Effect of tip winglets on stable operating margin of transonic compressor stage

-

摘要:

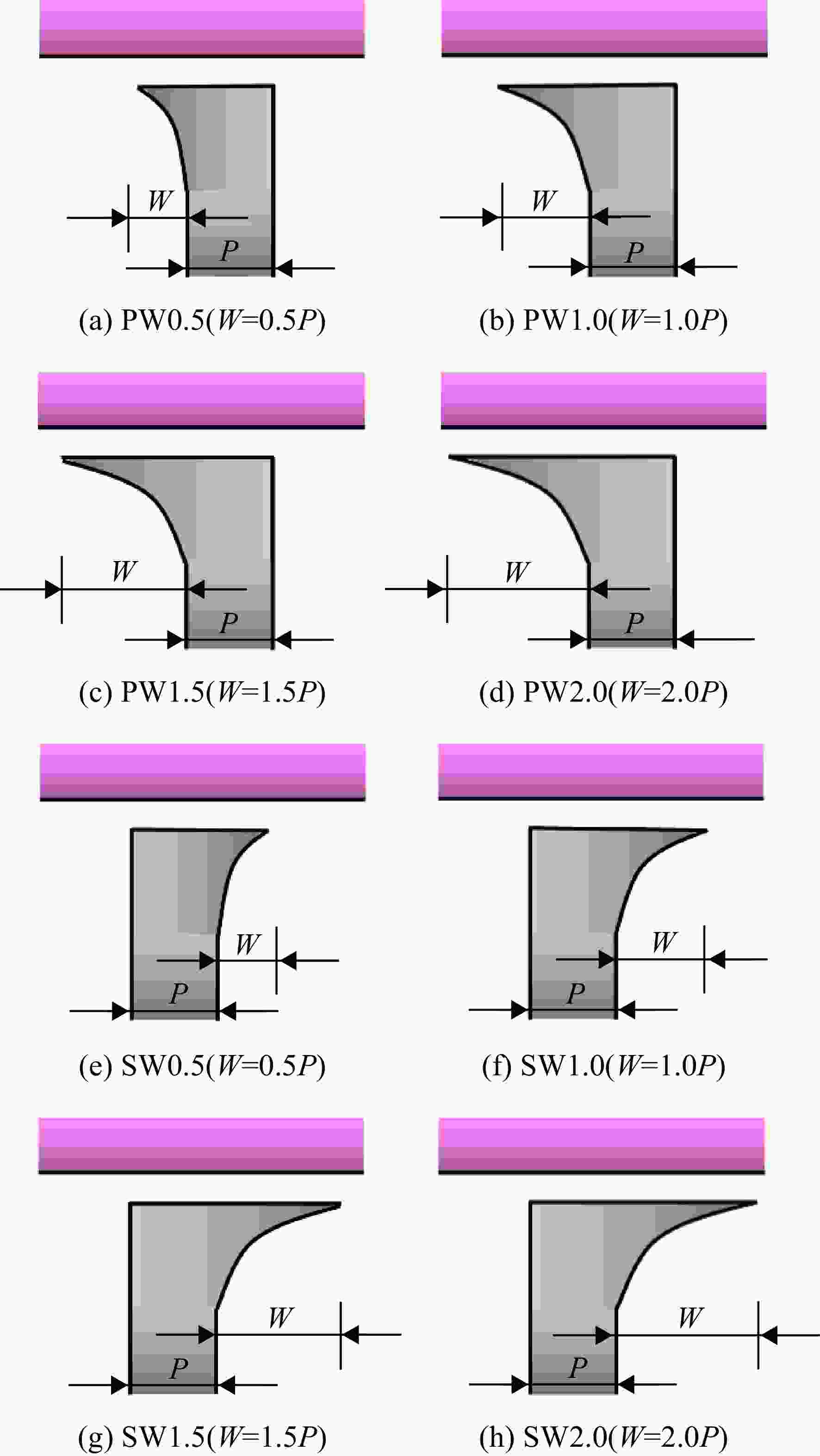

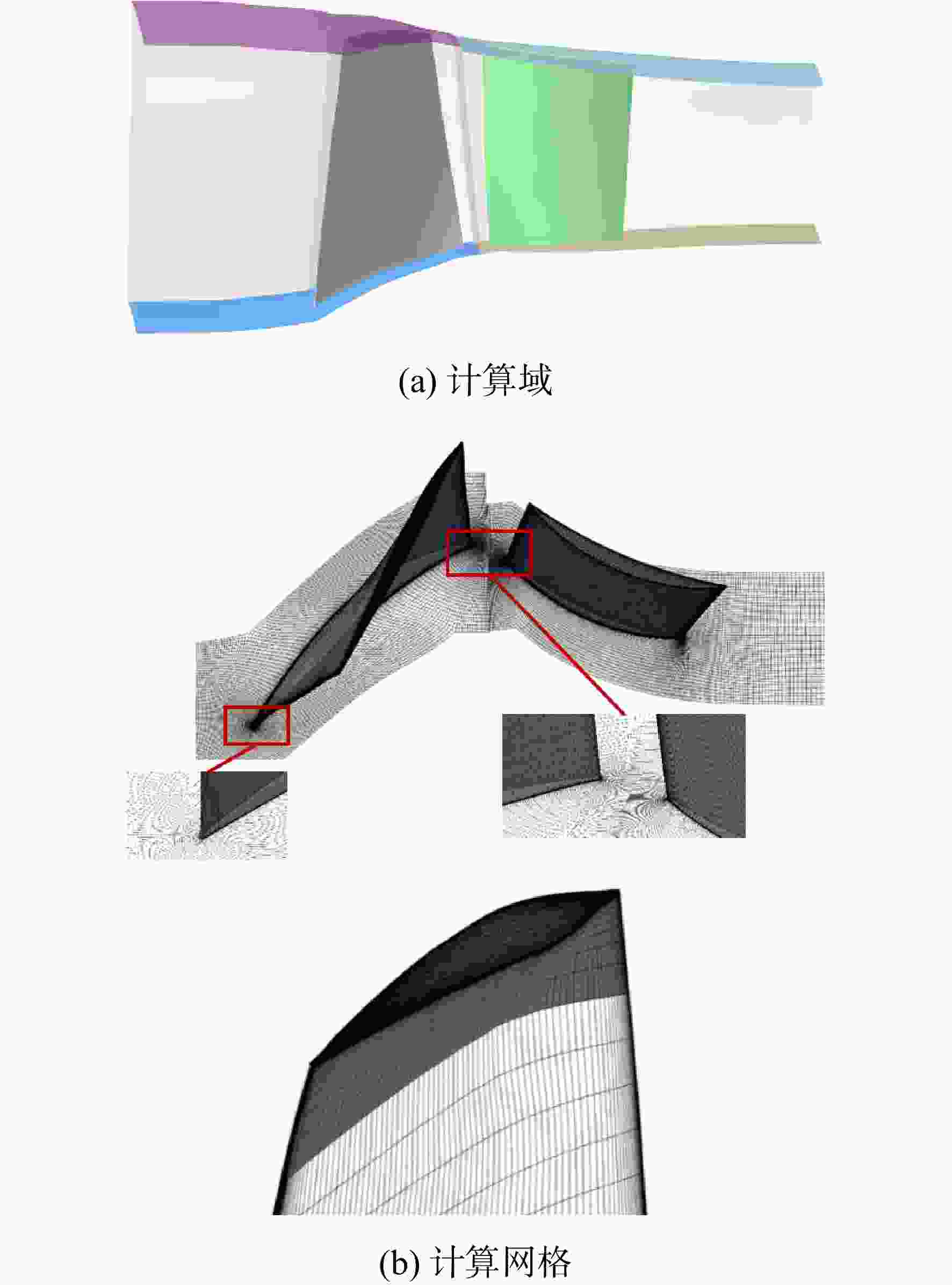

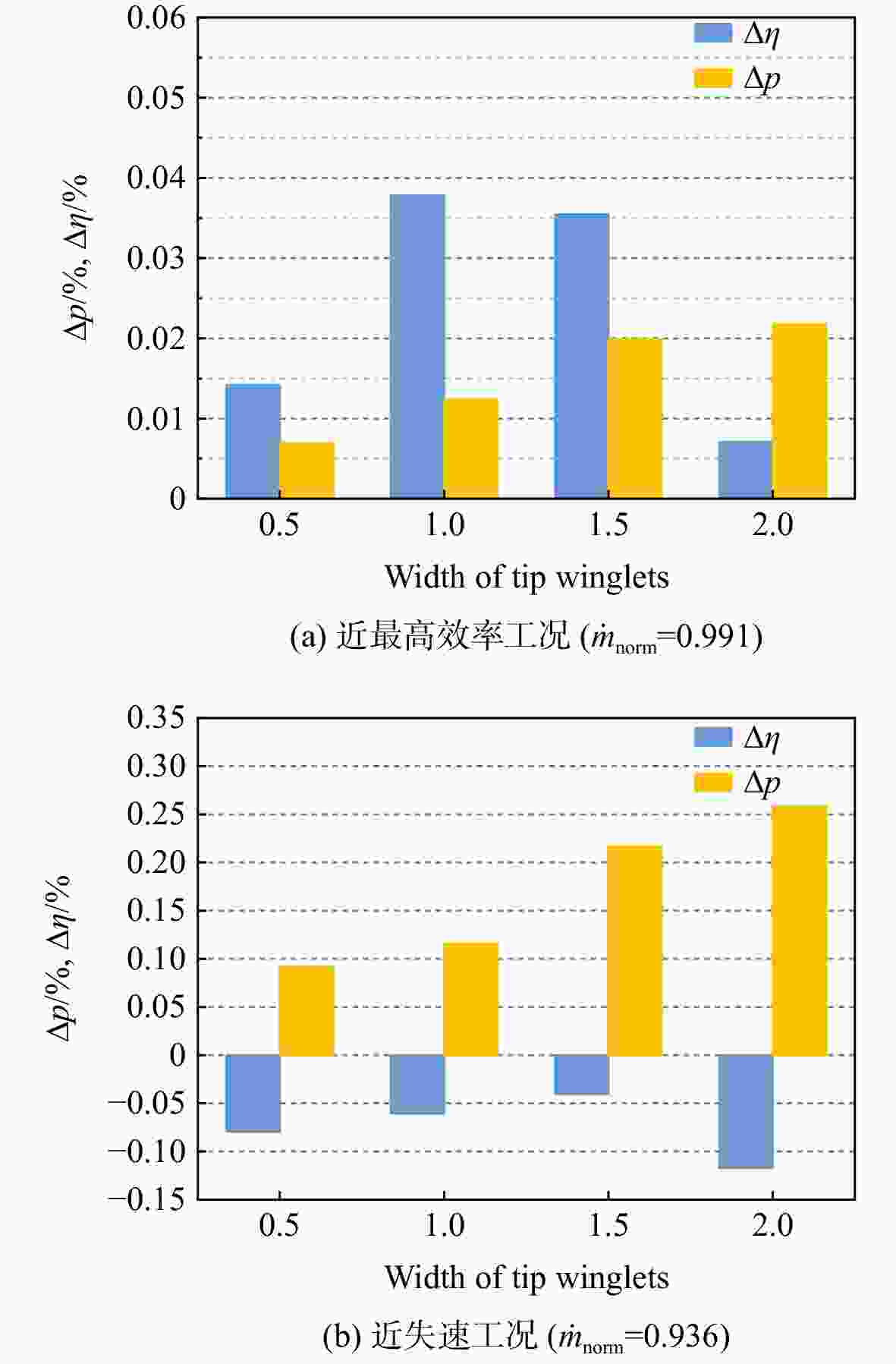

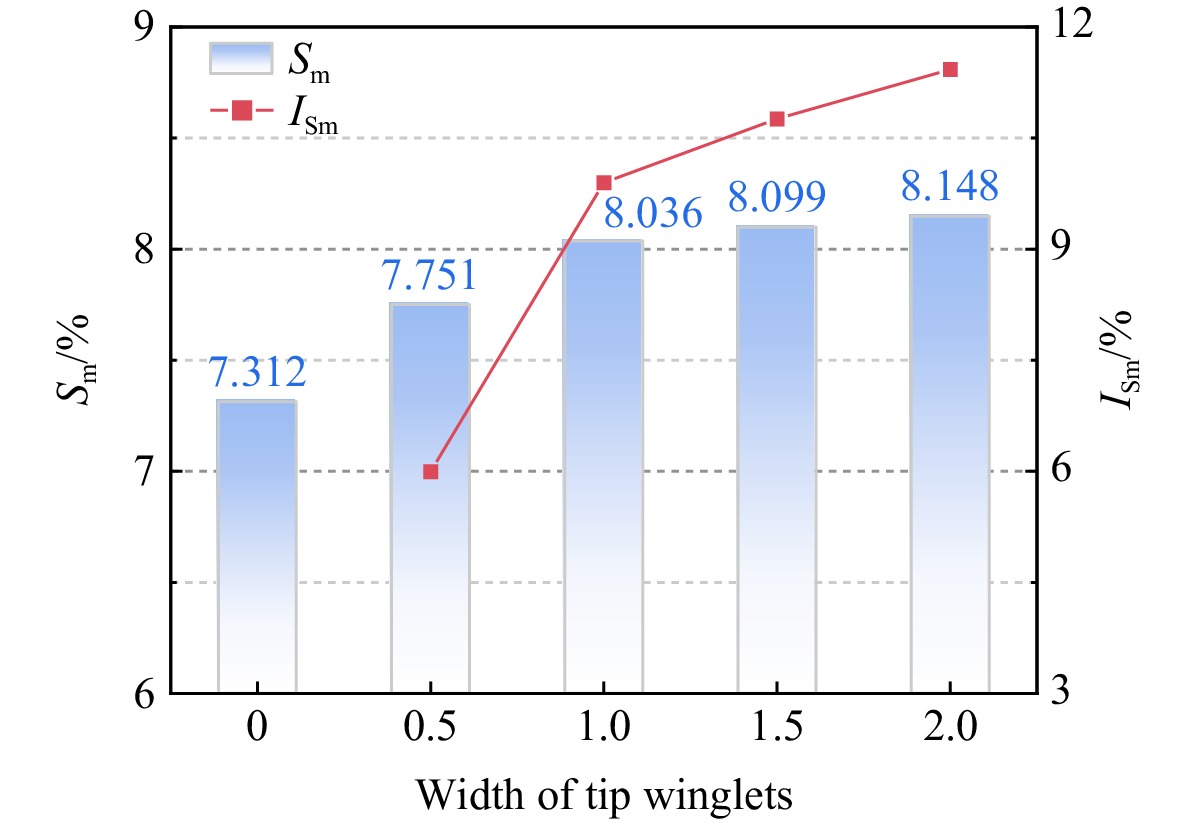

为了揭示叶尖小翼对跨声速压气机级气动性能的影响机制,利用数值方法研究了压气机级转子叶片上加装不同宽度压力面/吸力面叶尖小翼的作用效果和扩稳机制。同时,提出一种更加系统的叶尖小翼结构设计方法以优化叶尖小翼技术在压气机上的应用,使压气机级压比和绝热效率基本保持不变的前提下提升其稳定工作裕度。研究结果表明:随着压力面小翼宽度的增加,压气机级的稳定工作裕度分别增加了6.01%、9.90%、10.76%、11.43%,压力面叶尖小翼改变了转子叶顶气流偏转角,抑制了叶顶泄漏流的产生和泄漏涡破碎,提升了压气机级的流通能力,同时减弱了静子叶片吸力侧的分离损失。

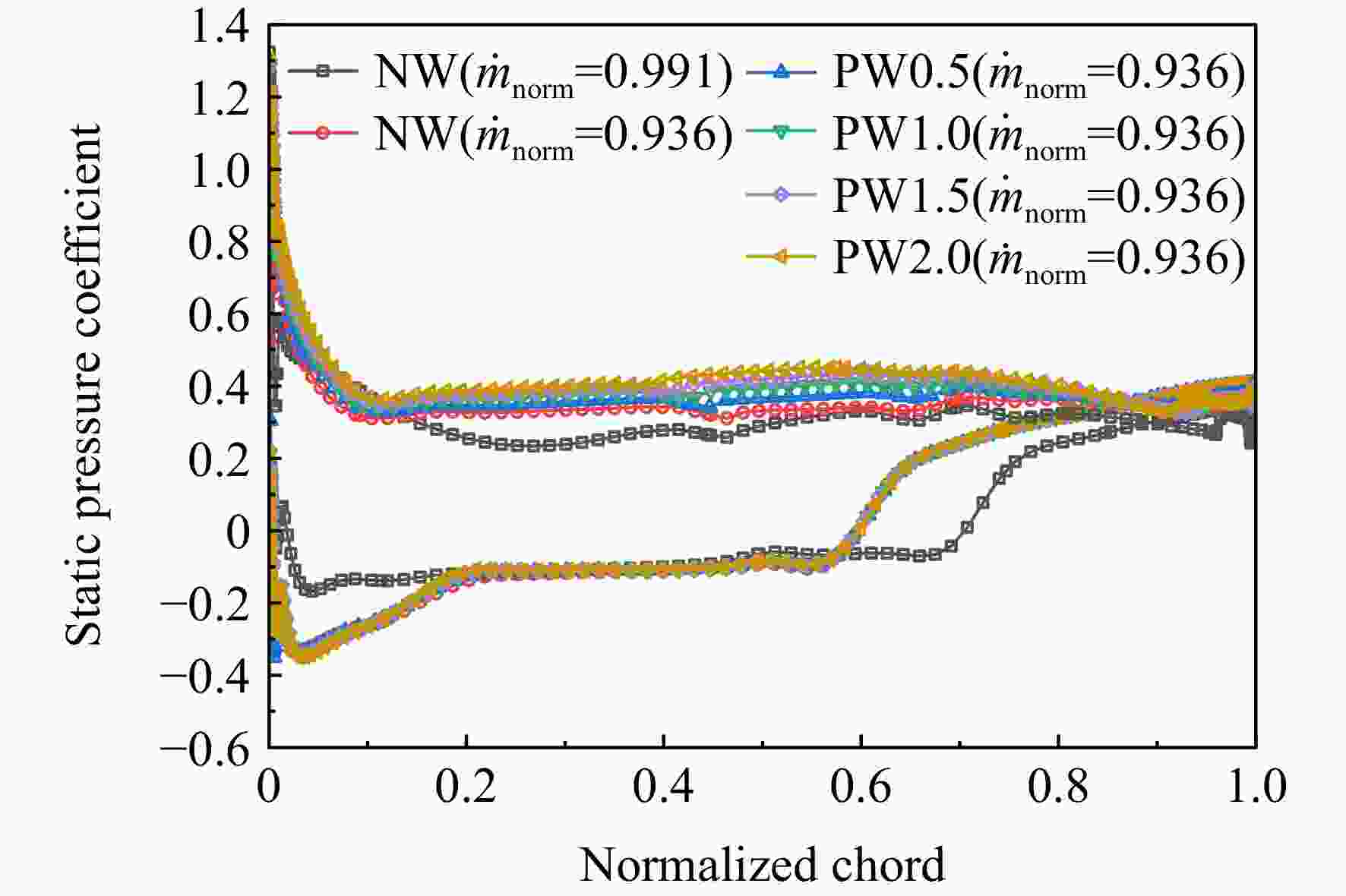

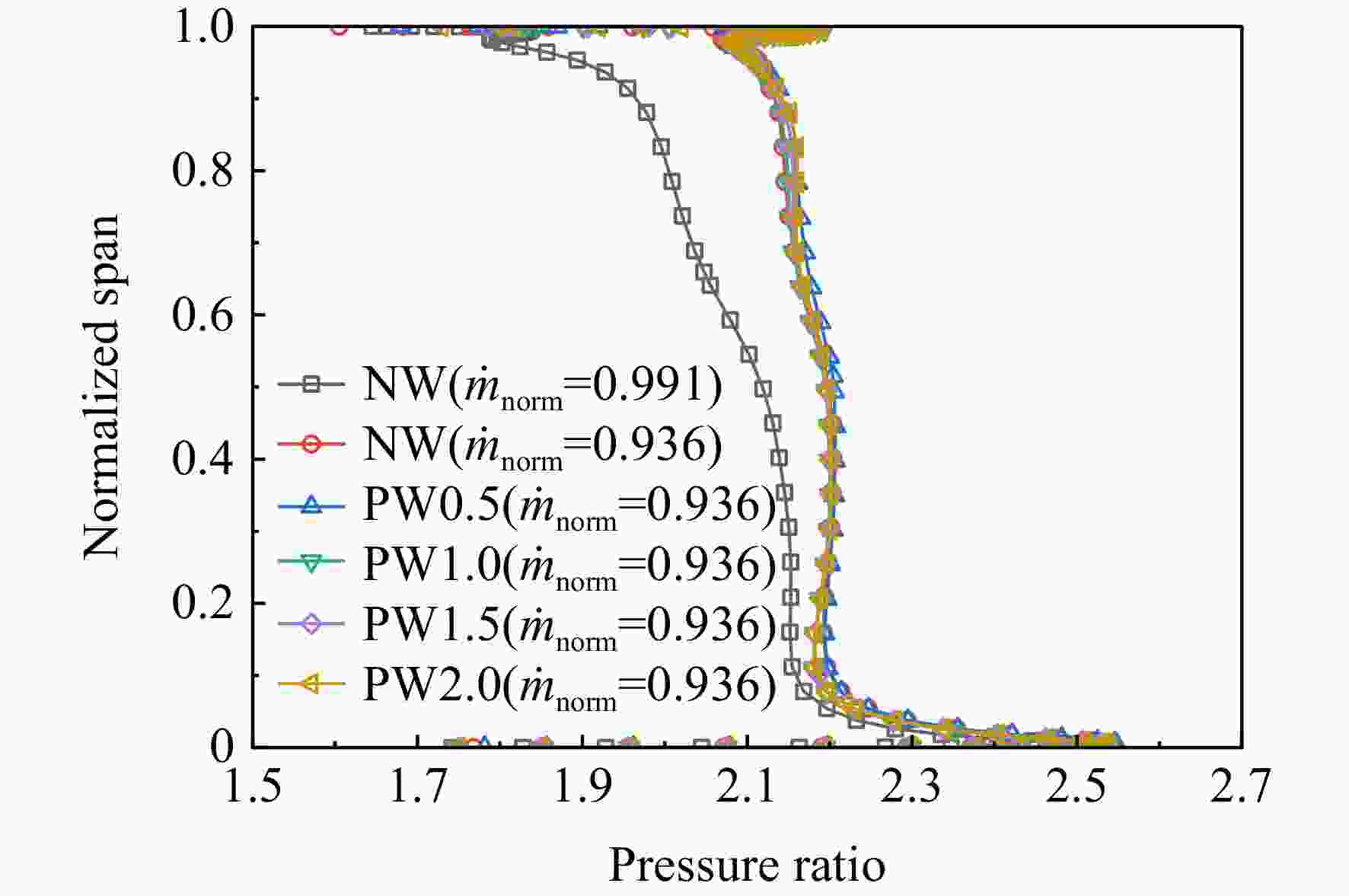

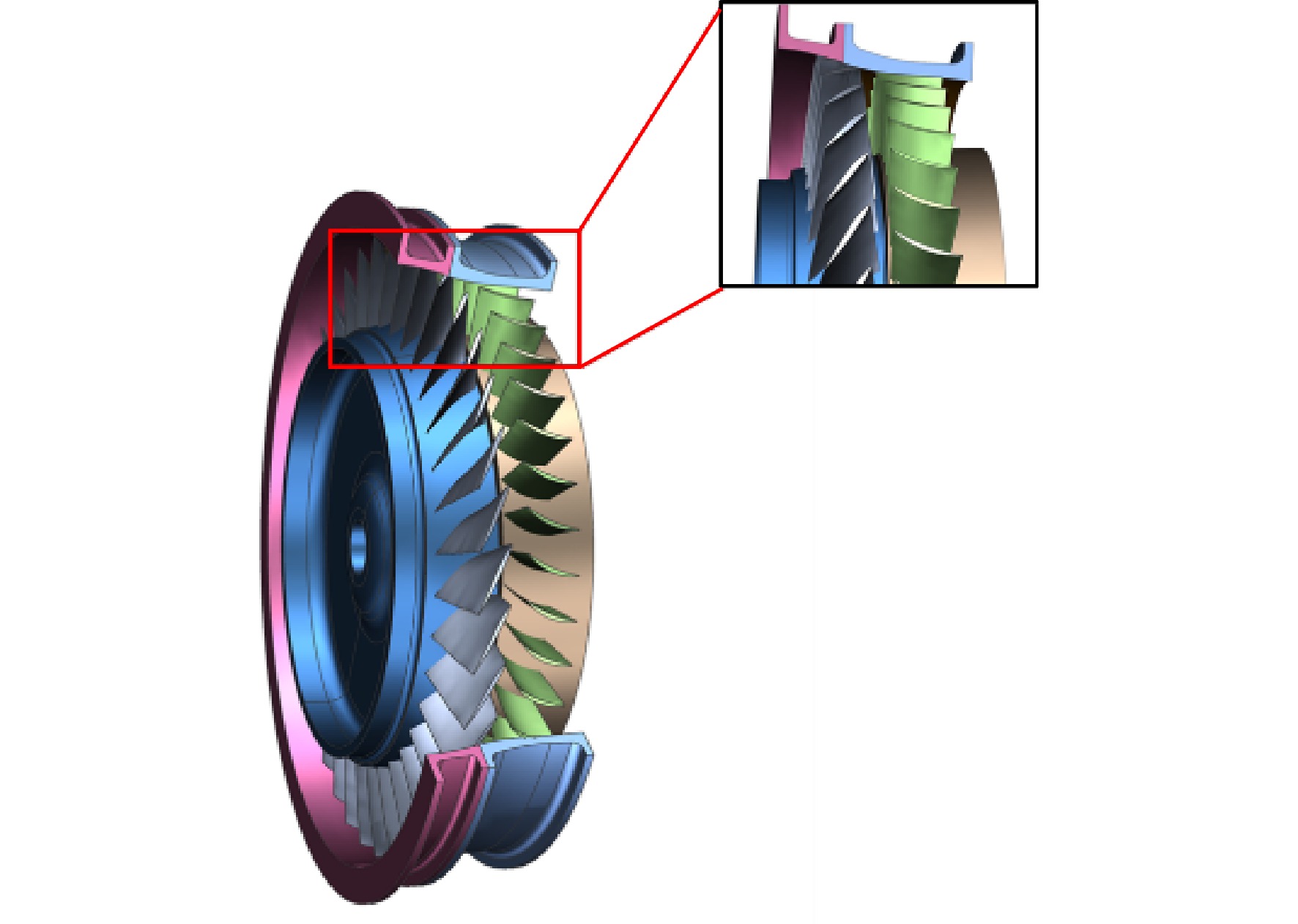

Abstract:In order to reveal the influence mechanism of tip winglet on the aerodynamic performance of the transonic compressor stage, the aerodynamic characteristics and stability expansion mechanism of compressor stage rotors with different width pressure-side/suction-side tip winglets were studied by numerical method. At the same time, a more systematic structural design method of tip winglet was proposed to optimize the application of tip winglet technology in compressor and improve its stable operating margin on the premise that the pressure ratio and adiabatic efficiency of the compressor stage are kept basically unchanged. The results showed that with the increase of pressure-side tip winglet width, the stable operating margin of the compressor stage increased by 6.01%, 9.90%, 10.76% and 11.43%, respectively. The tip winglet changed the rotor tip flow angle, inhibited the generation of the leakage and the break of the leakage vortex at the tip of rotor blades, improved the flow capacity of the passage, and reduced the separation loss of suction-side stator blades.

-

表 1 DMU37压气机级主要几何及结构参数

Table 1. Main geometric and structural parameters of DMU37 compressor stage

参数 数值 转子展弦比 1.17 转子叶片数 36 设计转速/(r/min) 24566.8 叶尖切线速度/(m/s) 452 设计间隙/mm 0.4 静子展弦比 1.26 静子叶片数 46 设计流量/(kg/s) 10 设计压比 2.05 -

[1] KUPFERSCHMIED P,KÖPPEL P,GIZZI W,et al. Time-resolved flow measurements with fast-response aerodynamic probes in turbomachines[J]. Measurement Science and Technology,2000,11(7): 1036-1054. doi: 10.1088/0957-0233/11/7/318 [2] GERTZ J B. Unsteady design-point flow phenomena in transonic compressors[D]. Cambridge, MA, USA: Massachusetts Institute of Technology, 1985. [3] SUDER K L,CELESTINA M L. Experimental and computational investigation of the tip clearance flow in a transonic axial compressor rotor[J]. Journal of Turbomachinery,1996,118(2): 218-229. doi: 10.1115/1.2836629 [4] HAH C, RABE D C. Role of tip clearance flows on flow instability in axial flow compressors[R]. ISABE 2001-1223, 2001 [5] PUTERBAUGH S L,BRENDEL M. Tip clearance flow-shock interaction in a transonic compressor rotor[J]. Journal of Propulsion and Power,1997,13(1): 24-30. doi: 10.2514/2.5146 [6] 张卓勋,吴艳辉,楚武利,等. 激波/泄漏涡相互干扰对跨声压气机流动稳定性的影响[J]. 航空动力学报,2010,25(7): 1615-1621.ZHANG Zhuoxun,WU Yanhui,CHU Wuli,et al. Influence of shock/tip leakage vortex interaction on flow stability in a single-stage transonic axial compressor[J]. Journal of Aerospace Power,2010,25(7): 1615-1621. (in Chinese) [7] 吴艳辉,安光耀,陈智洋,等. 跨声速压气机转子近失速工况非定常流动及相关机理研究[J]. 推进技术,2016,37(10): 1847-1854. doi: 10.13675/j.cnki.tjjs.2016.10.006WU Yanhui,AN Guangyao,CHEN Zhiyang,et al. Numerical investigation into unsteady flow and its associated flow mechanism in a transonic compressor rotor at near stall conditions[J]. Journal of Propulsion Technology,2016,37(10): 1847-1854. (in Chinese) doi: 10.13675/j.cnki.tjjs.2016.10.006 [8] 吴艳辉,张皓光,楚武利,等. 槽式处理机匣几何结构参数的正交试验[J]. 航空动力学报,2009,24(4): 825-829. doi: 10.13224/j.cnki.jasp.2009.04.016WU Yanhui,ZHANG Haoguang,CHU Wuli,et al. Orthogonal experimental investigation of geometry structure of grooved casing treatment[J]. Journal of Aerospace Power,2009,24(4): 825-829. (in Chinese) doi: 10.13224/j.cnki.jasp.2009.04.016 [9] 李亮,胡骏,王志强,等. 微喷气对压气机稳定性影响的实验[J]. 航空动力学报,2014,29(1): 161-168. doi: 10.13224/j.cnki.jasp.2014.01.021LI Liang,HU Jun,WANG Zhiqiang,et al. Experiment of effect of micro injection on compressor stability[J]. Journal of Aerospace Power,2014,29(1): 161-168. (in Chinese) doi: 10.13224/j.cnki.jasp.2014.01.021 [10] 樊琳. 处理机匣情形下的轴流压气机转子失速[J]. 航空动力学报,2015,30(11): 2647-2657. doi: 10.13224/j.cnki.jasp.2015.11.012FAN Lin. Stall of an axial-compressor rotor with casing treatment[J]. Journal of Aerospace Power,2015,30(11): 2647-2657. (in Chinese) doi: 10.13224/j.cnki.jasp.2015.11.012 [11] 钟兢军,韩少冰. 叶尖小翼控制压气机间隙流动的研究进展[J]. 推进技术,2017,38(10): 2200-2207. doi: 10.13675/j.cnki.tjjs.2017.10.005ZHONG Jingjun,HAN Shaobing. Research progress of compressor tip leakage flow control using blade tip winglet[J]. Journal of Propulsion Technology,2017,38(10): 2200-2207. (in Chinese) doi: 10.13675/j.cnki.tjjs.2017.10.005 [12] 韩少冰,钟兢军. 具有叶尖小翼的压气机叶栅间隙流动分析[J]. 工程热物理学报,2012,33(9): 1492-1496.HAN Shaobing,ZHONG Jingjun. Blade tip clearance flow analysis of a compressor cascade with tip winglet[J]. Journal of Engineering Thermophysics,2012,33(9): 1492-1496. (in Chinese) [13] WU Wanyang,ZHONG Jingjun. Variable clearance characteristics of high subsonic compressor cascades with blade tip winglets[J]. Journal of Thermal Science,2022,31(2): 495-510. doi: 10.1007/s11630-022-1532-x [14] 韩少冰,钟兢军. 叶尖小翼对跨声速压气机转子变工况性能的影响[J]. 航空动力学报,2016,31(3): 647-658.HAN Shaobing,ZHONG Jingjun. Influence of blade tip winglet on the off-design performance of a transonic compressor rotor[J]. Journal of Aerospace Power,2016,31(3): 647-658. (in Chinese) [15] 韩少冰,张雯棋,钟兢军. 跨声速风扇转子叶尖小翼设计与扩稳机理研究[J]. 推进技术,2020,41(7): 1484-1492.HAN Shaobing,ZHANG Wenqi,ZHONG Jingjun. Research on design of blade tip winglet for transonic fan rotor and mechanism of stability enhancement[J]. Journal of Propulsion Technology,2020,41(7): 1484-1492. (in Chinese) [16] ZHAO Qingjun,CUI Weiwei,XIANG Xiaorong,et al. Numerical investigation of blade tip winglet on flow structure in a high loading transonic rotor[J]. Proceedings of the Institution of Mechanical Engineers, Part G:Journal of Aerospace Engineering,2022,236(1): 96-108. doi: 10.1177/09544100211008093 [17] ZHONG Jingjun,WU Wanyang,HAN Shaobing. Research progress of tip winglet technology in compressor[J]. Journal of Thermal Science,2021,30(1): 18-31. doi: 10.1007/s11630-020-1402-3 [18] 钟兢军,魏曼. 压力面小翼对涡轮叶栅不同冲角下流场影响的实验研究[J]. 推进技术,2016,37(5): 892-899. doi: 10.13675/j.cnki.tjjs.2016.05.013ZHONG Jingjun,WEI Man. Experimental investigation of different pressure-side winglets on tip clearance flow in a turbine cascade with different incidences[J]. Journal of Propulsion Technology,2016,37(5): 892-899. (in Chinese) doi: 10.13675/j.cnki.tjjs.2016.05.013 [19] HAN Shaobing,ZHONG Jingjun. Effect of blade tip winglet on the performance of a highly loaded transonic compressor rotor[J]. Chinese Journal of Aeronautics,2016,29(3): 653-661. doi: 10.1016/j.cja.2016.04.014 [20] 张燕海. 转静子交界面处理方法和湍流模型对压气机数值计算影响研究[D]. 南昌: 南昌航空大学, 2016.ZHANG Yanhai. Research on effect of rotor/stator interface approach and turblence model on simulation of compressor[D]. Nanchang: Nanchang Hangkong University, 2016. (in Chinese) [21] 向宏辉,王掩刚,高杰,等. 轴流压气机效率测量两类影响因素的试验研究[J]. 燃气涡轮试验与研究,2019,32(3): 1-7. doi: 10.3969/j.issn.1672-2620.2019.03.001XIANG Honghui,WANG Yangang,GAO Jie,et al. Experimental investigation of two effect factors on axial flow compressor efficiency measurement[J]. Gas Turbine Experiment and Research,2019,32(3): 1-7. (in Chinese) doi: 10.3969/j.issn.1672-2620.2019.03.001 [22] 杜娟,王偲臣,李继超,等. 轴流压气机叶顶泄漏流与突尖先兆失稳机理的研究进展[J]. 推进技术,2017,38(10): 2208-2217. doi: 10.13675/j.cnki.tjjs.2017.10.006DU Juan,WANG Sichen,LI Jichao,et al. Research progress on tip leakage flow and spike-inception stall mechanism in axial compressors[J]. Journal of Propulsion Technology,2017,38(10): 2208-2217. (in Chinese) doi: 10.13675/j.cnki.tjjs.2017.10.006 -

下载:

下载: