Integrated design optimization of blade and casing treatment in axial compressor

-

摘要:

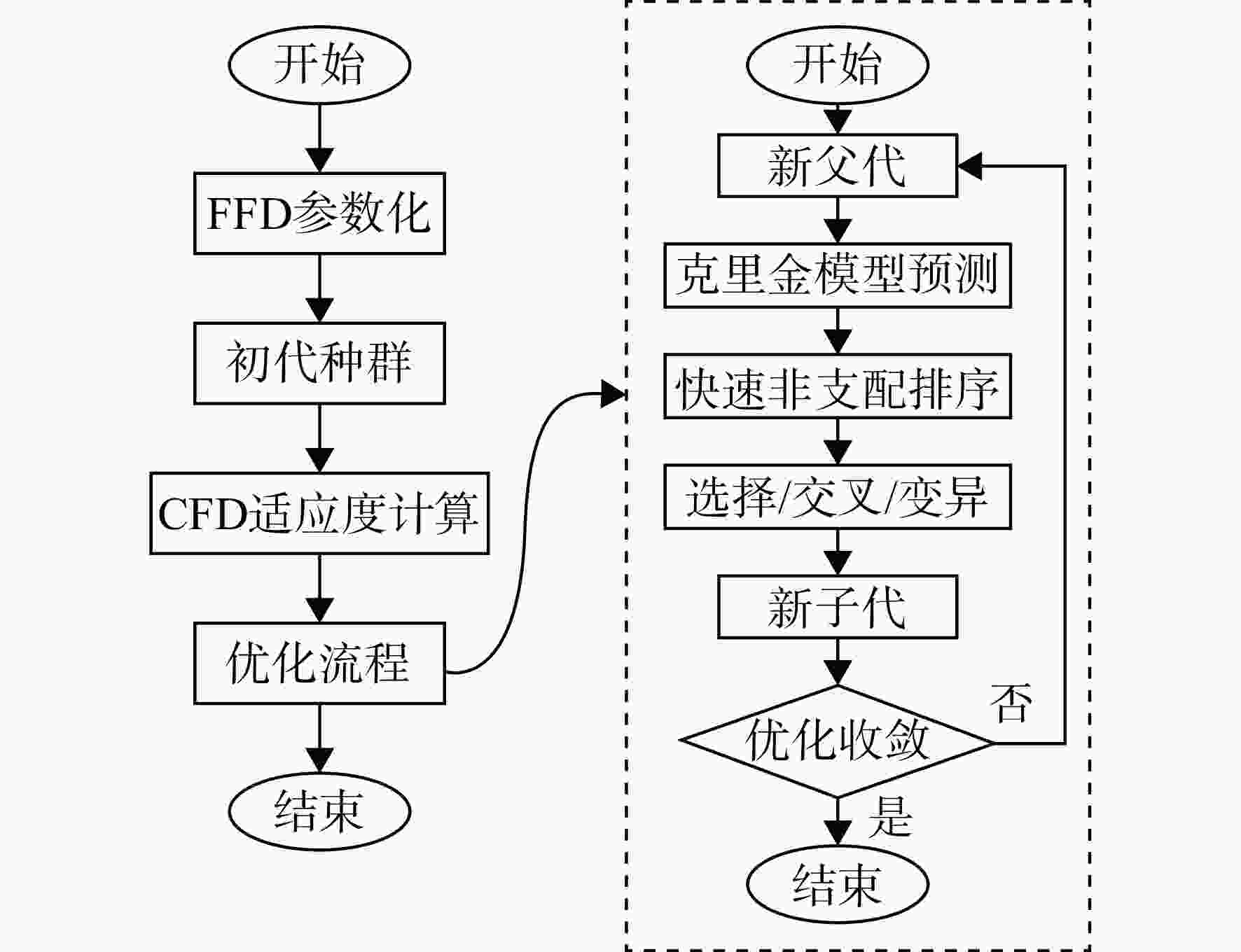

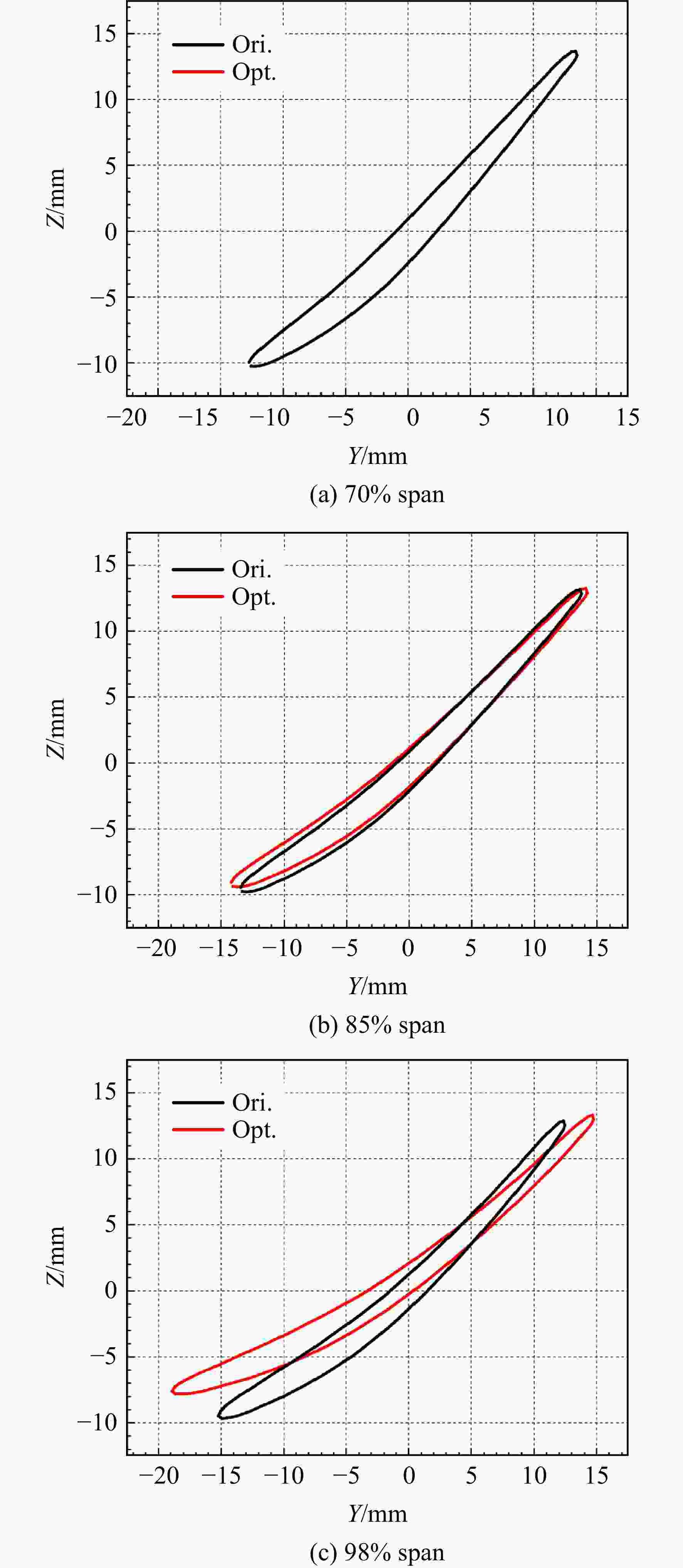

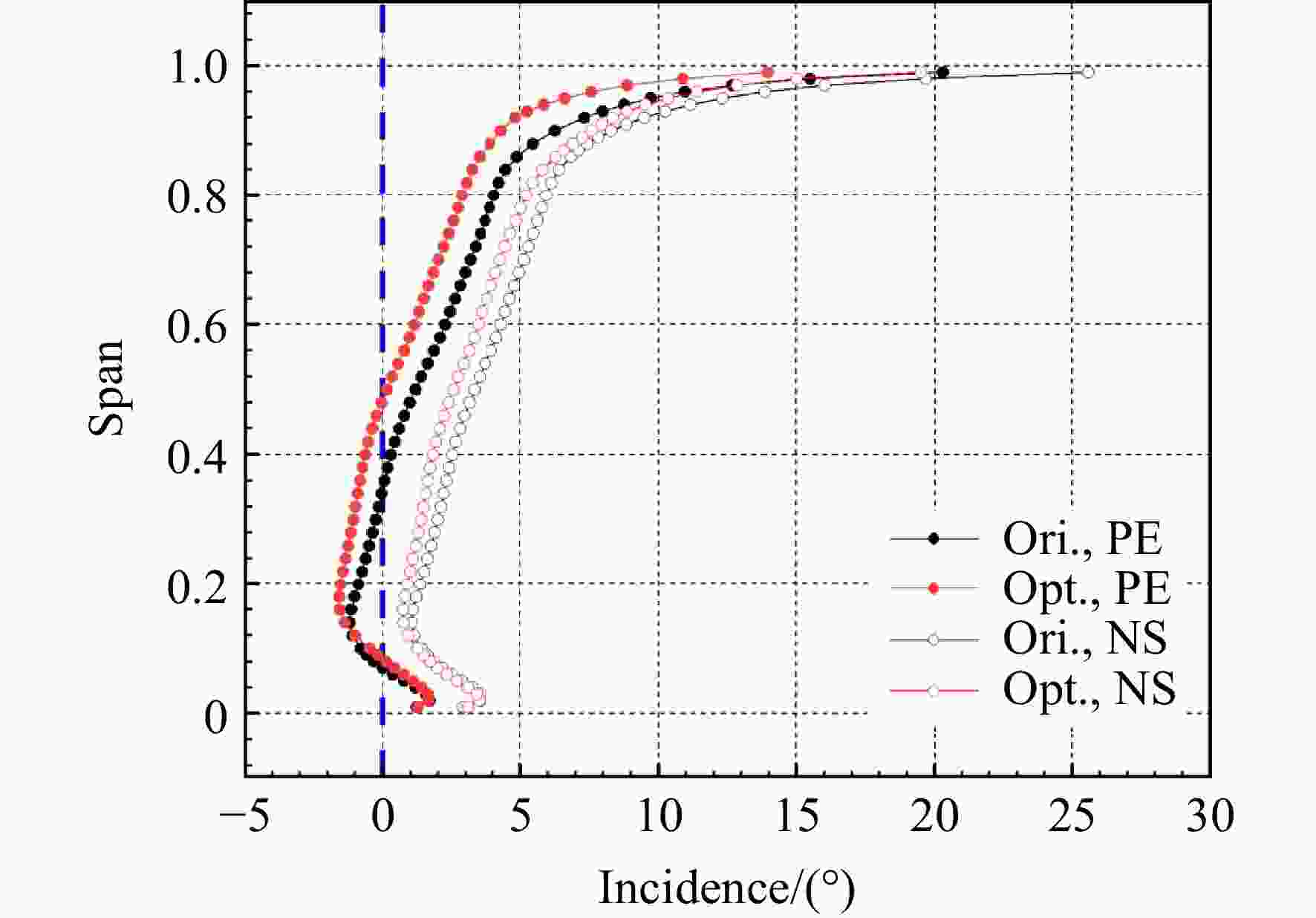

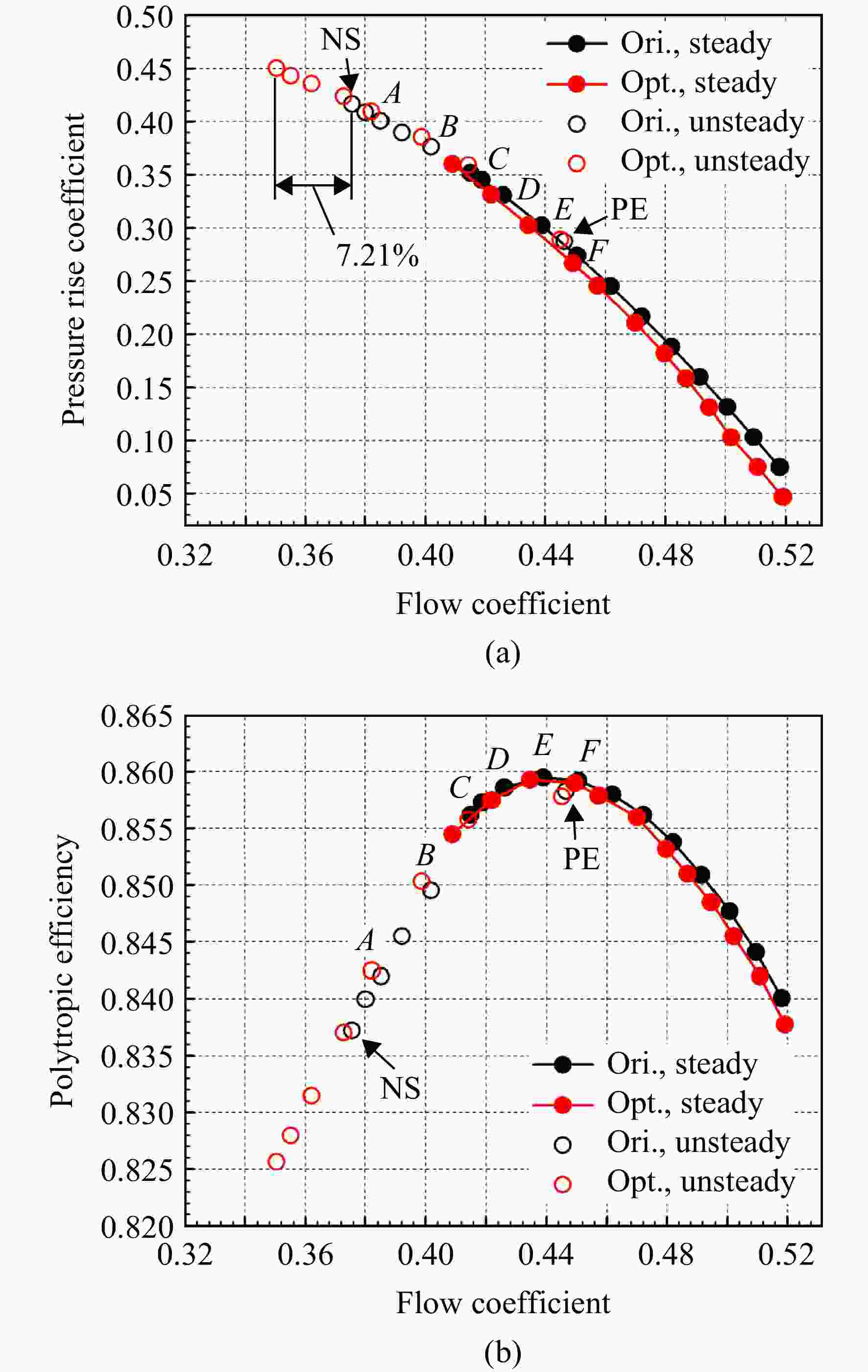

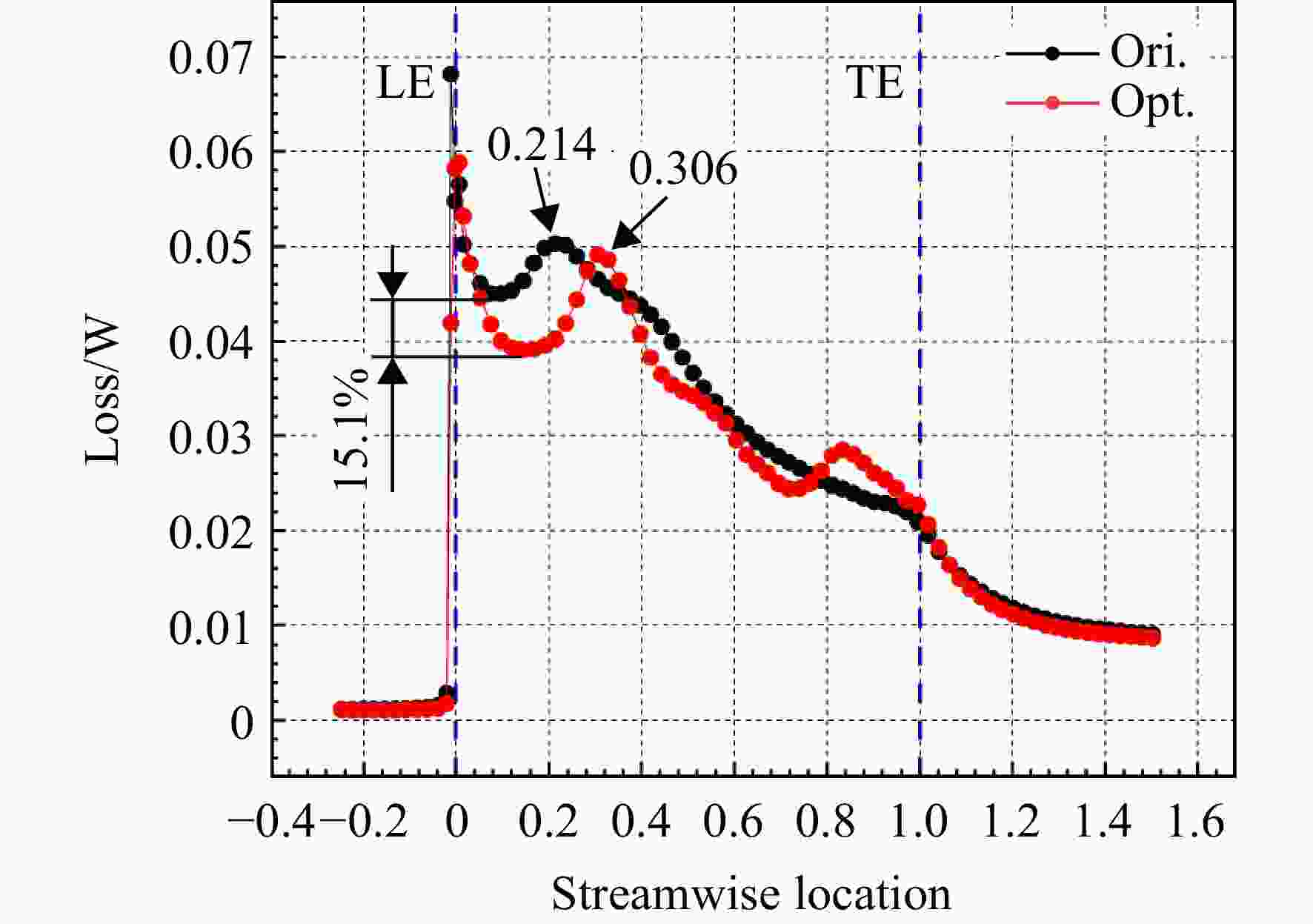

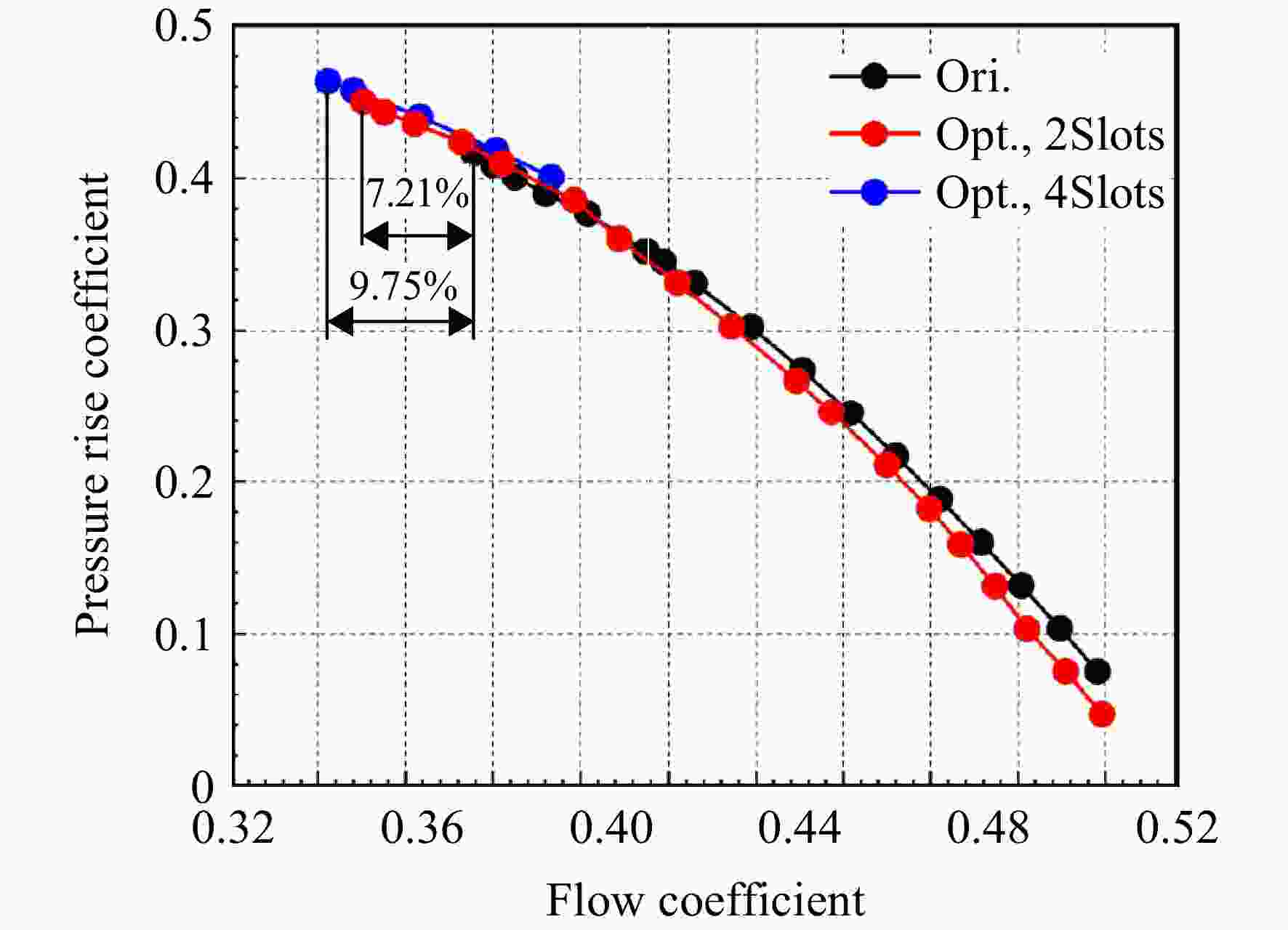

针对一台低速轴流压气机搭建了叶片与机匣处理一体化优化设计平台,基于自由变形技术关联设计参数与工程参数,实现多目标优化。综合考虑效率和裕度指标,在峰值效率不降的情况下获得了7.21%的裕度拓宽量。针对最优方案,分析了叶顶堵塞及损失分布,探讨了叶片与机匣处理一体化优化设计的扩稳机理。研究发现:叶片弯掠和机匣处理组合作用下,最大堵塞位置由24.7%叶顶轴向弦长后移至33.6%叶顶轴向弦长,最大损失位置由21.4%叶顶轴向弦长后移至30.6%叶顶轴向弦长,叶顶泄漏涡的抑制和低能堵塞区的消除是一体化优化设计扩稳的主要原因。

Abstract:An integrated optimization design platform of blade and casing treatments in a low-speed axial compressor was constructed. A practical partitioning approach for free-form deformation (FFD) parameterization combined with engineer parameters was applied to achieve multi-objective optimization. Taking both efficiency and stall margin into consideration, the optimal design improves the stall margin by 7.21% with negligible peak efficiency variation. After the analysis and calculation of blockage and loss distribution, the influence mechanism on stall margin and efficiency is further studied. Results show that with the combined effected of deformed blade and casing treatment, the location of peak blockage moves downstream from 24.7% rotor tip chord to 33.6% rotor tip chord and the location of peak efficiency moves downstream from 21.4% rotor tip chord to 30.6% rotor tip chord. The main reason for stall margin improvement is the suppression of tip leakage and the elimination of low energy blockage flow at tip region.

-

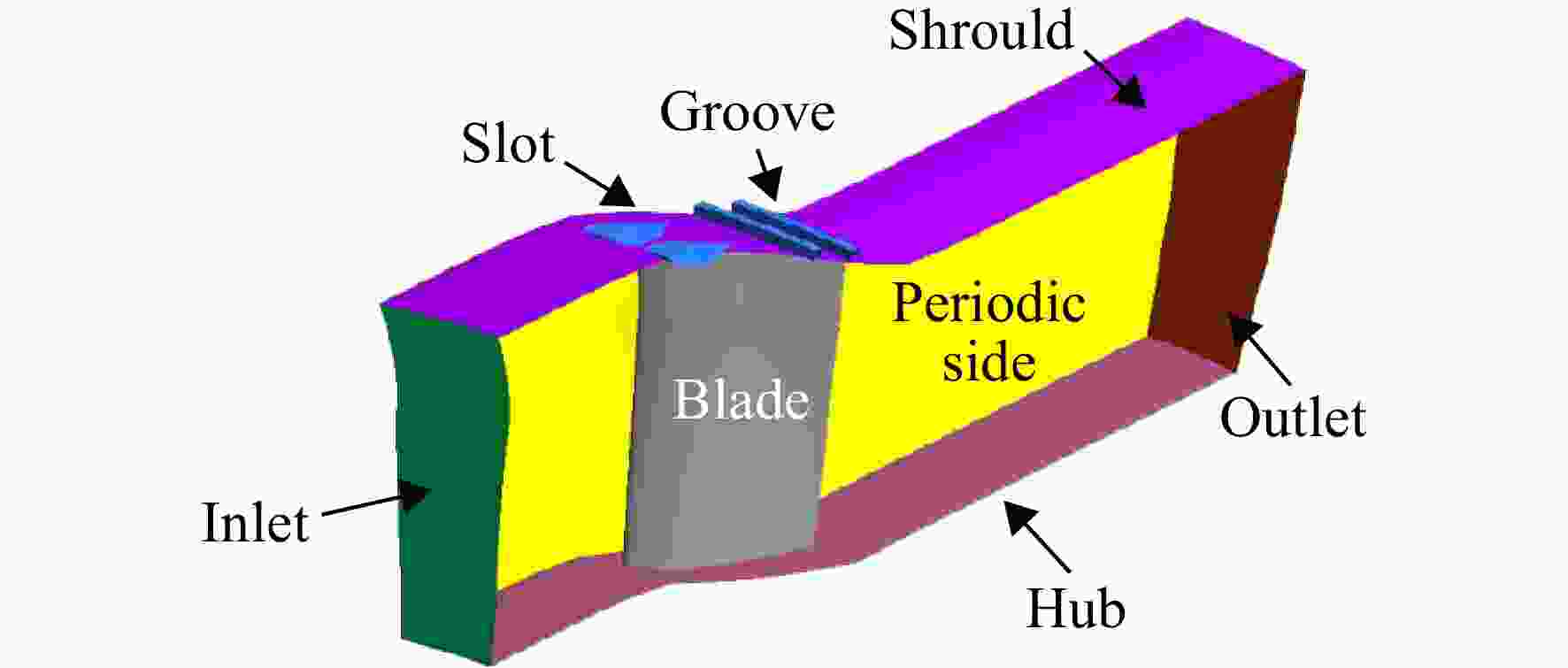

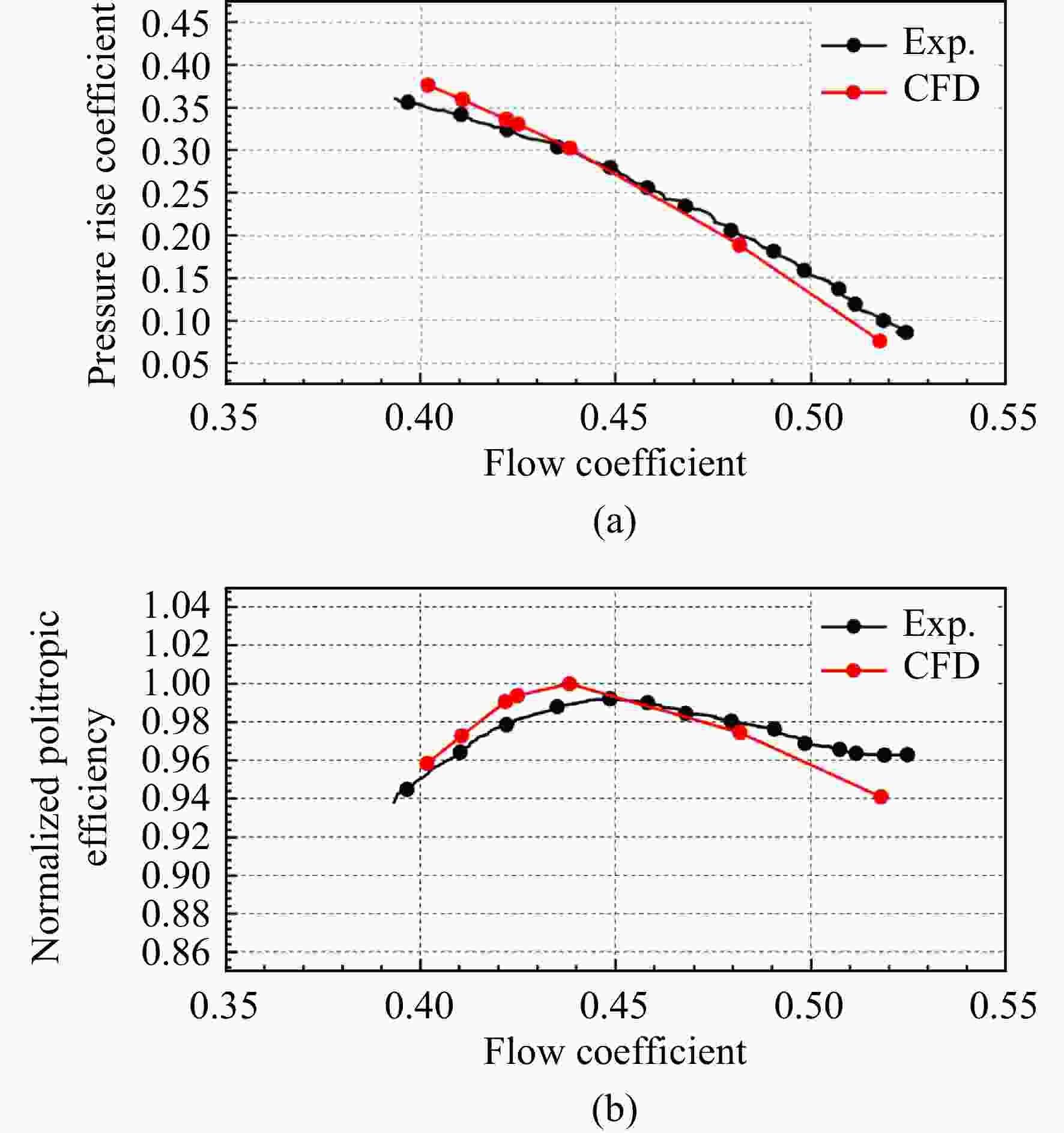

表 1 压气机单转子设计参数

Table 1. Design parameters of the compressor single rotor

参数 数值 设计转速/(r/min) 2400 设计流量/(kg/s) 2.9 马赫数 0.19 转子数 60 叶顶弦长/mm 36.3 叶顶间隙/mm 0.8 叶顶轴向弦长/mm 22.8 轮毂比 0.75 表 2 设计参数的变化范围

Table 2. Range of design parameters

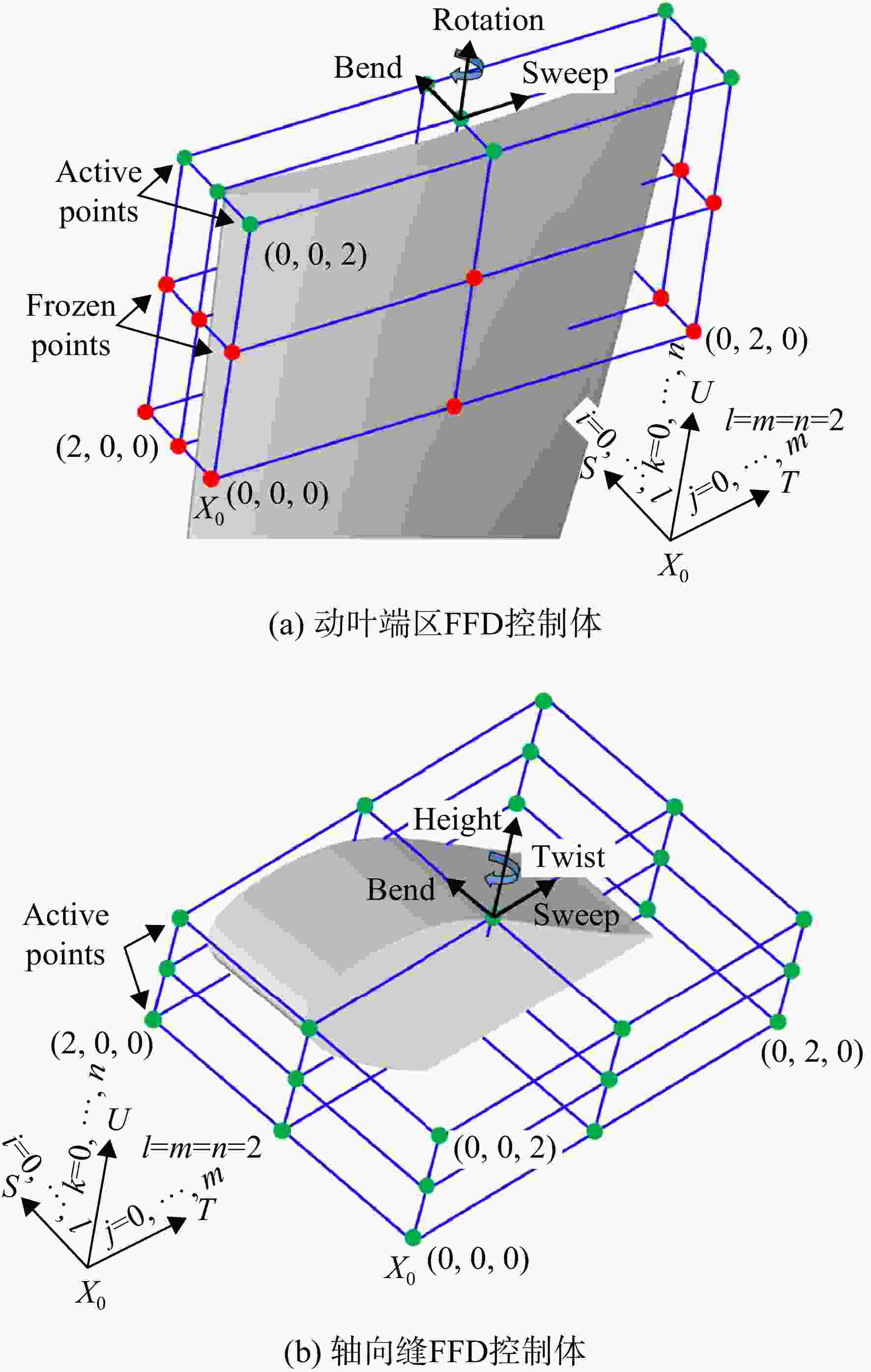

设计变量 控制点 范围 叶片控制体 叶片前缘弯(LE bend) Pijk (i=0~2; j=0; k=2) −0.1~0.25Cax 叶片尾缘弯(TE bend) Pijk (i=0~2; j=2; k=2) −0.1~0.25Cax 叶片前缘掠(LE sweep) Pijk (i=0~2; j=0; k=2) −0.1~0.25Cax 叶片尾缘掠(TE sweep) Pijk (i=0~2; j=2; k=2) −0.1~0.25Cax 叶片旋转(Rotation) Pijk (i=0~2; j=0~2; k=2; except i=j=1) −10°~10° 轴向缝控制体 轴向缝弯(Slot bend) Pijk (i =0~2; j=0~2; k=2) −0.15~0.15Cax 轴向缝掠(Slot sweep) Pijk (i =0~2; j=0~2; k=2) −0.15~0.15Cax 轴向缝扭(Slot twist) Pijk (i=0~2; j=1,2; k=0~2; except i=j=1) −60°~60° 轴向缝高(Slot height) Pijk (i=0~2; j=0~2; k=2) −0.05~0.2Cax 周向槽 周向槽缩放(Groove scale) 0.044~0.178Cax -

[1] DAY I J. Stall,surge,and 75 years of research[J]. Journal of Turbomachinery,2016,138(1): 011001. doi: 10.1115/1.4031473 [2] 卢新根,楚武利,朱俊强,等. 轴流压气机机匣处理研究进展及评述[J]. 力学进展,2006,36(2): 222-232. LU Xingen,CHU Wuli,ZHU Junqiang,et al. A review of studies on casing treatment of axial-flow compressor[J]. Advances in Mechanics,2006,36(2): 222-232. (in Chinese LU Xingen, CHU Wuli, ZHU Junqiang, et al . A review of studies on casing treatment of axial-flow compressor[J]. Advances in Mechanics,2006 ,36 (2 ):222 -232 . (in Chinese)[3] OSBORN W M,MOORE R D. Effect of casing treatment of overall performance of axial-flow transonic fan stage with pressure ratio of 1.75 and tip solidity of 1.5[R]. NASA-TM-X-3477. 1977. [4] BAILEY,EVERETT E. Effect of grooved casing treatment on the flow range capability of a single-stage axial-flow compressor[R]. NASA-TM-X-2459,1972. [5] 张皓光,谭锋,安康,等. 缝式机匣处理及其轴向偏转角对跨声速轴流压气机稳定性的改善[J]. 航空学报,2018,39(8): 108-122. ZHANG Haoguang,TAN Feng,AN Kang,et al. Effect of slot casing treatment and it’s axial deflection angle on stability of transonic axial flow compressor[J]. Acta Aeronautica et Astronautica Sinica,2018,39(8): 108-122. (in Chinese ZHANG Haoguang, TAN Feng, AN Kang, et al . Effect of slot casing treatment and it’s axial deflection angle on stability of transonic axial flow compressor[J]. Acta Aeronautica et Astronautica Sinica,2018 ,39 (8 ):108 -122 . (in Chinese)[6] 楚武利,卢新根,吴艳辉. 带周向槽机匣处理的压气机内部流动数值模拟与试验[J]. 航空动力学报,2006,21(1): 100-105. CHU Wuli,LU Xingen,WU Yanhui. Numerical and experimental investigations of the flow in a compressor with circumferential grooves[J]. Journal of Aerospace Power,2006,21(1): 100-105. (in Chinese CHU Wuli, LU Xingen, WU Yanhui . Numerical and experimental investigations of the flow in a compressor with circumferential grooves[J]. Journal of Aerospace Power,2006 ,21 (1 ):100 -105 . (in Chinese)[7] 张皓光,楚武利,吴艳辉,等. 自适应流通机匣处理改善压气机性能的机理[J]. 推进技术,2010,31(3): 301-308. ZHANG Haoguang,CHU Wuli,WU Yanhui,et al. Flow mechanisms of improving compressor performance through self recirculation casing treatment[J]. Journal of Propulsion Technology,2010,31(3): 301-308. (in Chinese ZHANG Haoguang, CHU Wuli, WU Yanhui, et al . Flow mechanisms of improving compressor performance through self recirculation casing treatment[J]. Journal of Propulsion Technology,2010 ,31 (3 ):301 -308 . (in Chinese)[8] 孙晓峰,孙大坤. 失速先兆抑制型机匣处理研究进展[J]. 航空学报,2015,36(8): 2529-2543. SUN Xiaofeng,SUN Dakun. Research progresses of stall precursor-suppressed casing treatment[J]. Acta Aeronautica et Astronautica Sinica,2015,36(8): 2529-2543. (in ChineseSUN Xiaofeng, SUN Dakun. Research progresses of stall precursor-suppressed casing treatment[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(8): 2529-2543. (in Chinese) [9] 孙大坤,孙晓峰. 非定常机匣处理对失速先兆波的抑制作用实验研究[J]. 航空动力学报,2008,23(4): 671-679. SUN Dakun,SUN Xiaofeng. An experimental study on inhibition of unsteady casing treatment on stall inception[J]. Journal of Aerospace Power,2008,23(4): 671-679. (in Chinese SUN Dakun, SUN Xiaofeng . An experimental study on inhibition of unsteady casing treatment on stall inception[J]. Journal of Aerospace Power,2008 ,23 (4 ):671 -679 . (in Chinese)[10] ZHAO Qingjun,ZHOU Xiaoyong,XIANG Xiaorong. Multi-objective optimization of groove casing treatment in a transonic compressor[J]. Proceedings of the Institution of Mechanical Engineers,Part A: Journal of Power and Energy,2014,228(6): 626-637. [11] BA Dun,ZHANG Qianfeng,DU Juan,et al. Design optimization of axial slot casing treatment in a highly-loaded mixed-flow compressor[J]. Aerospace Science and Technology,2020,107: 106262. doi: 10.1016/j.ast.2020.106262 [12] ZHU Guoming,YANG Bo. Optimization of slots-groove coupled casing treatment for an axial transonic compressor[J]. Journal of Turbomachinery,2020,142(8): 081003. doi: 10.1115/1.4046047 [13] 彭铖,李强,杨金广,等. 一种新的轴流压气机叶片参数化方法[J]. 燃气涡轮试验与研究,2020,33(2): 34-38,62. PENG Cheng,LI Qiang,YANG Jinguang,et al. A novel parameterization method of axial compressor blade[J]. Gas Turbine Experiment and Research,2020,33(2): 34-38,62. (in Chinese PENG Cheng, LI Qiang, YANG Jinguang, et al . A novel parameterization method of axial compressor blade[J]. Gas Turbine Experiment and Research,2020 ,33 (2 ):34 -38, 62 . (in Chinese)[14] GAGNON H,ZINGG D W. Two-level free-form and axial deformation for exploratory aerodynamic shape optimization[J]. AIAA Journal,2015,53(7): 2015-2026. doi: 10.2514/1.J053575 [15] JOHN A,SHAHPAR S,QIN Ning. Novel compressor blade shaping through a free-form method[J]. Journal of Turbomachinery,2017,139(8): 081002. doi: 10.1115/1.4035833 [16] BAERT L,BEAUCAIRE P,LEBORGNE M,et al. Tackling highly constrained design problems: efficient optimisation of a highly loaded transonic compressor[R]. Charlotte,US: ASME,2017. [17] ADJEI R A,FAN Chengwei,WANG Weizhe,et al. Multidisciplinary design optimization for performance improvement of an axial flow fan using free-form deformation[J]. Journal of Turbomachinery,2021,143(1): 011003. doi: 10.1115/1.4048793 [18] MENZEL S,SENDHOFF B. Representing the change - free form deformation for evolutionary design optimization[M]. Berlin,Heidelberg: Springer,2008: 63-86. [19] LI Lei,JIAO Jiangkun,SUN Shouyi,et al. Aerodynamic shape optimization of a single turbine stage based on parameterized Free-Form Deformation with mapping design parameters[J]. Energy,2019,169: 444-455. doi: 10.1016/j.energy.2018.12.031 [20] HU Handuo,YU Jianyang,SONG Yanping,et al. The application of support vector regression and mesh deformation technique in the optimization of transonic compressor design[J]. Aerospace Science and Technology,2021,112: 106589. doi: 10.1016/j.ast.2021.106589 [21] SEDERBERG T W,PARRY S R. Free-form deformation of solid geometric models[C]//Proceedings of the 13th annual conference on Computer graphics and interactive techniques. New York: ACM,1986: 151-160. [22] DU Juan,LIN Feng,LI Jichao,et al. A study of performance and flow mechanism of a slot-groove hybrid casing treatment in a low-speed compressor[R]. Montreal,Canada: ASME,2015. [23] BENINI E,BIOLLO R. Aerodynamics of swept and leaned transonic compressor-rotors[J]. Applied Energy,2007,84(10): 1012-1027. doi: 10.1016/j.apenergy.2007.03.003 [24] DU Juan,LIN Feng,ZHANG Hongwu,et al. Numerical investigation on the self-induced unsteadiness in tip leakage flow for a transonic fan rotor[J]. Journal of Turbomachinery,2010,132(2): 021017.1-021017.9 [25] LU Xingen,CHU Wuli,ZHU Junqiang,et al. Numerical investigations of the coupled flow through a subsonic compressor rotor and axial skewed slot[J]. Journal of Turbomachinery,2009,131(1): 011001-011008. doi: 10.1115/1.2948959 [26] 巴顿,杜娟,张千丰,等. 基于B样条的斜流压气机机匣处理优化设计[J]. 工程热物理学报,2020,41(9): 2171-2177. BA Dun,DU Juan,ZHANG Qianfeng,et al. Design and optimization of casing treatment based on B-spline curves in a mixed-flow compressor[J]. Journal of Engineering Thermophysics,2020,41(9): 2171-2177. (in Chinese BA Dun, DU Juan, ZHANG Qianfeng, et al . Design and optimization of casing treatment based on B-spline curves in a mixed-flow compressor[J]. Journal of Engineering Thermophysics,2020 ,41 (9 ):2171 -2177 . (in Chinese)[27] MUSTAFFA A F,KANJIRAKKAD V. Single and multiple circumferential casing groove for stall margin improvement in a transonic axial compressor[J]. Journal of Turbomachinery,2021,143(7): 071010. doi: 10.1115/1.4050444 [28] 李志远. RANS-LES混合方法轴流压气机数值模拟及熵产损失模型构建[D]. 北京: 中国科学院大学(中国科学院工程热物理研究所),2017. LI Zhiyuan. Numerical simulation of axial compressor and construction of entropy generation loss model based on the hybrid RANS/LES method[D]. Beijing: Institute of Engineering Thermophysics,Chinese Academy of Sciences,2017. (in ChineseLI Zhiyuan. Numerical simulation of axial compressor and construction of entropy generation loss model based on the hybrid RANS/LES method[D]. Beijing: Institute of Engineering Thermophysics, Chinese Academy of Sciences, 2017. (in Chinese) -

下载:

下载: