Shape optimization and mechanism of transverse groove for drag reduction based on genetic algorithm

-

摘要:

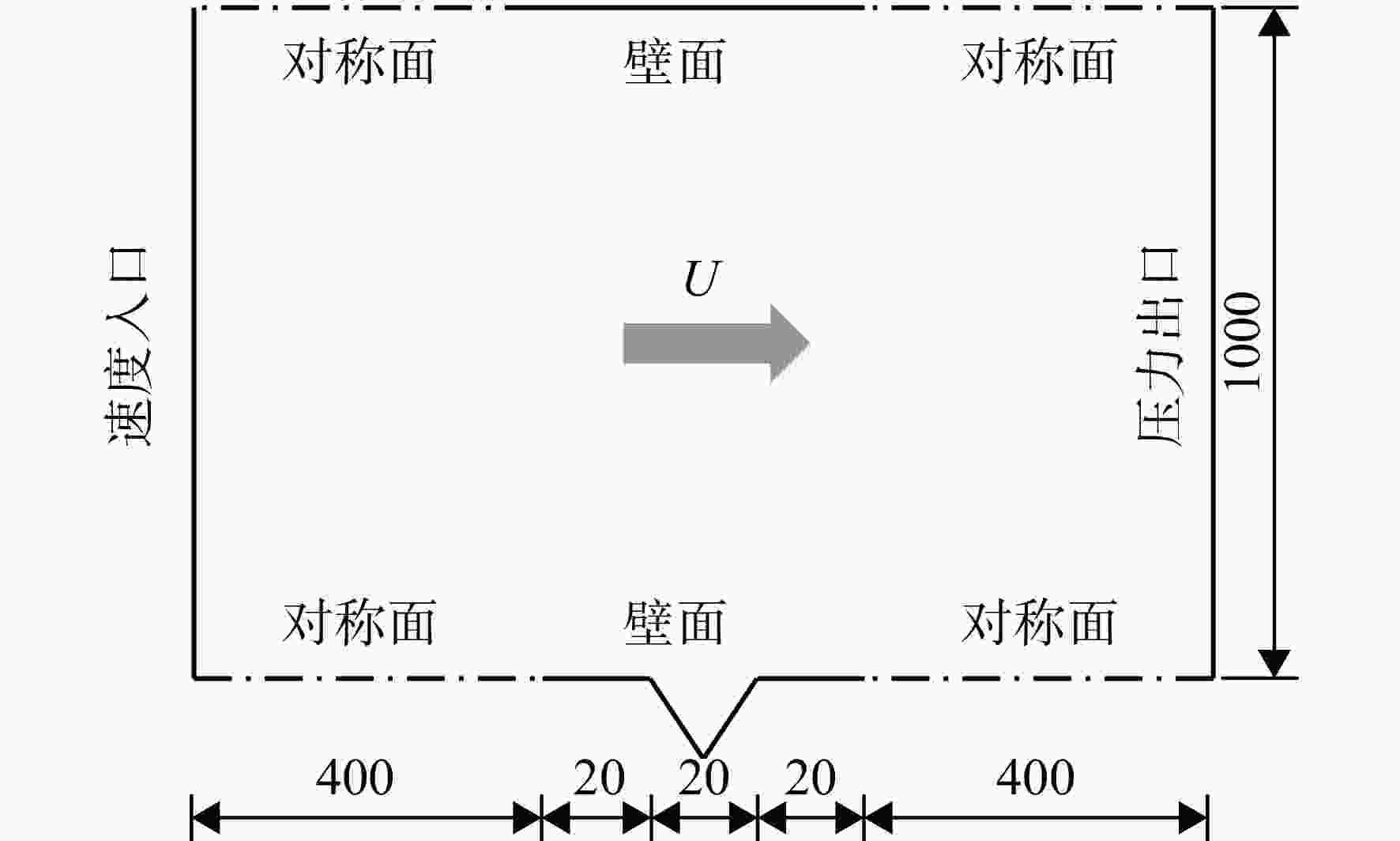

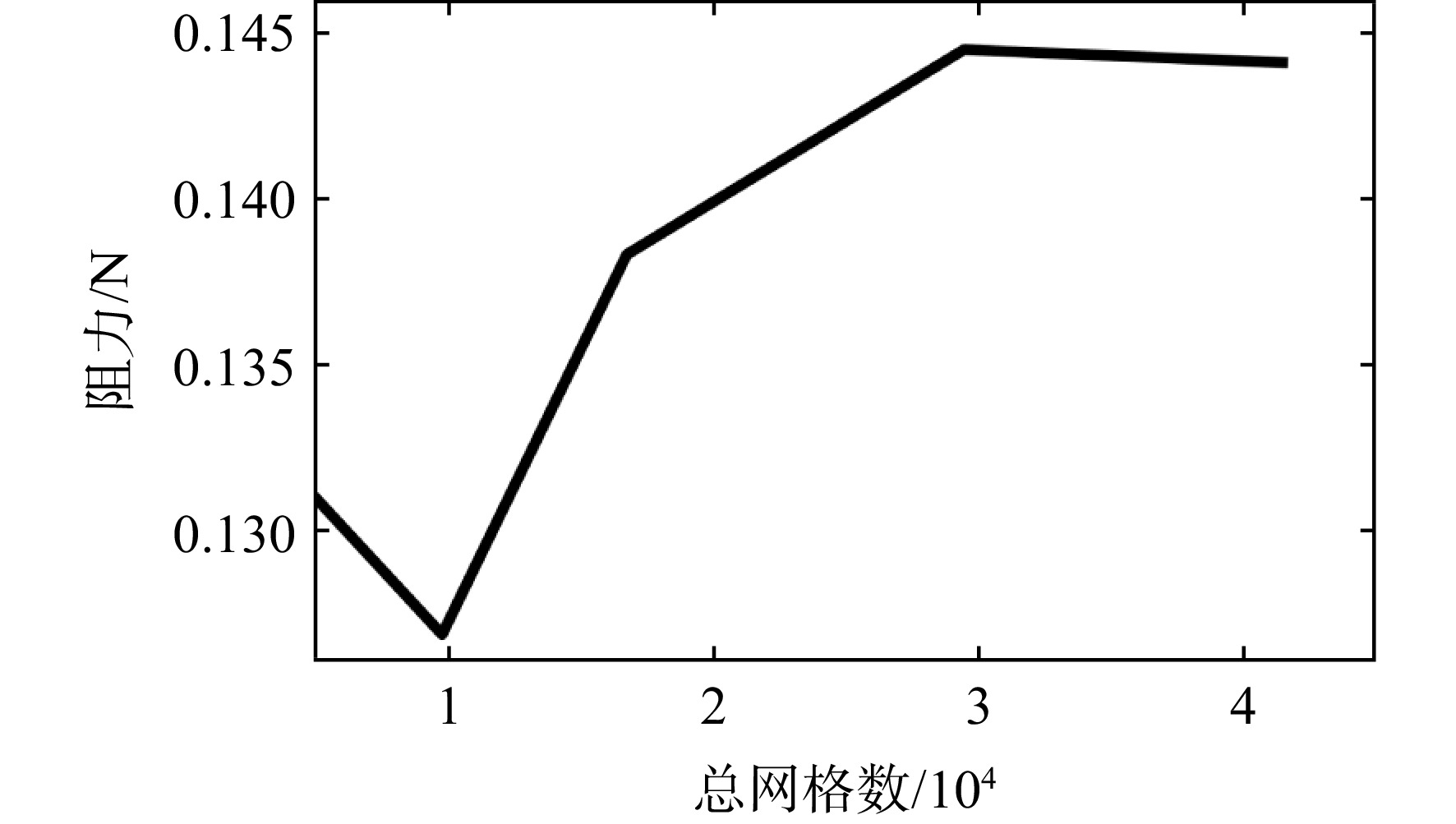

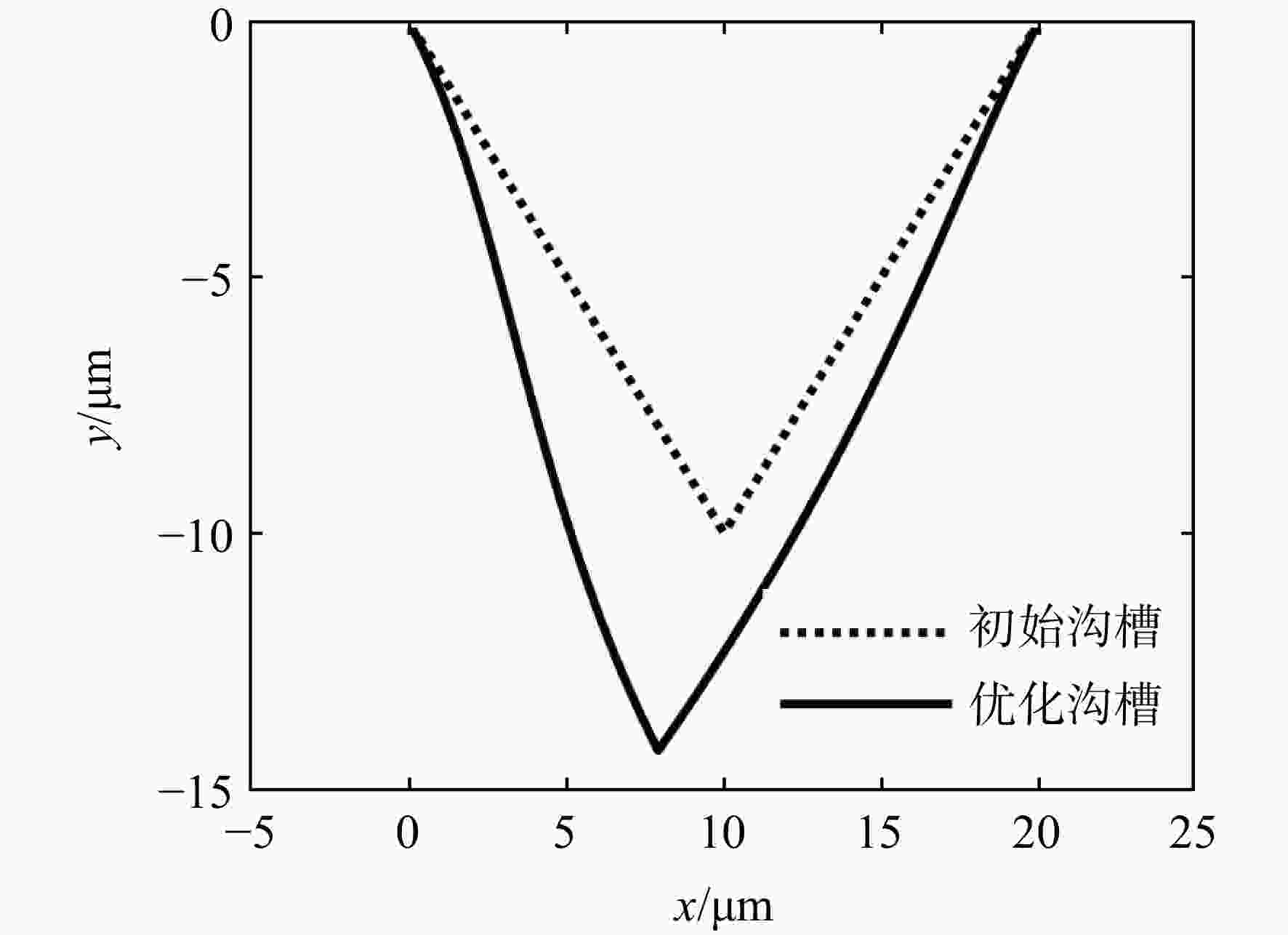

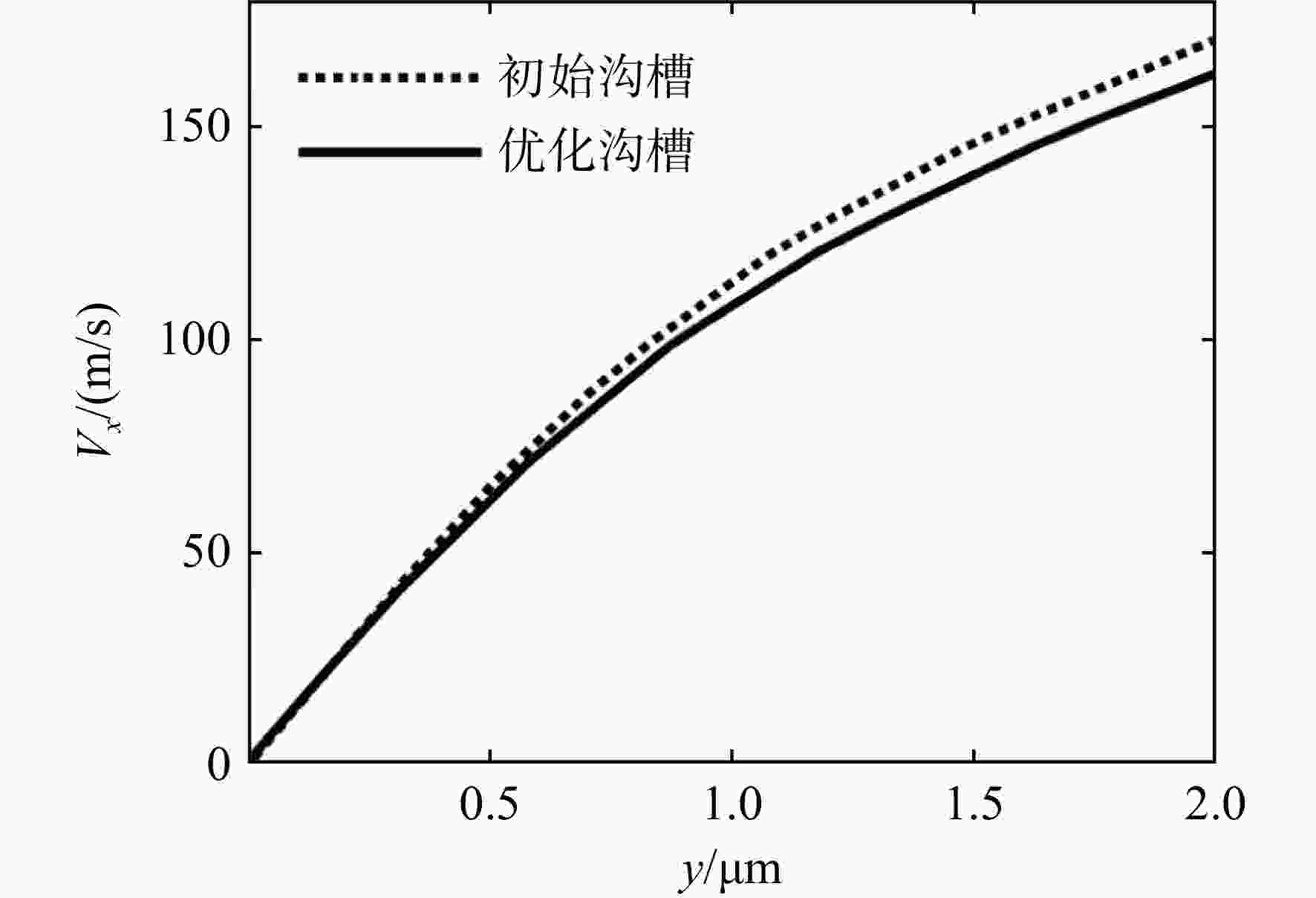

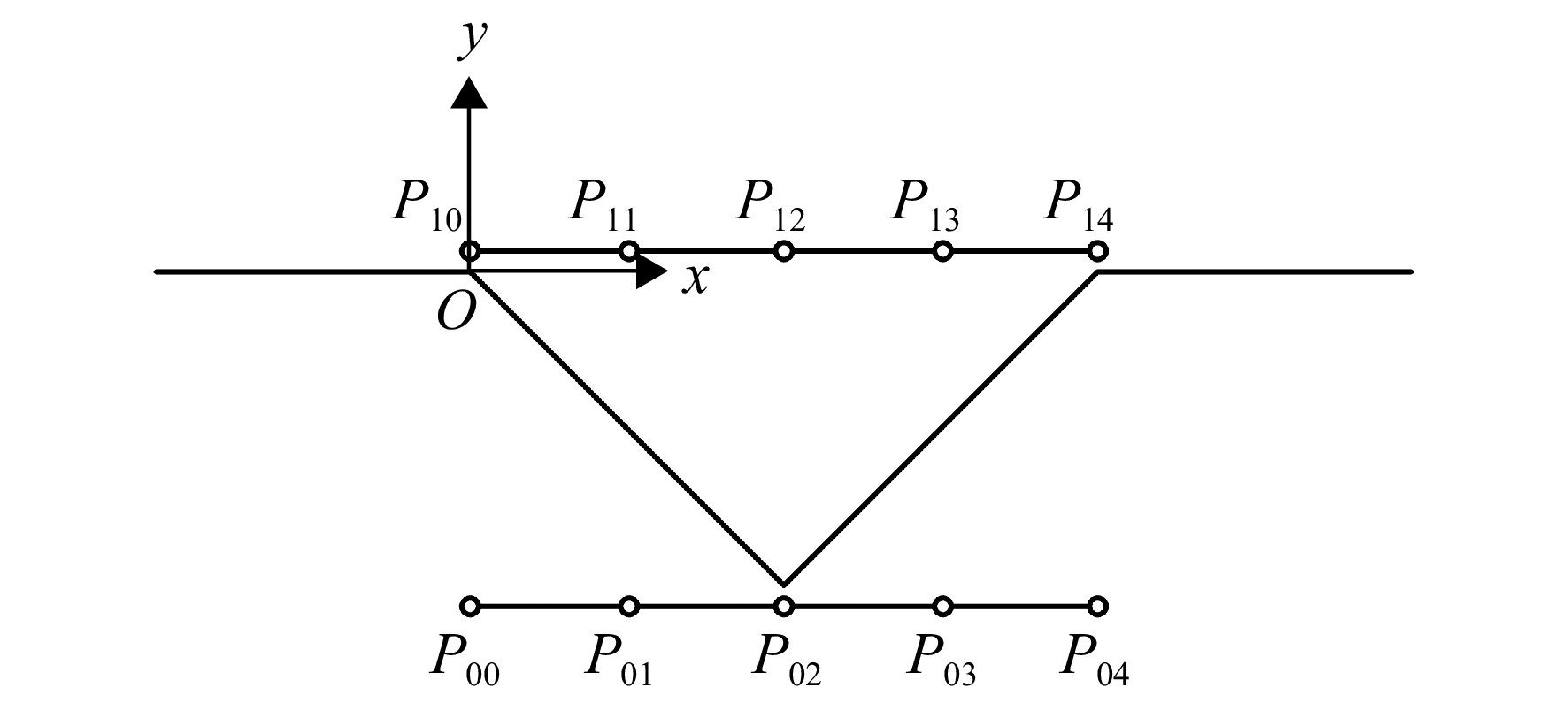

针对二维横向减阻沟槽的形状优化问题,提出了基于自由变形技术及遗传算法的优化方法。以三角形为初始减阻沟槽截面外形,基于自由变形技术对沟槽外形进行几何参数化。通过流场求解对沟槽壁面阻力进行计算,以沟槽壁面的流向气动阻力最小化为优化目标,以遗传算法为优化算法,对沟槽外形进行气动减阻优化。优化结果表明:在来流马赫数为0.8时,优化后的沟槽外形相比于初始的三角形沟槽壁面,减阻率从6.4%增加至10.1%。优化方法表明,自由变形方法结合遗传算法可以为减阻沟槽形状优化提供更大的设计空间,为减阻沟槽形状的优化设计提供了新的设计方法。

Abstract:An optimization approach based on free-form deformation technology and genetic algorithm was proposed for the shape optimization of two-dimensional transverse groove for drag reduction. The triangle was employed as the origin groove section, which was geometrically parameterized based on free-form deformation. The minimum groove drag force calculated by flow field simulation was used as optimization goal, while the genetic algorithm was adopted as the optimization method. The optimization results illustrated that the drag reduction rate of the optimized groove was improved from 6.4% to 10.1% at 0.8 Mach, compared with the origin triangular groove. The optimization approach indicated that the free-form deformation method and genetic algorithm can expand the design space for shape optimization of the drag reduction groove. The present work demonstrates a new approach for shape optimization of groove.

-

表 1 沟槽壁面减阻效果对比

Table 1. Comparison of the groove drag reduction

壁面

类型压差

阻力/N黏性

阻力/N总阻力/N 减阻率/% 光滑

平板0 0.1542 0.1542 三角形

沟槽单元0.0250 0.1193 0.1443 6.4 优化后的

沟槽单元0.0246 0.1140 0.1386 10.1 -

[1] WALSH M J. Riblets as a viscous drag reduction technique[J]. AIAA Journal,1983,21(4): 485-486. doi: 10.2514/3.60126 [2] WALSH M J. Effect of detailed surface geometry on riblet drag reduction performance[J]. Journal of Aircraft,1990,27(6): 572-573. doi: 10.2514/3.25323 [3] BECHERT D W,BRUSE M,HAGE W. Experiments with three-dimensional riblets as an idealized model of shark skin[J]. Experiments in Fluids,2000,28(5): 403-412. doi: 10.1007/s003480050400 [4] LI Chaoqun,TANG Shuo,LI Yi,et al. Numerical and experimental investigations on drag-reducing effects of riblets[J]. Engineering Applications of Computational Fluid Mechanics,2021,15(1): 1726-1745. doi: 10.1080/19942060.2021.1989043 [5] VISWANATH P R. Aircraft viscous drag reduction using riblets[J]. Progress in Aerospace Sciences,2002,38(6/7): 571-600. [6] 张子良,张明明. 仿生减阻翼型的气动性能[J]. 航空动力学报,2021,36(8): 1740-1748. ZHANG Ziliang,ZHANG Mingming. Aerodynamic performance for bionic drag-reducing airfoil[J]. Journal of Aerospace Power,2021,36(8): 1740-1748. (in Chinese doi: 10.13224/j.cnki.jasp.20200485ZHANG Ziliang, ZHANG Mingming. Aerodynamic performance for bionic drag-reducing airfoil[J]. Journal of Aerospace Power, 2021, 36(8): 1740-1748. (in Chinese) doi: 10.13224/j.cnki.jasp.20200485 [7] SEO S H,HONG C H. Performance improvement of airfoils for wind blade with the groove[J]. International Journal of Green Energy,2016,13(1): 34-39. doi: 10.1080/15435075.2014.910777 [8] HUANG Chonghai,LIU Dongjie,WEI Jinjia. Experimental study on drag reduction performance of surfactant flow in longitudinal grooved channels[J]. Chemical Engineering Science,2016,152: 267-279. doi: 10.1016/j.ces.2016.06.009 [9] AHMADI-BALOUTAKI M,CARRIVEAU R,TING D S K. Effect of free-stream turbulence on flow characteristics over a transversely-grooved surface[J]. Experimental Thermal and Fluid Science,2013,51: 56-70. doi: 10.1016/j.expthermflusci.2013.07.001 [10] WU Zhengren,YANG Yufei,LIU Mei,et al. Analysis of the influence of transverse groove structure on the flow of a flat-plate surface based on Liutex parameters[J]. Engineering Applications of Computational Fluid Mechanics,2021,15(1): 1282-1297. doi: 10.1080/19942060.2021.1968955 [11] WANG Baoguo,WANG Jiadao,ZHOU Gang,et al. Drag reduction by microvortexes in transverse microgrooves[J]. Advances in Mechanical Engineering, 2014,6: 734012.1-734012.7. [12] WANG Xiaona,GENG Xingguo,ZANG Duyang. Drag-reduction of one-dimensional period and puasiperiod groove structures[J]. Acta Physica Sinica,2013,62(5): 054701.1-054701.8. [13] 李超群,唐硕,李易,等. 基于神经网络的减阻沟槽壁面形状优化[J]. 航空动力学报,2022,37(3): 639-648. LI Chaoqun,TANG Shuo,LI Yi,et al. Sub-optimization of riblet shape based on neural networks[J]. Journal of Aerospace Power,2022,37(3): 639-648. (in ChineseLI Chaoqun, TANG Shuo, LI Yi, et al. Sub-optimization of riblet shape based on neural networks[J]. Journal of Aerospace Power, 2022, 37(3): 639-648. (in Chinese) [14] 汪志远,马建敏. 鲨鱼皮微沟槽结构减阻计算分析[J]. 力学季刊,2017,38(1): 160-168. WANG Zhiyuan,MA Jianmin. Calculation and analysis on drag reduction of shark’s skin tiny groove structure[J]. Chinese Quarterly of Mechanics,2017,38(1): 160-168. (in Chinese doi: 10.15959/j.cnki.0254-0053.2017.01.018WANG Zhiyuan, MA Jianmin. Calculation and analysis on drag reduction of shark’s skin tiny groove structure[J]. Chinese Quarterly of Mechanics, 2017, 38(1): 160-168. (in Chinese) doi: 10.15959/j.cnki.0254-0053.2017.01.018 [15] 杨绍琼,崔宏昭,姜楠. 纵向沟槽壁面湍流边界层内类开尔文-亥姆霍兹涡结构的流动显示[J]. 力学学报,2015,47(3): 529-533. YANG Shaoqiong,KWING-SO C,JIANG Nan. Flow visualizations on Kelvin-Helmholtz-like roller structures in turbulent boundary layer over riblets[J]. Chinese Journal of Theoretical and Applied Mechanics,2015,47(3): 529-533. (in Chinese doi: 10.6052/0459-1879-14-345YANG Shaoqiong, KWING-SO C, JIANG Nan. Flow visualizations on Kelvin-Helmholtz-like roller structures in turbulent boundary layer over riblets[J]. Chinese Journal of Theoretical and Applied Mechanics, 2015, 47(3): 529-533. (in Chinese) doi: 10.6052/0459-1879-14-345 [16] 封贝贝,陈大融,汪家道. 亚音速飞行器壁面沟槽减阻研究与应用[J]. 清华大学学报(自然科学版),2012,52(7): 967-972. FENG Beibei,CHEN Darong,WANG Jiadao. Riblet surface drag reduction on subsonic aircraft[J]. Journal of Tsinghua University (Science and Technology),2012,52(7): 967-972. (in Chinese doi: 10.16511/j.cnki.qhdxxb.2012.07.017FENG Beibei, CHEN Darong, WANG Jiadao. Riblet surface drag reduction on subsonic aircraft[J]. Journal of Tsinghua University (Science and Technology), 2012, 52(7): 967-972. (in Chinese) doi: 10.16511/j.cnki.qhdxxb.2012.07.017 [17] BECHERT D W,BRUSE M,HAGE W,et al. Experiments on drag-reducing surfaces and their optimization with an adjustable geometry[J]. Journal of Fluid Mechanics,1997,338: 59-87. doi: 10.1017/S0022112096004673 [18] CHEN Huawei,RAO Fugang,SHANG Xiaopeng,et al. Biomimetic drag reduction study on herringbone riblets of bird feather[J]. Journal of Bionic Engineering,2013,10(3): 341-349. doi: 10.1016/S1672-6529(13)60229-2 [19] BENSCHOP H O G,BREUGEM W P. Drag reduction by herringbone riblet texture in direct numerical simulations of turbulent channel flow[J]. Journal of Turbulence,2017,18(8): 717-759. doi: 10.1080/14685248.2017.1319951 [20] 崔光耀,潘翀,高琪,等. 沟槽方向对湍流边界层流动结构影响的实验研究[J]. 力学学报,2017,49(6): 1201-1212. CUI Guangyao,PAN Chong,GAO Qi,et al. Flow structure in the turbulent boundary layer over directional riblets surfaces[J]. Chinese Journal of Theoretical and Applied Mechanics,2017,49(6): 1201-1212. (in Chinese doi: 10.6052/0459-1879-17-252CUI Guangyao, PAN Chong, GAO Qi, et al. Flow structure in the turbulent boundary layer over directional riblets surfaces[J]. Chinese Journal of Theoretical and Applied Mechanics, 2017, 49(6): 1201-1212. (in Chinese) doi: 10.6052/0459-1879-17-252 [21] 郎莎莎,耿兴国,臧渡洋. 八重准周期排列的短沟槽结构减阻机理分析[J]. 物理学报,2014,63(8): 248-258. LANG Shasha,GENG Xingguo,ZANG Duyang. Drag reduction mechanisms of 8-fold quasi-periodic short groove structures[J]. Acta Physica Sinica,2014,63(8): 248-258. (in ChineseLANG Shasha, GENG Xingguo, ZANG Duyang. Drag reduction mechanisms of 8-fold quasi-periodic short groove structures[J]. Acta Physica Sinica, 2014, 63(8): 248-258. (in Chinese) [22] WU Zhengren,LI Shuguang,LIU Mei,et al. Numerical research on the turbulent drag reduction mechanism of a transverse groove structure on an airfoil blade[J]. Engineering Applications of Computational Fluid Mechanics,2019,13(1): 1024-1035. doi: 10.1080/19942060.2019.1665101 [23] FARIN G E. Curves and surfaces for computer-aided geometric design: a practical guide[M]. 4th ed. San Diego: Academic Press,1997. [24] KULFAN B M,BUSSOLETTI J E. “Fundamental” parametric geometry representations for aircraft component shapes[R]. AIAA-2006-6948,2006. [25] 关晓辉,李占科,宋笔锋. CST气动外形参数化方法研究[J]. 航空学报,2012,33(4): 625-633. GUAN Xiaohui,LI Zhanke,SONG Bifeng. A study on CST aerodynamic shape parameterization method[J]. Acta Aeronautica et Astronautica Sinica,2012,33(4): 625-633. (in ChineseGUAN Xiaohui, LI Zhanke, SONG Bifeng. A study on CST aerodynamic shape parameterization method[J]. Acta Aeronautica et Astronautica Sinica, 2012, 33(4): 625-633. (in Chinese) [26] SEDERBERG T W,PARRY S R. Free-form deformation of solid geometric models[C]//Proceedings of the 13th Annual Conference on Computer Graphics and Interactive Techniques. New York: ACM(Association for Computing Machinery),1986: 151-160. [27] GOLDBERG D E. Genetic algorithms in search,optimization and machine learing[M]. Boston,US: Addison Wesley Publishing Company,1989. [28] 王清,招启军. 基于遗传算法的旋翼翼型综合气动优化设计[J]. 航空动力学报,2016,31(6): 1486-1495. WANG Qing,ZHAO Qijun. Synthetical optimization design of rotor airfoil by genetic algorithm[J]. Journal of Aerospace Power,2016,31(6): 1486-1495. (in Chinese doi: 10.13224/j.cnki.jasp.2016.06.026WANG Qing, ZHAO Qijun. Synthetical optimization design of rotor airfoil by genetic algorithm[J]. Journal of Aerospace Power, 2016, 31(6): 1486-1495. (in Chinese) doi: 10.13224/j.cnki.jasp.2016.06.026 -

下载:

下载: