in Chinese) [12] 熊书春,臧孟炎. 基于非解析计算流体力学和离散单元法的大颗粒在流场中的高效率运动模拟[J]. 科学技术与工程,2021,21(15): 6140-6146. XIONG Shuchun,ZANG Mengyan. Efficient simulation about the motion of large particles in fluid based on unresolved computational fluid dynamics and discrete element method[J]. Science Technology and Engineering,2021,21(15): 6140-6146. (in Chinese doi: 10.3969/j.issn.1671-1815.2021.15.007XIONG Shuchun, ZANG Mengyan. Efficient simulation about the motion of large particles in fluid based on unresolved computational fluid dynamics and discrete element method[J]. Science Technology and Engineering, 2021, 21(15): 6140-6146. (in Chinese) doi: 10.3969/j.issn.1671-1815.2021.15.007 [13] 董长银,栾万里,周生田,等. 牛顿流体中的固体颗粒运动模型分析及应用[J]. 中国石油大学学报(自然科学版),2007,31(5): 55-59,63. DONG Changyin,LUAN Wanli,ZHOU Shengtian,et al. Analysis and application of model for solid particle movement in Newton fluid[J]. Journal of China University of Petroleum (Edition of Natural Science),2007,31(5): 55-59,63. (in ChineseDONG Changyin, LUAN Wanli, ZHOU Shengtian, et al. Analysis and application of model for solid particle movement in Newton fluid[J]. Journal of China University of Petroleum (Edition of Natural Science), 2007, 31(5): 55-59, 63. (in Chinese) [14] SHENG L T,XIAO Yilun,HSIAU S S,et al. A study of pneumatic conveying with high-density AM-using metal powder in a pipe bend[J]. International Journal of Mechanical Sciences,2020,181: 105763. doi: 10.1016/j.ijmecsci.2020.105763 [15] 胡国明. 颗粒系统的离散元素法分析仿真: 离散元素法的工业应用与EDEM软件简介[M]. 武汉: 武汉理工大学出版社,2010: 144-147. HU Guoming. Discrete element method analysis and simulation of granular system[M]. Wuhan: Wuhan University of Technology Press. 2010: 144-147. (in ChineseHU Guoming. Discrete element method analysis and simulation of granular system[M]. Wuhan: Wuhan University of Technology Press. 2010: 144-147. (in Chinese) [16] NIVEN R K. Physical insight into the Ergun and Wen & Yu equations for fluid flow in packed and fluidised beds[J]. Chemical Engineering Science,2002,57(3): 527-534. doi: 10.1016/S0009-2509(01)00371-2 [17] ZHOU Feng,LI Jianping,YANG Daolong,et al. Experimental study on collision characteristics of large coal particles (7-15 mm) in 90° elbows of pneumatic conveying systems[J]. Powder Technology,2022,396: 305-315. doi: 10.1016/j.powtec.2021.10.038 [18] 邹旭毛,李良星,孔刘波,等. 颗粒堆积床内两相流动阻力及相间摩擦力[J]. 上海交通大学学报,2017,51(4): 470-475. ZOU Xumao,LI Liangxing,KONG Liubo,et al. Two-phase flow resistance and interfacial drag in packed beds[J]. Journal of Shanghai Jiao Tong University,2017,51(4): 470-475. (in ChineseZOU Xumao, LI Liangxing, KONG Liubo, et al. Two-phase flow resistance and interfacial drag in packed beds[J]. Journal of Shanghai Jiao Tong University, 2017, 51(4): 470-475. (in Chinese) [19] 张四宗,温治,刘训良,等. 颗粒形状对烧结矿填充床内渗透系数和阻力系数的影响[J]. 中南大学学报(自然科学版),2021,52(4): 1066-1075. ZHANG Sizong,WEN Zhi,LIU Xunliang,et al. Effects of particle shape on permeability and resistance coefficients of sinter packed bed[J]. Journal of Central South University (Science and Technology),2021,52(4): 1066-1075. (in ChineseZHANG Sizong, WEN Zhi, LIU Xunliang, et al. Effects of particle shape on permeability and resistance coefficients of sinter packed bed[J]. Journal of Central South University (Science and Technology), 2021, 52(4): 1066-1075. (in Chinese) [20] 张承全,高军,吕立鹏,等. 单一尺寸圆柱颗粒填充床的阻力特性[J]. 化工学报,2019,70(11): 4181-4190. ZHANG Chengquan,GAO Jun,LYU Lipeng,et al. Resistance characteristics of bed packed with mono-size cylindrical particles[J]. CIESC Journal,2019,70(11): 4181-4190. (in ChineseZHANG Chengquan, GAO Jun, LYU Lipeng, et al. Resistance characteristics of bed packed with mono-size cylindrical particles[J]. CIESC Journal, 2019, 70(11): 4181-4190. (in Chinese) -

下载:

下载: