Multi-scale parallel topology optimization design method for missile seeker with thermo-dynamic coupling loads

-

摘要:

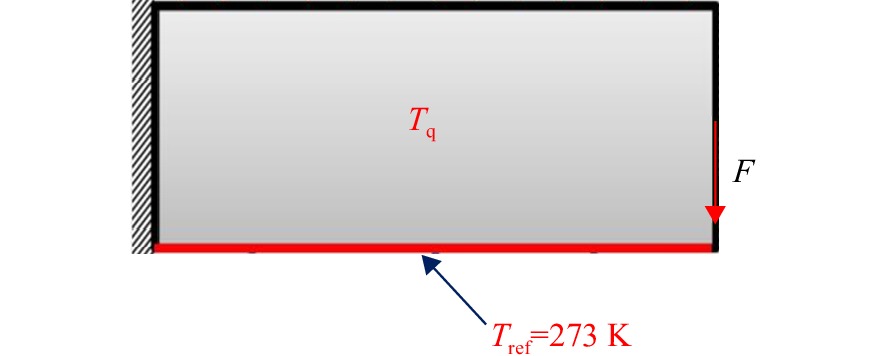

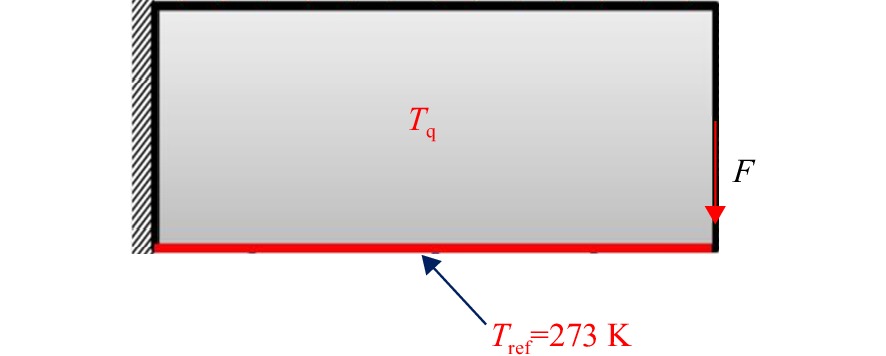

针对导弹导引头在高温高负载下的结构设计问题,引入多尺度拓扑优化设计方法对导弹导引头进行优化设计,提出了一种在稳态热源情况下热力耦合连续体结构多尺度并行化拓扑优化方法。该方法在宏观尺度上,将热源引入的等效热载荷耦合至力载荷当中,获得符合热力耦合载荷的宏观构型分布;在微观尺度上,通过聚类方法划分微结构类型,提升微结构计算效率和解决宏微观结构尺度分离问题。以结构柔度作为目标函数,材料的体分比为约束,建立了基于固体各向同性材料惩罚模型的多尺度并行拓扑优化模型;采用直接法对热力耦合情况下的灵敏度进行分析计算,运用OC准则法对设计变量进行优化,从而获得有效的热力耦合情况下的宏微观并行拓扑优化模型。利用悬臂梁结构对所提方法进行了验证,结果表明所设计的结构既具有热力耦合工况下的承载能力,也具有一定的热防护的能力。应用该方法对导弹引导头进行结构一体化优化设计,获得了较好的既具有承载性能,又具有隔热性能的引导头结构。两个案例展示了在保证质量减少50%的情况下,依然都获得了理想的优化结构,从而验证了所提方法的正确性与有效性。也为类似热力耦合工况下的结构一体化设计提供了可行方法,具有一定的工程应用意义。

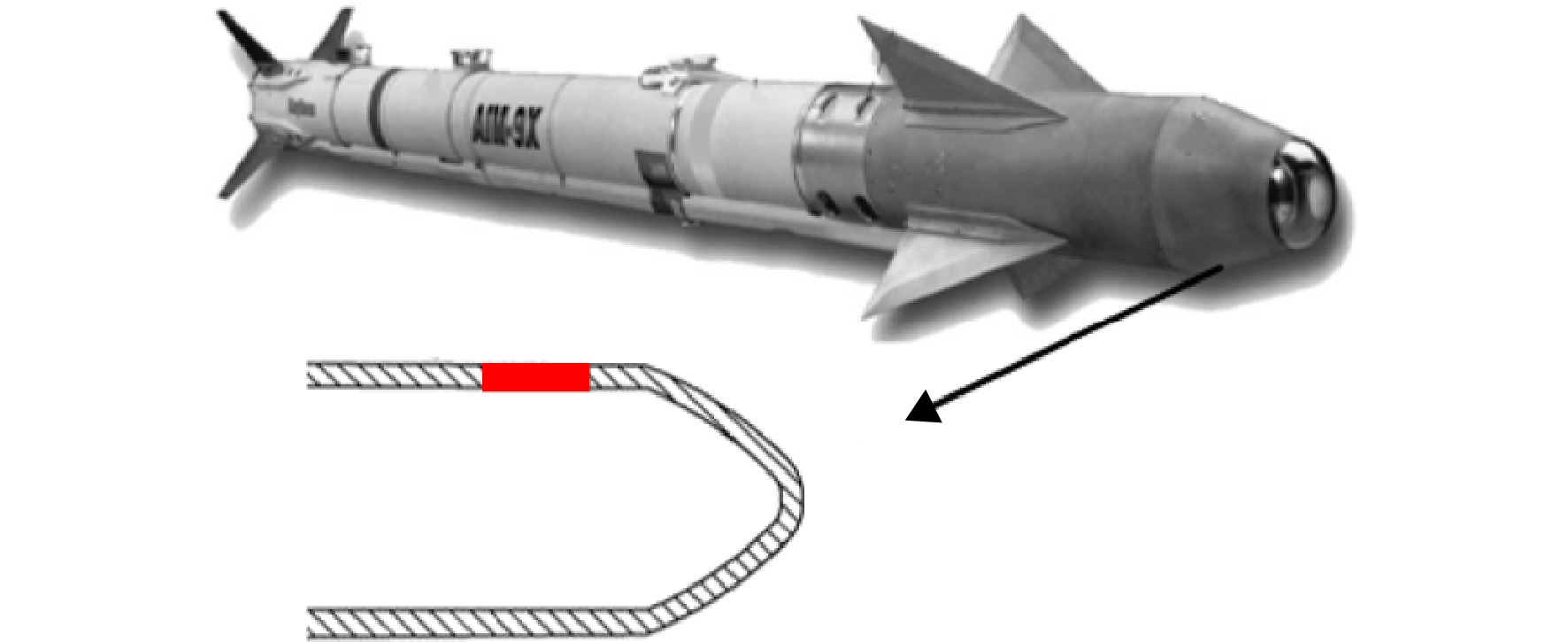

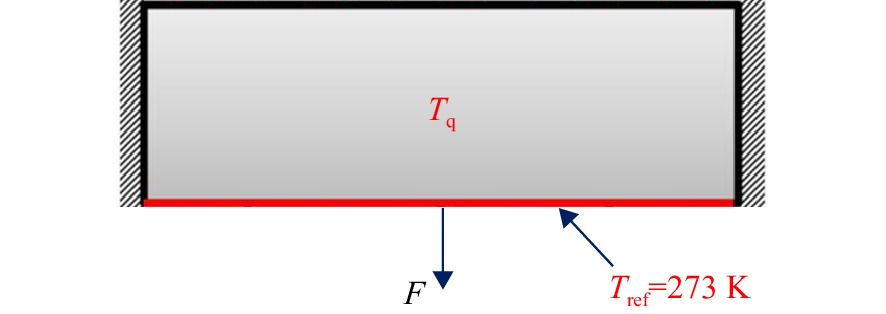

Abstract:In order to solve the structural design problem of missile seeker with high temperature and high loads, a multi-scale topology optimization design method was introduced to optimize the missile seeker. A multi-scale parallel topology optimization method for thermo-mechanical coupled continuum structures under steady-state heat source was proposed. With this method, the equivalent thermal load introduced by heat source was coupled to the force load on the macroscopic scale, and the macroscopic configuration distribution consistent with the thermo-mechanical coupled load was obtained. At the micro scale, the clustering method was used to classify microstructures to improve the computational efficiency and solve the problem of scale separation in macro and micro structures. A multi-scale parallel topology optimization model based on solid isotropic material with penalization model was established with the structural flexibility as the objective function and the volume fraction of materials as the constraint. The sensitivity was analyzed and calculated by the direct method under the thermodynamic coupling condition, and the design variables were optimized by the OC criterion method. Hence, the effective macro- and micro-scales parallel topology optimization model was obtained with thermo-mechanical coupled loads. The proposed method was validated by optimizing a cantilever beam structure and the results showed that the designed structure not only had the load-bearing capacity under thermo-mechanical coupling loads, but also had a certain degree of thermal protection ability. At last, the proposed method was applied for performing the integrated design of the missile seeker structure under the force-thermal coupling condition. A good structure of the missile seeker with both load-bearing performance and thermal insulation performance was designed. The two cases demonstrated that the ideal optimized structures were achieved while ensuring 50% mass reduction. Therefore, this has provided a feasible method for structure integrated design under the force-thermal coupling condition, showing that the present method is rational and valuable in engineering application.

-

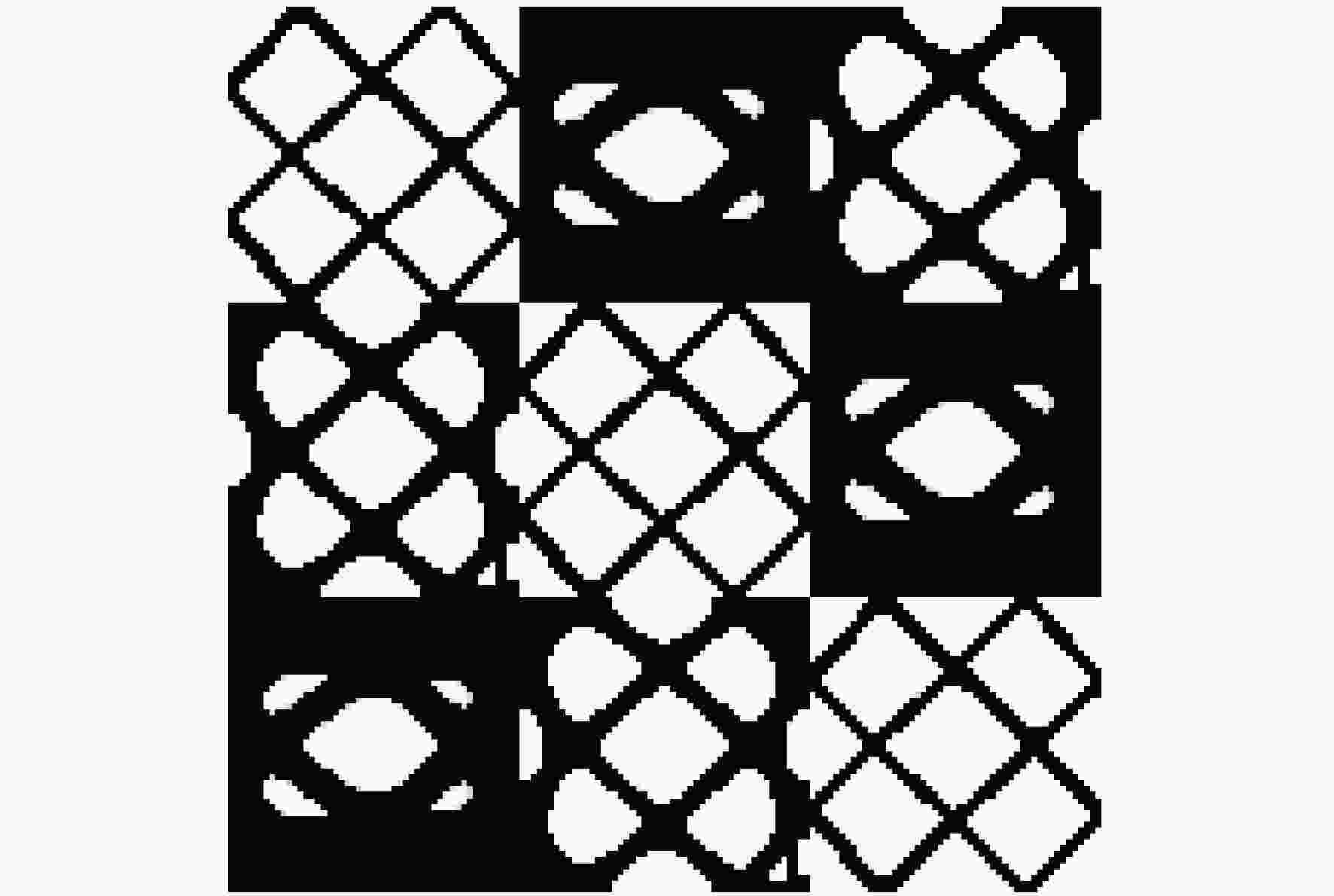

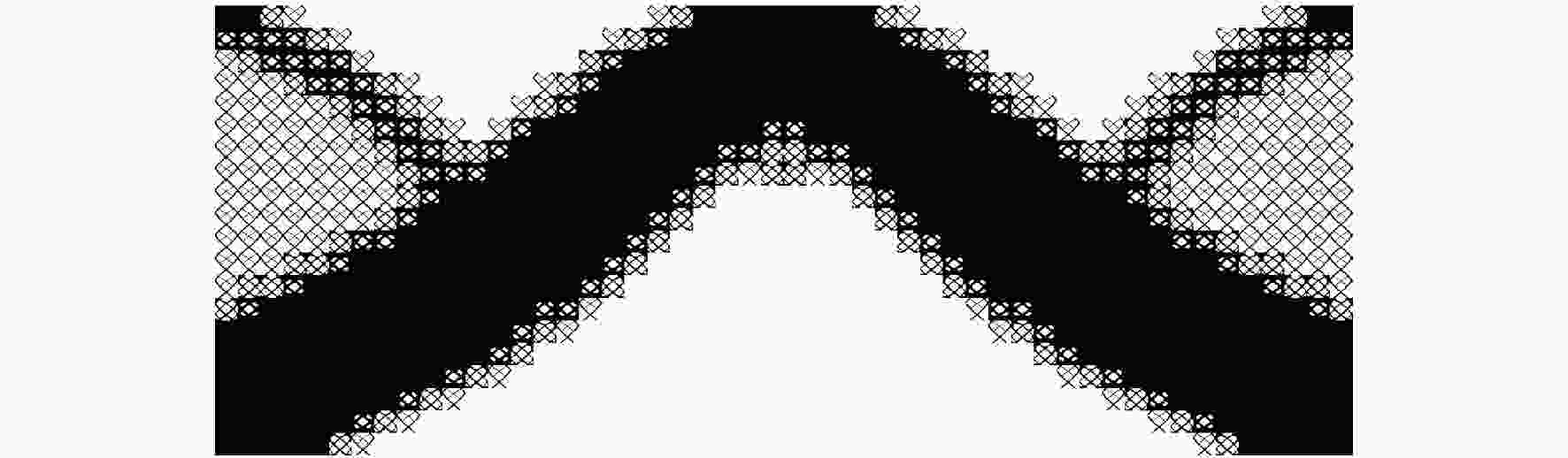

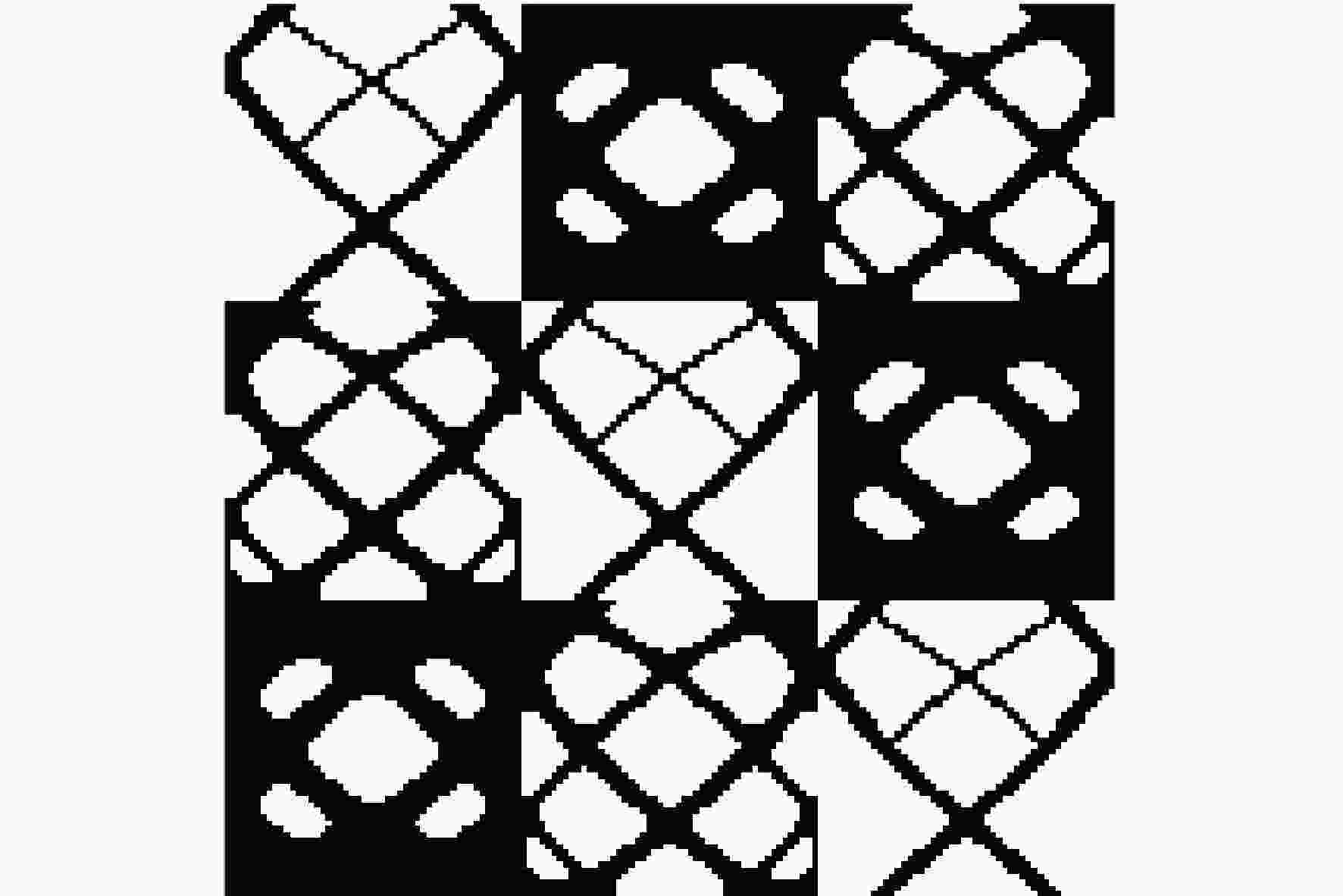

表 1 悬臂梁结构微结构并行优化结果

Table 1. Parallel optimization results of cantilever beam structure microstructure

体积分数 单胞 3×3微结构 0.272

0.517

0.816

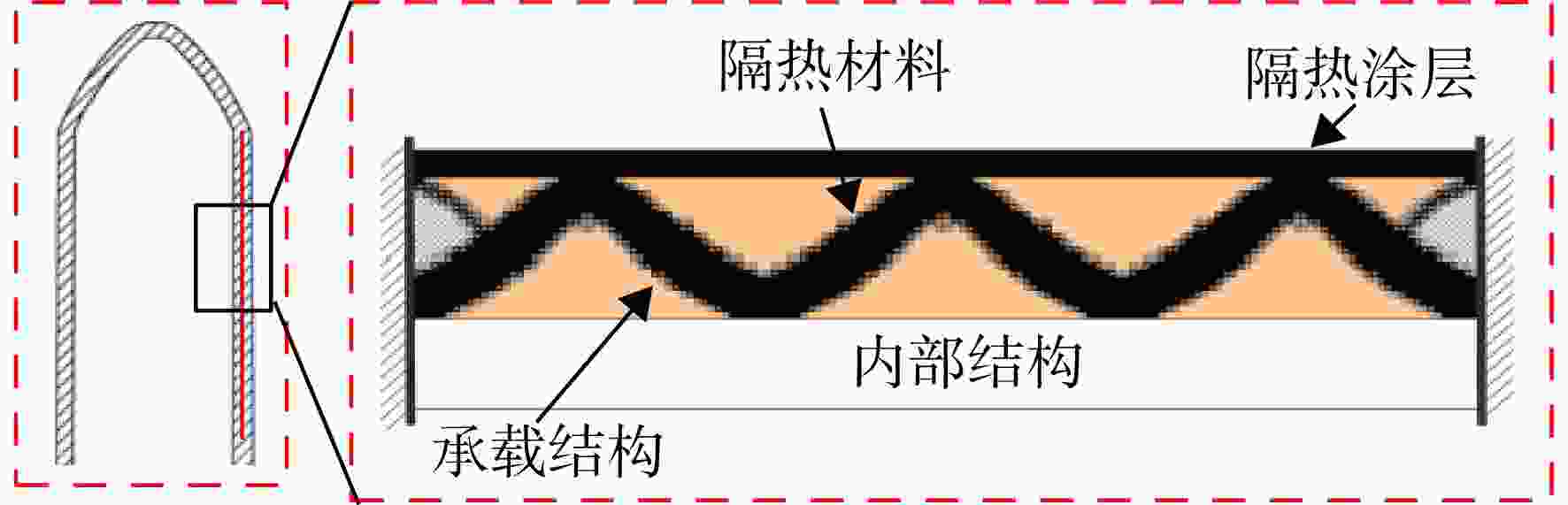

表 2 导引头结构微结构并行优化结果

Table 2. Parallel optimization results of the microstructure of the fairing structure

体积分数 单胞 3×3微结构 0.196

0.416

0.780

-

[1] 徐世南,吴催生. 超声速导弹多功能结构设计[J]. 计算机仿真,2020,37(5): 45-48, 54. doi: 10.3969/j.issn.1006-9348.2020.05.010XU Shinan,WU Cuisheng. Multi-functional structure design in supersonic missile[J]. Computer Simulation,2020,37(5): 45-48, 54. (in Chinese) doi: 10.3969/j.issn.1006-9348.2020.05.010 [2] 邢广鹏,孙志刚,崔向敏,等. 多工况载荷下航空发动机支架拓扑优化设计[J]. 航空动力学报,2020,35(11): 2248-2262. doi: 10.13224/j.cnki.jasp.2020.11.002XING Guangpeng,SUN Zhigang,CUI Xiangmin,et al. Topological optimization design of aero-engine support structure under multiple loading conditions[J]. Journal of Aerospace Power,2020,35(11): 2248-2262. (in Chinese) doi: 10.13224/j.cnki.jasp.2020.11.002 [3] SHI Guanghui,GUAN Chengqi,QUAN Dongliang,et al. An aerospace bracket designed by thermo-elastic topology optimization and manufactured by additive manufacturing[J]. Chinese Journal of Aeronautics,2020,33(4): 1252-1259. doi: 10.1016/j.cja.2019.09.006 [4] 温晶晶,吴斌,刘承骛. 导弹整体式翼面骨架结构的拓扑优化设计[J]. 兵工学报,2017,38(1): 81-88. doi: 10.3969/j.issn.1000-1093.2017.01.011WEN Jingjing,WU Bin,LIU Chengwu. Topology optimization design for frame structure of monolithic wing of missile[J]. Acta Armamentarii,2017,38(1): 81-88. (in Chinese) doi: 10.3969/j.issn.1000-1093.2017.01.011 [5] 兰凤崇,赖番结,陈吉清,等. 考虑动态特性的多工况车身结构拓扑优化研究[J]. 机械工程学报,2014,50(20): 122-128. doi: 10.3901/JME.2014.20.122LAN Fengchong,LAI Fanjie,CHEN Jiqing,et al. Multi-case topology optimization of body structure considering dynamic characteristic[J]. Journal of Mechanical Engineering,2014,50(20): 122-128. (in Chinese) doi: 10.3901/JME.2014.20.122 [6] CHUANG C H,CHEN Shikui,YANG R J,et al. Topology optimization with additive manufacturing consideration for vehicle load path development[J]. International Journal for Numerical Methods in Engineering,2018,113(8): 1434-1445. doi: 10.1002/nme.5549 [7] WANG Yiqiang,ZHANG Lei,DAYNES S,et al. Design of graded lattice structure with optimized mesostructures for additive manufacturing[J]. Materials & Design,2018,142: 114-123. [8] GAO Jie,LI Hao,GAO Liang,et al. Topological shape optimization of 3D micro-structured materials using energy-based homogenization method[J]. Advances in Engineering Software,2018,116: 89-102. doi: 10.1016/j.advengsoft.2017.12.002 [9] DU Zongliang,ZHOU Xiaoyi,PICELLI R,et al. Connecting microstructures for multiscale topology optimization with connectivity index constraints[J]. Journal of Mechanical Design,2018,140(11): 111417. doi: 10.1115/1.4041176 [10] GAO Jie,LUO Zhen,LI Hao,et al. Topology optimization for multiscale design of porous composites with multi-domain microstructures[J]. Computer Methods in Applied Mechanics and Engineering,2019,344: 451-476. doi: 10.1016/j.cma.2018.10.017 [11] GAO Jie,LUO Zhen,LI Hao,et al. Dynamic multiscale topology optimization for multi-regional micro-structured cellular composites[J]. Composite Structures,2019,211: 401-417. doi: 10.1016/j.compstruct.2018.12.031 [12] 杜义贤,尹鹏,李荣,等. 兼具吸能和承载特性的梯度结构宏细观跨尺度拓扑优化设计[J]. 机械工程学报,2020,56(7): 171-180. doi: 10.3901/JME.2020.07.171DU Yixian,YIN Peng,LI Rong,et al. Macro and micro trans-scale topological optimization design of gradient structure with both energy absorption and load-bearing characteristics[J]. Journal of Mechanical Engineering,2020,56(7): 171-180. (in Chinese) doi: 10.3901/JME.2020.07.171 [13] KUMAR T,SURESH K. A density-and-strain-based K-clustering approach to microstructural topology optimization[J]. Structural and Multidisciplinary Optimization,2020,61(4): 1399-1415. doi: 10.1007/s00158-019-02422-4 [14] SIGMUND O. Design of multiphysics actuators using topology optimization: Part Ⅰ one-material structures[J]. Computer Methods in Applied Mechanics and Engineering,2001,190(49/50): 6577-6604. [15] SIGMUND O. Design of multiphysics actuators using topology optimization: Part Ⅱ two-material structures[J]. Computer Methods in Applied Mechanics and Engineering,2001,190(49/50): 6605-6627. [16] 左孔天,赵雨东,陈立平. 传热结构的多目标拓扑优化设计研究[J]. 计算力学学报,2007,24(5): 620-627.ZUO Kongtian,ZHAO Yudong,CHEN Liping. Study on multiple objective topology optimization of thermal conductive structure[J]. Chinese Journal of Computational Mechanics,2007,24(5): 620-627. (in Chinese) [17] 孙士平,张卫红. 热弹性结构的拓扑优化设计[J]. 力学学报,2009,41(6): 878-887. doi: 10.6052/0459-1879-2009-6-2007-439SUN Shiping,ZHANG Weihong. Topology optimal design of thermo-elastic structures[J]. Chinese Journal of Theoretical and Applied Mechanics,2009,41(6): 878-887. (in Chinese) doi: 10.6052/0459-1879-2009-6-2007-439 [18] DEATON J D,GRANDHI R V. Stress-based design of thermal structures via topology optimization[J]. Structural and Multidisciplinary Optimization,2016,53(2): 253-270. doi: 10.1007/s00158-015-1331-z [19] 魏兆栋,高仁璟,王长生. 基于热固耦合问题的多尺度拓扑优化设计[J]. 计算力学学报,2021,38(2): 133-139.WEI Zhaodong,GAO Renjing,WANG Changsheng. Multi-scale topology optimization design based on thermo-mechanical coupling problem[J]. Chinese Journal of Computational Mechanics,2021,38(2): 133-139. (in Chinese) [20] GAO Tong,ZHANG Weihong. Topology optimization involving thermo-elastic stress loads[J]. Structural and Multidisciplinary Optimization,2010,42(5): 725-738. doi: 10.1007/s00158-010-0527-5 [21] 占金青,龙良明,林春辉,等. 非均匀温度场下的热固耦合结构多相材料拓扑优化[J]. 华东交通大学学报,2018,35(5): 117-123. doi: 10.16749/j.cnki.jecjtu.2018.05.017ZHAN Jinqing,LONG Liangming,LIN Chunhui,et al. Multi-material topology optimization of thermo-mechanical coupling structure in non-uniform temperature field[J]. Journal of East China Jiaotong University,2018,35(5): 117-123. (in Chinese) doi: 10.16749/j.cnki.jecjtu.2018.05.017 [22] ANAYA L M. Thermo-elastic topology optimization using a multi-Scale approach[D]. Campinas, Brazil: University of Campinas, 2018. -

下载:

下载: