Quantitative calculation method of the casing flange leakage based on equivalent clearance

-

摘要:

结合平行平板流动理论,结合流量因子法和粗糙面接触压力与接触间隙的关系,提出了一种基于等效间隙、能够考虑微观粗糙形貌及受不均匀分布载荷的机匣安装边泄漏量定量计算方法;采用有限元计算方法,研究了内部气体压力和轴向力对机匣安装边气体泄漏量的影响规律;研究表明,随着内部气体压力的增加,泄漏量增大,随着轴向力的增加,泄漏量略微减小;最后将计算结果与泄漏量实验结果进行对比,在内部气体压力和轴向力作用下的泄漏量最大误差分别为3.5%和3.6%,证明了本文计算方法的有效性。

Abstract:A quantitative calculation method of gas leakage in casing flange considering the rough surface morphology and various distributed loads was proposed by using the parallel plate flow theory, which combined the flow factor method and the relationship between contact pressure and contact gap on the rough surface. The influence of internal gas pressure and axial force on gas leakage in casing flange was studied by finite element method. The results showed that with the increase of internal gas pressure, the leakage increased, and with the increase of axial force, the leakage decreased slightly. Finally, the calculated results were compared with the experimental results of leakage, and the maximum errors of leakage under the action of internal gas pressure and axial force were 3.5% and 3.6%, respectively, which proved the effectiveness of the proposed calculation method.

-

Key words:

- casing flange /

- roughness /

- flow factor /

- equivalent clearance /

- leakage experiment

-

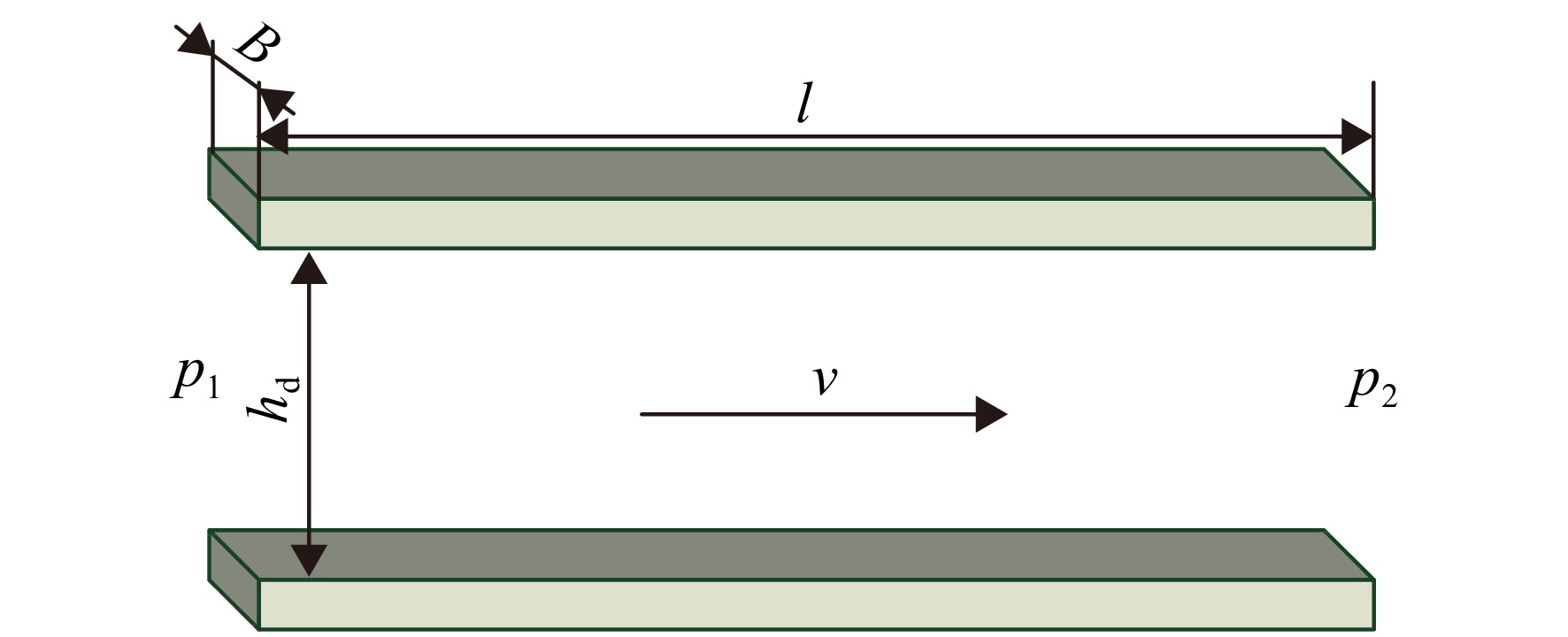

表 1 机匣安装边有限元模型几何参数

Table 1. Geometric parameters of finite element model of casing flange

mm 参数 数值 机匣长度 100 螺栓处机匣直径 640 机匣内径 740 机匣外径 720 安装边高度 4 -

[1] 刘广鑫,张定华,姚倡锋. 钛合金切削表层微观组织研究进展[J]. 机械工程学报,2021,57(15): 231-245. doi: 10.3901/JME.2021.15.231LIU Guangxin,ZHANG Dinghua,YAO Changfeng. Research progress of the microstructure on machined surface of titanium alloys[J]. Journal of Mechanical Engineering,2021,57(15): 231-245. (in Chinese) doi: 10.3901/JME.2021.15.231 [2] 吴宝海,郑志阳,张阳,等. 面向薄壁零件加工变形与振动控制的智能装夹技术研究进展[J]. 机械工程学报,2021,57(17): 21-34. doi: 10.3901/JME.2021.17.021WU Baohai,ZHENG Zhiyang,ZHANG Yang,et al. Intelligent clamping technology for machining deformation and vibration control of thin-wall parts: a review of recent progress[J]. Journal of Mechanical Engineering,2021,57(17): 21-34. (in Chinese) doi: 10.3901/JME.2021.17.021 [3] 聂祥樊,李应红,何卫锋,等. 航空发动机部件激光冲击强化研究进展与展望[J]. 机械工程学报,2021,57(16): 293-305. doi: 10.3901/JME.2021.16.293NIE Xiangfan,LI Yinghong,HE Weifeng,et al. Research progress and prospect of laser shock peening technology in aero-engine components[J]. Journal of Mechanical Engineering,2021,57(16): 293-305. (in Chinese) doi: 10.3901/JME.2021.16.293 [4] 程涛涛,王志平,戴士杰,等. 航空发动机陶瓷基高温封严涂层研究进展[J]. 机械工程学报,2021,57(10): 126-136, 147. doi: 10.3901/JME.2021.10.126CHENG Taotao,WANG Zhiping,DAI Shijie,et al. Research progress of ceramic-based high temperature sealing coating for aeroengines[J]. Journal of Mechanical Engineering,2021,57(10): 126-136, 147. (in Chinese) doi: 10.3901/JME.2021.10.126 [5] 艾延廷,李传喜,田晶,等. 基于环形板理论的机匣安装边密封特性分析方法研究[J]. 推进技术,2021,42(2): 431-439.AI Yanting,LI Chuanxi,TIAN Jing,et al. Sealing characteristic analysis method of casing installation edge based on annular plate theory[J]. Journal of Propulsion Technology,2021,42(2): 431-439. (in Chinese) [6] 艾延廷,来纯强,郝燕平,等. 航空发动机安装边螺栓连接密封特性试验[J]. 航空动力学报,2018,33(10): 2315-2323.AI Yanting,LAI Chunqiang,HAO Yanping,et al. Experiment on sealing characteristics of bolted flanged connections for aero-engines[J]. Journal of Aerospace Power,2018,33(10): 2315-2323. (in Chinese) [7] CHRISTENSEN H. Stochastic models for hydrodynamic lubrication of rough surfaces[J]. Proceedings of the Institution of Mechanical Engineers,1969,184(1): 1013-1026. doi: 10.1243/PIME_PROC_1969_184_074_02 [8] CHOW L S H,CHENG H S. The effect of surface roughness on the average film thickness between lubricated rollers[J]. Journal of Lubrication Technology,1976,98(1): 117-124. doi: 10.1115/1.3452743 [9] REYNOLDS O. On the theory of lubrication and its application to Mr. Beauchamp tower’s experiments, including an experimental determination of the viscosity of olive oil[J]. Philosophical Transactions of the Royal Society of London,1886,177: 157-234. doi: 10.1098/rstl.1886.0005 [10] PATIR N,CHENG H S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication[J]. Journal of Lubrication Technology,1978,100(1): 12-17. doi: 10.1115/1.3453103 [11] PATIR N,CHENG H S. Application of average flow model to lubrication between rough sliding surfaces[J]. Journal of Lubrication Technology,1979,101(2): 220-229. doi: 10.1115/1.3453329 [12] 任晓,吴承伟,周平. 粗糙表面的气体密封性能研究[J]. 机械工程学报,2010,46(16): 176-181. doi: 10.3901/JME.2010.16.176REN Xiao,WU Chengwei,ZHOU Ping. Gas sealing performance study of rough surface[J]. Journal of Mechanical Engineering,2010,46(16): 176-181. (in Chinese) doi: 10.3901/JME.2010.16.176 [13] 包超英,孟祥铠,李纪云,等. 基于渗流原理的液体润滑机械密封的泄漏率研究[J]. 流体机械,2014,42(11): 24-28,16.BAO Chaoying,MENG Xiangkai,LI Jiyun,et al. Study on leakage rate of liquid lubricatedmechanical seal based on percolation theory[J]. Fluid Machinery,2014,42(11): 24-28,16. (in Chinese) [14] 包超英,孟祥铠,李纪云,等. 基于多孔介质模型的机械密封静压泄漏特性分析[J]. 润滑与密封,2015,40(3): 57-63.BAO Chaoying,MENG Xiangkai,LI Jiyun,et al. The leakage performance analysis of mechanical seals under hydrostatic pressures based on porous media model[J]. Lubrication Engineering,2015,40(3): 57-63. (in Chinese) [15] LEWIS L V,FESSLER H,HYDE T H. Determination of the initial gaps between flat flanges without gaskets[J]. Proceedings of the Institution of Mechanical Engineers: Part A Power and Process Engineering,1987,201(4): 267-277. doi: 10.1243/PIME_PROC_1987_201_034_02 [16] FESSLER H,HYDE T H,LEWIS L V. Leakage through loaded flat-flanged joints without gaskets[J]. Proceedings of the Institution of Mechanical Engineers: Part A Power and Process Engineering,1988,202(1): 1-13. doi: 10.1243/PIME_PROC_1988_202_002_02 [17] 艾延廷,吴立夫,孙丹,等. 基于断裂力学理论的安装边泄漏特性分析[J]. 机械设计与制造,2017(2): 168-172.AI Yanting,WU Lifu,SUN Dan,et al. Leakage characteristics analysis of aero-engine case flange based on fracture mechanics[J]. Machinery Design & Manufacture,2017(2): 168-172. (in Chinese) [18] 焦磊. 压力管道法兰密封与泄漏的浅析[J]. 石油化工技术与经济,2012,28(4): 26-30.JIAO Lei. Tentative analysis on seal and emission of flange in pressure conduit[J]. Technology & Economics in Petrochemicals,2012,28(4): 26-30. (in Chinese) [19] 马奔奔,李源,王世建,等. 纵向无垫圈螺栓连接系统的密封性分析和轻量化设计[J]. 强度与环境,2019,46(4): 11-18.MA Benben,LI Yuan,WANG Shijian,et al. Lightweight optimal design and sealing analysis for longitudinal bolted joints without gaskets[J]. Structure & Environment Engineering,2019,46(4): 11-18. (in Chinese) [20] 张增禧,王曙,顾伯勤,等. 垫片密封泄漏模型研究[J]. 压力容器,2001,18(2): 4-6.ZHANG Zengxi,WANG Shu,GU Boqin,et al. Investigation of leakage models of gasket seal[J]. Pressure Vessel Technology,2001,18(2): 4-6. (in Chinese) [21] 杨文健. 硬密封结构界面泄漏特性的数值分析及理论预测方法[D]. 武汉: 华中科技大学, 2016.YANG Wenjian. Numerical analysis and theoretical prediction method of interface leakage characteristics in hard sealing structure[D]. Wuhan: Huazhong University of Science and Technology, 2016. (in Chinese) [22] PEEKEN H J,KNOLL G,RIENACKER A,et al. On the numerical determination of flow factors[J]. Journal of Tribology,1997,119(2): 259-264. doi: 10.1115/1.2833178 [23] WANG Q J,ZHU Dong,CHENG H S,et al. Mixed lubrication analyses by a macro-micro approach and a full-scale mixed EHL model[J]. Journal of Tribology,2004,126(1): 81-91. doi: 10.1115/1.1631017 [24] SAHLIN F,LARSSON R,ALMQVIST A,et al. A mixed lubrication model incorporating measured surface topography. Part 1: theory of flow factors[J]. Proceedings of the Institution of Mechanical Engineers: Part J Journal of Engineering Tribology,2010,224(4): 335-351. doi: 10.1243/13506501JET658 [25] ROTH A. The interface-contact vacuum sealing processes[J]. Journal of Vacuum Science and Technology,1972,9(1): 14-23. doi: 10.1116/1.1316537 -

下载:

下载: