Analytical aero-structural modeling and optimization method of three-dimensional wing based on CST

-

摘要:

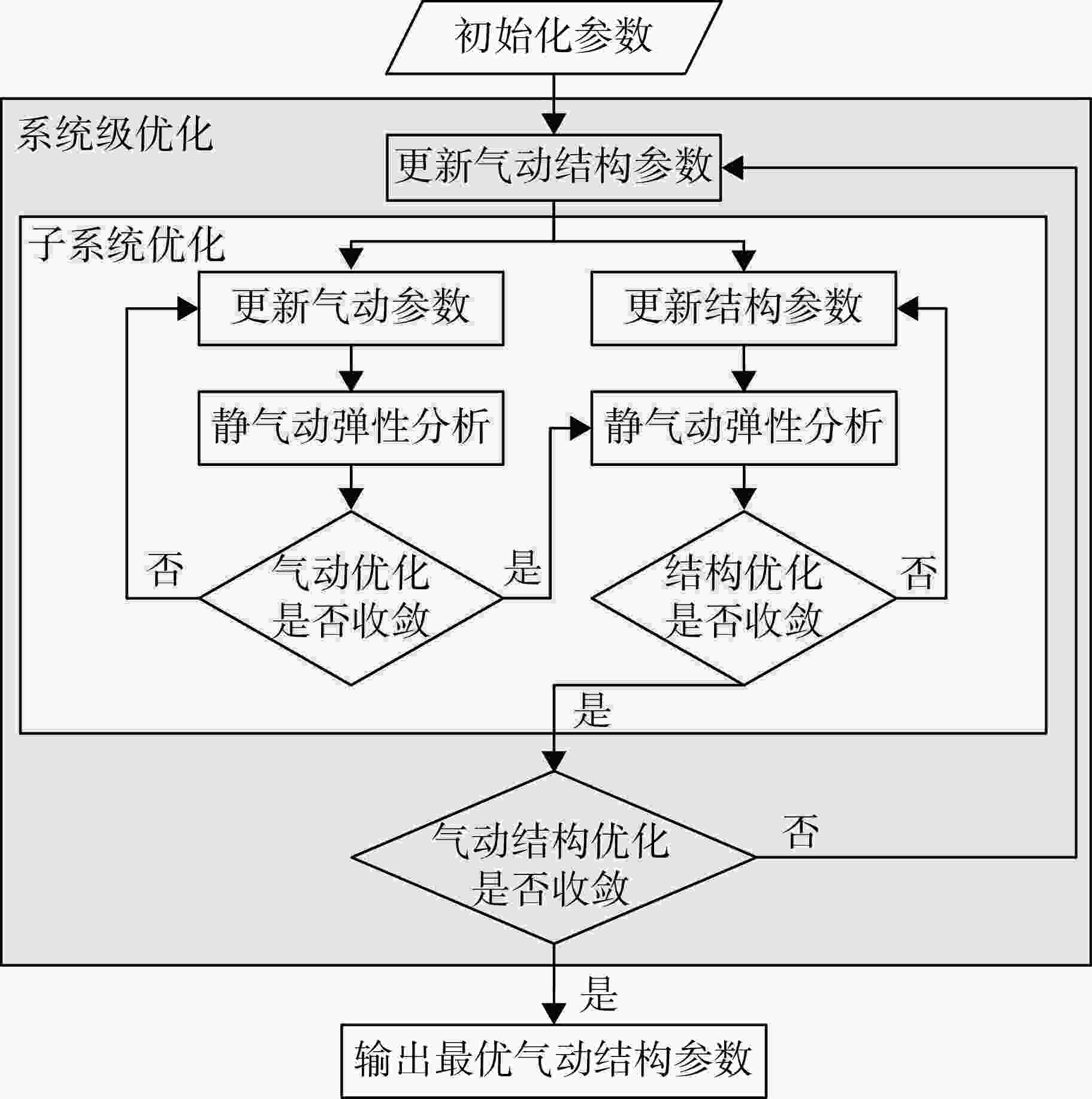

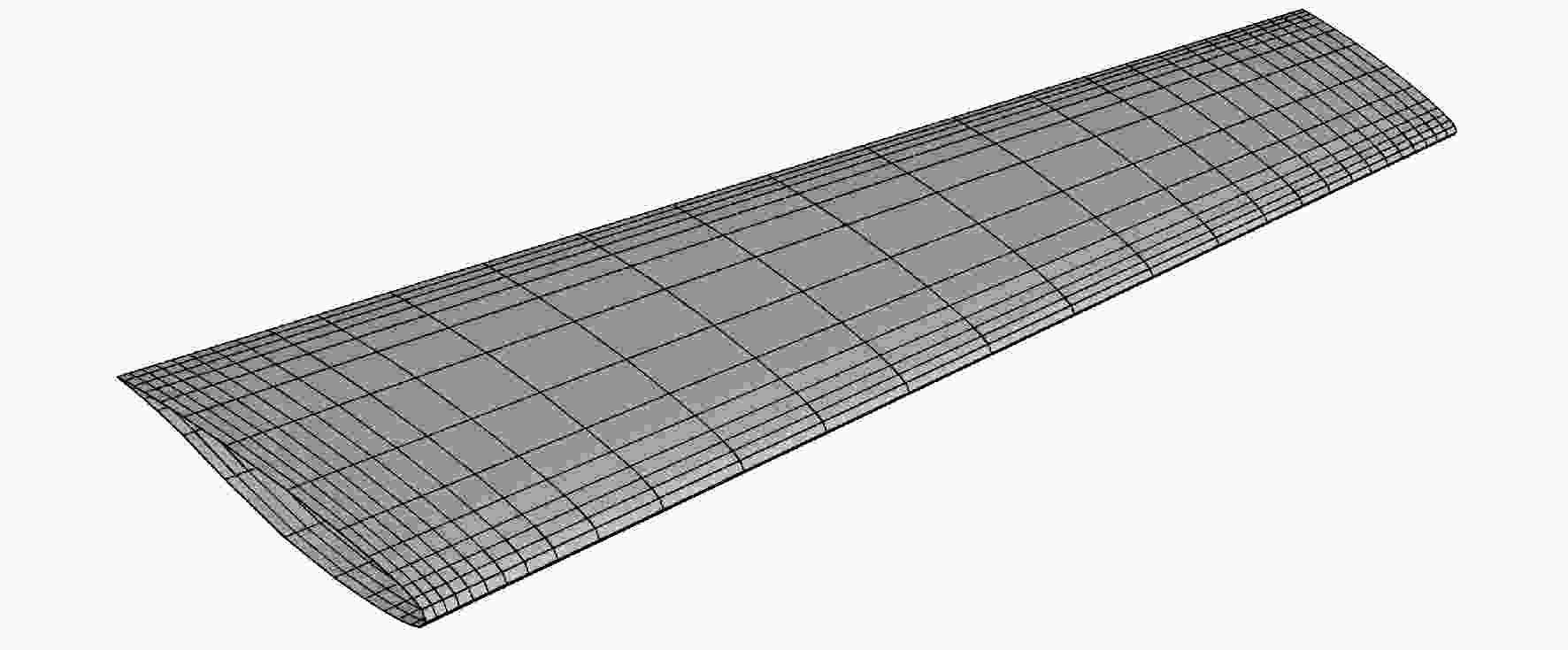

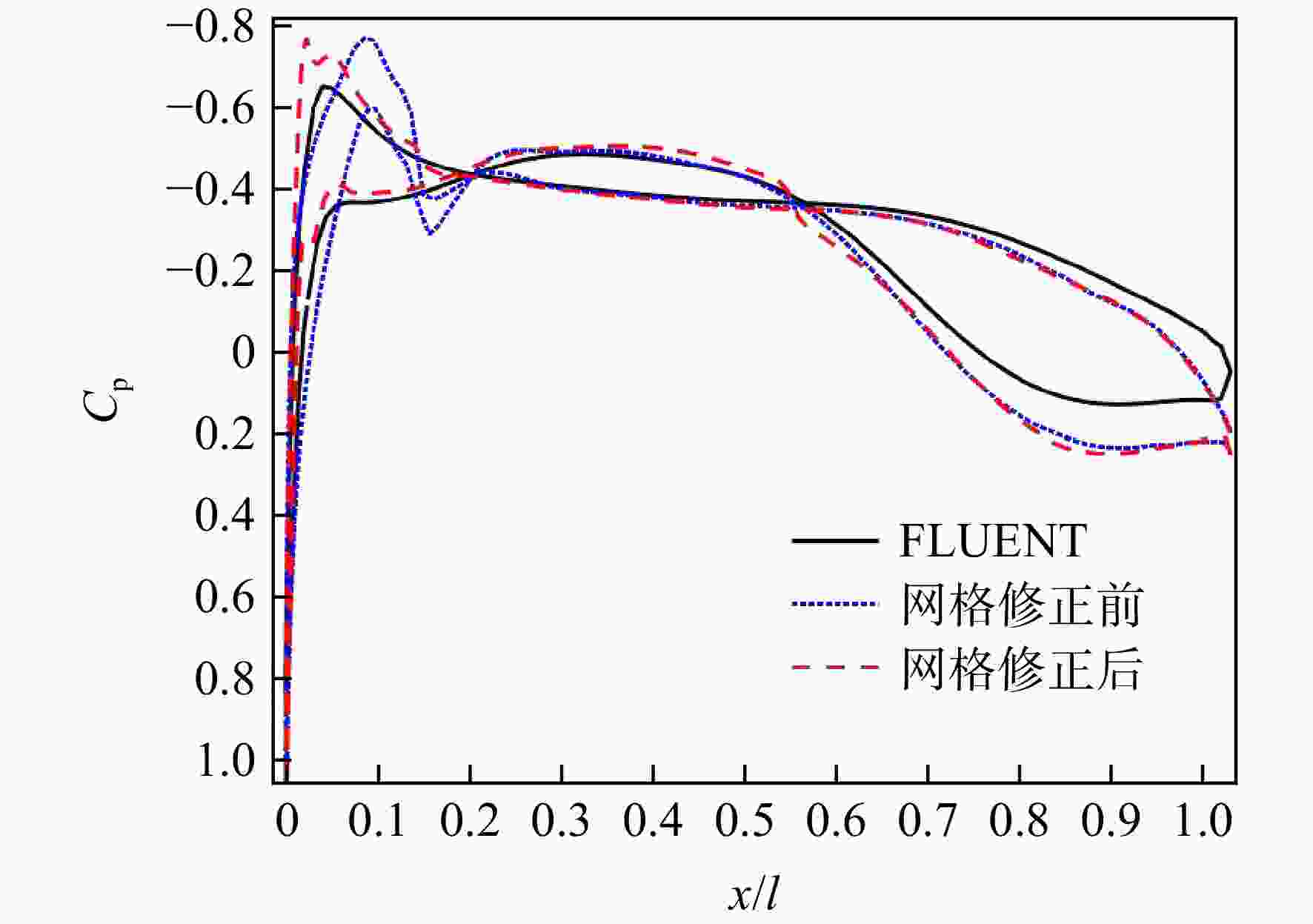

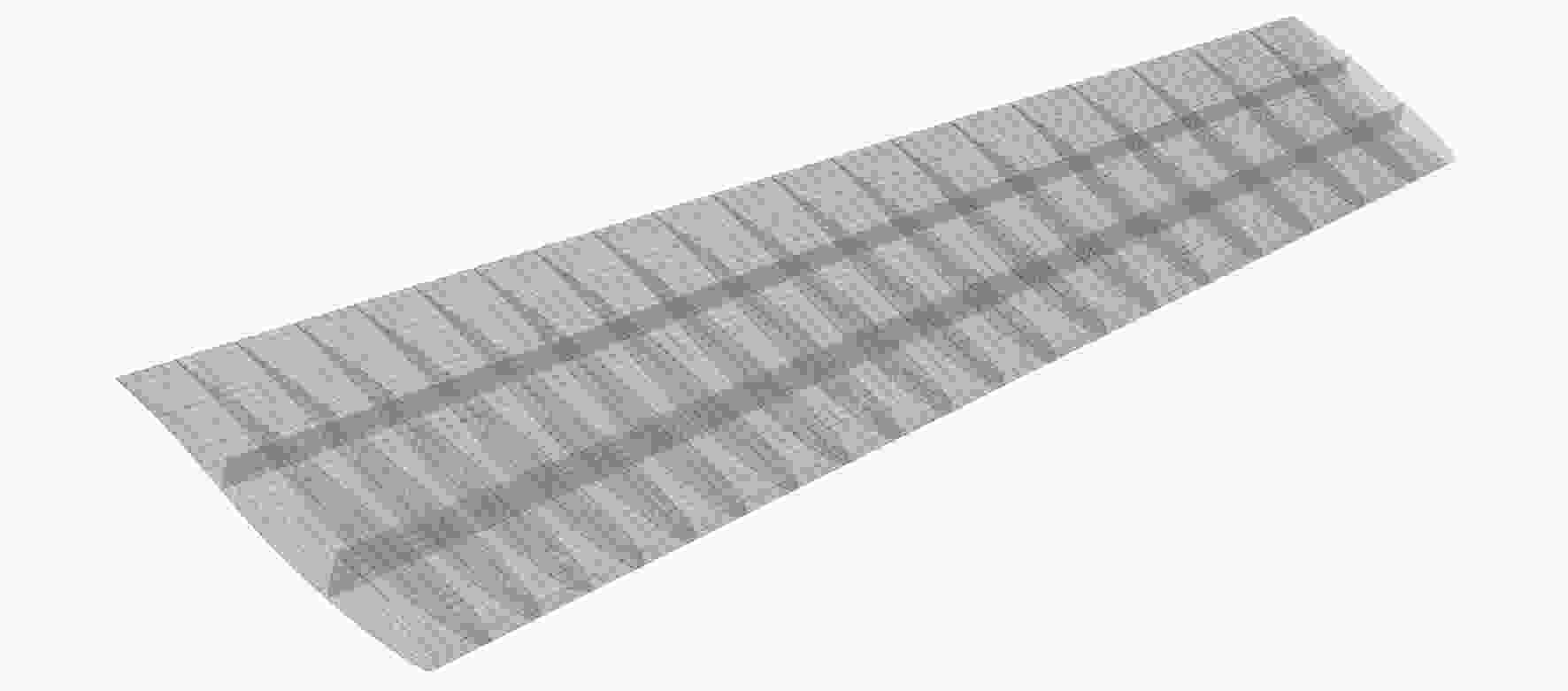

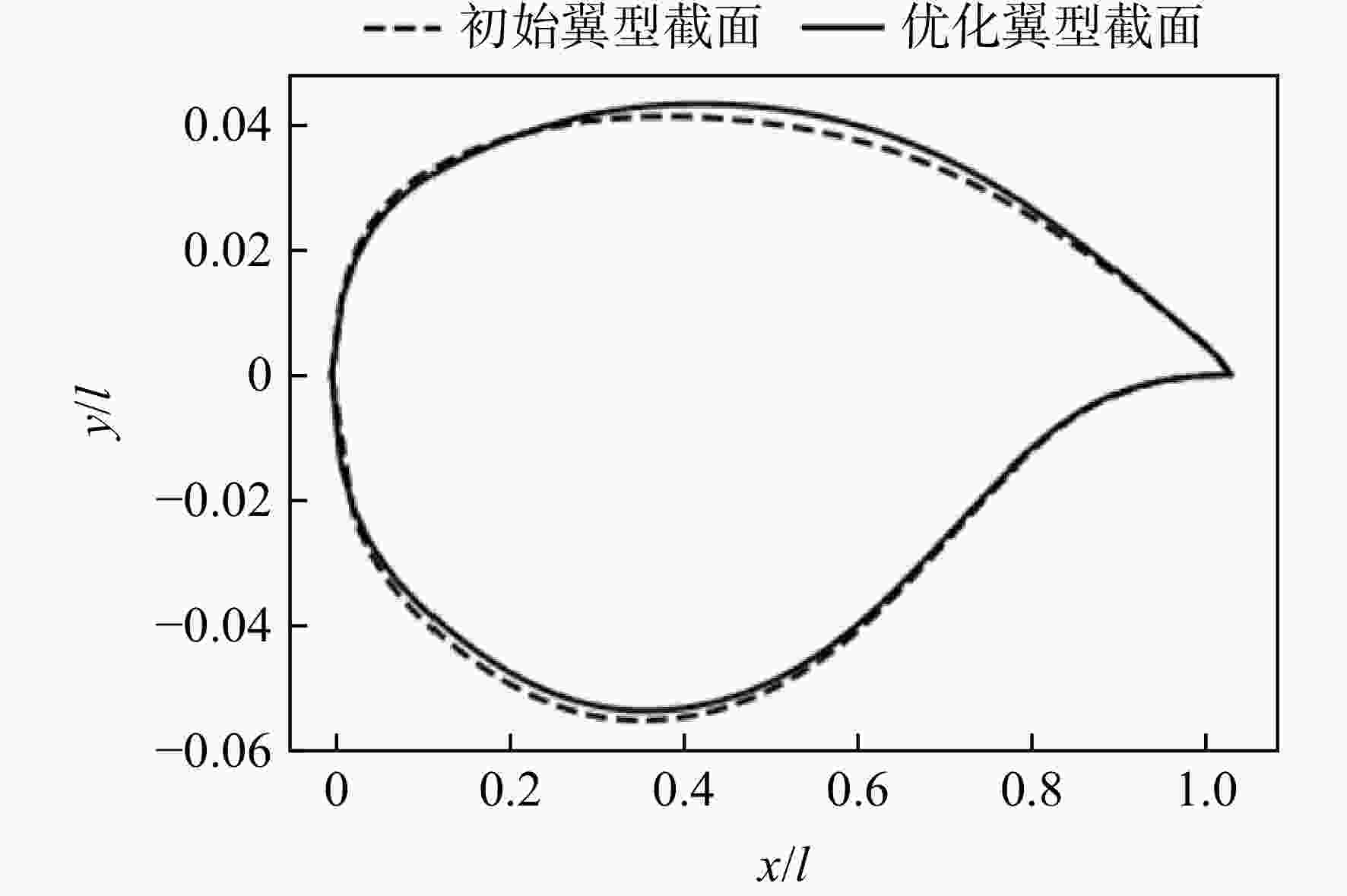

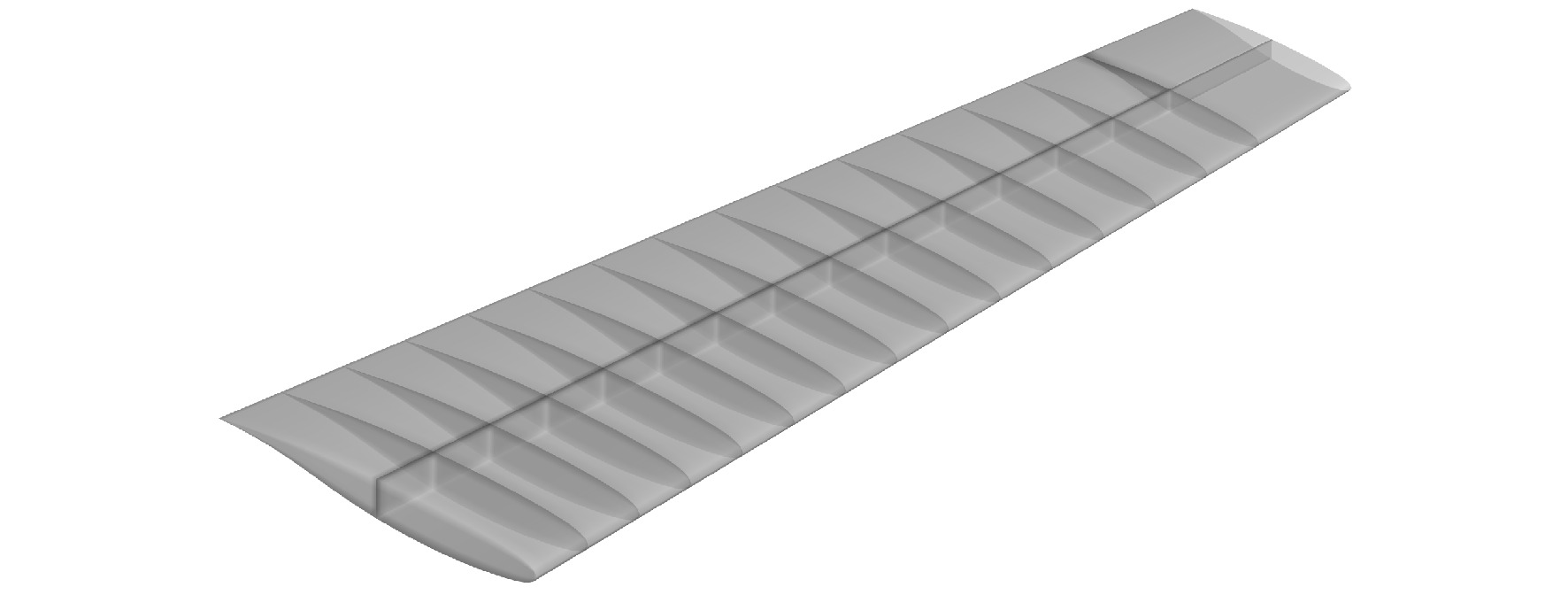

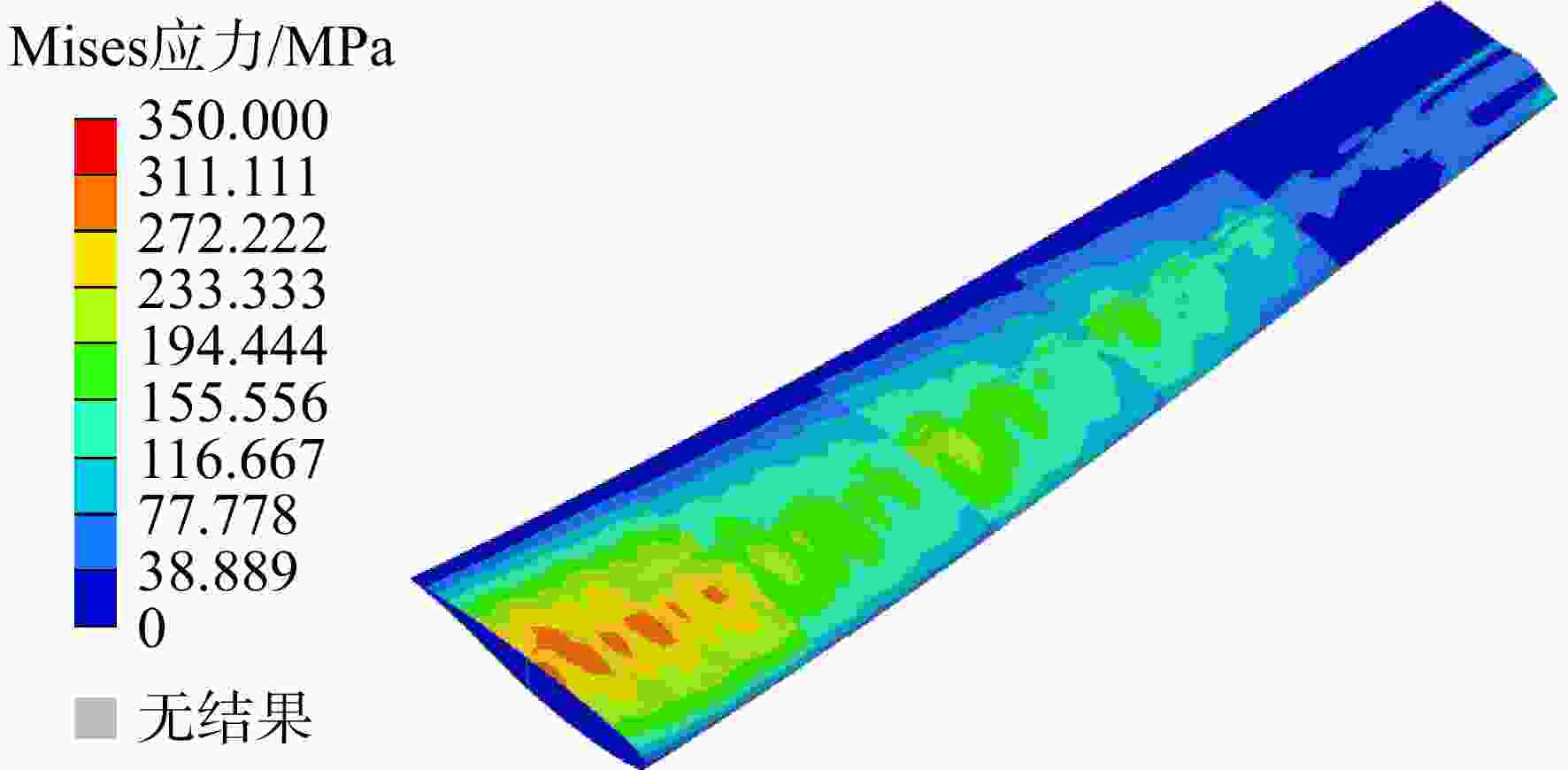

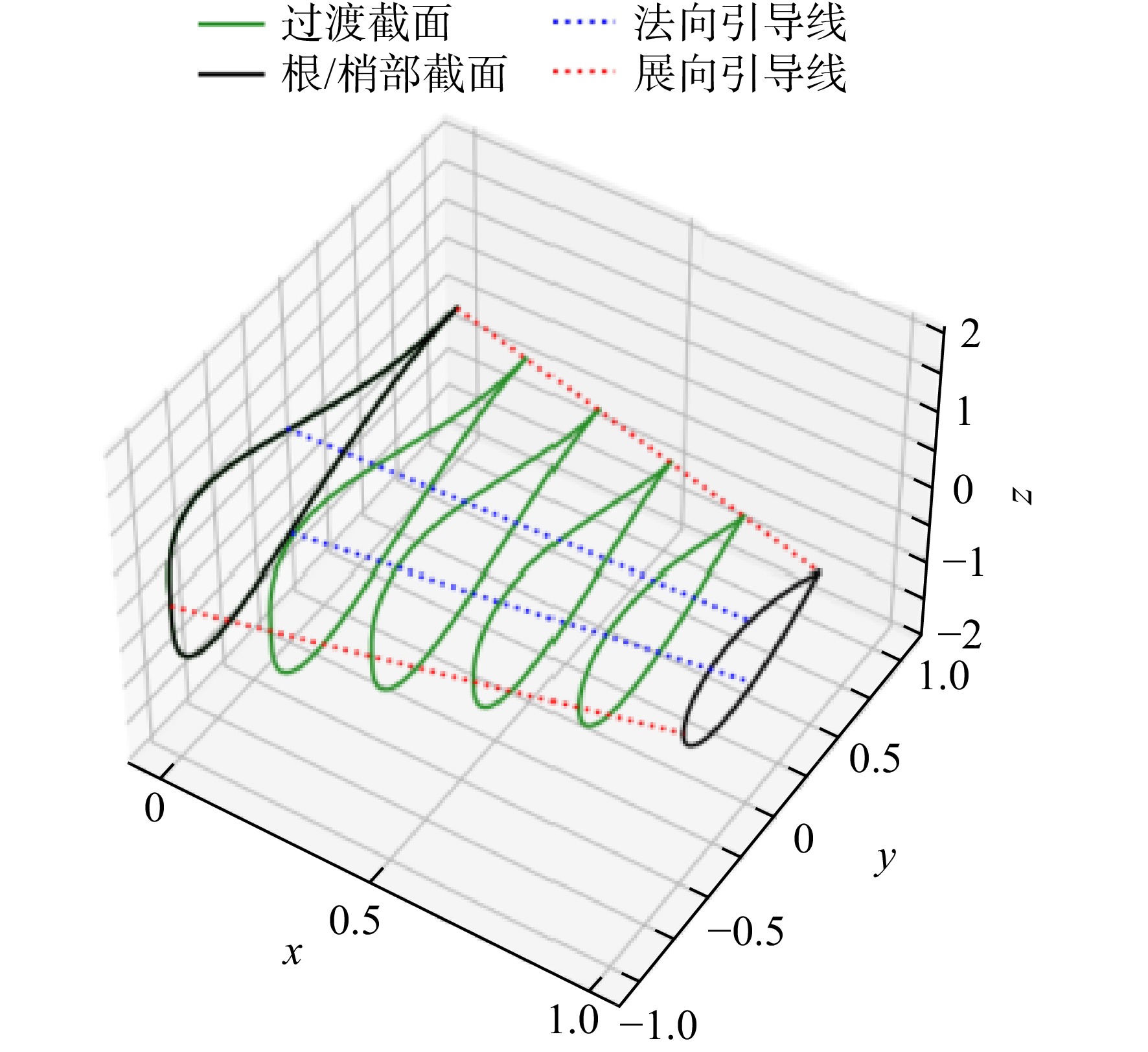

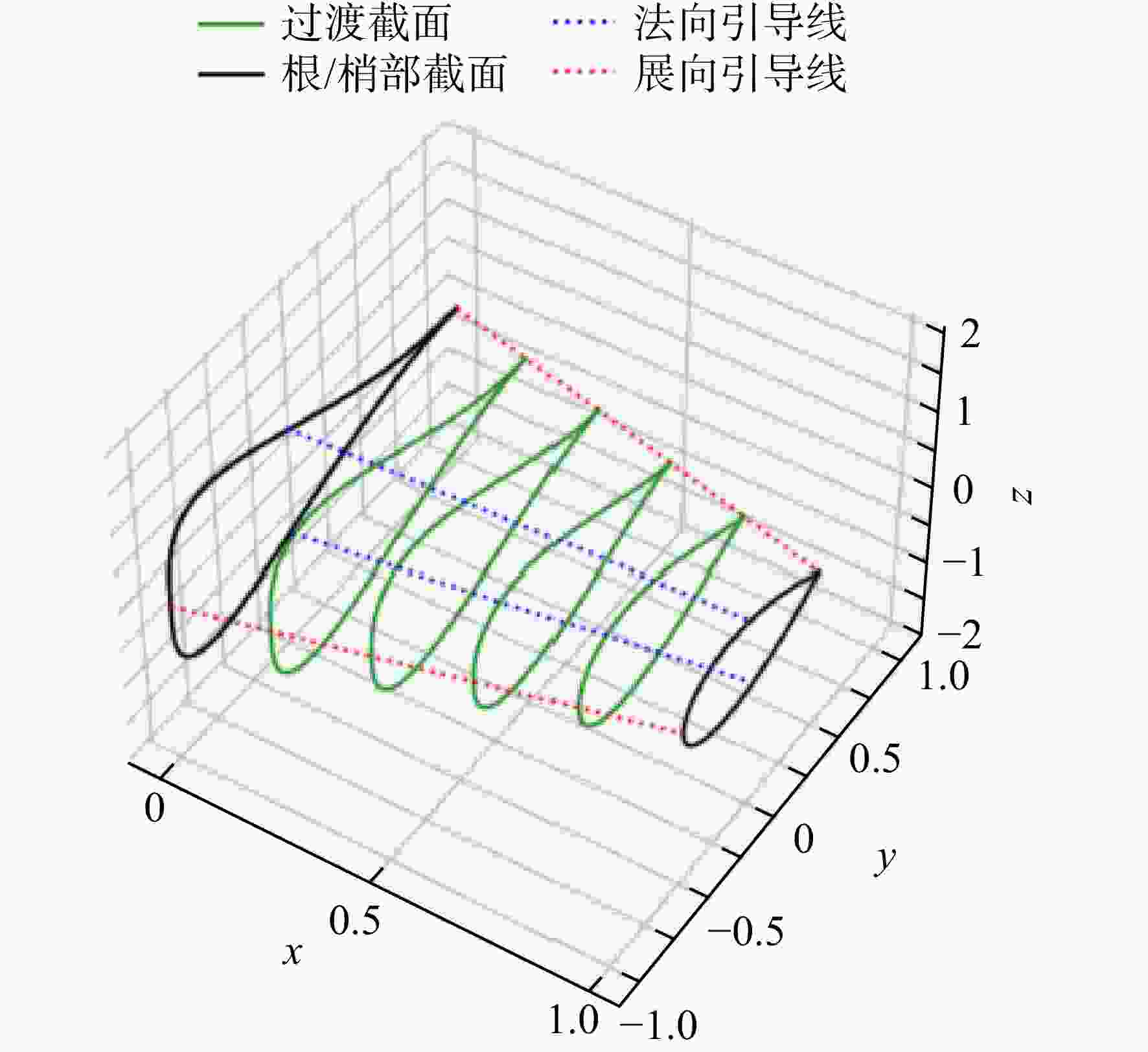

针对概念设计阶段机翼设计需要大范围探索设计空间并进行气动结构一体化设计的需求,提出一种基于类别/形状变换函数(class-shape function transformation, CST)的三维机翼气动结构解析参数化建模与优化方法。在二维CST基础上,推导三维CST参数化几何模型的解析函数形式,通过网格自适应离散与结构特征提取技术建立了三维机翼的气动和结构解析参数化模型,能够同时支持包括机翼几何构型、结构布局、结构尺寸、材料属性等参数的气动结构一体化快速建模与优化求解,具备几何模型大范围参数化以及气动、结构模型的建模过程自动化能力。采用该方法对某大展弦比机翼开展气动结构一体化优化设计,对比固定结构布局优化方案,优化结果梁由2个减至1个,翼肋由20个减至15个,质量相比减少26.1%。

Abstract:To facilitate the large-scale exploration of design space and the design of aero-structural integration in the conceptual design stage, a three-dimensional parametric modeling and optimization method for wing aero-structural analysis was proposed by using the class-shape function transformation (CST) method. Based on the two-dimensional CST, the analytical function form of the three-dimensional CST parametric geometric model was deduced. Established by using the mesh adaptive discrete and structural feature extraction technology, the aero-structural analysis parametric model of the three-dimensional wing can support the rapid modeling and optimization of the aerodynamic structure integration simultaneously, including parameters of the wing geometry configuration, structural layout, structural size, material properties, etc. Besides, it can automate the modeling process for the geometric models with a wide range of parameterization and aero-structural models. By applying this method, the aerodynamic structure of a large scale wing can be optimized from a multidisciplinary perspective. This method was adopted to work out the design of optimal aerodynamic structure integration for a large aspect ratio wing. According to the optimization result, the number of beams was reduced from 2 to 1, the number of wing ribs reduced from 20 to 15, and the mass reduced by 26.1%.

-

表 1 基本曲面设计变量

Table 1. Design variables of basic surface

设计变量 参数 翼根截面形状控制因子 $ {N_{11}} $,$ {N_{12}} $ 翼梢截面形状控制因子 $ {N_{21}} $,$ {N_{22}} $ 法向形状控制因子 ${M_1}$,${M_2}$ 展向形状控制因子 ${T_1}$,${T_2}$ 表面权重因子 $ {{{b}}_{i,j}} $ 展向权重因子 $ {{{b}}_t} $ 表 2 气动结果对比

Table 2. Comparison of aerodynamic results

表 3 优化结果对比

Table 3. Comparison of optimization results

参数 优化前 优化后 固定结构布局 可变结构布局 $ {C_L} $ 0.40348 0.40015 0.40001 $ {C_D} $ 0.01333 0.01311 0.01316 最大位移变形/m 2.66198 2.75547 2.73183 最大扭转变形/m 0.070146 0.067274 0.066811 结构质量/kg 20412.7 18849.5 13926.2 -

[1] GURUSWAMY G P,OBAYASHI S. Study on the use of high-fidelity methods in aeroelastic optimization[J]. Journal of Aircraft,2004,41(3): 616-619. doi: 10.2514/1.843 [2] 胡嘉欣,芮姝,高瑞朝,等. 飞行器结构布局与尺寸混合优化方法[J]. 航空学报,2022,43(5): 225363. HU Jiaxin,RUI Shu,GAO Ruichao,et al. Hybrid optimization method for structural layout and size of flight vehicles[J]. Acta Aeronautica et Astronautica Sinica,2022,43(5): 225363. (in Chinese HU Jiaxin, RUI Shu, GAO Ruichao, et al . Hybrid optimization method for structural layout and size of flight vehicles[J]. Acta Aeronautica et Astronautica Sinica,2022 ,43 (5 ):225363 . (in Chinese)[3] BENAOUALI A,KACHEL S. An automated CAD/CAE integration system for the parametric design of aircraft wing structures[J]. Journal of Theoretical and Applied Mechanics,2017,55(2): 447-459. [4] 陈婉春,孙刚. 基于气动特性翼型参数化方法的适用性研究[J]. 力学季刊,2015,36(4): 678-689. CHEN Wanchun,SUN Gang. Applicability of airfoil parameterization methods based on aerodynamic performance[J]. Chinese Quarterly of Mechanics,2015,36(4): 678-689. (in Chinese CHEN Wanchun, SUN Gang . Applicability of airfoil parameterization methods based on aerodynamic performance[J]. Chinese Quarterly of Mechanics,2015 ,36 (4 ):678 -689 . (in Chinese)[5] HICKS R M,HENNE P A. Wing design by numerical optimization[J]. Journal of Aircraft,1978,15(7): 407-412. doi: 10.2514/3.58379 [6] FUJII K,DULIKRAVICH G S. Recent development of aerodynamic design methodologies[M]. Wiesbaden,Germany:Vieweg+Teubner Verlag,1999. [7] VECCHIA P D,DANIELE E,DʼAMATO E. An airfoil shape optimization technique coupling PARSEC parameterization and evolutionary algorithm[J]. Aerospace Science and Technology,2014,32(1): 103-110. doi: 10.1016/j.ast.2013.11.006 [8] LEUNG T,ZINGG D. Single- and multi-point aerodynamic shape optimization using a parallel newton-krylov approach[R]. AIAA 2009-3803,2009. [9] BECKER G,SCHÄFER M,JAMESON A. An advanced NURBS fitting procedure for post-processing of grid-based shape optimizations[R]. AIAA2011-891,2011. [10] VALENCIA E,ALULEMA V,HIDALGO V,et al. A CAD-free methodology for volume and mass properties computation of 3-D lifting surfaces and wing-box structures[J]. Aerospace Science and Technology,2021,108: 106378. doi: 10.1016/j.ast.2020.106378 [11] KULFAN B M. Recent extensions and applications of the ‘CST’ universal parametric geometry representation method[J]. The Aeronautical Journal,2010,114(1153): 157-176. doi: 10.1017/S0001924000003614 [12] KULFAN B M,BUSSOLETTI J E. “Fundamental” parametric geometry representations for aircraft component shapes[R]. AIAA2006-6948,2006. [13] KULFAN B M. Universal parametric geometry representation method[J]. Journal of Aircraft,2008,45(1): 142-158. doi: 10.2514/1.29958 [14] 张德虎,席胜,田鼎. 典型翼型参数化方法的翼型外形控制能力评估[J]. 航空工程进展,2014,5(3): 281-288,295. ZHANG Dehu,XI Sheng,TIAN Ding. Geometry control ability evaluation of classical airfoil parametric methods[J]. Advances in Aeronautical Science and Engineering,2014,5(3): 281-288,295. (in Chinese ZHANG Dehu, XI Sheng, TIAN Ding . Geometry control ability evaluation of classical airfoil parametric methods[J]. Advances in Aeronautical Science and Engineering,2014 ,5 (3 ):281 -288, 295 . (in Chinese)[15] 关晓辉,李占科,宋笔锋. CST气动外形参数化方法研究[J]. 航空学报,2012,33(4): 625-633. GUAN Xiaohui,LI Zhanke,SONG Bifeng. A study on CST aerodynamic shape parameterization method[J]. Acta Aeronautica et Astronautica Sinica,2012,33(4): 625-633. (in Chinese GUAN Xiaohui, LI Zhanke, SONG Bifeng . A study on CST aerodynamic shape parameterization method[J]. Acta Aeronautica et Astronautica Sinica,2012 ,33 (4 ):625 -633 . (in Chinese)[16] LI Runze,DENG Kaiwen,ZHANG Yufei,et al. Pressure distribution guided supercritical wing optimization[J]. Chinese Journal of Aeronautics,2018,31(9): 1842-1854. doi: 10.1016/j.cja.2018.06.021 [17] 冯毅,唐伟,任建勋,等. 飞行器参数化几何建模方法研究[J]. 空气动力学学报,2012,30(4): 546-550. FENG Yi,TANG Wei,REN Jianxun,et al. Parametric geometry representation method for hypersonic vehicle configuration[J]. Acta Aerodynamica Sinica,2012,30(4): 546-550. (in Chinese doi: 10.3969/j.issn.0258-1825.2012.04.020 FENG Yi, TANG Wei, REN Jianxun, et al . Parametric geometry representation method for hypersonic vehicle configuration[J]. Acta Aerodynamica Sinica,2012 ,30 (4 ):546 -550 . (in Chinese) doi: 10.3969/j.issn.0258-1825.2012.04.020[18] 粟华,龚春林,谷良贤. 基于三维CST建模方法的两层气动外形优化策略[J]. 固体火箭技术,2014,37(1): 1-6,22. SU Hua,GONG Chunlin,GU Liangxian. Two-level aerodynamic shape optimization strategy based on three-dimensional CST modeling method[J]. Journal of Solid Rocket Technology,2014,37(1): 1-6,22. (in Chinese SU Hua, GONG Chunlin, GU Liangxian . Two-level aerodynamic shape optimization strategy based on three-dimensional CST modeling method[J]. Journal of Solid Rocket Technology,2014 ,37 (1 ):1 -6, 22 . (in Chinese)[19] SU Hua,GU Liangxian,GONG Chunlin. Research on geometry modeling method based on three-dimensional CST parameterization technology[R]. AIAA2015-3241,2015. [20] SU Hua,GONG Chunlin,GU Liangxian. Three-dimensional CST parameterization method applied in aircraft aeroelastic analysis[J]. International Journal of Aerospace Engineering,2017,2017: 1-15. [21] STRAATHOF M H,VAN TOOREN M J L. Extension to the class-shape-transformation method based on B-splines[J]. AIAA Journal,2011,49(4): 780-790. doi: 10.2514/1.J050706 [22] De BOOR C. A practical guide to splines[J]. Applied Mathematical Sciences,1978,27(149): 157-157. [23] 胡婕. 客机机翼气动/结构多学科设计优化研究[D]. 南京: 南京航空航天大学,2012. HU Jie. Application of MDO to integrated aerodynamic/structural design of wings[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2012. (in ChineseHU Jie. Application of MDO to integrated aerodynamic/structural design of wings[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012. (in Chinese) [24] VASSBERG J C,TINOCO E N,MANI M,et al. Summary of the third AIAA CFD drag prediction workshop[R]. AIAA 2007-260,2007. [25] XU Zhaoke,XIA Jian. Aerodynamic optimization based on continuous adjoint method for a flexible wing[J]. International Journal of Aerospace Engineering,2016,2016: 1-16. -

下载:

下载: