High-order contact analysis method of spiral bevel gear tooth surface based on ease-off

-

摘要:

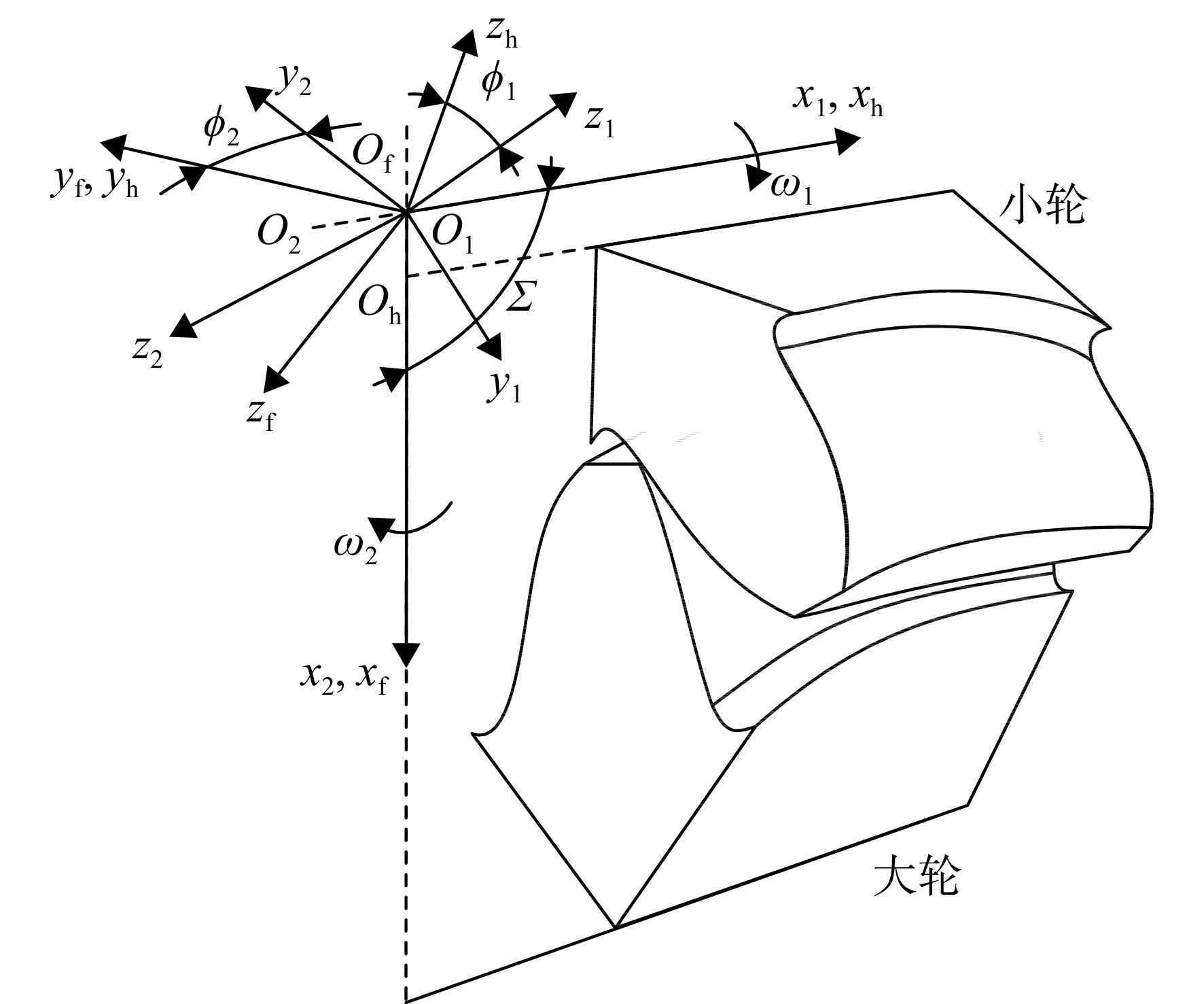

为应对弧齿锥齿轮二阶接触分析方法的不足与其高阶接触理论实现的复杂问题,基于ease-off拓扑曲面方程与弧齿锥齿轮齿面方程的结合以及传动误差与接触迹线和ease-off之间的解析关系,提出以传动比高阶导数和接触迹线短程曲率为高阶接触参数的离散齿面的高阶接触分析方法,并建立基于有限差分的简便计算方法。结果表明,高阶齿面的传动比高阶导数波动值分别为0.0031、0.0019与0.001,数值反映齿面形貌的全局特性;接触线短程曲率波动值分别为0.0000769、0.000586和0.000127,说明沿接触迹线的齿面接触过程的复杂性。结果不仅验证了离散齿面高阶接触分析方法的正确性与有效性,而且说明该方法降低了高阶接触参数的计算难度,为齿面全局设计提供了可能。

Abstract:In order to deal with the shortcomings of the second-order contact analysis method of spiral bevel gears and the complex problems of its high-order contact theory realization, based on the combination of ease-off topological surface equation and tooth surface equation of spiral bevel gears and the analytical relationship between transmission error and contact trace and ease-off, a high-order contact analysis method for discrete tooth surfaces with high-order contact parameters of high-order derivative of transmission ratio and short-range curvature of contact trace was proposed, and a simple calculation method based on finite difference was established. The results showed that the fluctuation values of the high-order derivative of the transmission ratio of the high-order tooth surface were 0.0031, 0.0019 and 0.001, respectively, which reflected the global characteristics of the tooth surface morphology. The short-range curvature fluctuation values of the contact line were 0.0000769, 0.000586 and 0.000127, respectively, indicating the complexity of the tooth surface contact process along the contact trace. The results not only verified the correctness and effectiveness of the discrete tooth surface high-order contact analysis method, but also showed that the method reduced the calculation difficulty of high-order contact parameters, providing the possibility for the global design of tooth surface.

-

表 1 齿轮副基本参数

Table 1. Basic parameters of gear

参数 数值或说明 小轮 大轮 齿数 34 43 大端模数/mm 2.0 齿宽/mm 15 压力角/(°) 20 螺旋角/(°) 20 轴交角/(°) 108 节锥角/(°) 44.8608 63.1392 面锥角/(°) 49.4637 66.0355 根锥角/(°) 41.9645 58.5362 旋向 右旋 左旋 表 2 小轮工作面切齿参数

Table 2. Pinion cutting parameters of working surface

参数 数值 刀尖半径$ {R_{\text{c}}} $/mm 44.4713 角向刀位$ {q_0} $/rad 1.0827 径向刀位$ {S_{\text{k}}} $/mm 51.5697 滚比$ {R_{\text{a}}} $ 1.4391 垂直轮位$ E $/mm −3.2839 轴向轮位$ {X_{\text{p}}} $/mm −0.2389 床位$ {X_{\text{b}}} $/mm 0.1598 安装角$ {\delta _{\text{m}}} $/rad 0.7324 表 3 预置ease-off修形参数

Table 3. Preset ease-off trim parameters

参数 a11 a12 a13 a14 a15 1 0 0.000005 0 0.0000012 0.0002063 2 0 −0.000005 0 0.0000014 0.0002063 3 0.00001 0 0.000006 0.0000014 0.0002063 -

[1] 天津齿轮机床研究所. 格利森锥齿轮技术资料译文集[M]. 北京: 机械工业出版社,1982. [2] LITVIN F L,FUENTES A. Gear geometry and applied theory[M]. Cambridge,UK: Cambridge University Press,2004. [3] LITVIN F L,CUTMAN Y. A method of local synthesis of gears grounded on the connection between the principal and geodetic curvatures of surfaces[J]. ASME Journal of Mechanical Design,1981,103(1): 114-125. doi: 10.1115/1.3254841 [4] LITVIN F L,ZHANG Y,LUNDY M,et al. Determination of settings of a tilted head cutter for generation of hypoid and spiral bevel gears[J]. Journal of Mechanisms,Transmissions,and Automation in Design,1988,110(4): 495-500. doi: 10.1115/1.3258950 [5] LITVIN F,LEE Hongtao. Generation and tooth contact analysis of spiral bevel gears with predesigned parabolic functions of transmission errors[R]. NASA CR4259,1989. [6] LITVIN F,ZHANG Yi. Local synthesis and tooth contact analysis of face-milled spiral bevel gears[R]. NASA CR4342,1991. [7] XING Yuan,WANG Taiyong. Accuracy enhancement in manufacture of spiral bevel gear with multi-axis CNC machine tools by a new compensation method[C]//2011 International Conference on Consumer Electronics,Communications and Networks. Piscataway,US: IEEE,2011: 3891-3894. [8] SHIH Y P,FONG Z H. Flank modification methodology for face-hobbing hypoid gears based on ease-off topography[J]. Journal of Mechanical Design,2007,129(12): 1294-1302. doi: 10.1115/1.2779889 [9] SHIH Y P. A novel ease-off flank modification methodology for spiral bevel and hypoid gears[J]. Mechanism and Machine Theory,2010,45(8): 1108-1124. doi: 10.1016/j.mechmachtheory.2010.03.010 [10] SHIH Y P. Study on the flank modification of face hobbed hypoid gears[D]. Tainan,Taiwan: National Chungcheng University,2007. [11] FAN Q. Ease-off and application in tooth contact analysis for face-milled and face-hobbed spiral bevel and hypoid gears[M]//Goldfarb V,Barmina N. Theory and practice of gearing and transmissions. New York: Springer,2016: 321-339. [12] 魏冰阳,邓效忠,仝昂鑫,等. 曲面综合法弧齿锥齿轮加工参数计算[J]. 机械工程学报,2016,52(1): 20-25. WEI Bingyang,DENG Xiaozhong,TONG Angxin,et al. Surface synthesis method on generating parameters computation of spiral bevel-gears[J]. Journal of Mechanical Engineering,2016,52(1): 20-25. (in Chinese doi: 10.3901/JME.2016.01.020 WEI Bingyang, DENG Xiaozhong, TONG Angxin, et al . Surface synthesis method on generating parameters computation of spiral bevel-gears[J]. Journal of Mechanical Engineering,2016 ,52 (1 ):20 -25 . (in Chinese) doi: 10.3901/JME.2016.01.020[13] DING Han,TANG Jinyuan,ZHONG Jue,et al. A hybrid modification approach of machine-tool setting considering high tooth contact performance in spiral bevel and hypoid gears[J]. Journal of Manufacturing Systems,2016,41: 228-238. doi: 10.1016/j.jmsy.2016.09.003 [14] DING Han,TANG Jinyuan,SHAO Wen,et al. Optimal modification of tooth flank form error considering measurement and compensation of cutter geometric errors for spiral bevel and hypoid gears[J]. Mechanism and Machine Theory,2017,118: 14-31. doi: 10.1016/j.mechmachtheory.2017.07.020 [15] MU Yanming,LI Wenli,FANG Zongde,et al. A novel tooth surface modification method for spiral bevel gears with higher-order transmission error[J]. Mechanism and Machine Theory,2018,126: 49-60. doi: 10.1016/j.mechmachtheory.2018.04.001 [16] 牟彦铭,方宗德,张西金. 高重合度弧齿锥齿轮高阶传动误差设计与分析[J]. 华中科技大学学报(自然科学版),2018,46(7): 67-72. MU Yanming,FANG Zongde,ZHANG Xijin. Design and analysis of high-order transmission error for high contact ratio spiral bevel gears[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition),2018,46(7): 67-72. (in Chinese MU Yanming, FANG Zongde, ZHANG Xijin . Design and analysis of high-order transmission error for high contact ratio spiral bevel gears[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition),2018 ,46 (7 ):67 -72 . (in Chinese)[17] MU Yanming,FANG Zongde. An ease-off flank modification method for high contact ratio spiral bevel gears with modified curvature motion[J]. Journal of Advanced Mechanical Design,Systems,and Manufacturing,2017,11(3): JAMDSM0034. doi: 10.1299/jamdsm.2017jamdsm0034 [18] FONG Z H. Mathematical model of universal hypoid generator with supplemental kinematic flank correction motions[J]. Journal of Mechanical Design,2000,122(1): 136-142. doi: 10.1115/1.533552 [19] STADTFELD H J. Advanced bevel gear technology[M]. Roche-ster,US: The Gleason Works,2000. [20] FAN Qi. Optimization of face cone element for spiral bevel and hypoid gears[J]. Journal of Mechanical Design,2011,133(9): 189-195. [21] FAN Qi,DAFOE R S,SWANGER J W. Higher-order tooth flank form error correction for face-milled spiral bevel and hypoid gears[J]. Journal of Mechanical Design,2008,130(7): 1029-1033. [22] 王小椿. 点啮合曲面的三阶接触分析[J]. 西安交通大学学报,1983,17(3): 4-17. WANG Xiaochun. Third order contact analysis of point contact surfaces[J]. Journal of Xi’an Jiaotong University,1983,17(3): 4-17. (in Chinese WANG Xiaochun . Third order contact analysis of point contact surfaces[J]. Journal of Xi’an Jiaotong University,1983 ,17 (3 ):4 -17 . (in Chinese)[23] 刘鹄然,赵东福,楼少敏,等. 齿轮与齿条的2阶接触理论[J]. 现代机械,2005(5): 31-34. LIU Huran,ZHAO Dongfu,LOU Shaomin,et al. Theory of high degree contact gear profile[J]. Modern Machinery,2005(5): 31-34. (in Chinese doi: 10.13667/j.cnki.52-1046/th.2005.05.015 LIU Huran, ZHAO Dongfu, LOU Shaomin, et al . Theory of high degree contact gear profile[J]. Modern Machinery,2005 (5 ):31 -34 . (in Chinese) doi: 10.13667/j.cnki.52-1046/th.2005.05.015[24] 刘鹄然,赵东福,宋德玉. 现代啮合理论[M]. 杭州: 浙江大学出版社,2008. [25] ZHU Limin,DING Han,XIONG Youlun. Third-order point contact approach for five-axis sculptured surface machining using non-ball-end tools: I third-order approximation of tool envelope surface[J]. Science China Technological Sciences,2010,53(7): 1904-1912. doi: 10.1007/s11431-010-3184-4 [26] ZHU Limin,DING Han,XIONG Youlun. Third-order point contact approach for five-axis sculptured surface machining using non-ball-end tools (II): tool positioning strategy[J]. Science China Technological Sciences,2010,53(8): 2190-2197. doi: 10.1007/s11431-010-3184-4 [27] 武宝林. 空间共轭啮合齿面间的法曲率和短程挠率的关系及其应用[J]. 天津工业大学学报,2005,24(1): 44-47. WU Baolin. Relationships between normal curvature and geodesic torsion of conjugate surfaces of gearing tooth in three dimension space and its application[J]. Journal of Tianjin Institute of Textile Science and Technology,2005,24(1): 44-47. (in Chinese doi: 10.3969/j.issn.1671-024X.2005.01.012 WU Baolin . Relationships between normal curvature and geodesic torsion of conjugate surfaces of gearing tooth in three dimension space and its application[J]. Journal of Tianjin Institute of Textile Science and Technology,2005 ,24 (1 ):44 -47 . (in Chinese) doi: 10.3969/j.issn.1671-024X.2005.01.012[28] 郑刚,卢耀安,朱利民. 三阶切触法加工自由曲面无干涉刀位规划[J]. 上海交通大学学报,2012,46(2): 172-177. ZHENG Gang,LU Yaoan,ZHU Limin. Interference-free tool positioning for five-axis sculptured surface machining using third-order point contact approach[J]. Journal of Shanghai Jiao Tong University,2012,46(2): 172-177. (in Chinese ZHENG Gang, LU Yaoan, ZHU Limin . Interference-free tool positioning for five-axis sculptured surface machining using third-order point contact approach[J]. Journal of Shanghai Jiao Tong University,2012 ,46 (2 ):172 -177 . (in Chinese)[29] DO CARMO M P. Differential geometry of curves and surfaces[M]. Englewood Cliffs,US: Prentice-Hall,1976. [30] DE LEÓN M,GASET J,LAÍNZ M,et al. Higher-order contact mechanics[J]. Annals of Physics,2021,425: 168396. doi: 10.1016/j.aop.2021.168396 -

下载:

下载: