Outlet temperature field measurement for small annular combustor by gas analysis

-

摘要:

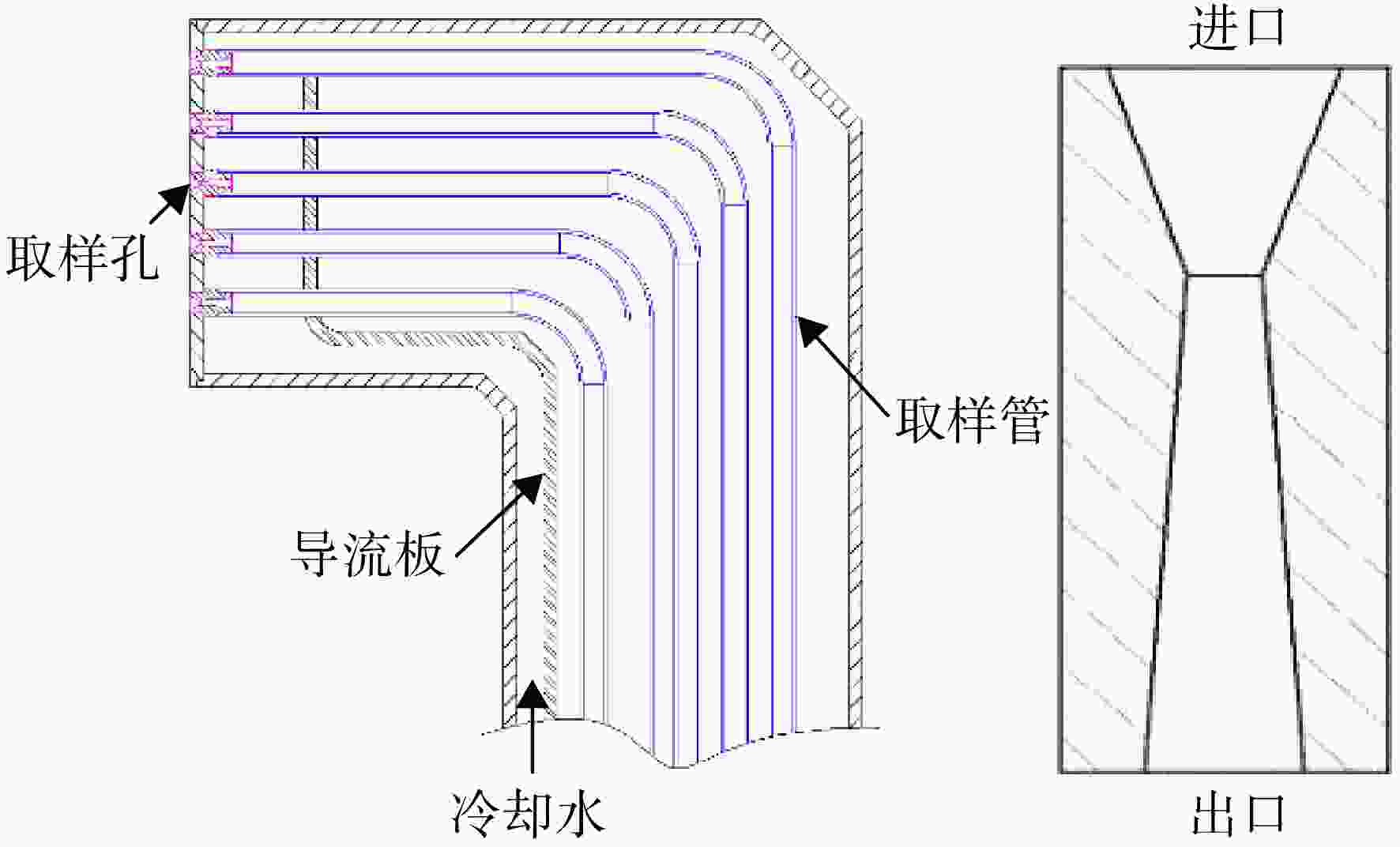

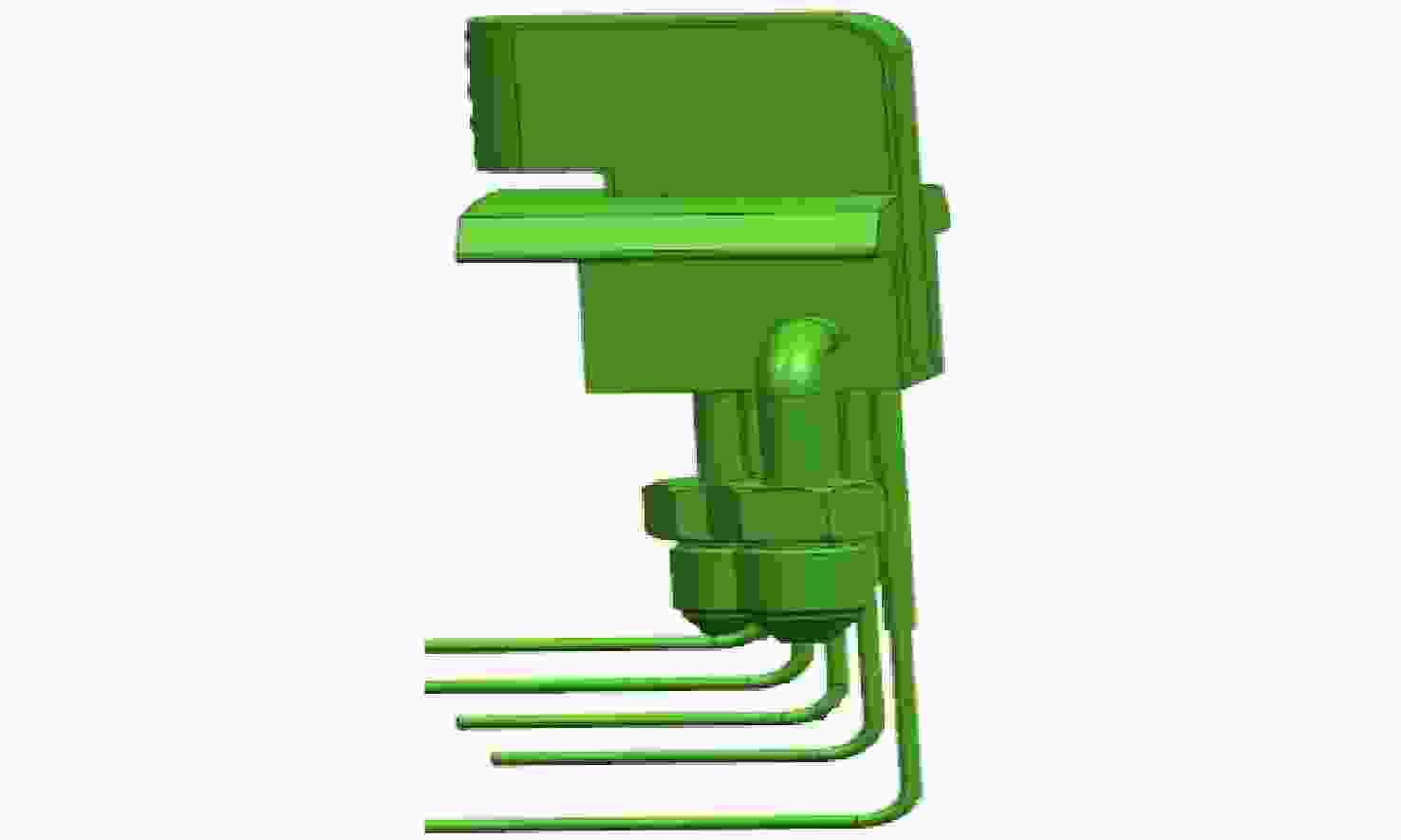

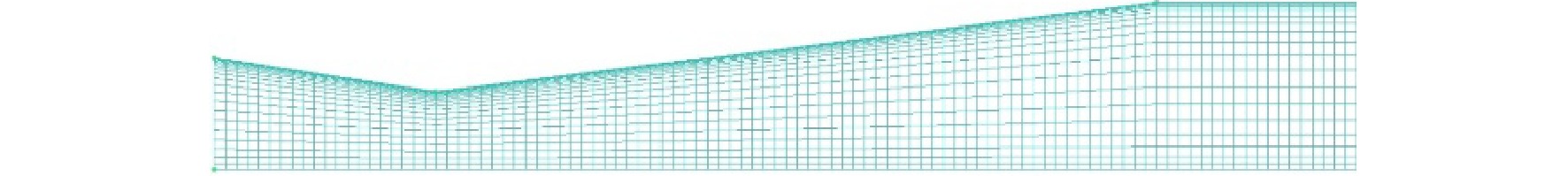

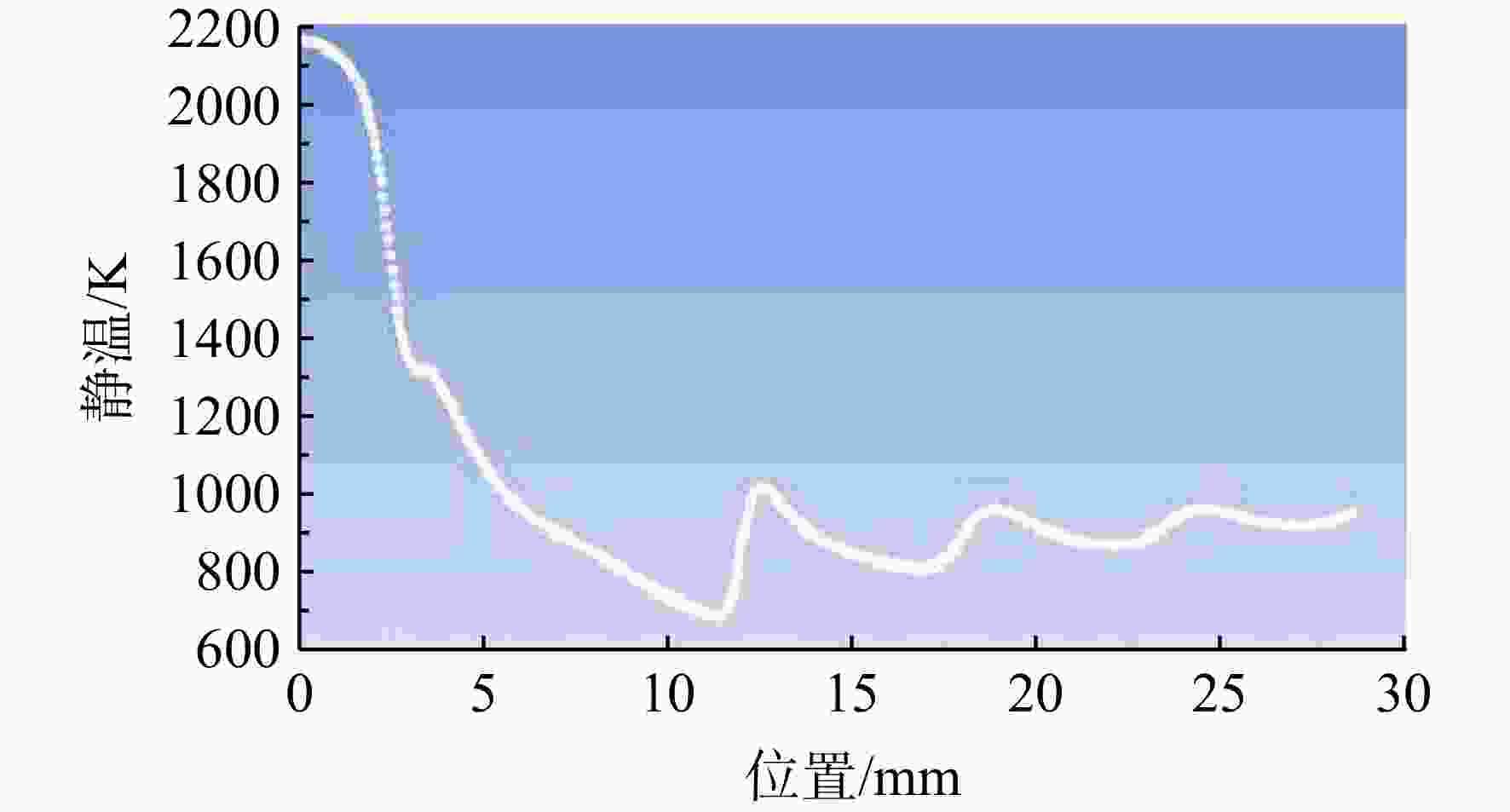

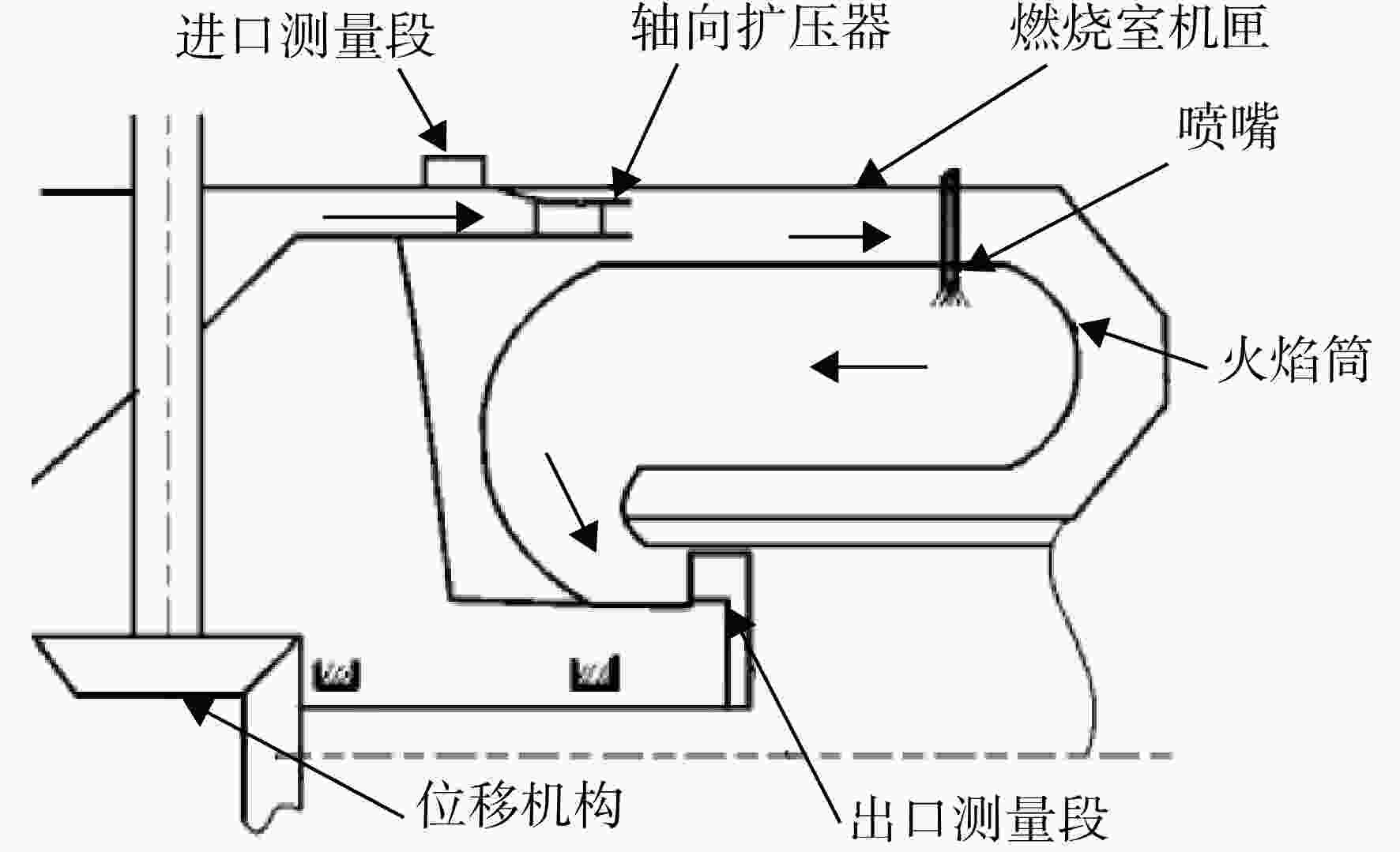

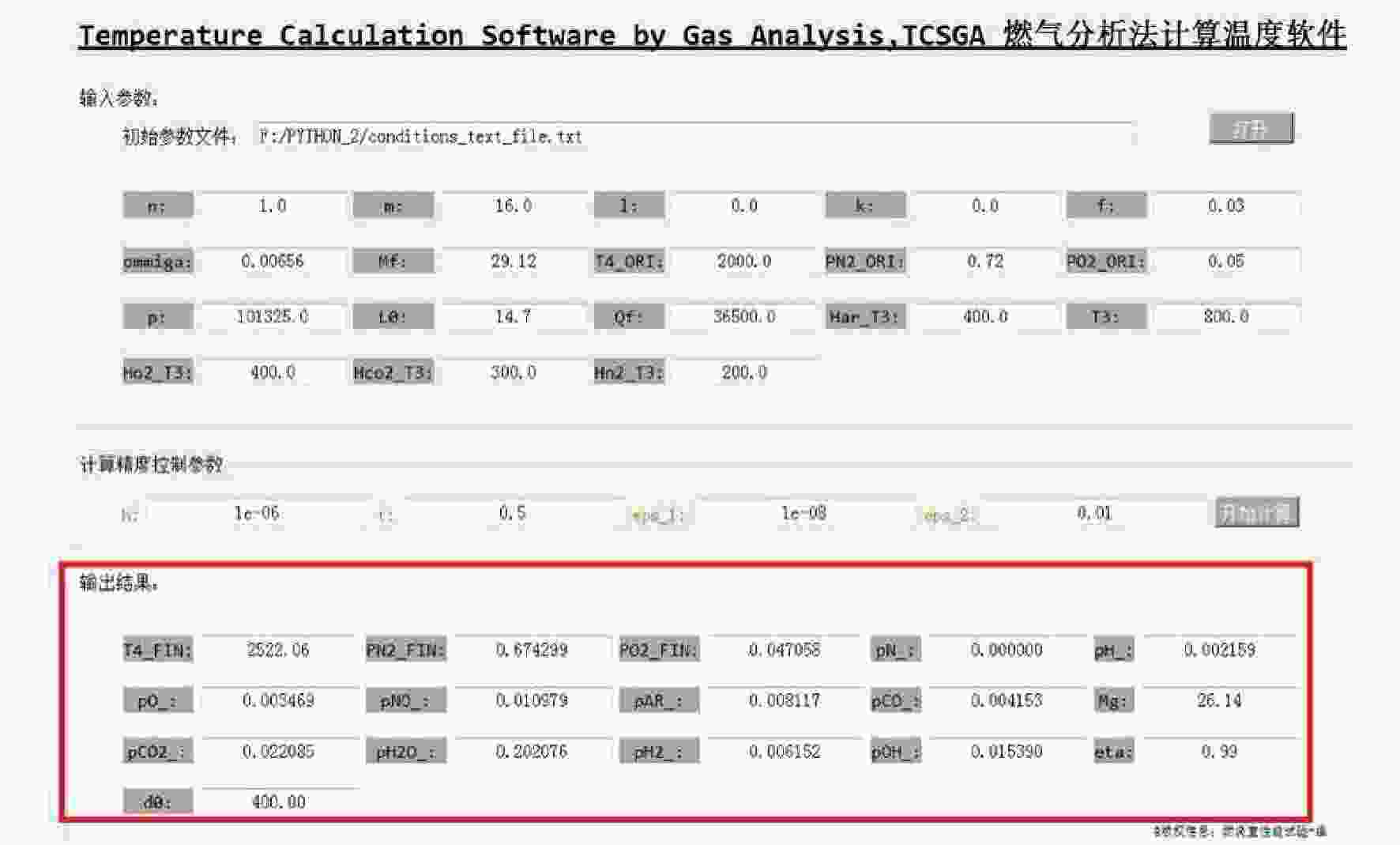

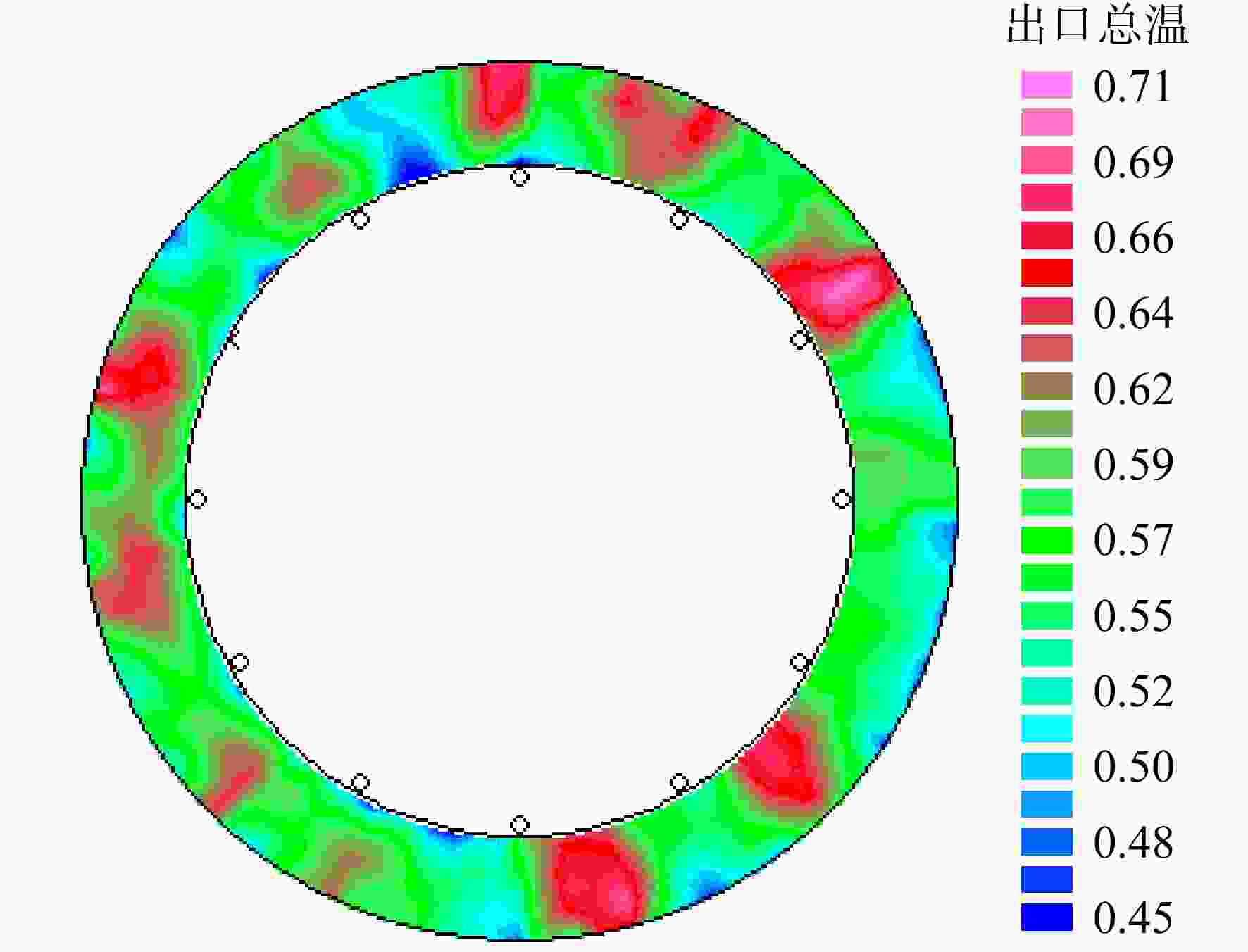

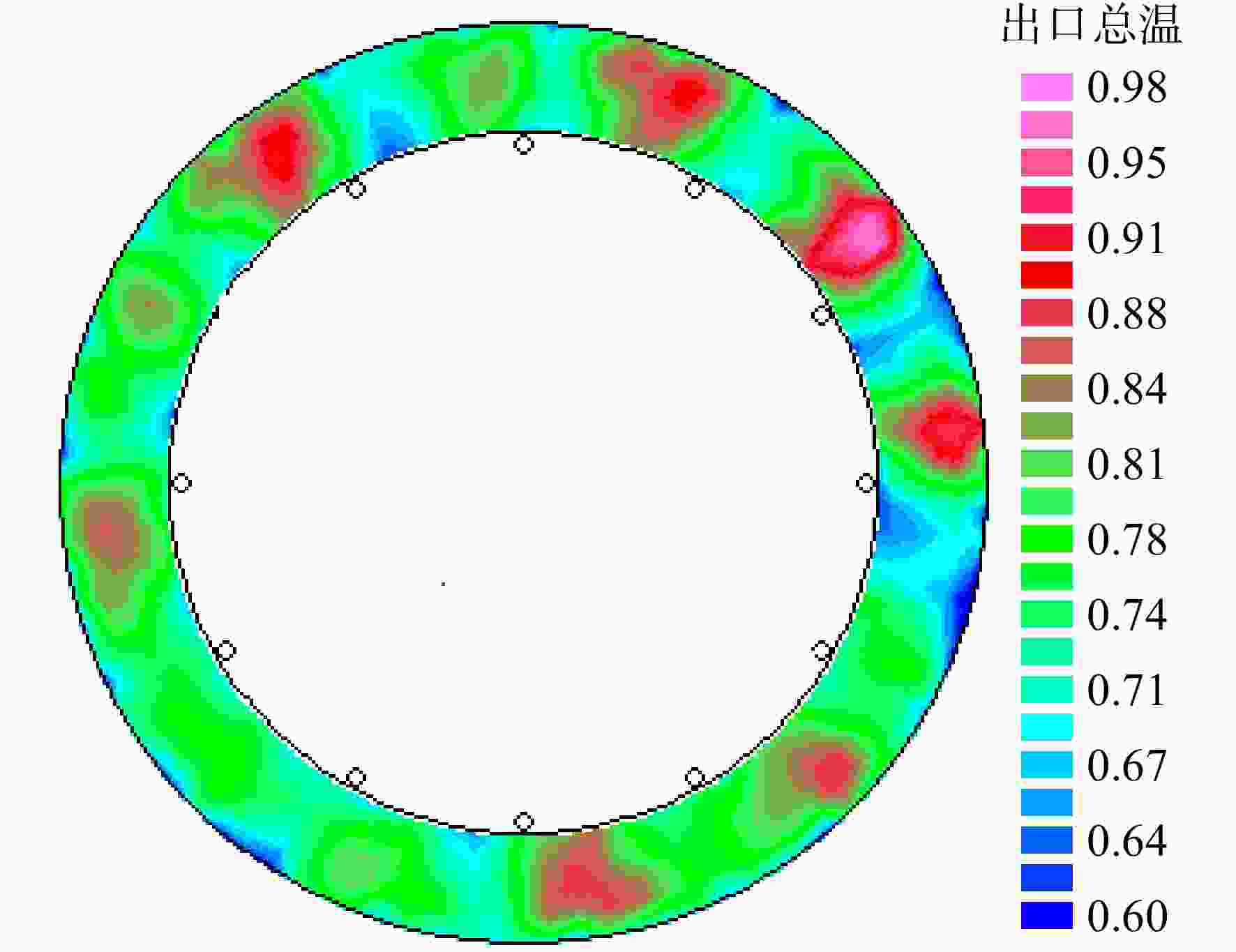

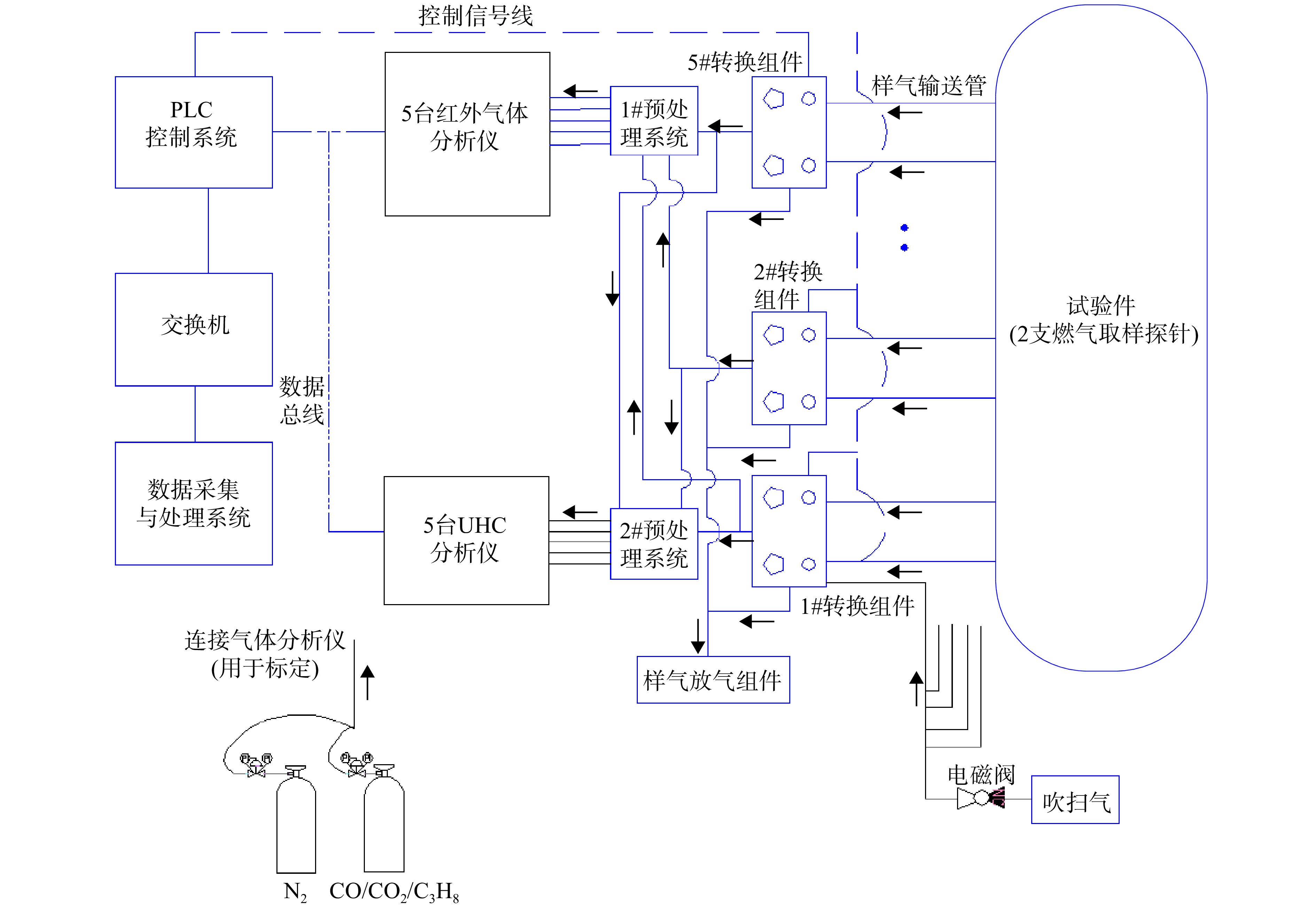

为探索燃气分析法测量小尺寸全环燃烧室出口温度场的应用,介绍了适应小尺寸全环燃烧室出口通道高度的多点非混合式水冷燃气取样探针设计,燃烧室出口分别布置2 支5 点非混合式水冷燃气取样探针和双铂铑热电偶,随位移机构旋转180°,实现正、反双向数据采集,测量二氧化碳(CO2)、一氧化碳(CO)和未燃碳氢化合物(UHC)3种组分的体积分数进而计算燃气温度。试验结果表明:燃气分析法与热电偶法测量的燃烧室出口温度分布基本一致,两者测量的相对偏差在2%以内;同时表明燃气分析法在测量航空发动机燃烧室温度场具有测温上限高、测量准确的优点。

Abstract:In order to explore the applications of outlet temperature field measurement for a small annular combustor by gas analysis, the design of multipoint non-mixed water -cooled gas sampling probe was introduced for adaptation of a small annular combustor, two five-point non-mixed water -cooled gas sampling probes and double platinum rhodium thermocouple were fixed respectively on a displacement mechanism at the combustor outlet; swinging 180° with displacement mechanism, bidirectional data measurements were achieved; the gas temperature was calculated by measuring carbon dioxide (CO2), carbon monoxide (CO) and unburned hydrocarbons (UHC). Test results showed that the combustor outlet temperature fields measured by gas analysis method and thermocouple method were consistent basically, the relative deviation of them was within 2%; at the same time, gas analysis method was proven to be dominant in measuring high gas temperature from aeroengine combustor with high upper limit of temperature measurement and high precision.

-

表 1 气体分析仪测量范围及精度

Table 1. Measurement range and accuracy of gas analyzer

测量原理 测量参数 测量范围 精度/% 非分光红外分析法 CO/10−6 0~2500 ±1.0 CO2/10−2 0~10 ±1.0 火焰离子检测法 UHC/10−6 0~10 ±5.0 10~100 ±2.0 100~5000 ±1.0 表 2 试验状态参数

Table 2. Test state parameters

试验

状态进口压力

p3/kPa进口温度

T3/K进口空气流量

Wa/(kg/s)油气比

f1 370 490 1.00 0.020 2 1500 710 3.65 0.024 表 3 油气比对比

Table 3. Comparisons of fuel-air ratio

试验

状态流量法

油气比燃气分析法

油气比相对偏差/% 1 0.0200 0.0209 4.50 2 0.0240 0.0248 3.33 表 4 测温结果对比

Table 4. Comparisons of temperature measurement results

试验状态 Tt4avg Tt4avr 相对偏差/% 1 0.589 0.579 1.73 2 0.788 0.779 1.16 注:Tt4avg为燃气分析法测量的燃烧室出口平均温度;Tt4avr为双 铂铑热电偶测量的燃烧室出口平均温度。 -

[1] LEFEBVRE A H,BALLAL D B. 燃气涡轮发动机燃烧[M]. 刘永泉, 译. 3版. 北京: 航空工业出版社,2016: 1-2. [2] 钟华贵,吉洪湖,李继保. 燃气分析测量高温燃气温度的方法[J]. 航空动力学报,2005,20(3): 460-466. ZHONG Huagui,JI Honghu,LI Jibao. Methods for gas temperature measurement by gas analysis[J]. Journal of Aerospace Power,2005,20(3): 460-466. (in Chinese doi: 10.3969/j.issn.1000-8055.2005.03.023ZHONG Huagui, JI Honghu, LI Jibao. Methods for gas temperature measurement by gas analysis[J]. Journal of Aerospace Power, 2005, 20(3): 460-466. (in Chinese) doi: 10.3969/j.issn.1000-8055.2005.03.023 [3] VAN ERP C A,RICHMAN M H. Technical challenges associated with the development of advanced combustion systems[R]. Lisbon,Portugal: The RTO AVT Symposium on “Gas Turbine Engine Combustion,Emissions and Alternative Fuels”,1998. [4] 黄春峰,石小江,钟华贵. 燃气涡轮发动机高温燃气温度测量技术[R]. 北京: 第九届发动机试验与测试技术学术会议,2008. [5] WILLIAMSON R C,STANFORTH C M. Measurement of jet engine combustion temperature by the use of thermocouples and gas analysis[C]//SAE Technical Paper Series. 400 Commonwealth Drive,Warrendale,PA,US: SAE International,1969: 1-19. [6] BIDEAU R J. The development of a computer code for the estimation of combustor exhaust temperature using simple gas analysis measurements[J]. Journal of Engineering for Gas Turbines and Power,1999,121(1): 80-88. doi: 10.1115/1.2816317 [7] 王明瑞,肖阳,韩冰,等. 航空燃气涡轮发动机燃气分析测试及计算方法[J]. 航空动力学报,2015,30(11): 2568-2574. WANG Mingrui,XIAO Yang,HAN Bing,et al. Gas analysis test and calculation method of aeroengine[J]. Journal of Aerospace Power,2015,30(11): 2568-2574. (in ChineseWANG Mingrui, XIAO Yang, HAN Bing, et al. Gas analysis test and calculation method of aeroengine[J]. Journal of Aerospace Power, 2015, 30(11): 2568-2574. (in Chinese) [8] 韩冰,王明瑞,李亚娟,等. 燃气分析法在高温升全环燃烧室出口温度场试验中的应用[J]. 航空发动机,2017,43(5): 79-84. HAN Bing,WANG Mingrui,LI Yajuan,et al. Application of gas analysis method on high temperature rise full annular combustor outlet temperature field test[J]. Aeroengine,2017,43(5): 79-84. (in ChineseHAN Bing, WANG Mingrui, LI Yajuan, et al. Application of gas analysis method on high temperature rise full annular combustor outlet temperature field test[J]. Aeroengine, 2017, 43(5): 79-84. (in Chinese) [9] 王明瑞,王振华,韩冰,等. 航空发动机主燃烧室高温测试技术[J]. 航空发动机,2016,42(5): 87-93. WANG Mingrui,WANG Zhenhua,HAN Bing,et al. High temperature measurement technology for main combustion chamber of aeroengine[J]. Aeroengine,2016,42(5): 87-93. (in ChineseWANG Mingrui, WANG Zhenhua, HAN Bing, et al. High temperature measurement technology for main combustion chamber of aeroengine[J]. Aeroengine, 2016, 42(5): 87-93. (in Chinese) [10] 韩冰,王明瑞,贾琳妍. 基于摆动测量方式的主燃烧室燃气分析测试研究[R]. 北京: 2014航空试验测试技术学术交流会论文集,2014: 77-79. [11] 李乐,索建秦,于涵,等. 燃气分析系统优化设计及应用研究[J]. 西北工业大学学报,2020,38(1): 104-113. LI Le,SUO Jianqin,YU Han,et al. Optimal design and application of gas analysis system[J]. Journal of Northwestern Polytechnical University,2020,38(1): 104-113. (in Chinese doi: 10.3969/j.issn.1000-2758.2020.01.013LI Le, SUO Jianqin, YU Han, et al. Optimal design and application of gas analysis system[J]. Journal of Northwestern Polytechnical University, 2020, 38(1): 104-113. (in Chinese) doi: 10.3969/j.issn.1000-2758.2020.01.013 [12] 王民升. 燃气分析法测量燃烧室出口燃气温度研究[D]. 西安: 西北工业大学,2004. WANG Minsheng. Study on measuring gas temperature at the exit of combustion chamber by gas analysis method[D]. Xi’an: Northwestern Polytechnical University,2004. (in ChineseWANG Minsheng. Study on measuring gas temperature at the exit of combustion chamber by gas analysis method[D]. Xi’an: Northwestern Polytechnical University, 2004. (in Chinese) [13] 中华人民共和国工业和信息化部. 航空燃气涡轮发动机气态污染物的连续取样及测量程序规范: HB6117-1987[S]. 北京: 中国标准出版社,1987: 1-19. [14] 范作民,傅巽权. 热力过程计算与燃气表-下卷[M]. 北京: 国防工业出版社,1987: 32-44. FAN Zuomin,FU Xunquan. Thermal process calculation and gas meter: Volume Ⅱ[M]. Beijing: National Defense Industry Press,1987: 32-44. (in ChineseFAN Zuomin, FU Xunquan. Thermal process calculation and gas meter: Volume Ⅱ[M]. Beijing: National Defense Industry Press, 1987: 32-44. (in Chinese) [15] 范作民. 焓值表及其应用[M]. 北京: 国防工业出版社,1976. FAN Zuomin. Enthalpy table and its application[M]. Beijing: National Defense Industry Press,1976. (in ChineseFAN Zuomin. Enthalpy table and its application[M]. Beijing: National Defense Industry Press, 1976. (in Chinese) [16] 李卫东. 一种根据燃气成分计算燃气温度的方法[J]. 中国民航学院学报,2006,24(4): 23-26. LI Weidong. Method of calculating gas temperature based on gas composition[J]. Journal of Civel Aviation University of China,2006,24(4): 23-26. (in ChineseLI Weidong. Method of calculating gas temperature based on gas composition[J]. Journal of Civel Aviation University of China, 2006, 24(4): 23-26. (in Chinese) [17] 张群,黄希桥. 航空发动机燃烧学[M]. 北京: 国防工业出版社,2015: 15-20. ZHANG Qun,HUANG Xiqiao. Aeroengine combustion[M]. Beijing: National Defense Industry Press,2015: 15-20. (in ChineseZHANG Qun, HUANG Xiqiao. Aeroengine combustion[M]. Beijing: National Defense Industry Press, 2015: 15-20. (in Chinese) [18] PLANA V,VAUTHIER J S,CASTELOOT C. Design and optimization of a high temperature water cooled probe for gas analysis measurement on K11 combustion test rig[R]. ASME Paper GT2011-45177,2021. [19] E-31 Engine Aircraft Exhaust Emissions Committee. Procedure for the continuous sampling and measurement of gaseous emissions from aircraft turbine engines: ARP1256D [S]. Washington,US: SAE International,2016: 1-19. [20] E-31 Engine Aircraft Exhaust Emissions Committee. Procedure for the analysis and evaluation of gaseous emissions from aircraft engines: ARP1533C [S]. Washington,US: SAE International,2016: 1-44. [21] 尉署名. 先进燃气轮机燃烧室设计研[M]. 上海: 上海交通大学出版社,2014. -

下载:

下载: