Effect of blockage rate on spray characteristics of liquid-liquid pintle multi-injector elements

-

摘要:

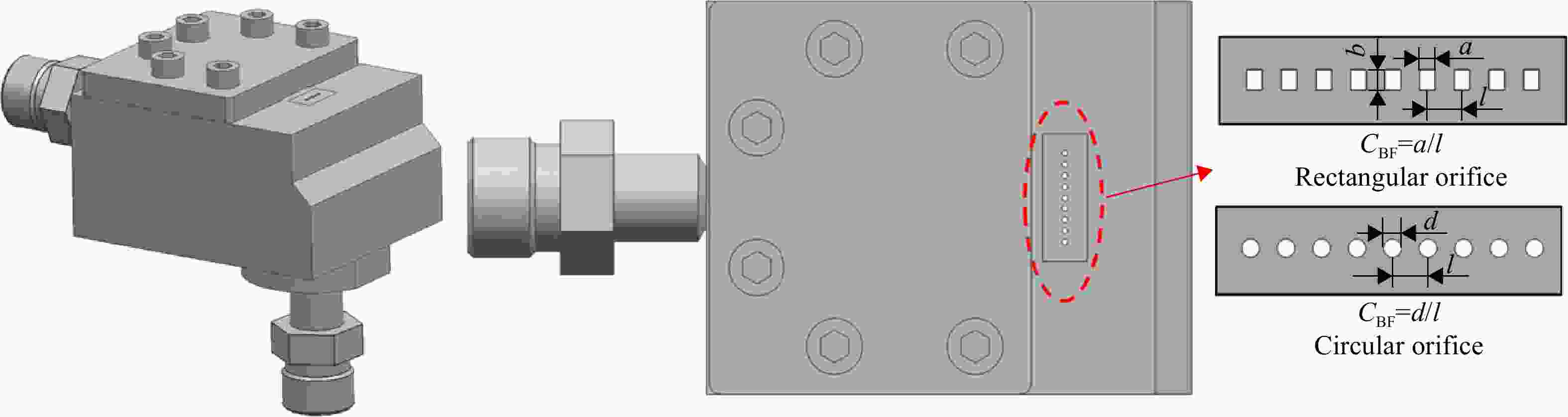

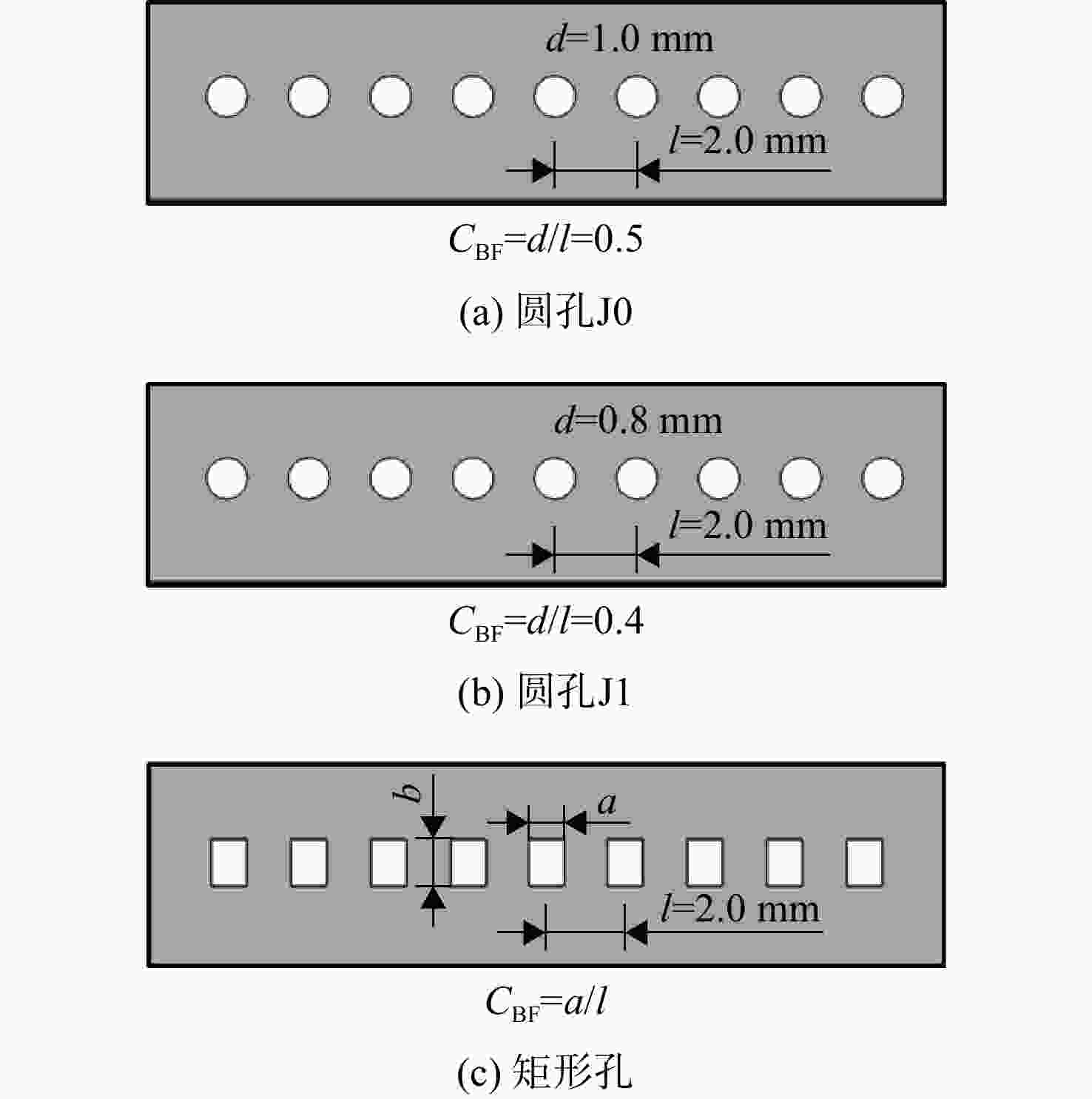

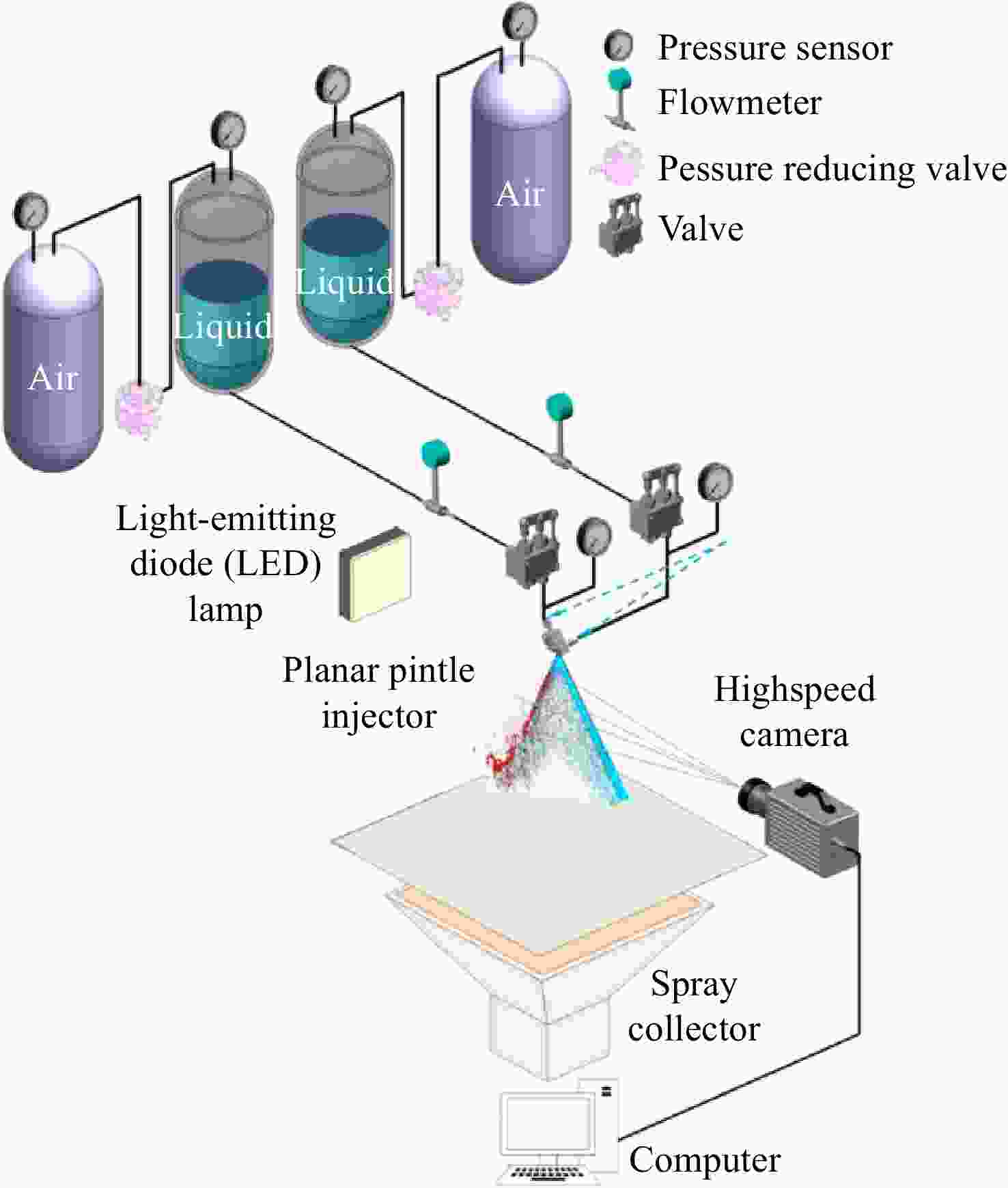

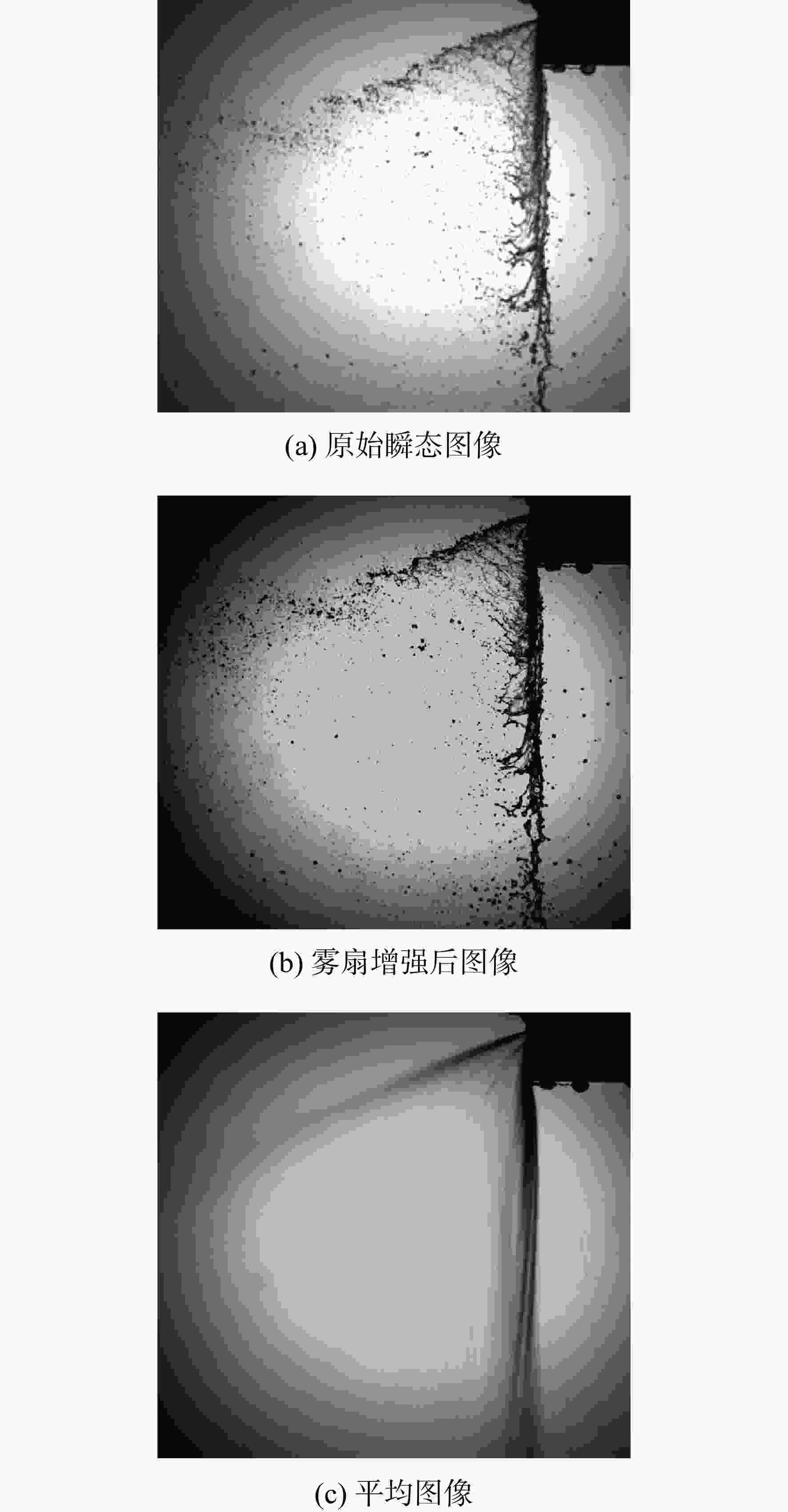

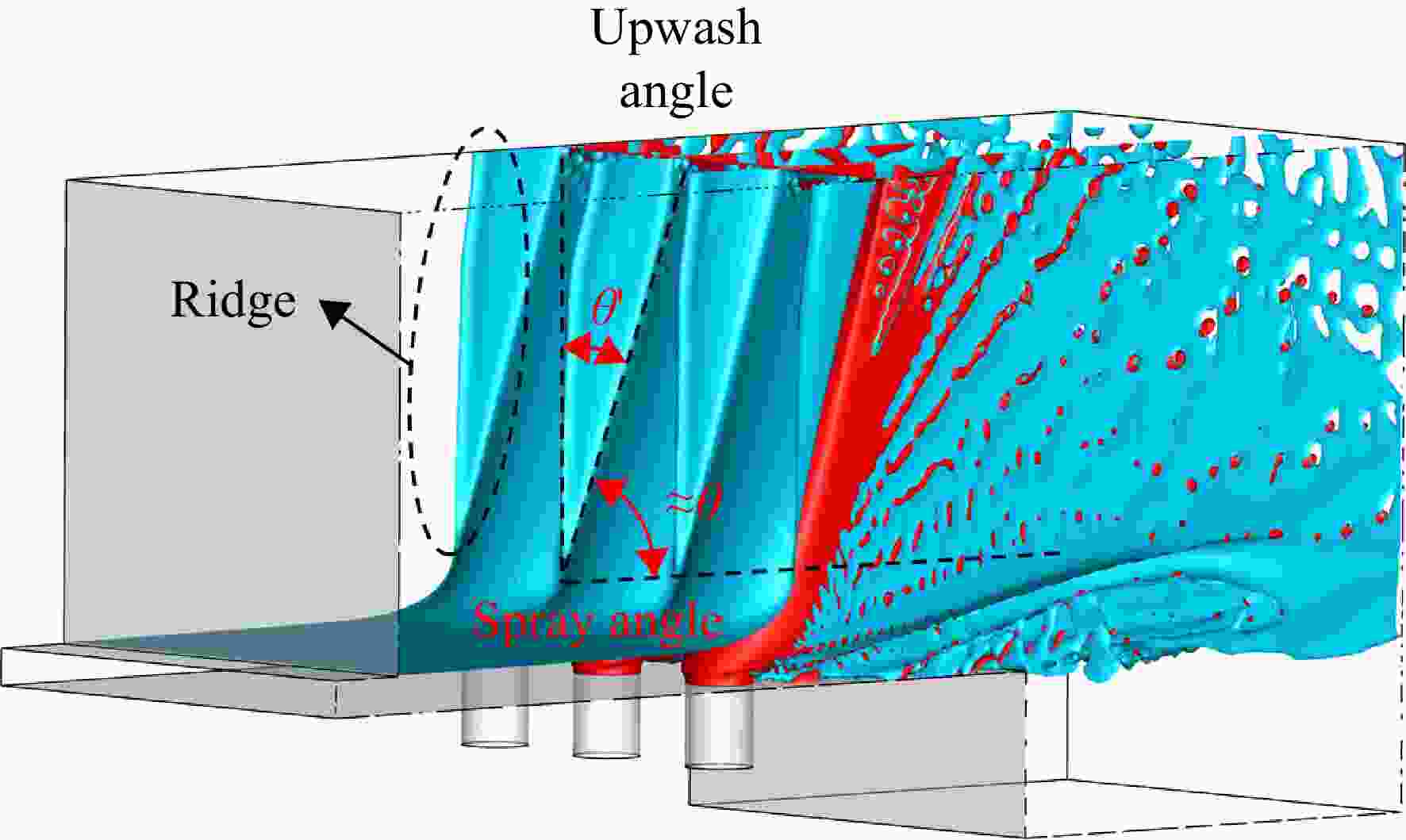

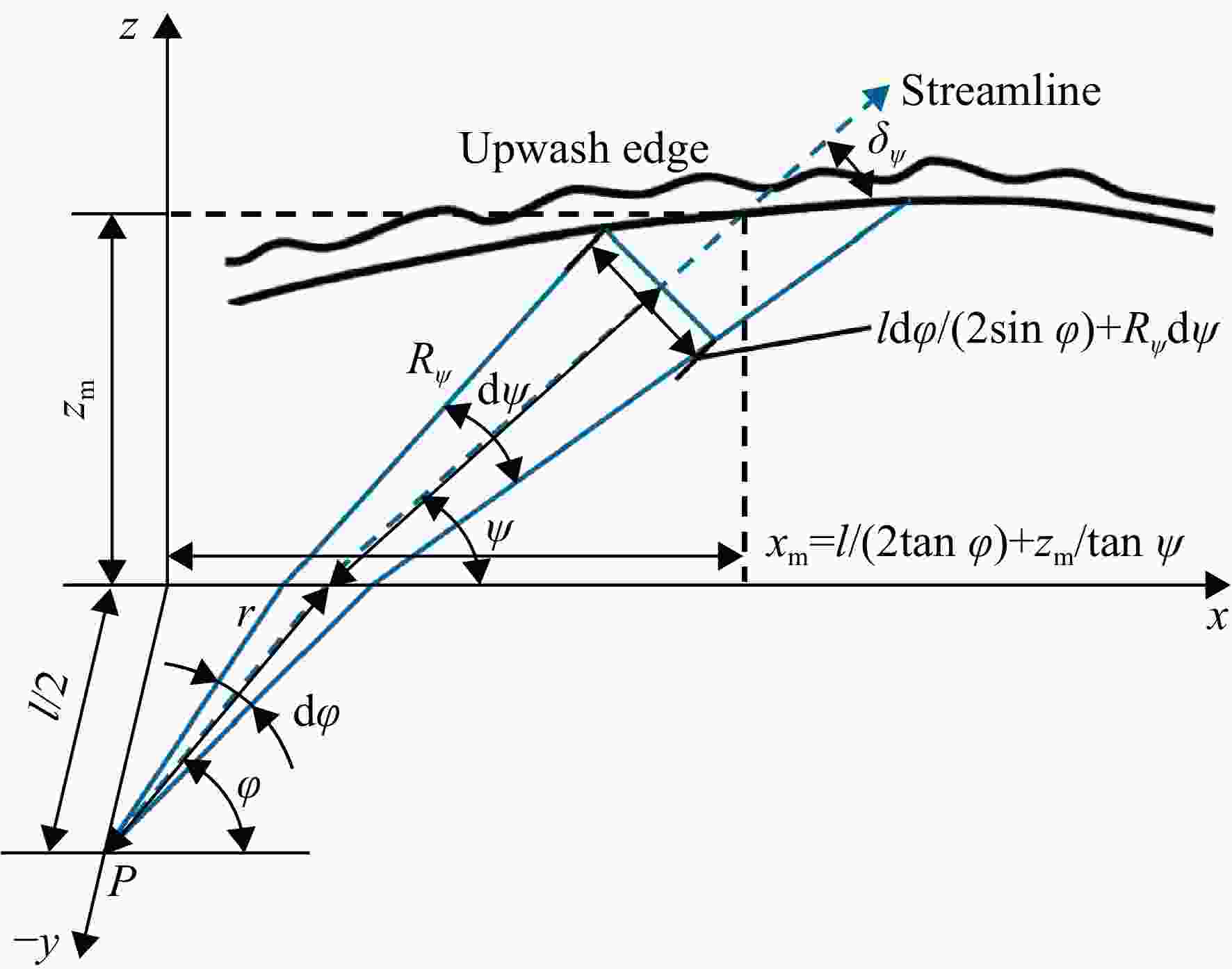

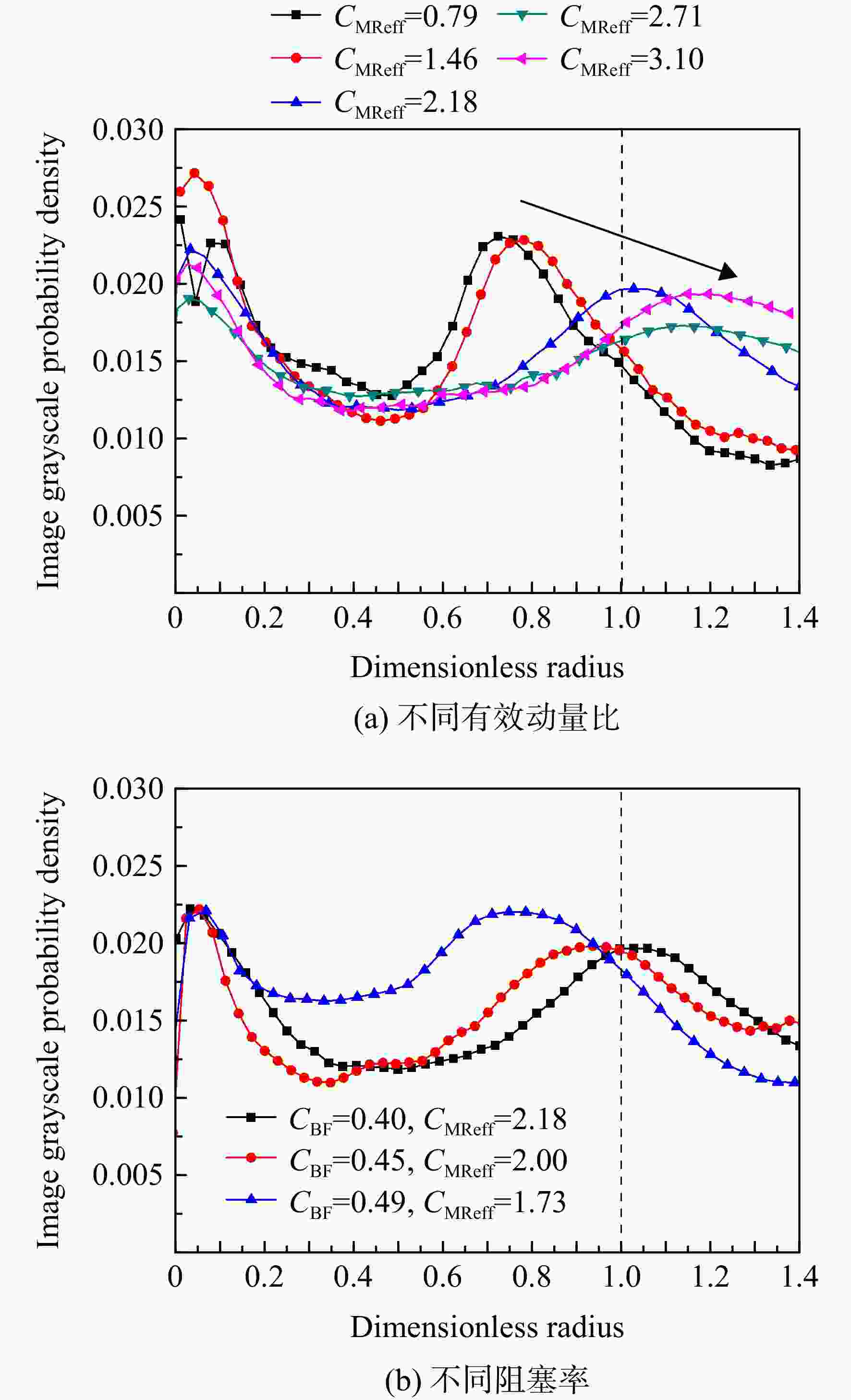

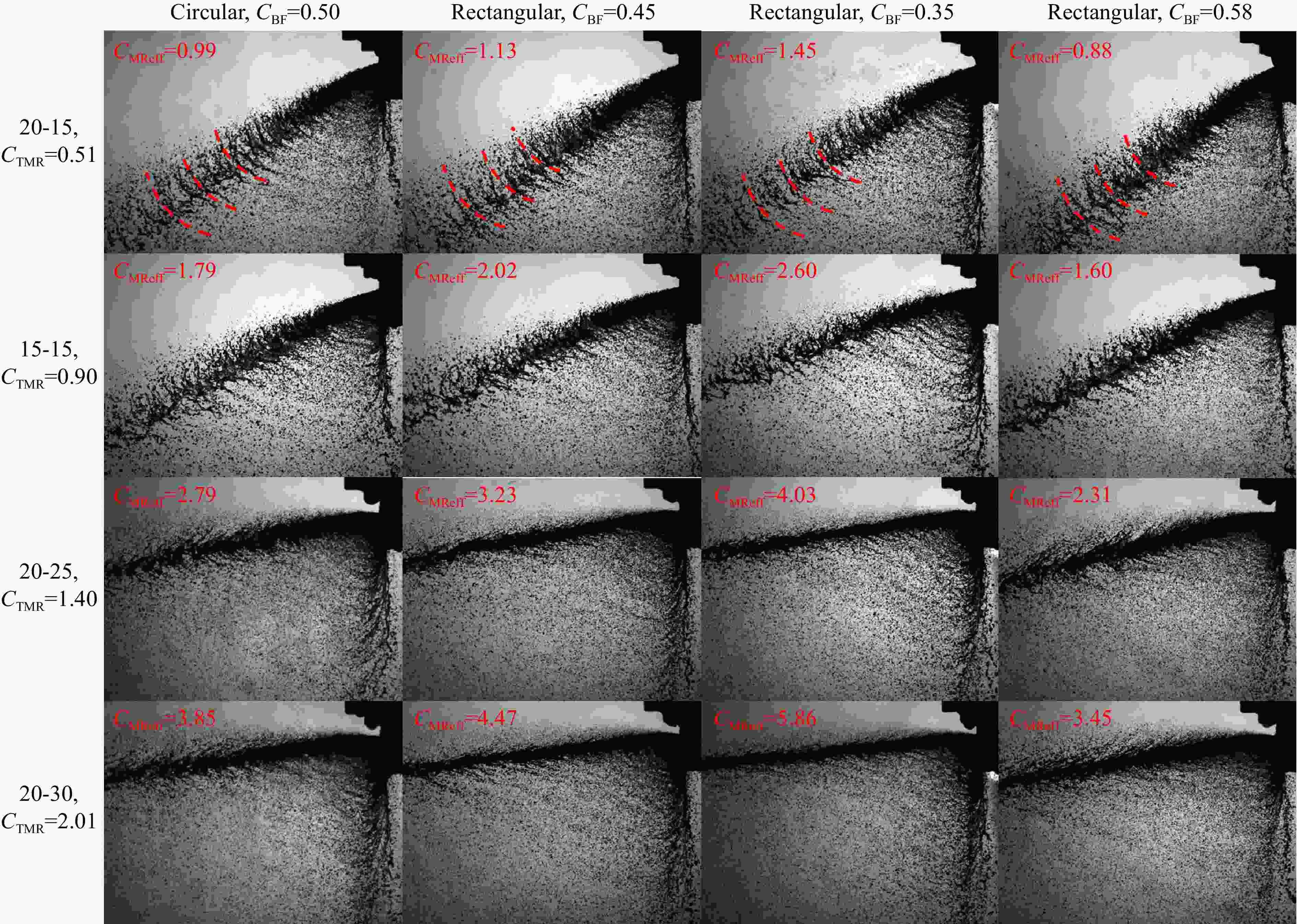

为了研究阻塞率对针栓式喷注器喷雾场特性的影响,基于平面针栓喷注单元的研究思路,设计了结构可更换的平面针栓多喷注单元试验件,同时采用分相识别的PLIC VOF(piecewise linear interface calculation volume of fluid)多相流仿真方法及高速摄影试验方法,开展了阻塞率对液液针栓多喷注单元的雾化角、喷雾扩散角及液雾空间分布的影响规律研究。对于径向圆孔,阻塞率的改变通过改变径向孔直径及个数实现;对于径向矩形孔,阻塞率的改变还可以通过改变矩形的高宽比实现。研究发现:阻塞率对喷雾场的液雾空间分布有重要影响。在径向喷注孔总动量比不变时,阻塞率对喷雾场的影响主要通过喷雾扇空间间距的直接影响和转化为有效动量比的间接影响两种途径实现,径向孔形状对喷雾场的影响本质上也转化为阻塞率及有效动量比的影响。径向孔直径改变和形状改变造成的阻塞率变化对雾化角的影响仅通过有效动量比间接实现,喷注单元的雾化角理论模型也适用于多喷注单元;阻塞率对喷雾扩散角和液雾空间分布的影响则通过两种途径共同产生。另外,高的总动量比工况下,液雾径向分布范围会增大,相邻单元间相互作用会使得雾扇中心区和外侧区液雾分布量均增加。

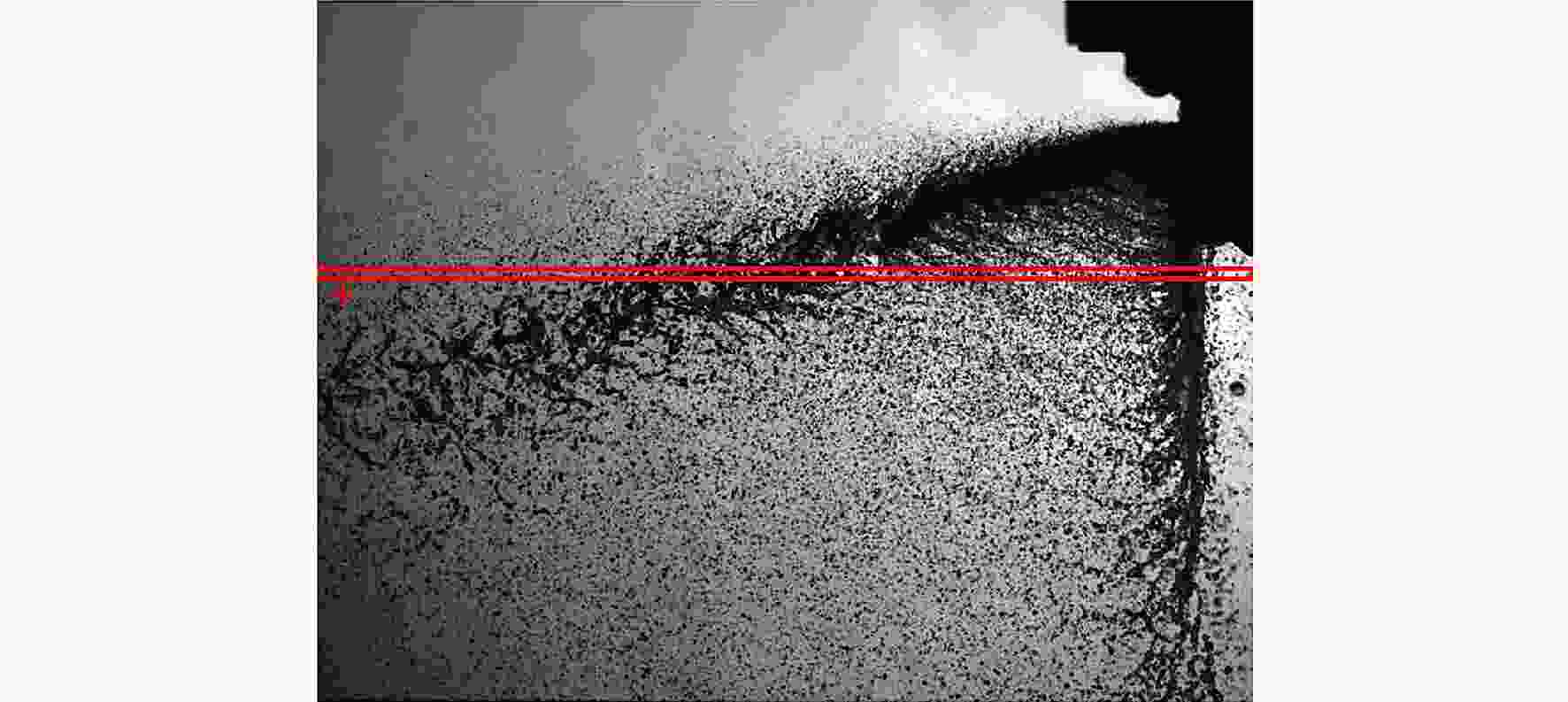

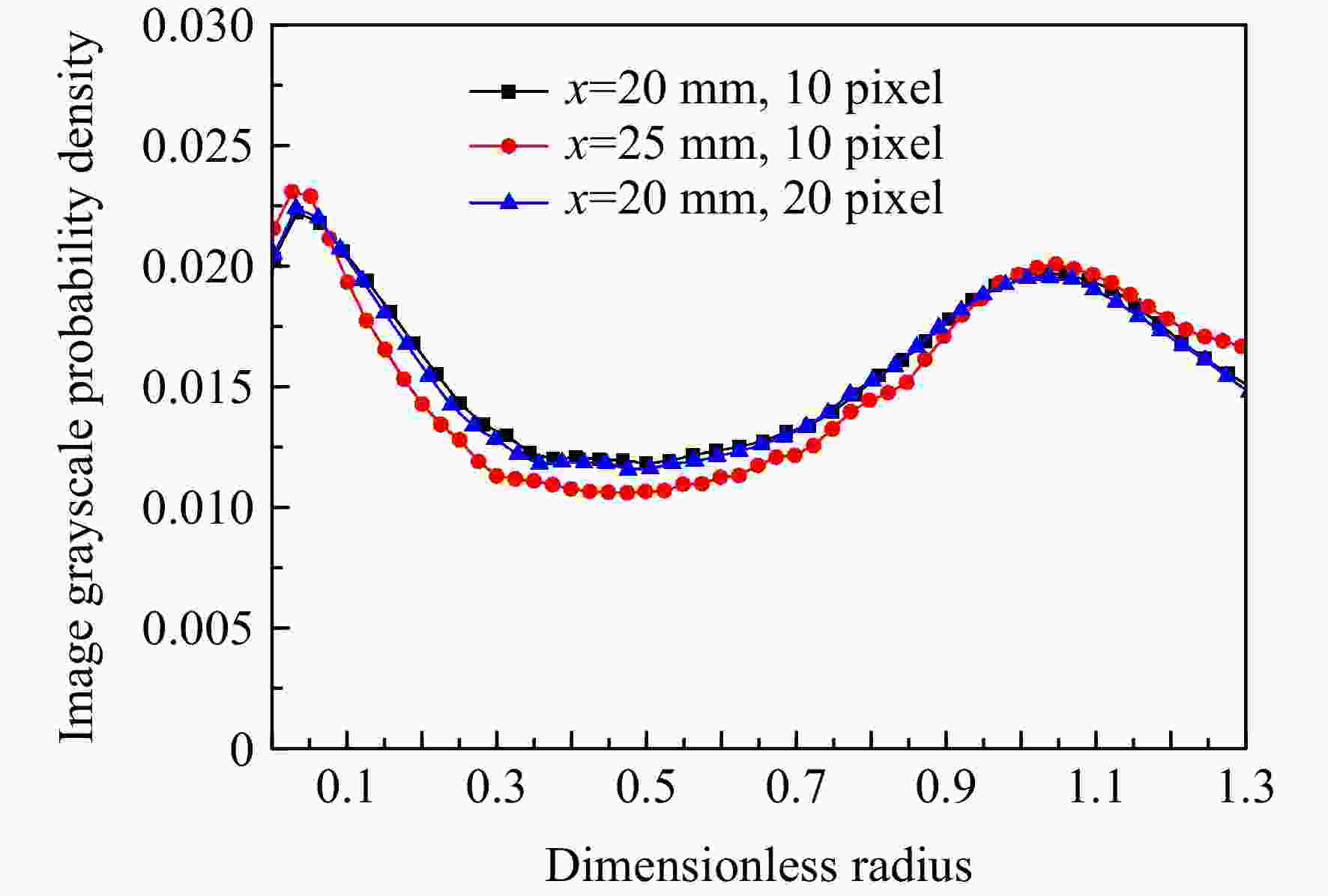

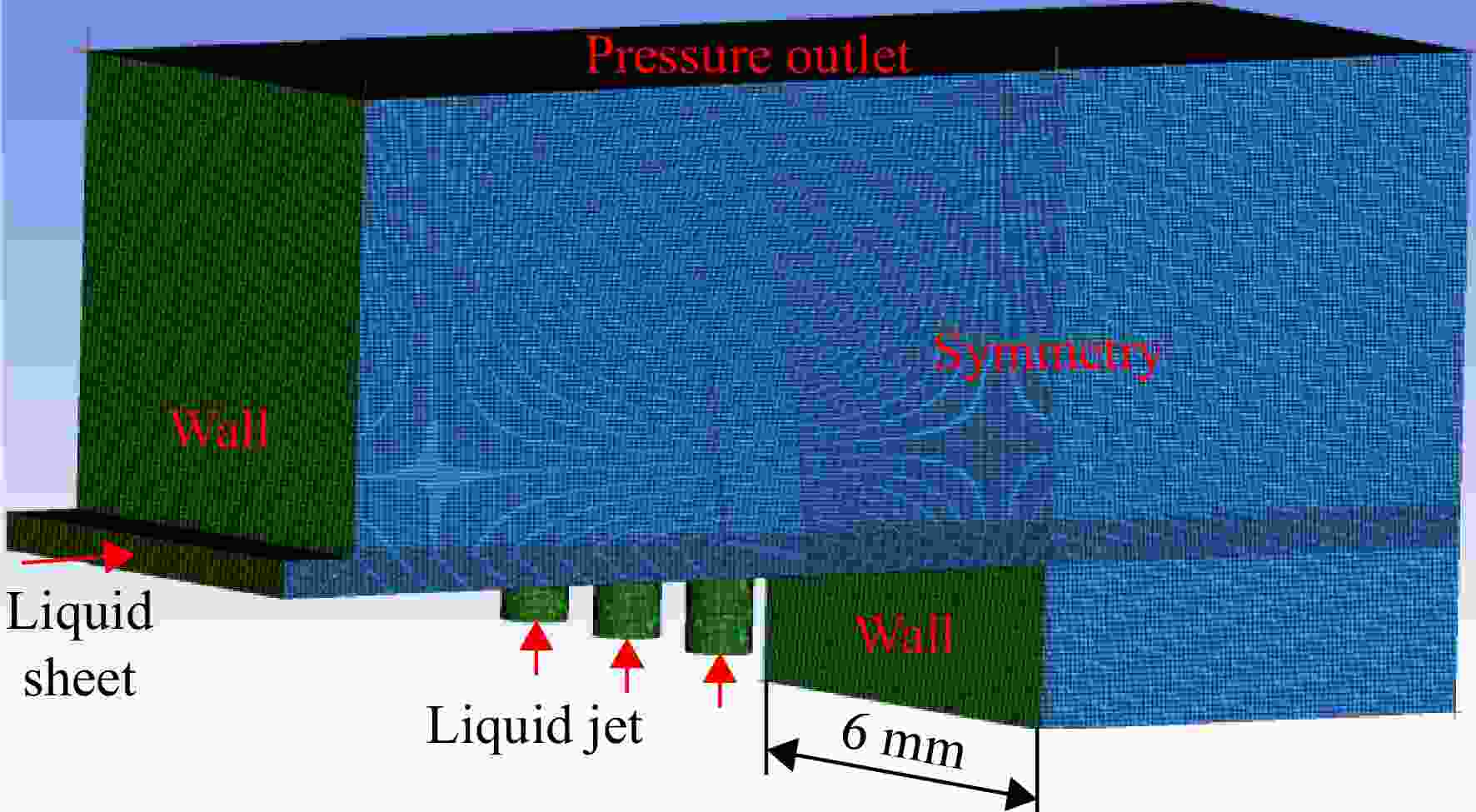

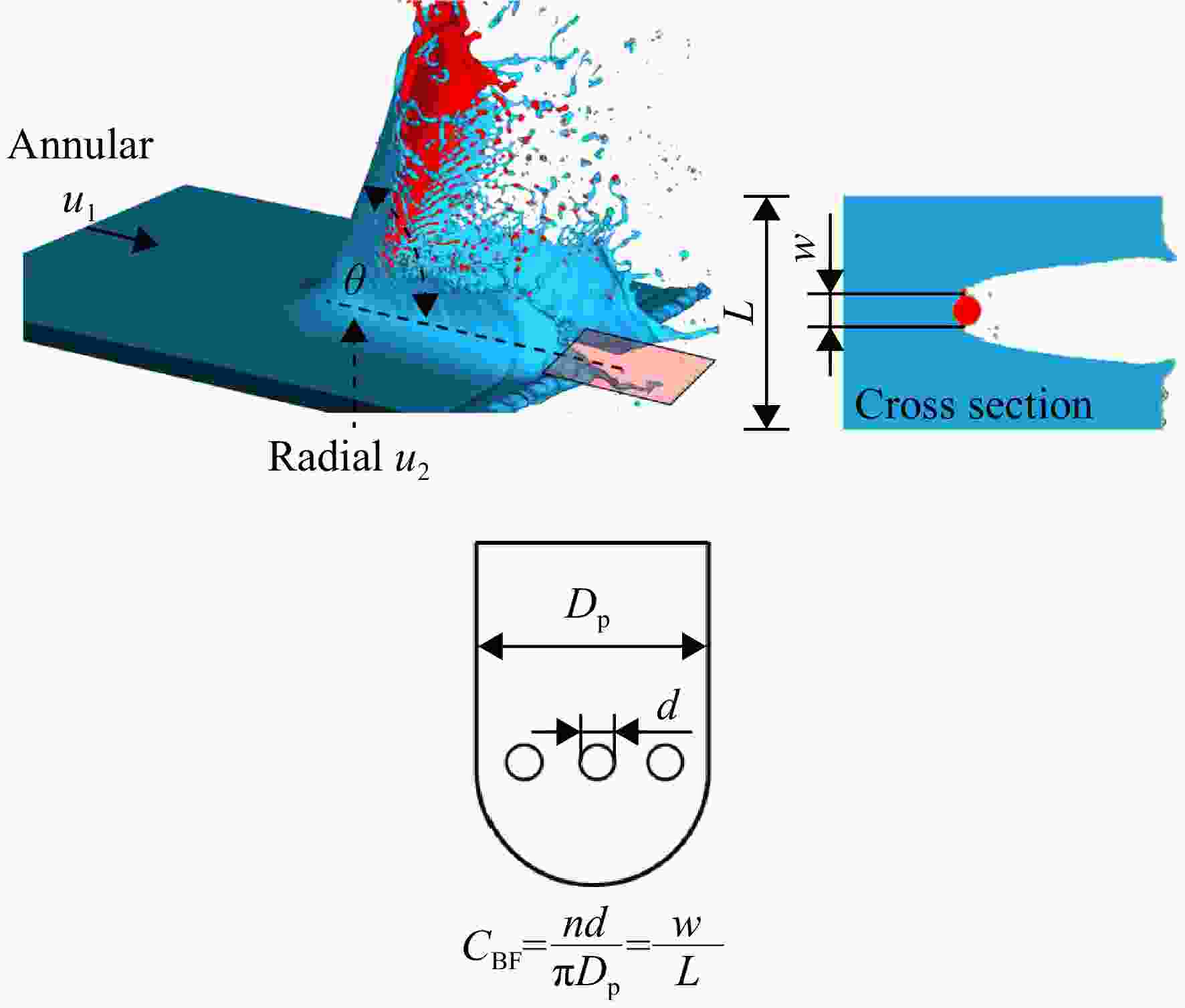

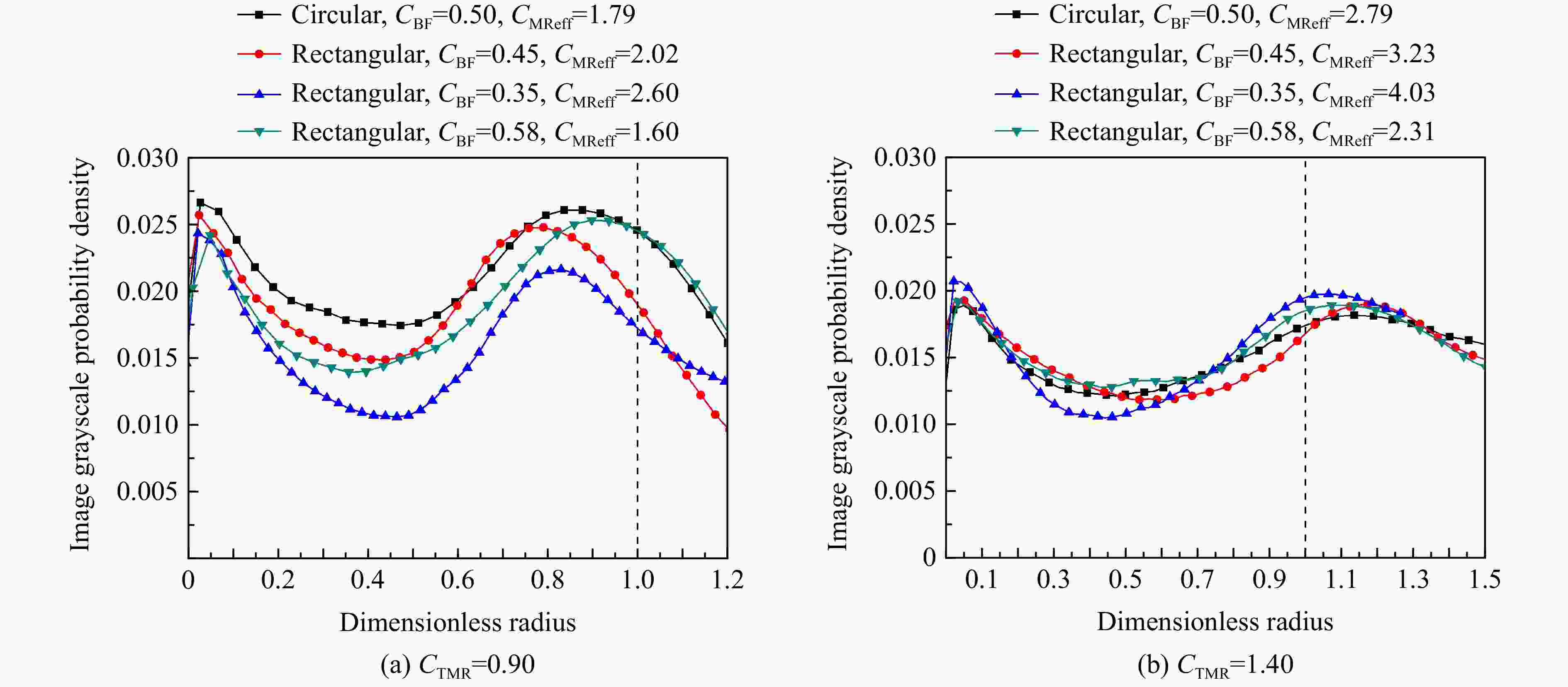

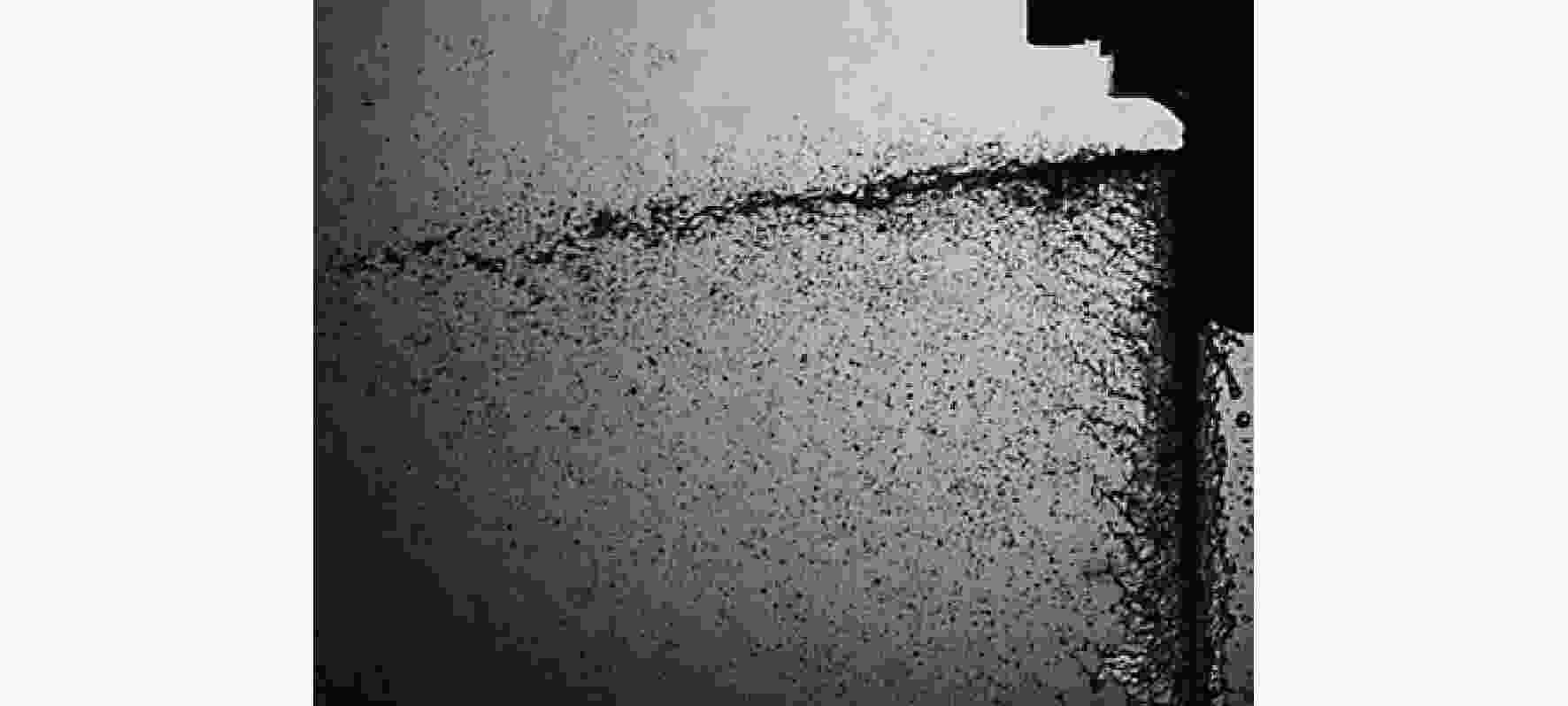

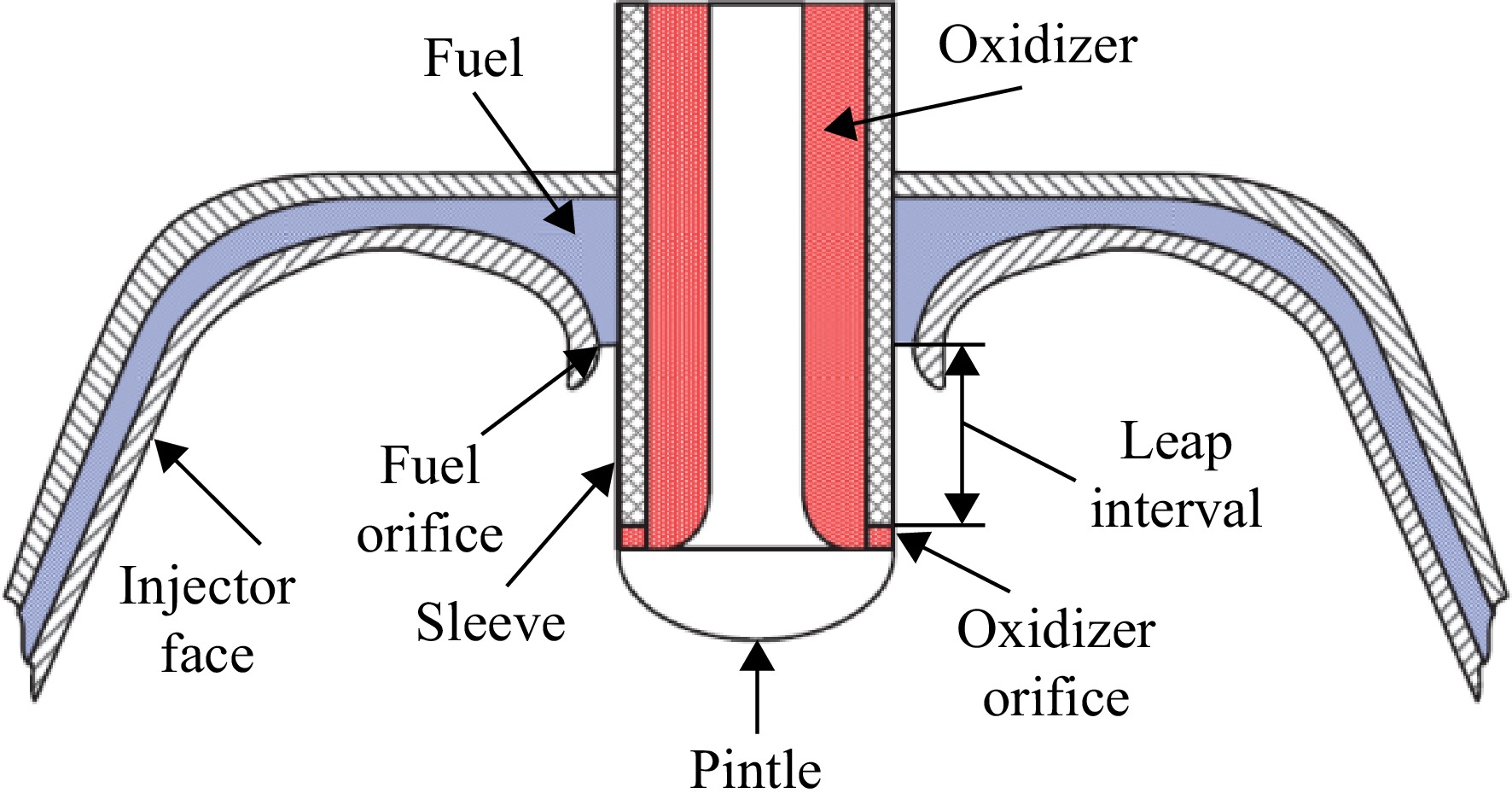

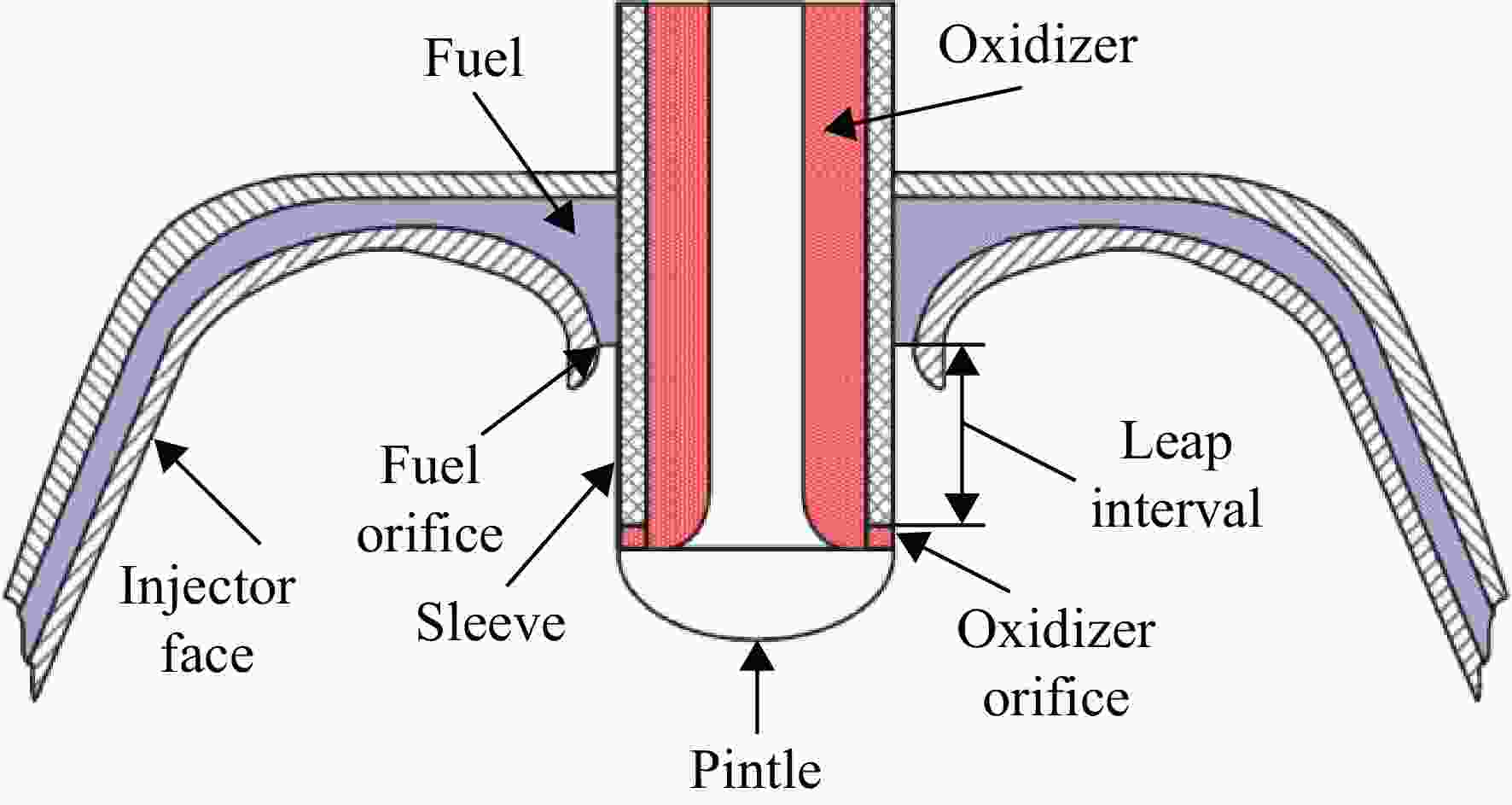

Abstract:In order to study the influence of blockage rate on the spray characteristics of pintle injector, based on the design idea of a plane pintle injector element, the test parts of the plane pintle multi-injector elements with replaceable components were designed. At the same time, PLIC VOF (piecewise linear interface calculation volume of fluid) multiphase flow simulation method with each phase individually identified and the high-speed photography test method were used to study the influence of blockage rate on the spray angle, spray diffusion angle and spatial distribution of liquid spray in the liquid-liquid pintle multi-injector elements. For the multi-pintle injector element with radial circular orifices, the blockage rate was changed by changing the diameter and the number of radial orifices. For the multi-pintle injector element with radial rectangular orifices, the blockage rate was also changed by changing the rectangular aspect ratio of radial orifices. It was found that the blockage rate had important effect on the spray concentration spatial distribution of spray field. When the total momentum ratio remained unchanged, the effect of blockage rate on the spray field was directly produced by the spatial distance between the adjacent spray fans, and also indirectly produced by the effective momentum ratio on the other hand. The influence of radial orifice shape on the spray field was also essentially transformed into the influence of the blockage rate and effective momentum ratio. The influence of the blockage rate change on the spray angle was only indirectly realized by the effective momentum ratio, which was caused by the change of radial orifice diameter and shape. The spray angle theoretical model of pintle injector element was also applicable to multi-pinlte injector element. Meanwhile, the influence of the blockage rate on the spray diffusion angle and the spray concentration spatial distribution was achieved through two action ways. In addition, the spray radial distribution range increased under the condition of high total momentum ratio, and the liquid spray mass rate increased in the central and outer regions of the spray fan due to the interaction between adjacent injector elements.

-

表 1 径向圆孔的结构参数

Table 1. Geometry parameters of radial circular orifices

喷嘴

编号孔数 有效

孔数孔径d/

mm孔心间距l/

mm阻塞率

CBFJ0 9 8 0.80 2.00 0.40 J0-1 11 10 0.72 1.60 0.45 J0-2 13 12 0.65 1.33 0.49 J1 9 8 1.00 2.00 0.50 J1-1 7 6 1.15 2.67 0.43 J1-2 11 10 0.90 1.60 0.56 J1-3 13 12 0.82 1.33 0.615 表 2 径向矩形孔的结构参数

Table 2. Geometry parameters of radial rectangular orifices

喷嘴

编号孔数 有效

孔数孔宽a/

mm孔高b/

mm孔心间距l/

mm阻塞率

CBFJ2 9 8 0.90 0.90 2.00 0.45 J2-1 9 8 0.704 1.15 2.00 0.35 J2-2 9 8 1.15 0.704 2.00 0.575 -

[1] 刘昌波. 针栓式喷注器雾化特性的多尺度仿真研究[D]. 西安: 西安航天动力研究所,2014. LIU Changbo. Multiscale simulations of primary atomization for the pintle injector[D]. Xi’an: Xi’an Aerospace Propulsion Institute,2014. (in ChineseLIU Changbo. Multiscale simulations of primary atomization for the pintle injector[D]. Xi’an: Xi’an Aerospace Propulsion Institute, 2014. (in Chinese) [2] 岳春国,李进贤,侯晓,等. 变推力液体火箭发动机综述[J]. 中国科学:E辑 技术科学,2009,39(3): 464-468. YUE Chunguo,LI Jinxian,HOU Xiao,et al. Summary of variable thrust liquid rocket engine[J]. Science in China: Series E Technological Sciences,2009,39(3): 464-468. (in ChineseYUE Chunguo, LI Jinxian, HOU Xiao, et al. Summary of variable thrust liquid rocket engine[J]. Science in China: Series E Technological Sciences, 2009, 39(3): 464-468. (in Chinese) [3] 安鹏,姚世强,王京丽,等. 针栓式喷注器的特点及设计方法[J]. 导弹与航天运载技术,2016(3): 50-54. AN Peng,YAO Shiqiang,WANG Jingli,et al. Characteristics and design of pintle injector[J]. Missiles and Space Vehicles,2016(3): 50-54. (in ChineseAN Peng, YAO Shiqiang, WANG Jingli, et al. Characteristics and design of pintle injector[J]. Missiles and Space Vehicles, 2016(3): 50-54. (in Chinese) [4] YU I,CHOI J,KIM T,et al. A study on combustion performance by the shape of slit of the canted slit type pintle injector[J]. Journal of the Korean Society of Propulsion Engineers,2017,21(2): 111-118. doi: 10.6108/KSPE.2017.21.2.111 [5] YU I,KIM S,KO Y,et al. Combustion performance of a pintle injector rocket engine with canted slit shape by characteristic length and total momentum ratio[J]. Journal of the Korean Society of Propulsion Engineers,2017,21(1): 36-43. doi: 10.6108/KSPE.2017.21.1.036 [6] LEE K,NAM J,KOO J. Experimental research about combustion of multi-hole pintle injector using LOx/GCH4[R]. Beijing: 27th International Colloquium on the Dynamics of Explosions and Reactive Systems,2019. [7] LEE Suji,KOO J,YOON Y. Technology and developing trends of pintle injector for throttleable engine[J]. Journal of the Korean Society of Propulsion Engineers,2017,21(4): 107-118. doi: 10.6108/KSPE.2017.21.4.107 [8] RYU H,YU I,KIM W,et al. Experimental investigation on combustion performance of a pintle injector engine with double-row rectangular slot[J]. Journal of the Korean Society of Propulsion Engineers,2017,21(3): 25-33. doi: 10.6108/KSPE.2017.21.3.025 [9] LEE S,KIM D,KOO J,et al. Spray characteristics of a pintle injector based on annular orifice area[J]. Acta Astronautica,2020,167: 201-211. doi: 10.1016/j.actaastro.2019.11.008 [10] CHEN Huiyuan,LI Qinglian,CHENG Peng. Experimental research on the spray characteristics of pintle injector[J]. Acta Astronautica,2019,162: 424-435. doi: 10.1016/j.actaastro.2019.06.032 [11] SAKAKI K,KAKUDO H,NAKAYA S,et al. Combustion characteristics of ethanol/liquid-oxygen rocket-engine combustor with planar pintle injector[J]. Journal of Propulsion and Power,2017,33(2): 514-521. doi: 10.2514/1.B36144 [12] SAKAKI K,KAKUDO H,NAKAYA S,et al. Performance evaluation of rocket engine combustors using ethanol/liquid oxygen pintle injector[R]. AIAA2016-5080,2016. [13] KIM H,KANG H,KWON S. Liquid sheet-sheet impinging structure for pintle injector with nontoxic hypergolic bipropellant[J]. Journal of Propulsion and Power,2019,36(2): 302-307. [14] 成鹏. 变推力火箭发动机喷雾燃烧动态过程研究[D]. 长沙: 国防科技大学,2018. CHENG Peng. The dynamics of spray combustion in variable thrust rocket engines[D]. Changsha: National University of Defense Technology,2018. (in ChineseCHENG Peng. The dynamics of spray combustion in variable thrust rocket engines[D]. Changsha: National University of Defense Technology, 2018. (in Chinese) [15] 王凯,雷凡培,杨岸龙,等. 针栓式喷注器液膜下漏率预估模型[J]. 航空动力学报,2020,35(10): 2223-2234. WANG Kai,LEI Fanpei,YANG Anlong,et al. Prediction model of leakage rate of liquid sheet in pintle injector[J]. Journal of Aerospace Power,2020,35(10): 2223-2234. (in Chinese doi: 10.13224/j.cnki.jasp.2020.10.023WANG Kai, LEI Fanpei, YANG Anlong, et al. Prediction model of leakage rate of liquid sheet in pintle injector[J]. Journal of Aerospace Power, 2020, 35(10): 2223-2234. (in Chinese) doi: 10.13224/j.cnki.jasp.2020.10.023 [16] 王凯,雷凡培,杨岸龙,等. 径向孔形状对针栓式喷注器液膜下漏率的影响[J]. 航空学报,2021,42(6): 124384. WANG Kai,LEI Fanpei,YANG Anlong,et al. Effect of radial orifice shape on leakage rate of liquid sheet in pintle injector[J]. Acta Aeronautica et Astronautica Sinica,2021,42(6): 124384. (in ChineseWANG Kai, LEI Fanpei, YANG Anlong, et al. Effect of radial orifice shape on leakage rate of liquid sheet in pintle injector[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(6): 124384. (in Chinese) [17] 王凯,雷凡培,张波涛,等. 针栓式喷注单元雾化角模型分析[J]. 航空学报,2020,41(10): 123622. WANG Kai,LEI Fanpei,ZHANG Botao,et al. Analysis on spray angle model for pintle injector element[J]. Acta Aeronautica et Astronautica Sinica,2020,41(10): 123622. (in ChineseWANG Kai, LEI Fanpei, ZHANG Botao, et al. Analysis on spray angle model for pintle injector element[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(10): 123622. (in Chinese) [18] 王凯,雷凡培,李鹏飞,等. 壁面边界对撞击合成动量角的影响研究[J]. 推进技术,2019,40(10): 2288-2295. WANG Kai,LEI Fanpei,LI Pengfei,et al. Effects of wall boundary on resultant momentum angle of impinging jets[J]. Journal of Propulsion Technology,2019,40(10): 2288-2295. (in Chinese doi: 10.13675/j.cnki.tjjs.180749WANG Kai, LEI Fanpei, LI Pengfei, et al. Effects of wall boundary on resultant momentum angle of impinging jets[J]. Journal of Propulsion Technology, 2019, 40(10): 2288-2295. (in Chinese) doi: 10.13675/j.cnki.tjjs.180749 [19] 刘昌波,周立新,雷凡培. 雾化过程的数值模拟研究综述[J]. 火箭推进,2014,40(1): 10-17. LIU Changbo,ZHOU Lixin,LEI Fanpei. Overview on numerical simulations of primary atomization[J]. Journal of Rocket Propulsion,2014,40(1): 10-17. (in ChineseLIU Changbo, ZHOU Lixin, LEI Fanpei. Overview on numerical simulations of primary atomization[J]. Journal of Rocket Propulsion, 2014, 40(1): 10-17. (in Chinese) [20] 王凯,杨国华,李鹏飞,等. 离心式喷嘴内部流动过程数值仿真分析[J]. 火箭推进,2016,42(4): 14-20. WANG Kai,YANG Guohua,LI Pengfei,et al. Numerical simulation of internal flow process in pressure swirl injector[J]. Journal of Rocket Propulsion,2016,42(4): 14-20. (in Chinese doi: 10.3969/j.issn.1672-9374.2016.04.003WANG Kai, YANG Guohua, LI Pengfei, et al. Numerical simulation of internal flow process in pressure swirl injector[J]. Journal of Rocket Propulsion, 2016, 42(4): 14-20. (in Chinese) doi: 10.3969/j.issn.1672-9374.2016.04.003 [21] INAMURA T,NAGAI N,SUNANAGA H. Improvement of spray performance of a low-pressure atomizer by conical sheet formation[J]. JSME International Journal Series B,1994,37(4): 924-930. doi: 10.1299/jsmeb.37.924 [22] KATE R P,DAS P K,CHAKRABORTY S. An experimental investigation on the interaction of hydraulic jumps formed by two normal impinging circular liquid jets[J]. Journal of Fluid Mechanics,2007,590: 355-380. doi: 10.1017/S0022112007008063 [23] INAMURA T. Upwash formation on splash plate atomization[J]. International Journal of Multiphase Flow,2016,85: 67-75. doi: 10.1016/j.ijmultiphaseflow.2016.05.012 [24] INAMURA T,ENDO S,OKABE T,et al. Characteristics of liquid upwash formed on a splash plate[J]. International Journal of Multiphase Flow,2018,99: 446-453. doi: 10.1016/j.ijmultiphaseflow.2017.11.011 -

下载:

下载: