Intelligent diagnosis of aviation bearings based on frequency domain features

-

摘要:

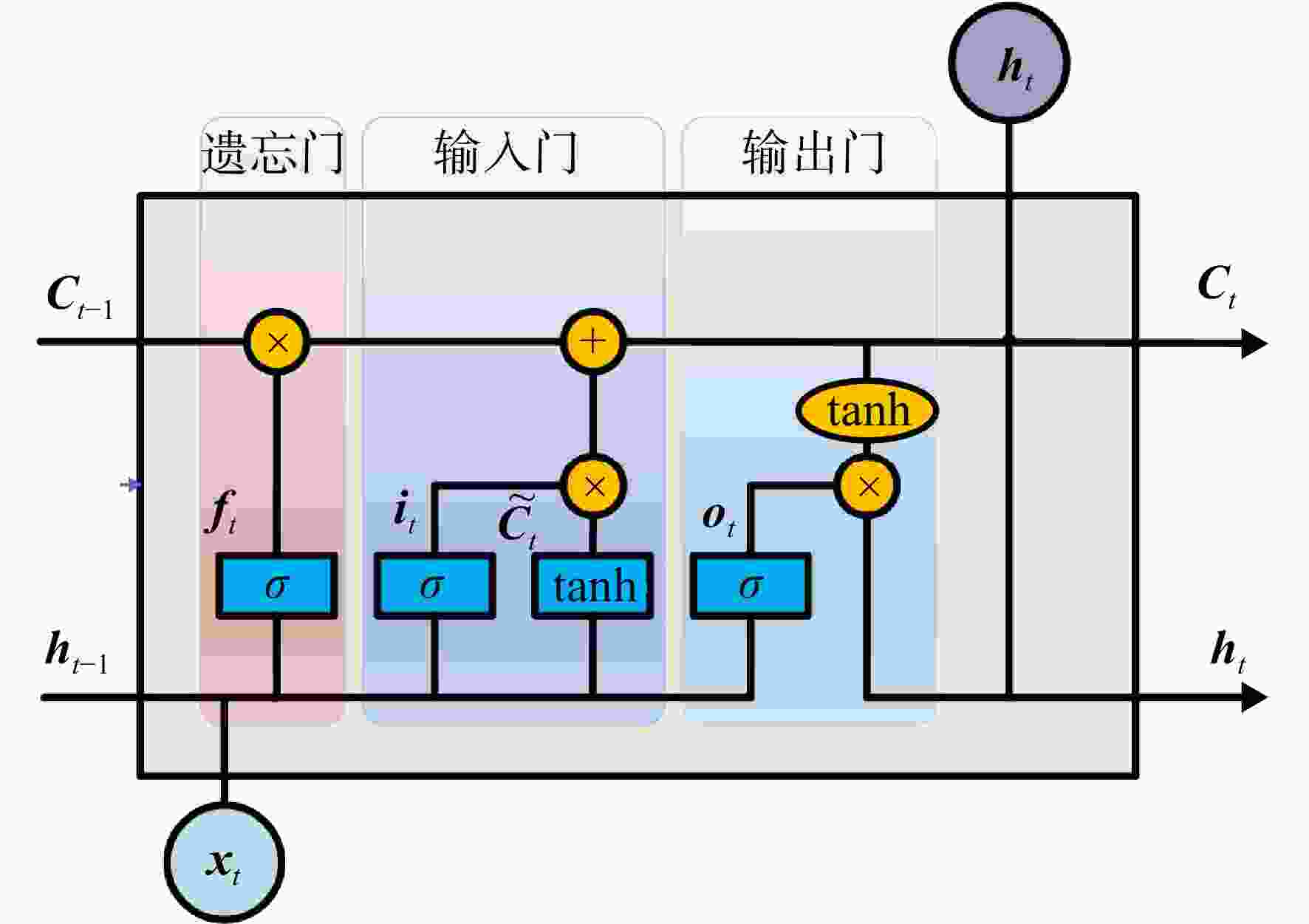

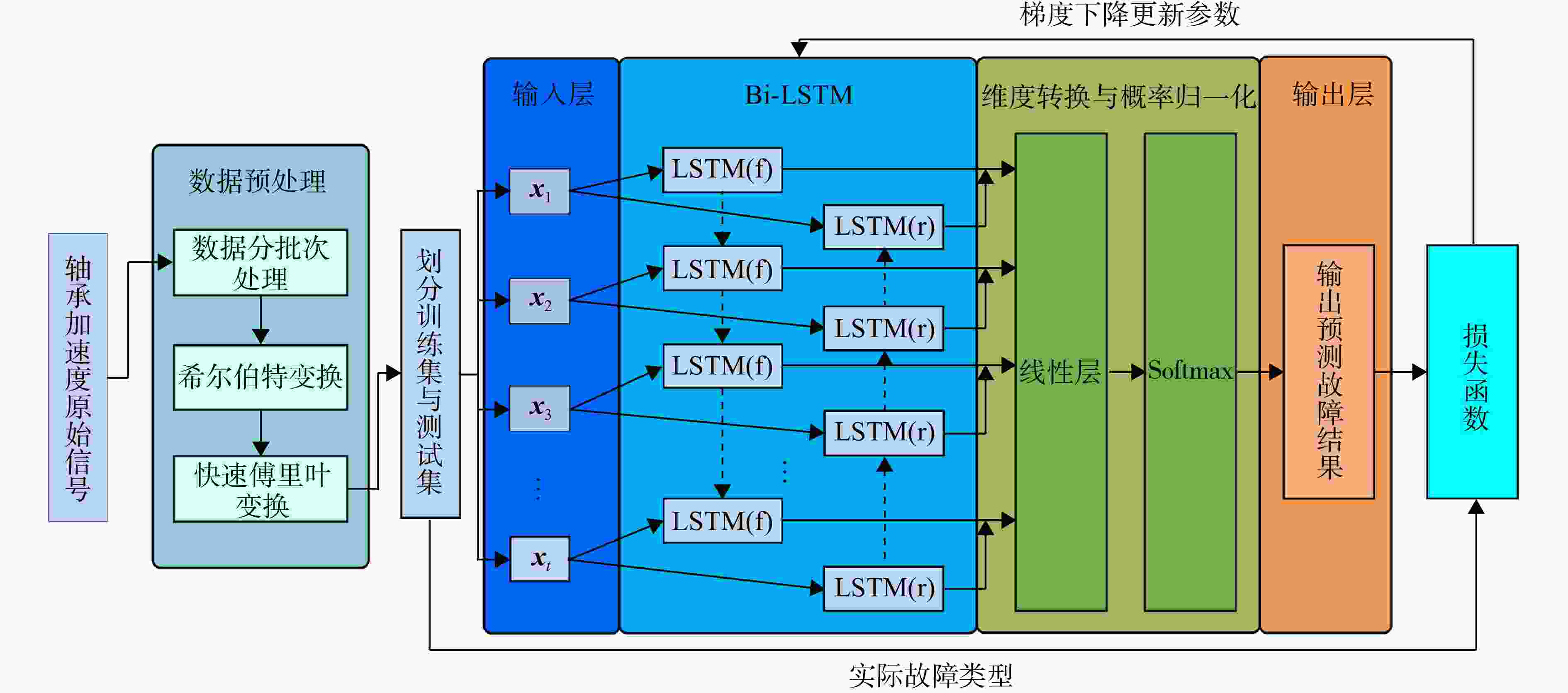

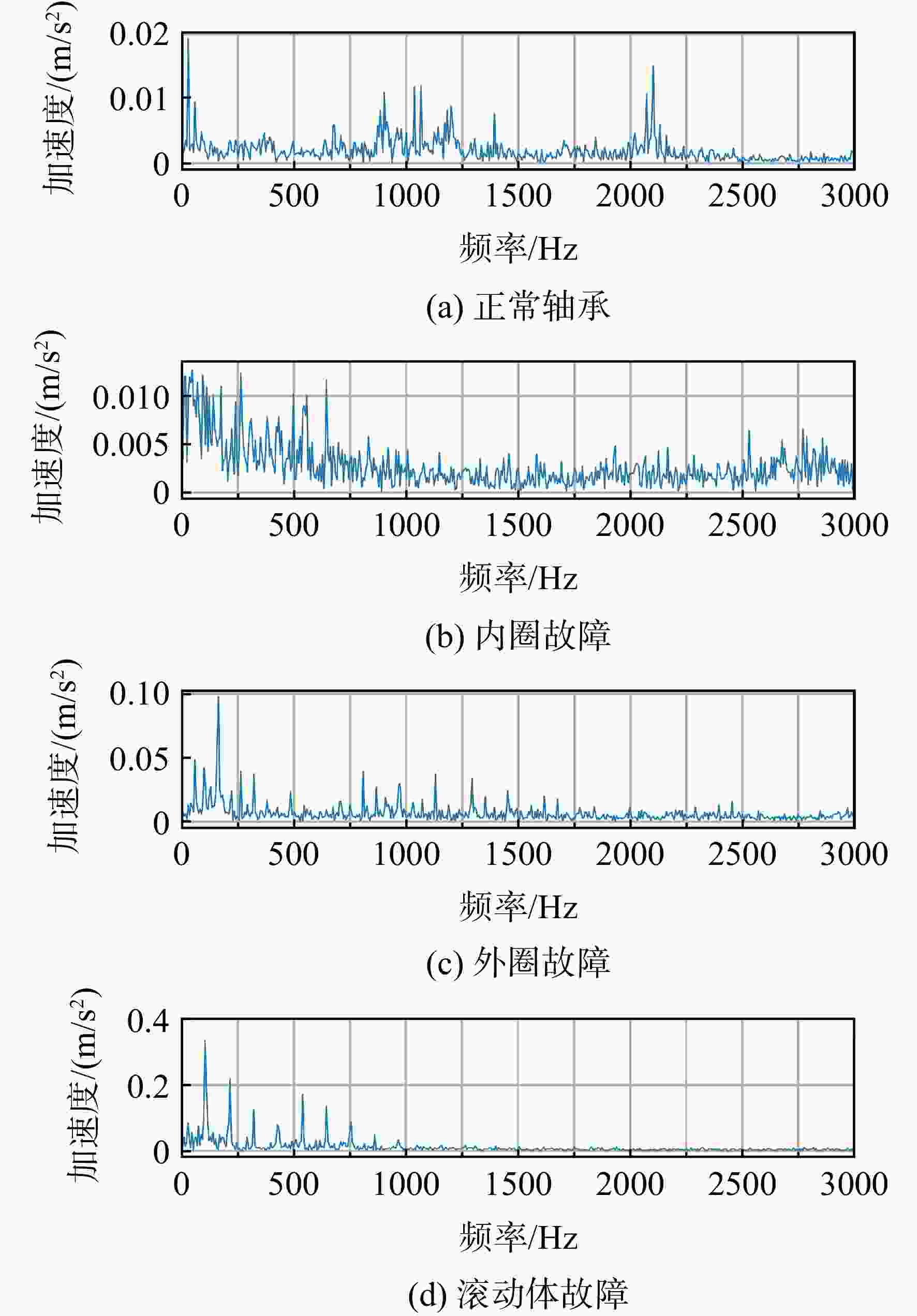

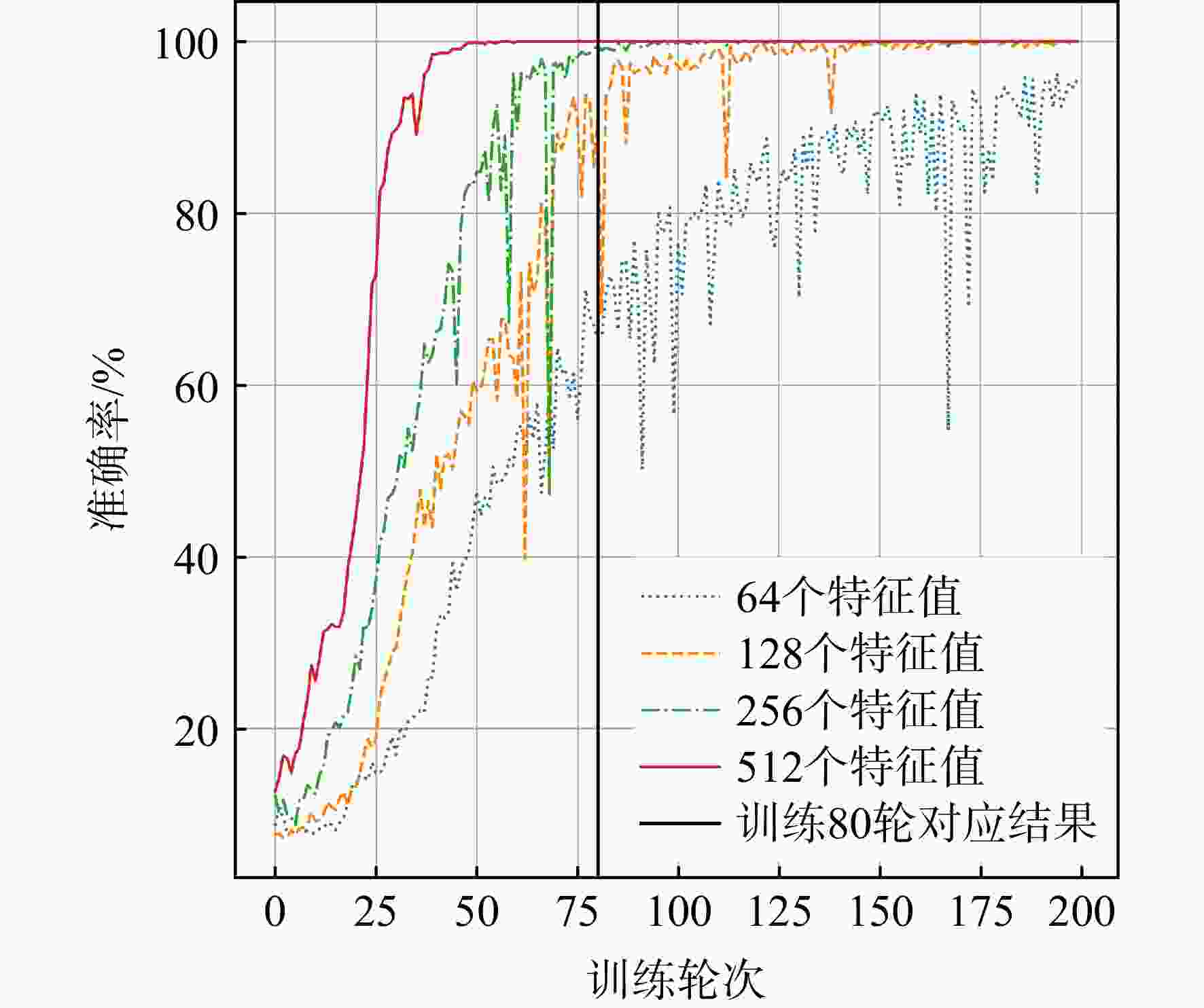

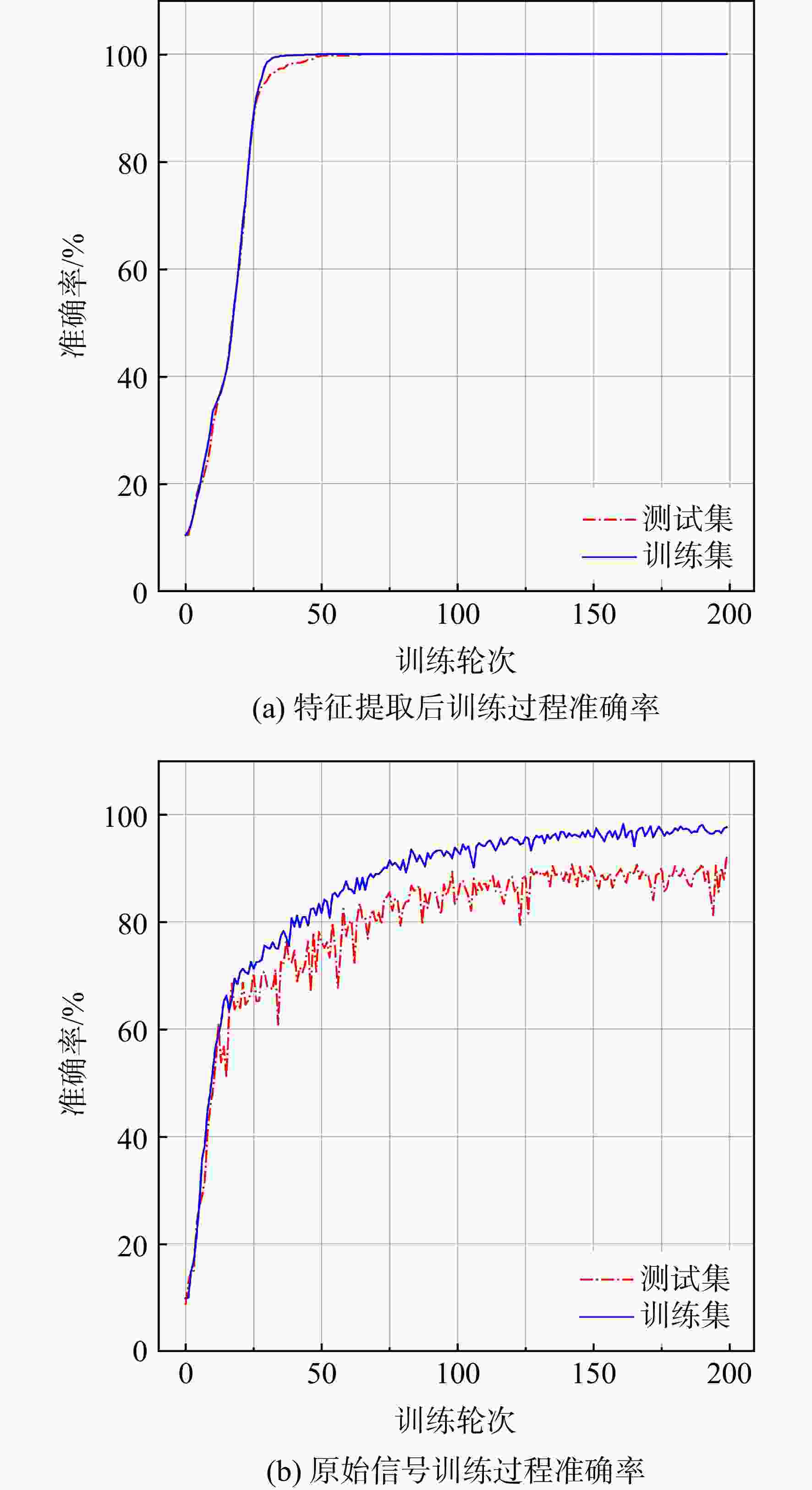

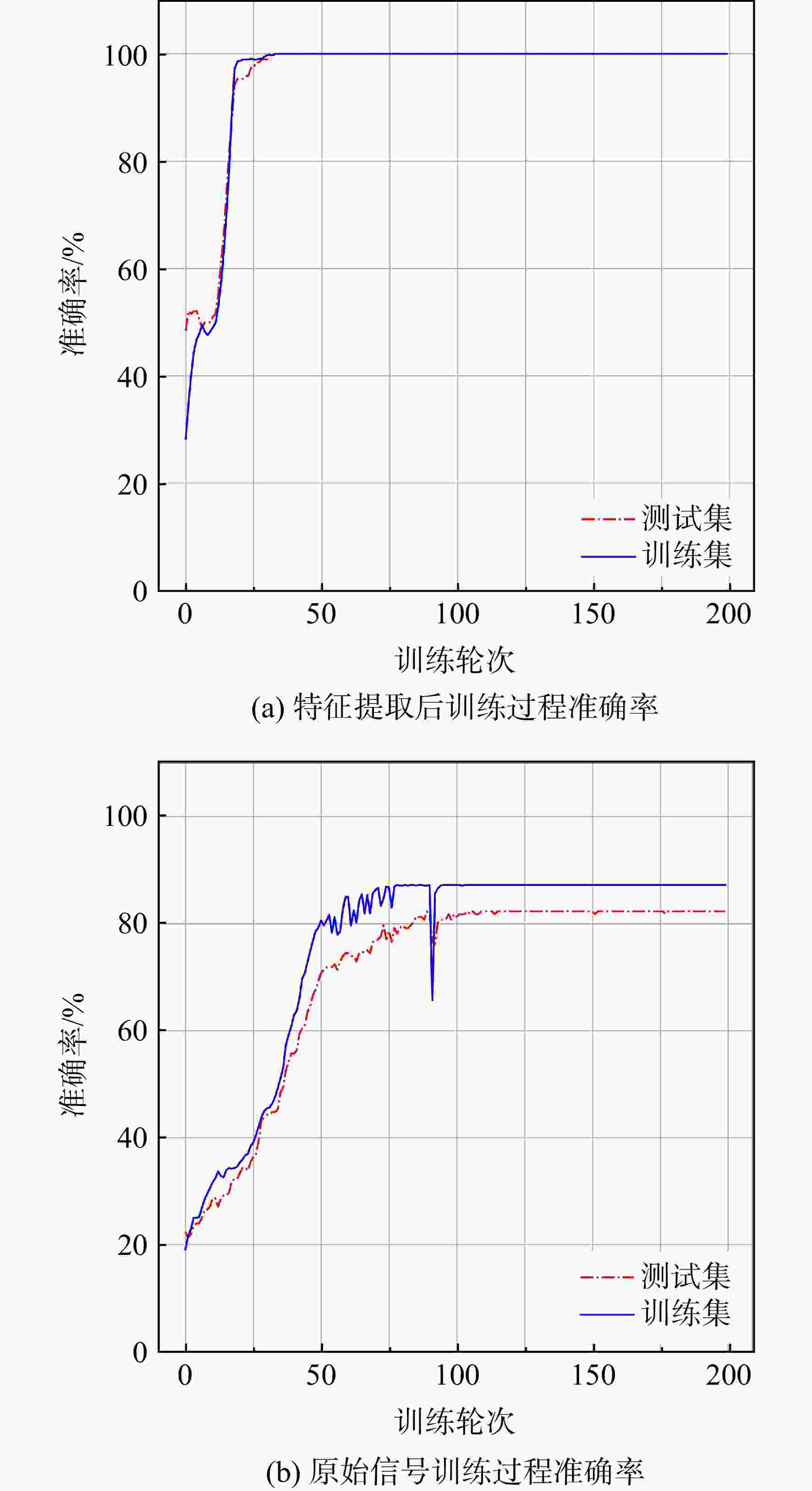

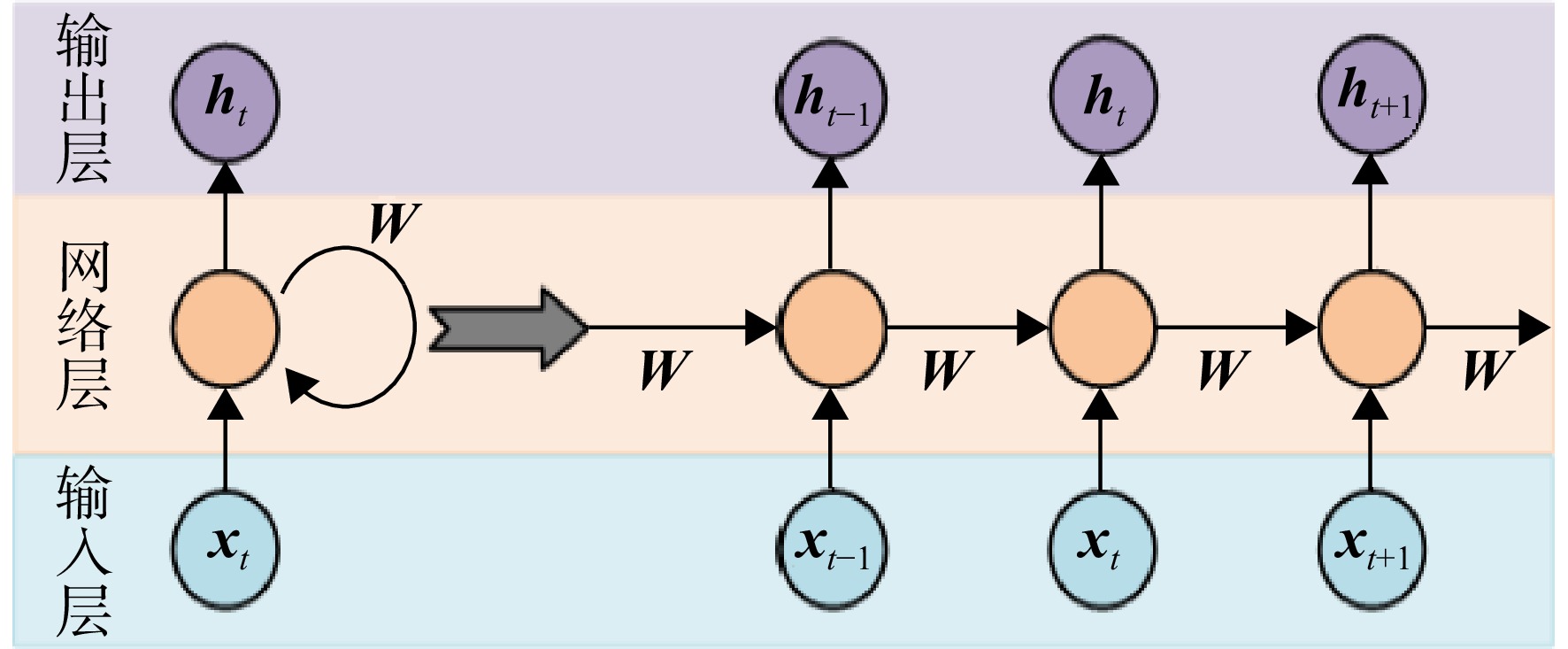

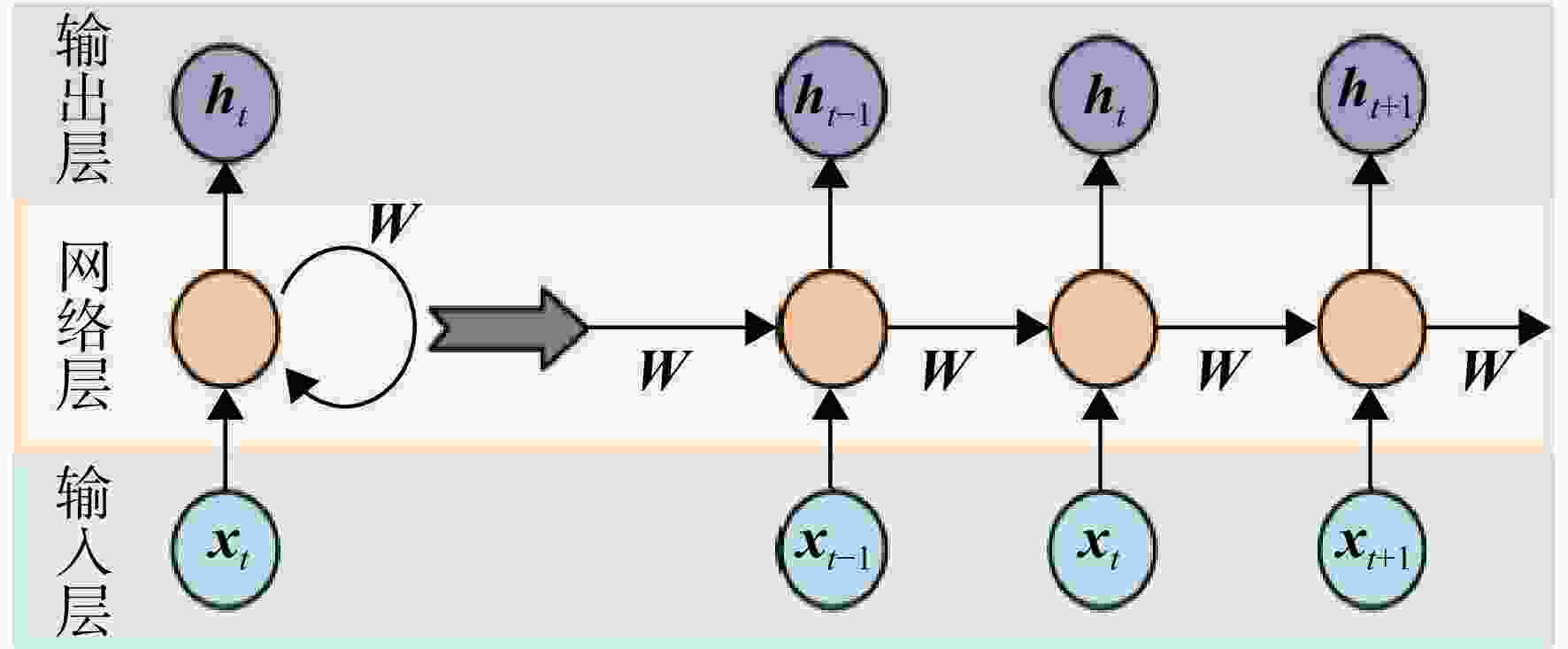

针对航空发动机滚动轴承的故障诊断,提出一种基于频域特征的故障诊断模型。将原始振动信号进行包络解调预处理,仅取每段数据处理后的512个点作为故障特征,将其作为双向循环长短期记忆网络(BiLSTM)模型的输入,可对内圈故障、外圈故障、滚动体故障及每种故障所对应3种不同的故障程度进行诊断。该模型不仅弥补完全由原始振动信号输入导致输入数据冗长,特征不明显等缺点,也弥补由人工提取振动特征来进行故障诊断的不确定性。在滚动轴承公开数据集上进行实验,结果表明故障识别的准确度达到99.8%以上。搭建航空轴承实验器来对方法与模型进行检验。基于频域特征的双向循环长短期记忆网络模型能够更准确的对轴承进行故障诊断,所提方法对于航空发动机滚动轴承故障诊断具有重要工程价值。

-

关键词:

- 故障诊断 /

- 特征提取 /

- 神经网络 /

- 滚动轴承 /

- 双向循环长短期记忆网络

Abstract:A fault diagnosis model based on feature extraction was proposed for aeroengine rolling bearing fault diagnosis. The original vibration signals were preprocessed by envelope demodulation, and only 512 points of each segment of data were taken as fault features, and used as input of bidirectional long short-term memory (BiLSTM) model to diagnose the inner ring faults, outer ring faults, rolling body faults and three different fault degrees corresponding to each fault. The model made up for not only the disadvantages of long input data and obscure features caused by the original vibration signal input, but also the uncertainty of fault diagnosis by extracting vibration features manually. Experiments on the open data set of rolling bearings showed that the accuracy of fault identification was above 99.8%. An aero-bearing tester was built to verify the method and model. BiLSTM based on feature extraction can diagnose the bearing faults more accurately. The proposed method has important engineering value for the fault diagnosis of aeroengine rolling bearings.

-

表 1 详细实验数据

Table 1. Detailed experimental data

序号 故障类型 故障直径/mm 样本长度 特征长度 训练

样本数测试

样本数标记

标签值1 正常 0 2048 512 278 70 0 2 内圈 0.1778 2048 512 278 70 1 3 外圈六点钟 0.1778 2048 512 278 70 2 4 滚动体 0.1778 2048 512 278 70 3 5 内圈 0.3556 2048 512 278 70 4 6 外圈六点钟 0.3556 2048 512 278 70 5 7 滚动体 0.3556 2048 512 278 70 6 8 内圈 0.5334 2048 512 278 70 7 9 外圈六点钟 0.5334 2048 512 278 70 8 10 滚动体 0.5334 2048 512 278 70 9 表 2 故障模拟方案

Table 2. Fault simulation scheme

mm 序号 故障

类型损伤长 损伤宽度 损伤深度 1 内圈 0.3 0.1 1 2 外圈 0.3 0.1 1 3 滚动体 0.3 0.1 1 表 3 实验器详细数据表

Table 3. Detailed data sheet of tester

序号 故障类型 训练样本数 测试样本数 标记标签值 1 正常 188 48 0 2 内圈 188 48 1 3 外圈 188 48 2 4 滚动体 188 48 3 表 4 实验器数据验证结果

Table 4. Results of tester data validation

序号 故障类型 诊断准确率/% 标记标签值 1 正常 100 0 2 内圈 98 1 3 外圈 100 2 4 滚动体 100 3 -

[1] 刘朋,王黎钦,张传伟,等. 航空发动机主轴轴承状态监测研究现状与发展趋势[J]. 航空动力学报,2022,37(2): 330-343. LIU Peng,WANG Liqin,ZHANG Chuanwei,et al. Research status and development trend of condition monitoring on main-shaft bearings used in aircraft engines[J]. Journal of Aerospace Power,2022,37(2): 330-343. (in Chinese doi: 10.13224/j.cnki.jasp.20210083 LIU Peng, WANG Liqin, ZHANG Chuanwei, et al . Research status and development trend of condition monitoring on main-shaft bearings used in aircraft engines[J]. Journal of Aerospace Power,2022 ,37 (2 ):330 -343 . (in Chinese) doi: 10.13224/j.cnki.jasp.20210083[2] ZHANG Weitao,JI Xiaofan,HUANG Ju,et al. Compound fault diagnosis of aero-engine rolling element bearing based on CCA blind extraction[J]. IEEE Access,2021,9: 159873-159881. doi: 10.1109/ACCESS.2021.3130637 [3] 韩磊,洪杰,王冬. 基于小波包分析的航空发动机轴承故障诊断[J]. 推进技术,2009,30(3): 328-331,341. HAN Lei,HONG Jie,WANG Dong. Fault diagnosis of aero-engine bearings based on wavelet package analysis[J]. Journal of Propulsion Technology,2009,30(3): 328-331,341. (in Chinese doi: 10.3321/j.issn:1001-4055.2009.03.014 HAN Lei, HONG Jie, WANG Dong . Fault diagnosis of aero-engine bearings based on wavelet package analysis[J]. Journal of Propulsion Technology,2009 ,30 (3 ):328 -331, 341 . (in Chinese) doi: 10.3321/j.issn:1001-4055.2009.03.014[4] 李先锋,颉潭成,徐彦伟,等. 轴承故障智能诊断专家系统的研究[J]. 制造业自动化,2020,42(1): 7-9,14. LI Xianfeng,XIE Tancheng,XU Yanwei,et al. The research on the intelligent diagnosis expert system for bearing fault[J]. Manufacturing Automation,2020,42(1): 7-9,14. (in Chinese LI Xianfeng, XIE Tancheng, XU Yanwei, et al . The research on the intelligent diagnosis expert system for bearing fault[J]. Manufacturing Automation,2020 ,42 (1 ):7 -9, 14 . (in Chinese)[5] BEN ALI J,FNAIECH N,SAIDI L,et al. Application of empirical mode decomposition and artificial neural network for automatic bearing fault diagnosis based on vibration signals[J]. Applied Acoustics,2015,89: 16-27. doi: 10.1016/j.apacoust.2014.08.016 [6] 王平,廖明夫. 滚动轴承故障诊断的自适应共振解调技术[J]. 航空动力学报,2005,20(4): 606-612. WANG Ping,LIAO Mingfu. Adaptive demodulated resonance technique for the rolling bearing fault diagnosis[J]. Journal of Aerospace Power,2005,20(4): 606-612. (in Chinese doi: 10.3969/j.issn.1000-8055.2005.04.015 WANG Ping, LIAO Mingfu . Adaptive demodulated resonance technique for the rolling bearing fault diagnosis[J]. Journal of Aerospace Power,2005 ,20 (4 ):606 -612 . (in Chinese) doi: 10.3969/j.issn.1000-8055.2005.04.015[7] 叶亮,邓四二,崔永存,等. 滚动轴承振动性能状态演变的非线性特征和不确定性特征的灰关系分析[J]. 航空动力学报,2022,37(6): 1121-1133. YE Liang,DENG Sier,CUI Yongcun,et al. Grey relation analysis on nonlinear characteristics and uncertainty characteristics of evolution of rolling bearing vibration performance state[J]. Journal of Aerospace Power,2022,37(6): 1121-1133. (in Chinese YE Liang, DENG Sier, CUI Yongcun, et al . Grey relation analysis on nonlinear characteristics and uncertainty characteristics of evolution of rolling bearing vibration performance state[J]. Journal of Aerospace Power,2022 ,37 (6 ):1121 -1133 . (in Chinese)[8] 王晓龙,唐贵基. 一种基于连续小波变换的滚动轴承早期故障诊断新方法[J]. 推进技术,2016,37(8): 1431-1437. WANG Xiaolong,TANG Guiji. A new diagnosis method based on continuous wavelet transform for incipient fault of rolling bearing[J]. Journal of Propulsion Technology,2016,37(8): 1431-1437. (in Chinese doi: 10.13675/j.cnki.tjjs.2016.08.004 WANG Xiaolong, TANG Guiji . A new diagnosis method based on continuous wavelet transform for incipient fault of rolling bearing[J]. Journal of Propulsion Technology,2016 ,37 (8 ):1431 -1437 . (in Chinese) doi: 10.13675/j.cnki.tjjs.2016.08.004[9] 向丹,岑健. 基于EMD熵特征融合的滚动轴承故障诊断方法[J]. 航空动力学报,2015,30(5): 1149-1155. XIANG Dan,CEN Jian. Method of roller bearing fault diagnosis based on feature fusion of EMD entropy[J]. Journal of Aerospace Power,2015,30(5): 1149-1155. (in Chinese doi: 10.13224/j.cnki.jasp.2015.05.016 XIANG Dan, CEN Jian . Method of roller bearing fault diagnosis based on feature fusion of EMD entropy[J]. Journal of Aerospace Power,2015 ,30 (5 ):1149 -1155 . (in Chinese) doi: 10.13224/j.cnki.jasp.2015.05.016[10] KHAKIPOUR M H,SAFAVI A A,SETOODEH P. Bearing fault diagnosis with morphological gradient wavelet[J]. Journal of the Franklin Institute,2017,354(6): 2465-2476. doi: 10.1016/j.jfranklin.2016.11.013 [11] WANG Yi,XU Guanghua,ZHANG Qing,et al. Rotating speed isolation and its application to rolling element bearing fault diagnosis under large speed variation conditions[J]. Journal of Sound and Vibration,2015,348: 381-396. doi: 10.1016/j.jsv.2015.03.018 [12] 李巍华,单外平,曾雪琼. 基于深度信念网络的轴承故障分类识别[J]. 振动工程学报,2016,29(2): 340-347. LI Weihua,SHAN Waiping,ZENG Xueqiong. Bearing fault identification based on deep belief network[J]. Journal of Vibration Engineering,2016,29(2): 340-347. (in Chinese doi: 10.16385/j.cnki.issn.1004-4523.2016.02.020 LI Weihua, SHAN Waiping, ZENG Xueqiong . Bearing fault identification based on deep belief network[J]. Journal of Vibration Engineering,2016 ,29 (2 ):340 -347 . (in Chinese) doi: 10.16385/j.cnki.issn.1004-4523.2016.02.020[13] LU Chen,WANG Zhenya,ZHOU Bo. Intelligent fault diagnosis of rolling bearing using hierarchical convolutional network based health state classification[J]. Advanced Engineering Informatics,2017,32: 139-151. doi: 10.1016/j.aei.2017.02.005 [14] 王坤,侯树贤. 基于深度学习的辅助动力装置性能参数预测方法研究[J]. 推进技术,2022,43(1): 290-299. WANG Kun,HOU Shuxian. Prediction method of auxiliary power unit performance parameter based on deep learning[J]. Journal of Propulsion Technology,2022,43(1): 290-299. (in Chinese doi: 10.13675/j.cnki.tjjs.200580 WANG Kun, HOU Shuxian . Prediction method of auxiliary power unit performance parameter based on deep learning[J]. Journal of Propulsion Technology,2022 ,43 (1 ):290 -299 . (in Chinese) doi: 10.13675/j.cnki.tjjs.200580[15] 周飞燕,金林鹏,董军. 卷积神经网络研究综述[J]. 计算机学报,2017,40(6): 1229-1251. ZHOU Feiyan,JIN Linpeng,DONG Jun. Review of convolutional neural network[J]. Chinese Journal of Computers,2017,40(6): 1229-1251. (in Chinese ZHOU Feiyan, JIN Linpeng, DONG Jun . Review of convolutional neural network[J]. Chinese Journal of Computers,2017 ,40 (6 ):1229 -1251 . (in Chinese)[16] 魏晓良,潮群,陶建峰,等. 基于LSTM和CNN的高速柱塞泵故障诊断[J]. 航空学报,2021,42(3): 423876. WEI Xiaoliang,CHAO Qun,TAO Jianfeng,et al. Cavitation fault diagnosis method for high-speed plunger pumps based on LSTM and CNN[J]. Acta Aeronautica et Astronautica Sinica,2021,42(3): 423876. (in Chinese WEI Xiaoliang, CHAO Qun, TAO Jianfeng, et al . Cavitation fault diagnosis method for high-speed plunger pumps based on LSTM and CNN[J]. Acta Aeronautica et Astronautica Sinica,2021 ,42 (3 ):423876 . (in Chinese)[17] 张鹏,束小曼,厉雪衣,等. 基于LSTM的交流电机系统故障诊断方法研究[J]. 电机与控制学报,2022,26(3): 109-116. ZHANG Peng,SHU Xiaoman,LI Xueyi,et al. LSTM-based fault diagnosis of AC electric machine system[J]. Electric Machines and Control,2022,26(3): 109-116. (in Chinese ZHANG Peng, SHU Xiaoman, LI Xueyi, et al . LSTM-based fault diagnosis of AC electric machine system[J]. Electric Machines and Control,2022 ,26 (3 ):109 -116 . (in Chinese)[18] 曹正志,叶春明. 改进CNN-LSTM模型在滚动轴承故障诊断中的应用[J]. 计算机系统应用,2021,30(3): 126-133. CAO Zhengzhi,YE Chunming. Application of improved CNN-LSTM model in fault diagnosis of rolling bearings[J]. Computer Systems & Applications,2021,30(3): 126-133. (in Chinese doi: 10.15888/j.cnki.csa.007830 CAO Zhengzhi, YE Chunming . Application of improved CNN-LSTM model in fault diagnosis of rolling bearings[J]. Computer Systems & Applications,2021 ,30 (3 ):126 -133 . (in Chinese) doi: 10.15888/j.cnki.csa.007830[19] GRAVES A,SCHMIDHUBER J. Framewise phoneme classification with bidirectional LSTM and other neural network architectures[J]. Neural Networks,2005,18(5/6): 602-610. [20] 查文舒,乔奇,刘子雄,等. 基于相关性分析的Bi-LSTM测井曲线预测方法[J]. 合肥工业大学学报(自然科学版),2022,45(5): 700-706. ZHA Wenshu,QIAO Qi,LIU Zixiong,et al. A method for well log prediction using bidirectional long short-term memory based on correlation analysis[J]. Journal of Hefei University of Technology (Natural Science),2022,45(5): 700-706. (in Chinese ZHA Wenshu, QIAO Qi, LIU Zixiong, et al . A method for well log prediction using bidirectional long short-term memory based on correlation analysis[J]. Journal of Hefei University of Technology (Natural Science),2022 ,45 (5 ):700 -706 . (in Chinese)[21] ERRO D,NAVAS E,SAINZ I,et al. Efficient spectral envelope estimation from harmonic speech signals[J]. Electronics Letters,2012,48(16): 1019-1021. doi: 10.1049/el.2012.0756 [22] 景新,曹宏瑞,陈雪峰. 保持架打滑对航空发动机主轴承故障特征频率的影响[J]. 航空动力学报,2019,34(5): 1145-1152. JING Xin,CAO Hongrui,CHEN Xuefeng. Effect of cage slipping on fault characteristic frequencies of aeroengine main-shaft bearings[J]. Journal of Aerospace Power,2019,34(5): 1145-1152. (in Chinese JING Xin, CAO Hongrui, CHEN Xuefeng . Effect of cage slipping on fault characteristic frequencies of aeroengine main-shaft bearings[J]. Journal of Aerospace Power,2019 ,34 (5 ):1145 -1152 . (in Chinese)[23] 刘西洋,陈果,郝腾飞,等. 基于卷积双向长短期记忆网络的轴承故障尺寸估计[J]. 航空动力学报,2023,38(4): 1005-1016. LIU Xiyang,CHEN Guo,HAO Tengfei,et al. Bearing fault size estimation based on convolutional bidirectional long and short term memory networks[J]. Journal of Aerospace Power,2023,38(4): 1005-1016. (in Chinese doi: 10.13224/j.cnki.jasp.20210292 LIU Xiyang, CHEN Guo, HAO Tengfei, et al . Bearing fault size estimation based on convolutional bidirectional long and short term memory networks[J]. Journal of Aerospace Power,2023 ,38 (4 ):1005 -1016 . (in Chinese) doi: 10.13224/j.cnki.jasp.20210292[24] 马奇友,刘可薇,杜坚,等. 基于深度长短期记忆网络的发动机叶片剩余寿命预测[J]. 推进技术,2021,42(8): 1888-1897. MA Qiyou,LIU Kewei,DU Jian,et al. Prediction of residual life of engine blades based on deep short term memory network[J]. Journal of Propulsion Technology,2021,42(8): 1888-1897. (in Chinese MA Qiyou, LIU Kewei, DU Jian, et al . Prediction of residual life of engine blades based on deep short term memory network[J]. Journal of Propulsion Technology,2021 ,42 (8 ):1888 -1897 . (in Chinese)[25] CHANDRIAH K K,NARAGANAHALLI R V. RNN/LSTM with modified Adam optimizer in deep learning approach for automobile spare parts demand forecasting[J]. Multimedia Tools and Applications,2021,80(17): 26145-26159. doi: 10.1007/s11042-021-10913-0 [26] GUSTAFSSON O G,TALLIAN T. Detection of damage in assembled rolling element bearings[J]. ASLE Transactions,1962,5(1): 197-209. doi: 10.1080/05698196208972466 -

下载:

下载: