Investigation on turbine inter-vane combustion performance based on fuel cooled vane

-

摘要:

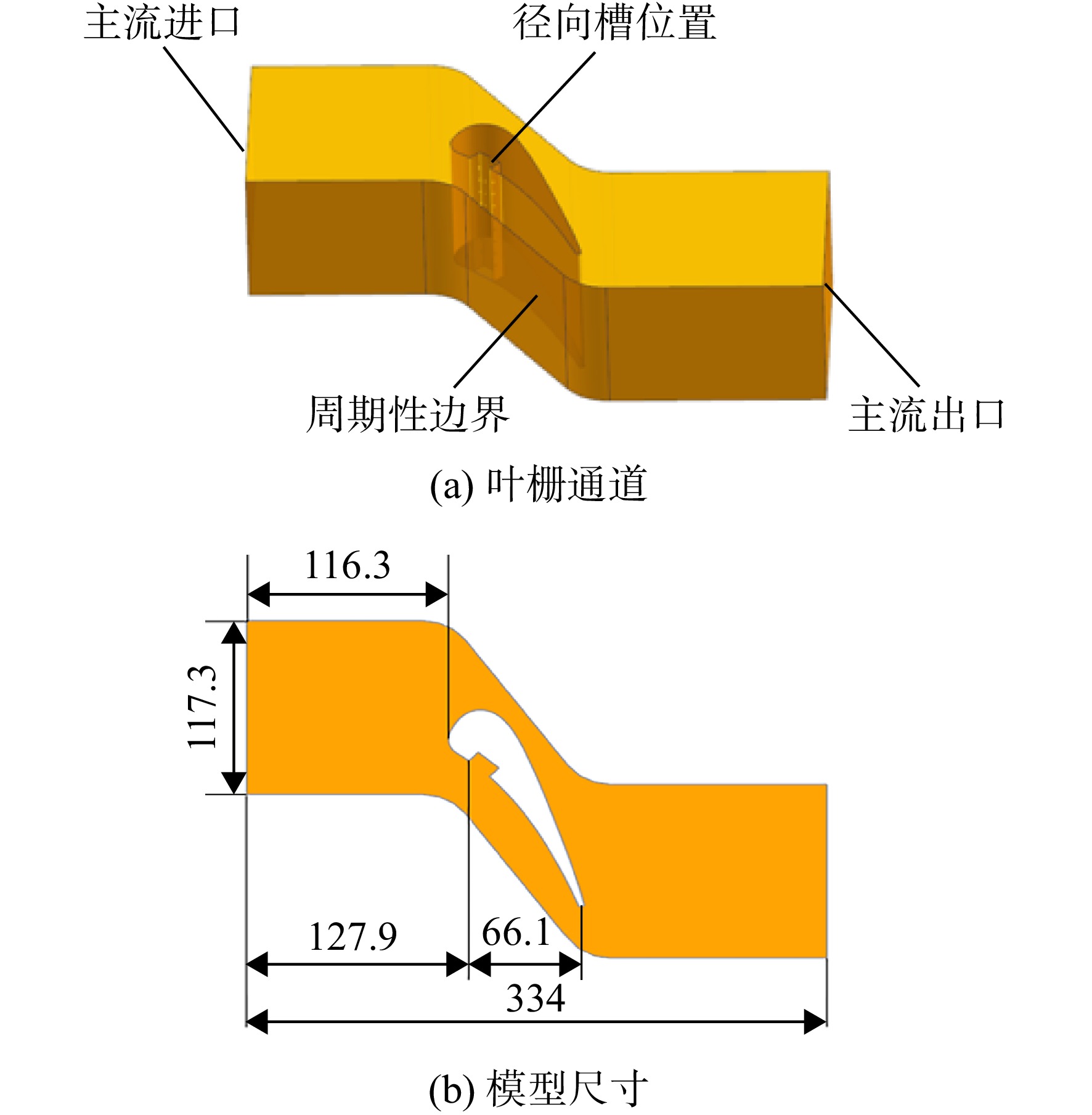

为进一步提升航空燃气涡轮发动机性能,提出一种高压涡轮叶间燃烧的结构,采用叶片油冷后的高温燃油喷入叶间通道燃烧,利用径向槽(radial vane cavity,RVC)稳定火焰,以涡轮导向叶片C3X为叶间燃烧叶片模型,数值研究了径向槽尺寸(深长比为0.4~0.6)、油气比(0.007~0.0105)和燃油温度(300~500 K)对叶间燃烧性能的影响。结果表明:径向槽深长比为0.5时获得最佳燃烧效果,由燃烧引起的热阻损失在7%左右,可实现在叶间的近似等温燃烧;叶间燃烧性能随油气比增大而降低,油气比为0.007时距叶片出口 20 mm处燃烧效率达到98.86%;高温燃油在叶间通道内燃烧性能要明显优于低温燃油的燃烧性能,在叶片出口处燃烧效率提升约13%。相关结论可为叶间燃烧技术的发展提供参考。

Abstract:To expand the performance of aero-gas turbine engine, a structure of high-pressure turbine inter-vane combustion was proposed. The high-temperature fuel was injected into the inter-vane channel after cooling the vane. And the flame was stabilized by radial vane cavity (RVC). The C3X turbine guide vane was used as the inter-vane combustion model and the effects of radial vane cavity (depth length ratio 0.4−0.6), fuel-air ratio (0.007−0.0105) and fuel temperature (300−500 K) on inter-vane combustion performance were numerically studied. It was observed that the optimization combustion effect was obtained with depth length ratio 0.5. The thermal resistance loss caused by combustion was about 7%, which can realize the approximately isothermal combustion between the vanes. The inter-vane combustion performance decreased with the increase of fuel-air ratio, and the combustion efficiency reached 98.86% at 20 mm away from the blade outlet when the fuel-air ratio was 0.007. The combustion performance of high-temperature fuel in the inter-vane channel was better than that of low-temperature fuel, and the combustion efficiency at the outlet of the blade increased about 13%. The conclusions can provide a reference for the development of inter-vane burner technology.

-

图 1 C3X叶片物理模型[18](单位:mm)

Figure 1. Physical model of the C3X vane (unit:mm)

表 1 叶片径向槽尺寸

Table 1. Dimension of the radial vane cavity

结构名称 D/L CS0 0 CS1 0.4 CS2 0.5 CS3 0.6 表 2 边界参数

Table 2. Boundary parameters

边界条件参数 数值 主流进口总压/Pa 413286 主流进口总温/K 818 主流出口静压/Pa 254172 主流进口湍流强度 8.3 主流进口湍流黏性比 30 前后壁冷气流量/(kg/s) 0.0068 尾缘劈缝流量/(kg/s) 0.020 -

[1] JANSOHN P. Modern Gas Turbine Systems: High efficiency,low emission,fuel flexible power generation[M]. Duxford,UK: Woodhead Publishing,2013. [2] 尚守堂,程明,刘殿春,等. 涡轮级间燃烧室技术的研究现状与发展趋势[J]. 航空科学技术,2011,22(4): 79-82. SHANG Shoutang,CHENG Ming,LIU Dianchun,et al. The status and direction of inter-stage turbine burner technology[J]. Aeronautical Science & Technology,2011,22(4): 79-82. (in Chinese SHANG Shoutang, CHENG Ming, LIU Dianchun, et al . The status and direction of inter-stage turbine burner technology[J]. Aeronautical Science & Technology,2011 ,22 (4 ):79 -82 . (in Chinese)[3] LIU F,SIRIGNANO W A. Turbojet and turbofan engine performance increases through turbine burners[J]. Journal of Propulsion and Power,2001,17(3): 695-705. doi: 10.2514/2.5797 [4] SIRIGNANO W A,LIU F. Performance increases for gas-turbine engines through combustion inside the turbine[J]. Journal of Propulsion and Power,1999,15(1): 111-118. doi: 10.2514/2.5398 [5] BOHAN B T,POLANKA M D. Analysis of flow migration in an ultra-compact combustor[J]. Journal of Engineering for Gas Turbines and Power,2013,135(5): 420-431. [6] ZELINA J,EHRET J,HANCOCK R,et al. Ultra-compact combustion technology using high swirl for enhanced burning rate[C]//Proceedings of the 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. Reston,US: AIAA,2002: 7-10. [7] THORNBURG H J,SEKAR B,ZELINA J,et al. Prediction of inter-turbine burner (ITB) performance with curved radial vane cavity at various equivalence ratios[C]//Proceedings of ASME Turbo Expo: Power for Land,Sea,and Air. Berlin: ASME,2009: 2131-2139. [8] GREENWOOD R. Numerical analysis and optimization of the ultra compact combustor: AD434747 [R]. Ala,US: Department of the Air force,Air University,2005. [9] GREENWOOD R,ANTHENIEN R,ZELINA J. Computational analysis of the ultra compact combustor: AIAA-2005-220[R]. Reston,US: the 43rd AIAA Aerospace Sciences Meeting and Exhibit,2005. [10] 李明,唐豪,张超,等. 一种新型涡轮叶间燃烧室的数值模拟[J]. 航空动力学报,2012,27(1): 55-62. LI Ming,TANG Hao,ZHANG Chao,et al. Numerical simulation of a novel turbine inter-vane burner[J]. Journal of Aerospace Power,2012,27(1): 55-62. (in Chinese LI Ming, TANG Hao, ZHANG Chao, et al . Numerical simulation of a novel turbine inter-vane burner[J]. Journal of Aerospace Power,2012 ,27 (1 ):55 -62 . (in Chinese)[11] 李明,唐豪,郑海飞,等. 径向槽对涡轮叶间补燃室性能影响的数值研究[J]. 航空动力学报,2014,29(12): 2836-2844. LI Ming,TANG Hao,ZHENG Haifei,et al. Numerical investigation of influence of radial vane cavity on turbine inter-vane burner performance[J]. Journal of Aerospace Power,2014,29(12): 2836-2844. (in Chinese LI Ming, TANG Hao, ZHENG Haifei, et al . Numerical investigation of influence of radial vane cavity on turbine inter-vane burner performance[J]. Journal of Aerospace Power,2014 ,29 (12 ):2836 -2844 . (in Chinese)[12] 郑海飞,唐豪,李明,等. 基于涡轮导向器增燃技术的总体性能与燃烧组织[J]. 航空动力学报,2014,29(5): 1053-1061. ZHENG Haifei,TANG Hao,LI Ming,et al. Overall performance and combustion organization based on turbine inter-vane burning technology[J]. Journal of Aerospace Power,2014,29(5): 1053-1061. (in Chinese ZHENG Haifei, TANG Hao, LI Ming, et al . Overall performance and combustion organization based on turbine inter-vane burning technology[J]. Journal of Aerospace Power,2014 ,29 (5 ):1053 -1061 . (in Chinese)[13] BOHAN B T,POLANKA M D,RUTLEDGE J L. Computational analysis of a novel cooling scheme for ultra compact combustor turbine vanes[C]//Proceedings of ASME Turbo Expo: Turbomachinery Technical Conference and Exposition. Charlotte,US: ASME,2017: 1-12. [14] 俞刚,李建国,赵震,等. 超声速模型燃烧室中气化煤油喷注研究[J]. 推进技术,2005,26(2): 97-100. YU Gang,LI Jianguo,ZHAO Zhen,et al. Investigation of vaporized kerosene injection in a supersonic model combustor[J]. Journal of Propulsion Technology,2005,26(2): 97-100. (in Chinese YU Gang, LI Jianguo, ZHAO Zhen, et al . Investigation of vaporized kerosene injection in a supersonic model combustor[J]. Journal of Propulsion Technology,2005 ,26 (2 ):97 -100 . (in Chinese)[15] FAN Xuejun,YU Gong,LI Jianguo,et al. Investigation of vaporized kerosene injection and combustion in a supersonic model combustor[J]. Journal of Propulsion and Power,2006,22(1): 103-110. doi: 10.2514/1.15427 [16] 刘德彰,刘明候,武卫东. 高温涡轮叶片用航空煤油冷却的机理研究[J]. 航空动力学报,1992,7(3): 261-265,292. LIU Dezhang,LIU Minghou,WU Weidong. The mechanism of liquid-cooling of vane in high-temperature turbine[J]. Journal of Aerospace Power,1992,7(3): 261-265,292. (in Chinese LIU Dezhang, LIU Minghou, WU Weidong . The mechanism of liquid-cooling of vane in high-temperature turbine[J]. Journal of Aerospace Power,1992 ,7 (3 ):261 -265, 292 . (in Chinese)[17] WILLS R W,SEBASTIAN J R,COLE A,et al. Experiments in a heated,rotating test rig simulating a fuel cooled turbine[C]//Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference. Reston,US: AIAA,2014: 3575-3596. [18] HYLTON L,MIHELC M S,TURNER E,et al. Analytical and experimental evaluation of the heat transfer distribution over the surfaces of turbine vanes: NASA CR168015 [R]. Chicago,US: NASA Lewis Research Center,1983 [19] FLUENT Incorporation. FLUENT User’s Guide[M]. New Hampshire,US: Fluent Incorporation,2020. [20] 彭瀚,黄玥,邢菲,等. 入口流量分配对超紧凑级间燃烧室性能的影响[J]. 航空动力学报,2017,32(1): 60-65. PENG Han,HUANG Yue,XING Fei,et al. Performance of ultra-compact inter-turbine burner with different inlet mass flow splits[J]. Journal of Aerospace Power,2017,32(1): 60-65. (in Chinese PENG Han, HUANG Yue, XING Fei, et al . Performance of ultra-compact inter-turbine burner with different inlet mass flow splits[J]. Journal of Aerospace Power,2017 ,32 (1 ):60 -65 . (in Chinese)[21] 黄勇. 燃烧与燃烧室[M]. 北京: 北京航空航天大学出版社,2009. [22] 李庆. 基于凹腔火焰稳定器的亚燃冲压发动机燃烧室点火过程研究[D]. 长沙: 国防科学技术大学,2010. LI Qing. Research on the ignition process of cavity-based flameholder in ramjet combustor[D]. Changsha: National University of Defense Technology,2010. (in ChineseLI Qing. Research on the ignition process of cavity-based flameholder in ramjet combustor[D]. Changsha: National University of Defense Technology, 2010. (in Chinese) -

下载:

下载: