Numerical study on coupling effects of particle deposition and film cooling over flat plate surfaces

-

摘要:

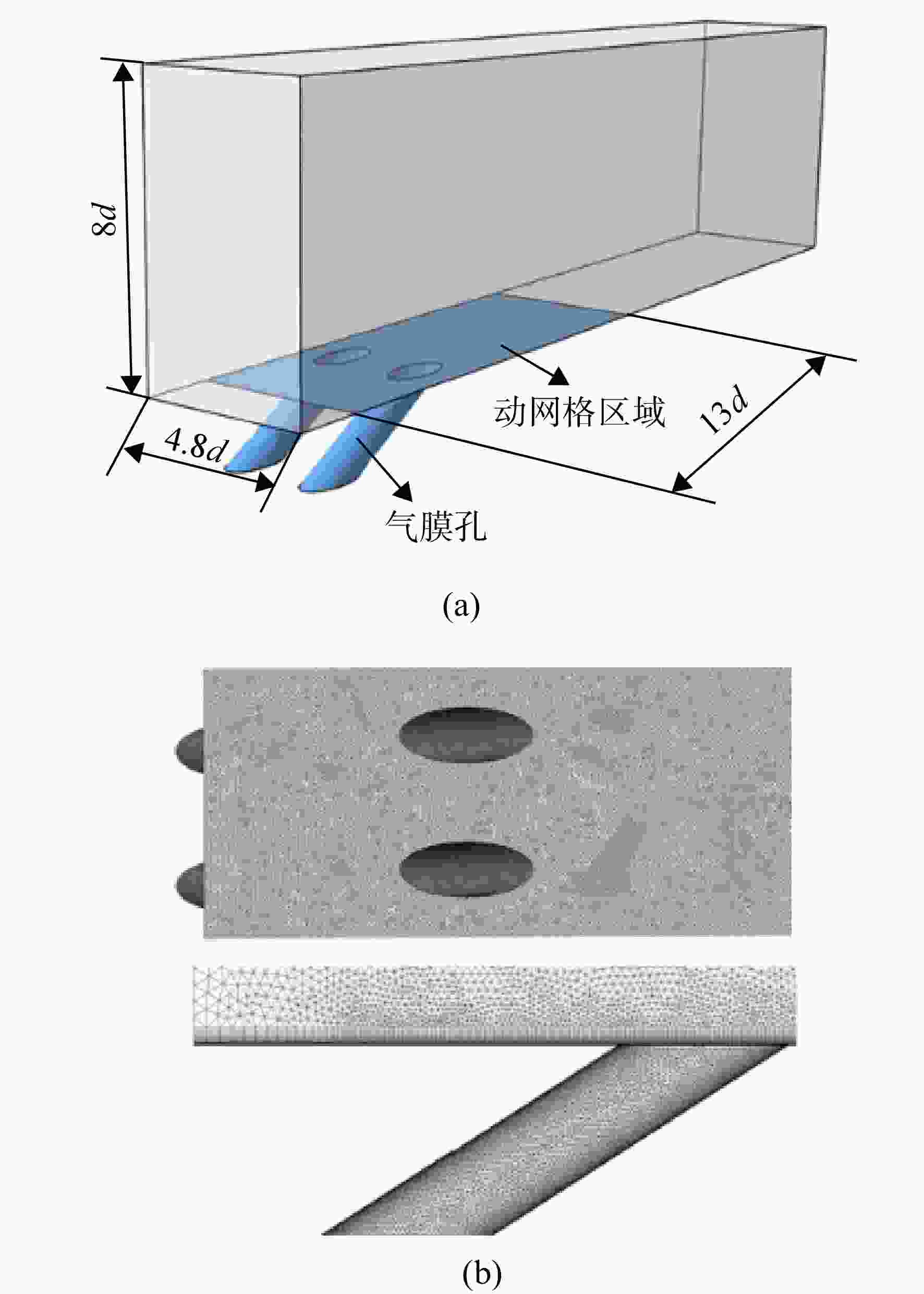

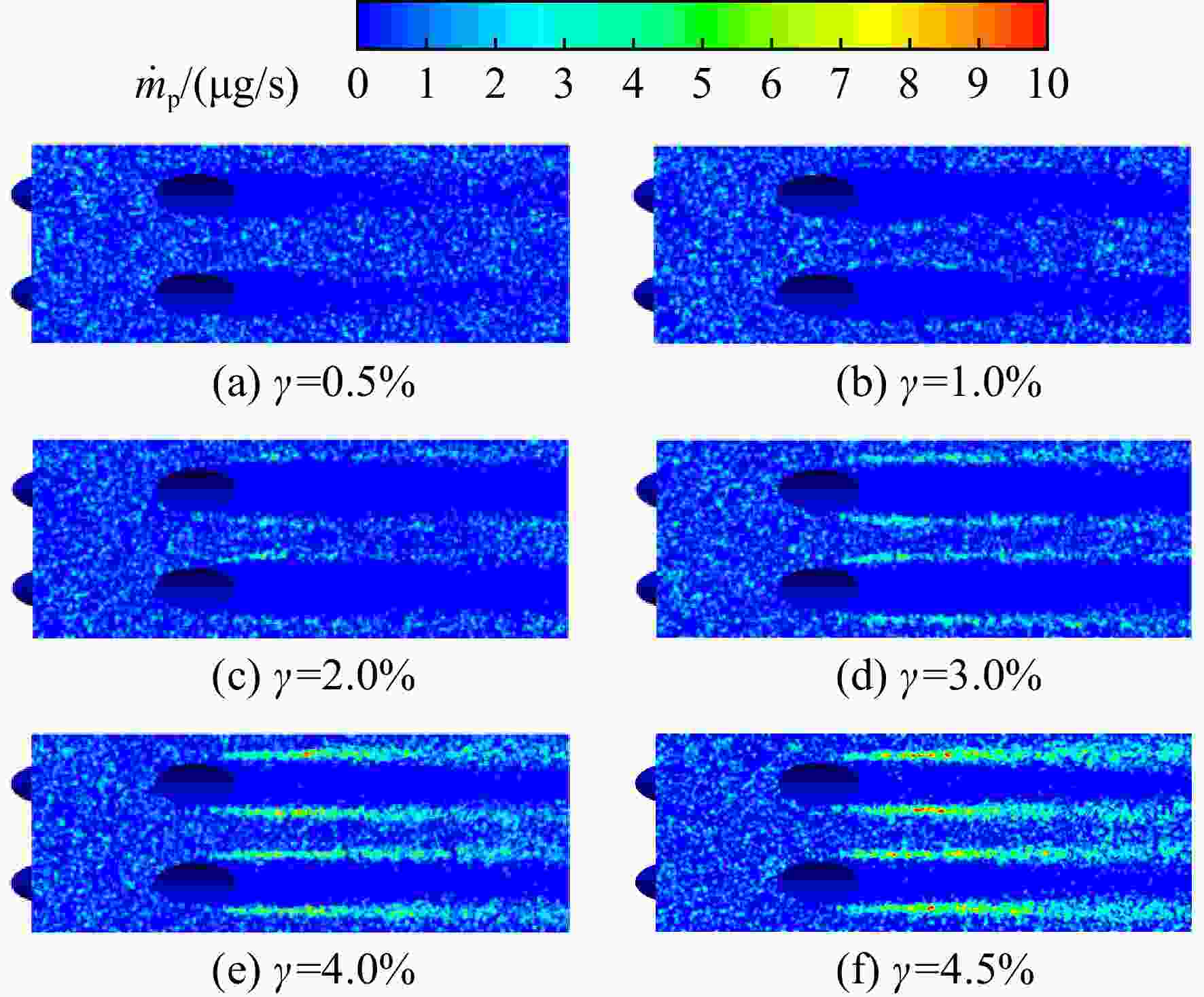

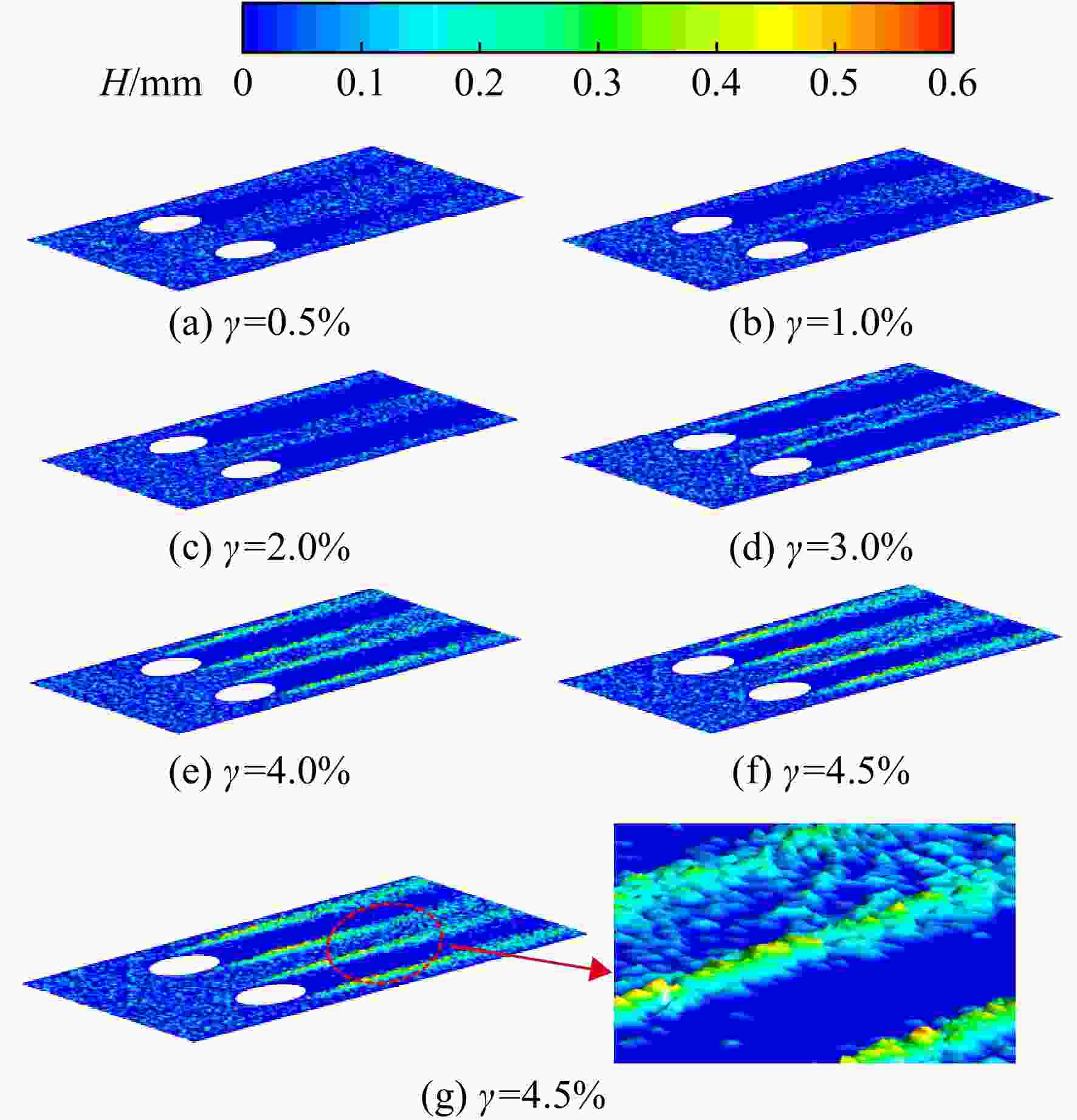

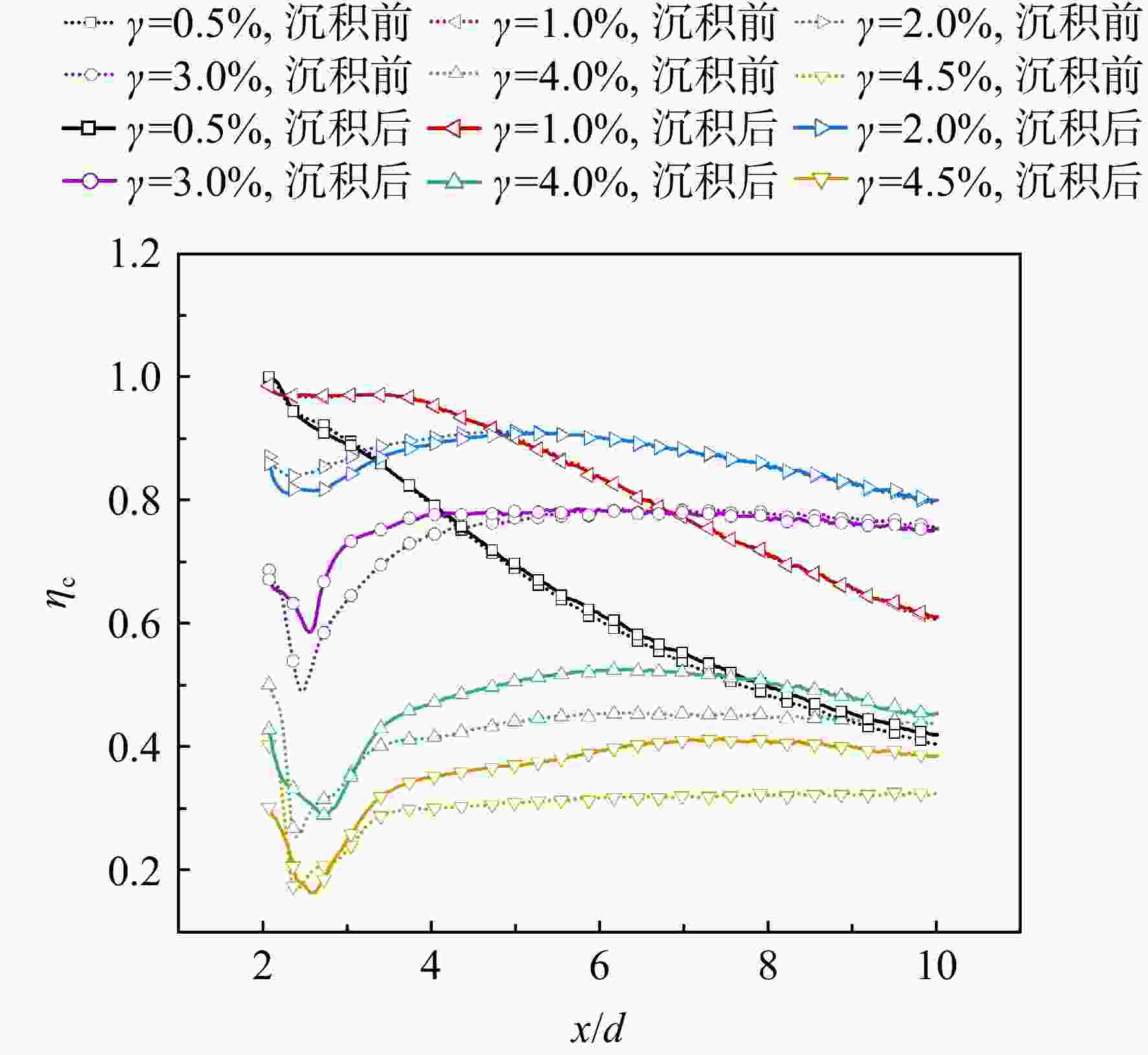

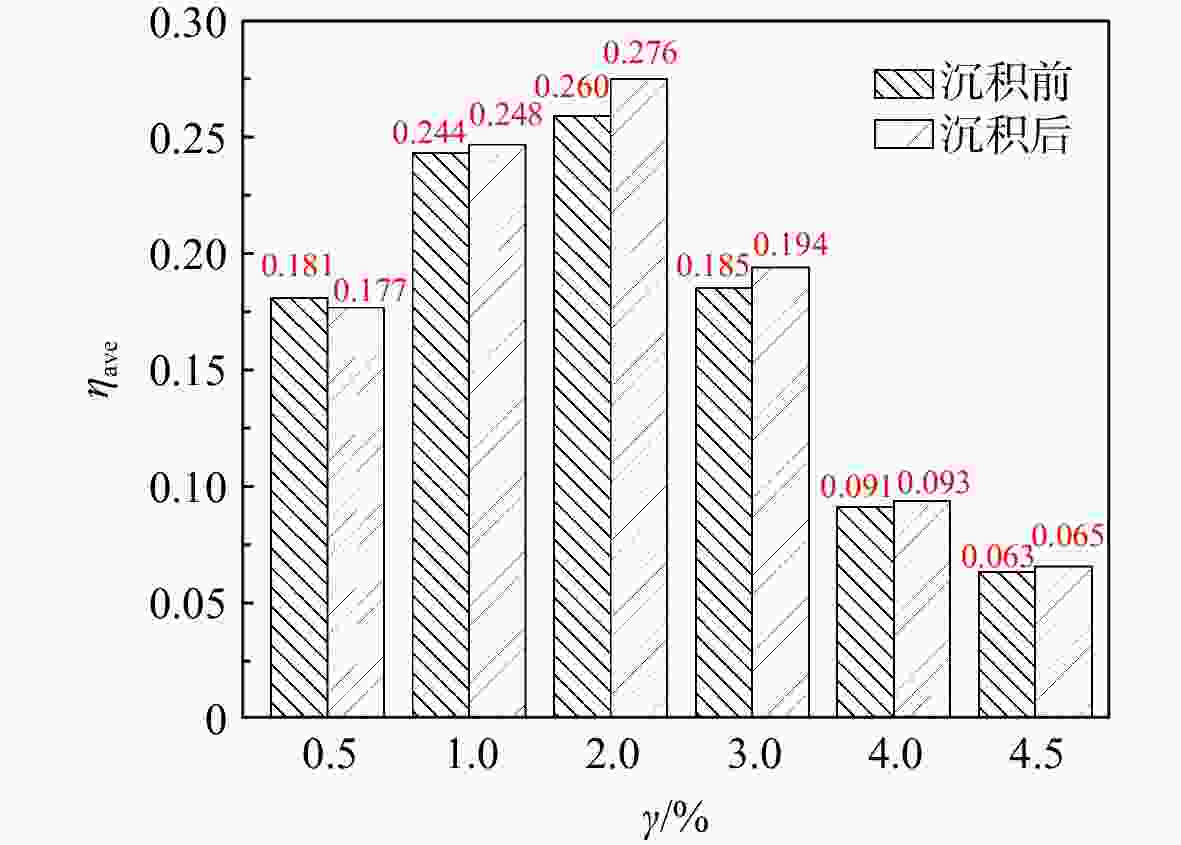

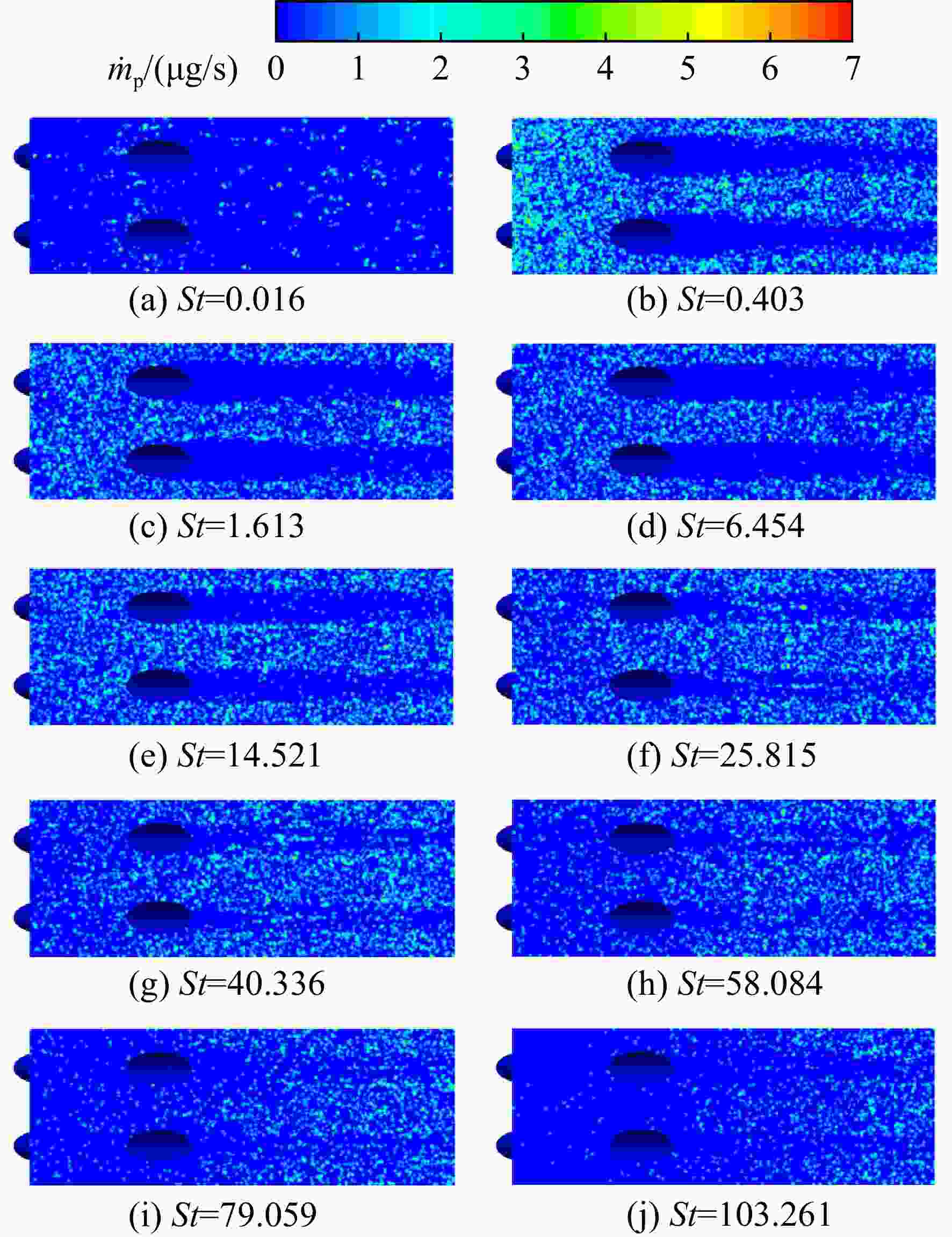

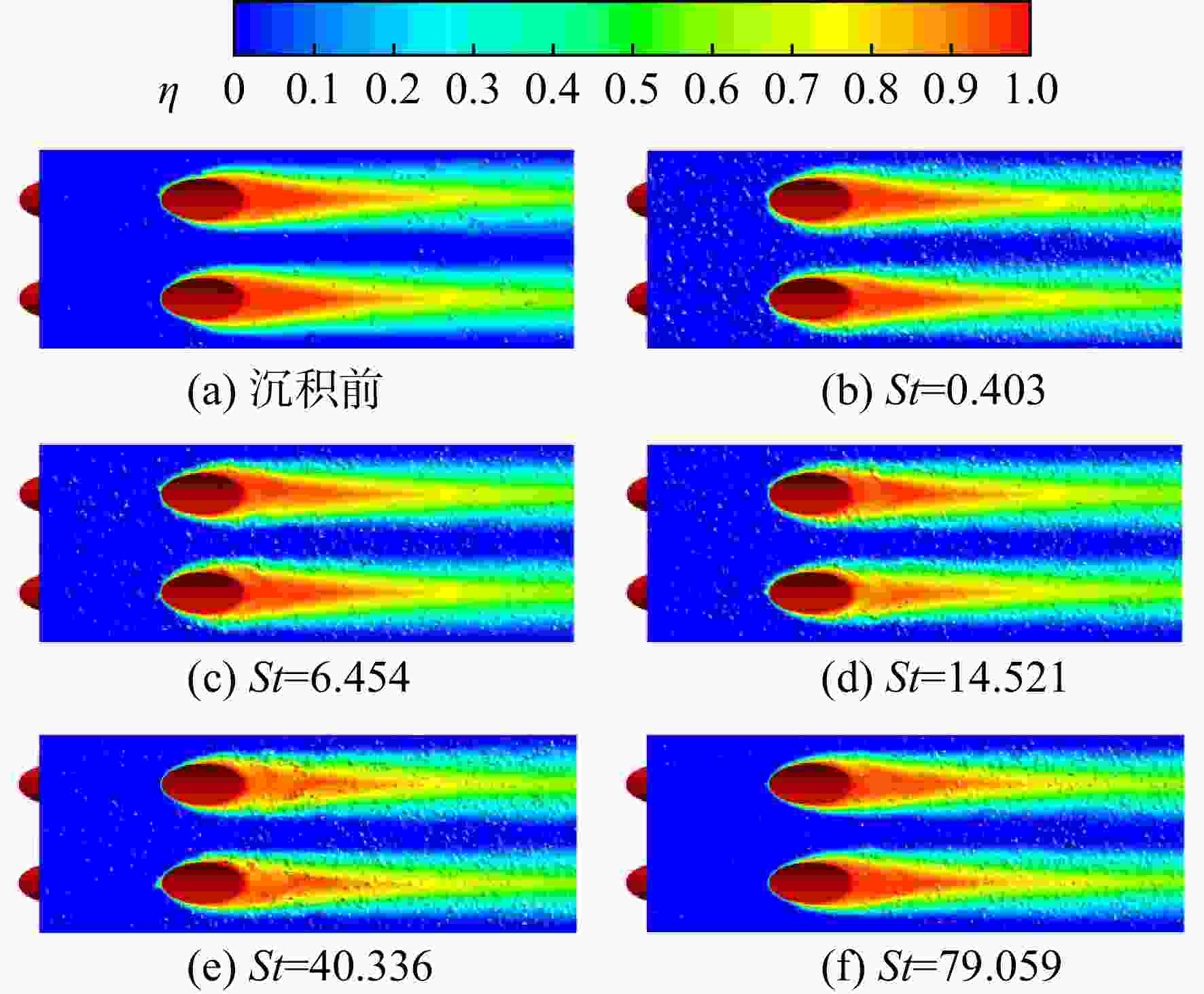

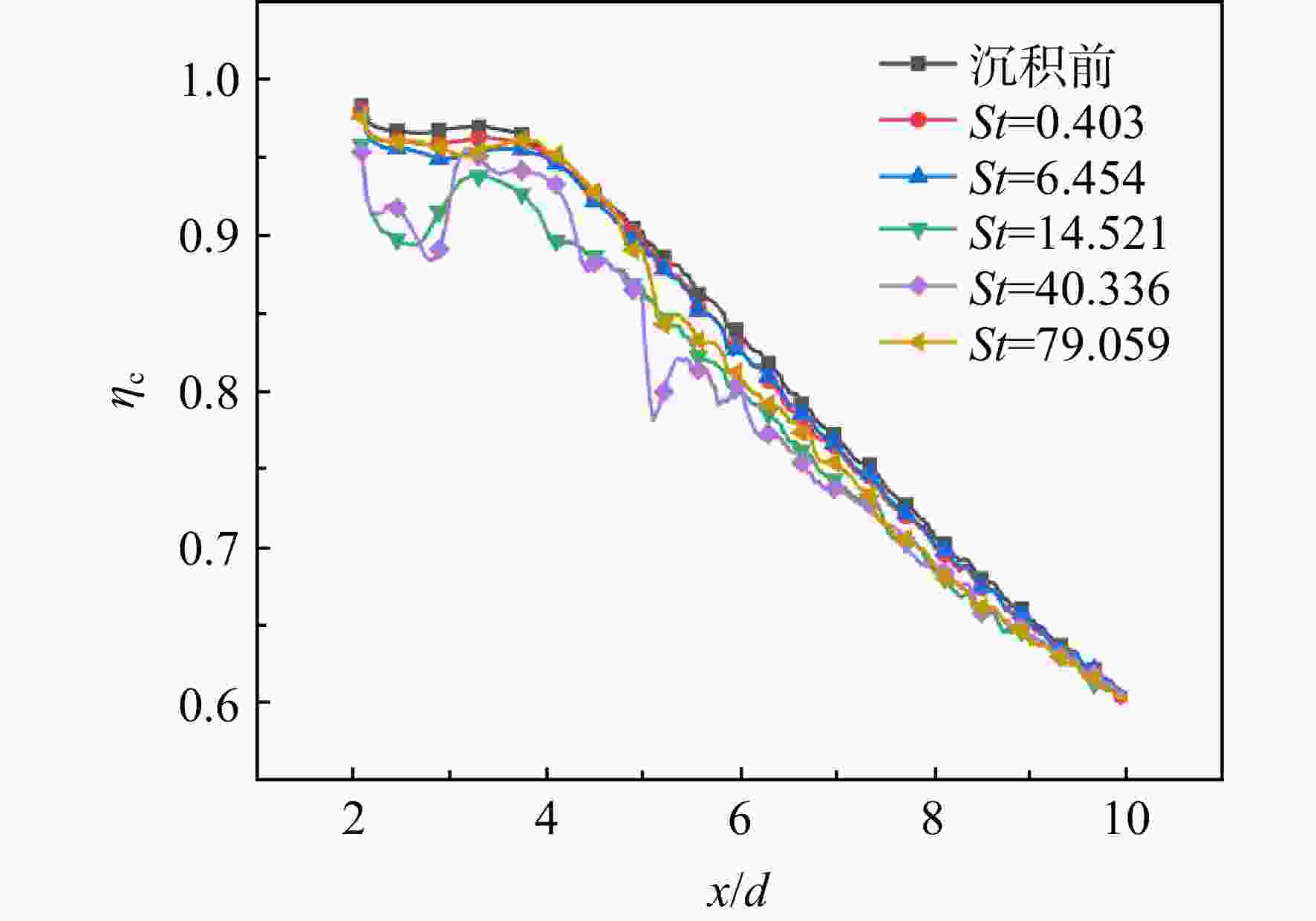

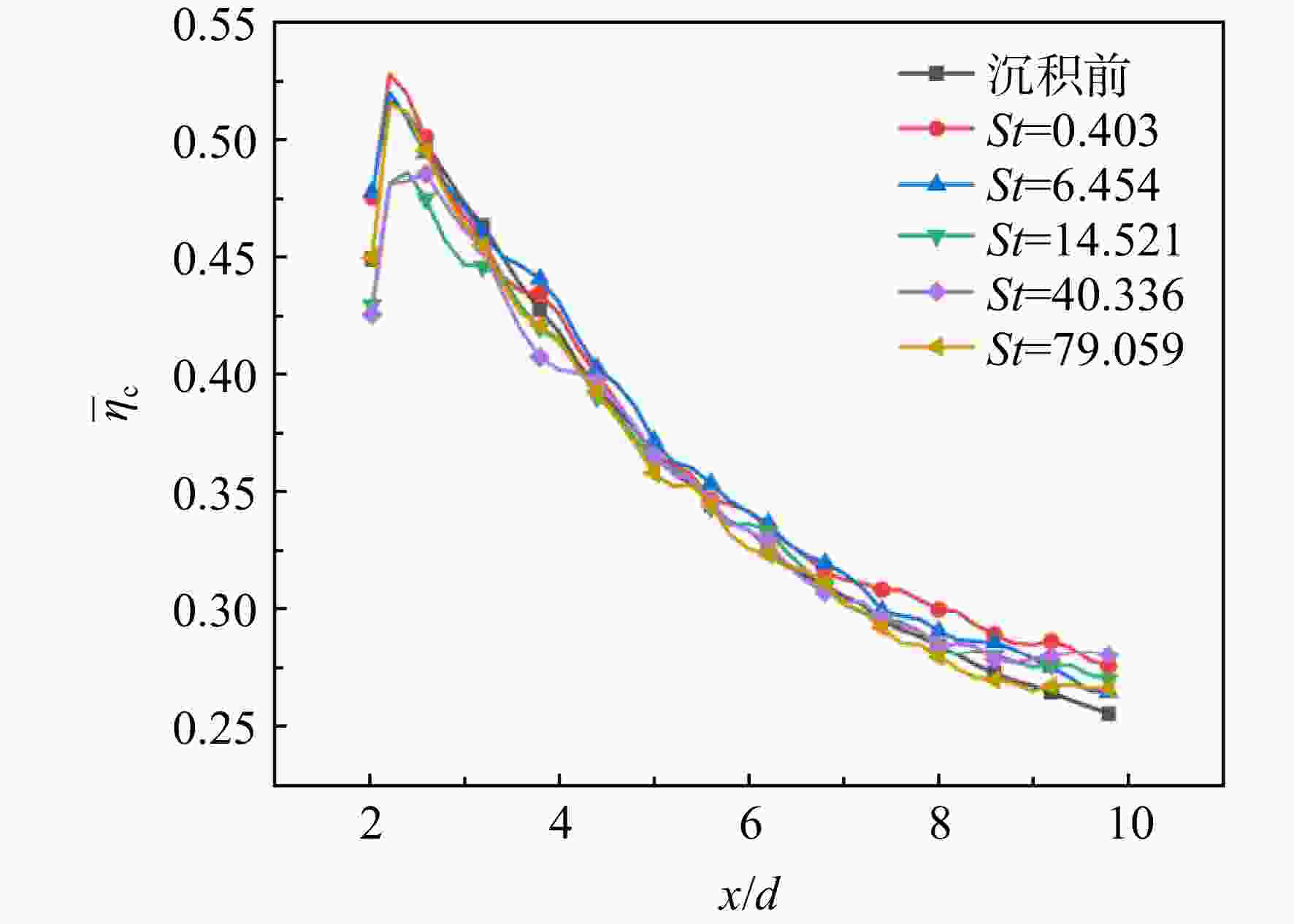

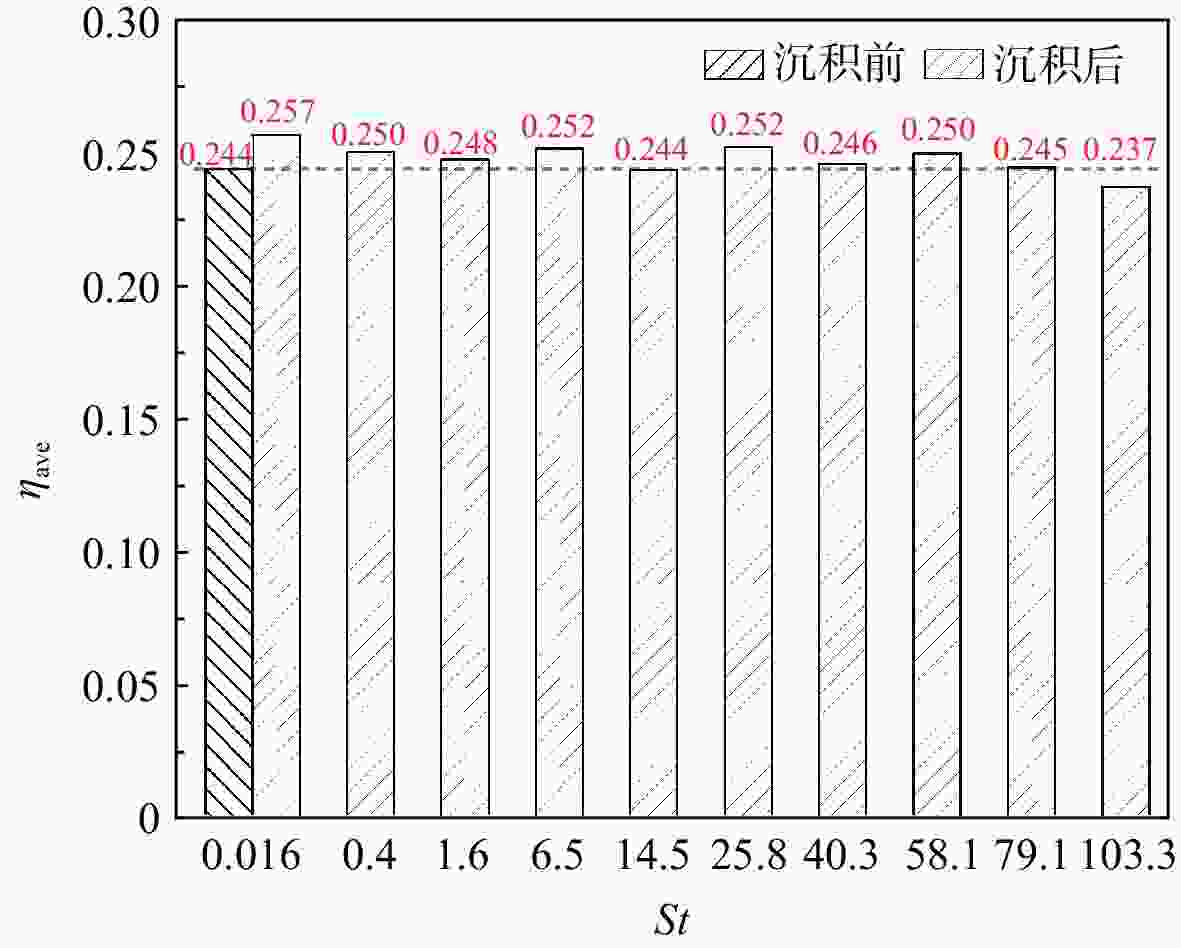

基于颗粒物沉积模型与动网格技术,研究了不同冷气质量流量比与颗粒物直径下气膜冷却平板表面的沉积特性及颗粒形成沉积物后对平板气膜冷却性能的影响。结果表明:在颗粒速度较低时,冷气射流对颗粒的吹拂作用使其难以在气膜孔下游沉积,且冷气射流结构对颗粒的阻隔与卷吸作用使得气膜孔下游两侧形成明显的脊状沉积带;平板表面的沉积效率随颗粒直径的变化呈现双峰分布;在较大的质量流量比下,冷气射流两侧拢起的脊状沉积带会使得气膜冷却效率显著提高,相比沉积前最大提升了6.15%;同时,颗粒沉积物能增强冷气的横向扩散,使得横向平均冷却效率有一定程度的提升。总体而言,颗粒沉积物对气膜冷却性能的影响由沉积分布特征与沉积量共同决定。

Abstract:Using a particle deposition model and a dynamic mesh technique, the deposition characteristics over a flat plate surface with film cooling under different mass flow ratios and particle sizes were studied. In addition, the effects of particle deposition on film cooling over the flat plate were investigated. Results revealed that at a low particle velocity, the blowing of the coolant acting on the particles made it difficult to deposit in the downstream region of film holes, and an obvious ridged shape of deposits was formed on both sides due to the blocking and entrainment of the cooling jet. However, distribution of the capture efficiency presented a bimodal pattern with the change of particle sizes. At high mass flow ratios, the ridged deposition significantly improved the cooling effectiveness, which was 6.15% higher than that before deposition. Additionally, particle deposition could enhance the lateral spreading of the coolant and improved the laterally-averaged cooling effectiveness. In general, the effects of particle deposition on film cooling performance were determined by both distribution characteristics and thickness of the deposition.

-

Key words:

- particle deposition /

- film cooling /

- coolant mass flow ratio /

- Stokes number /

- dynamic mesh

-

表 1 颗粒直径与斯托克斯数的对应关系

Table 1. Particle diameter and Stokes number

颗粒直径dp/μm 斯托克斯数St 1 0.016 5 0.403 10 1.613 20 6.454 30 14.521 40 25.815 50 40.336 60 58.084 70 79.059 80 103.261 -

[1] DUNN M G. Operation of gas turbine engines in an environment contaminated with volcanic ash[J]. Journal of Turbomachinery,2012,134(5): 051001. doi: 10.1115/1.4006236 [2] KIM J,DUNN M G,BARAN A J,et al. Deposition of volcanic materials in the hot sections of two gas turbine engines[J]. Journal of Engineering for Gas Turbines and Power,1993,115(3): 641-651. doi: 10.1115/1.2906754 [3] 杨星,郝子晗,丰镇平. 颗粒污染物在涡轮中的沉积效应[J]. 航空动力,2020(1): 27-31.YANG Xing,HAO Zihan,FENG Zhenping. Deposition effects of particles in turbines[J]. Aerospace Power,2020(1): 27-31. (in Chinese) [4] DRING R P,CASPAR J R,SUO M. Particle trajectories in turbine cascades[J]. Journal of Energy,1979,3(3): 161-166. doi: 10.2514/3.47996 [5] JENSEN J W,SQUIRE S W,BONS J P,et al. Simulated land-based turbine deposits generated in an accelerated deposition facility[J]. Journal of Turbomachinery,2005,127(3): 462-470. doi: 10.1115/1.1860380 [6] CROSBY J M,LEWIS S,BONS J P,et al. Effects of temperature and particle size on deposition in land based turbines[J]. Journal of Engineering for Gas Turbines and Power,2008,130(5): 819-825. [7] LAWSON S A, THOLE K A, OKITA Y, et al. Simulations of multi-phase particle deposition on a showerhead with staggered film-cooling holes[C]//Proceedings of ASME Turbo Expo. Vancouver, Canada: ASME, 2011: 91-103. [8] YANG Xing,HAO Zihan,FENG Zhenping. An experimental study on turbine vane Leading-Edge film cooling with deposition[J]. Applied Thermal Engineering,2021,198: 117447. doi: 10.1016/j.applthermaleng.2021.117447 [9] LAWSON S, THOLE K. Simulations of multi-phase particle deposition on endwall film-cooling holes in transverse trenches[C]//Proceedings of ASME Turbo Expo. Vancouver, Canada: ASME, 2011: 79-90. [10] ALBERT J E,BOGARD D G. Experimental simulation of contaminant deposition on a film-cooled turbine vane pressure side with a trench[J]. Journal of Turbomachinery,2013,135(5): 051008. doi: 10.1115/1.4007821 [11] LYNCH S P,THOLE K A,KOHLI A,et al. Computational predictions of heat transfer and film-cooling for a turbine blade with nonaxisymmetric endwall contouring[J]. Journal of Turbomachinery,2011,133(4): 1. [12] 周君辉,张靖周. 涡轮叶栅内粒子沉积特性的数值研究[J]. 航空学报,2013,34(11): 2492-2499. doi: 10.7527/S1000-6893.2013.0216ZHOU Junhui,ZHANG Jingzhou. Numerical investigation on particle deposition characteristic inside turbine cascade[J]. Acta Aeronautica et Astronautica Sinica,2013,34(11): 2492-2499. (in Chinese) doi: 10.7527/S1000-6893.2013.0216 [13] 杨晓军,祝佳雄. 涡轮叶栅通道内颗粒物沉积过程的数值模拟[J]. 航空学报,2017,38(5): 120530.YANG Xiaojun,ZHU Jiaxiong. Numerical simulation of particle deposition process inside turbine cascade[J]. Acta Aeronautica et Astronautica Sinica,2017,38(5): 120530. (in Chinese) [14] YANG Xing,HAO Zihan,FENG Zhenping. Particle deposition patterns on high-pressure turbine vanes with aggressive inlet swirl[J]. Chinese Journal of Aeronautics,2022,35(3): 75-89. doi: 10.1016/j.cja.2021.06.005 [15] HAO Z H,YANG X,FENG Z. Unsteady simulations of migration and deposition of fly-ash particles in the first-stage turbine of an aero-engine[J]. The Aeronautical Journal,2021,125(1291): 1566-1586. doi: 10.1017/aer.2021.27 [16] YANG Xing,HAO Zihan,FENG Zhenping. Variations of cooling performance on turbine vanes due to incipient particle deposition[J]. Proceedings of the Institution of Mechanical Engineers: Part A Journal of Power and Energy,2021,235(8): 1832-1846. doi: 10.1177/09576509211010530 [17] 杨星,郝子晗,丰镇平. 考虑进口旋流的涡轮静叶流动传热的颗粒物沉积效应[J]. 西安交通大学学报,2021,55(7): 61-70. doi: 10.7652/xjtuxb202107007YANG Xing,HAO Zihan,FENG Zhenping. Particle deposition effect of the flow and heat transfer in a turbine vane passage with inlet swirl[J]. Journal of Xi’an Jiaotong University,2021,55(7): 61-70. (in Chinese) doi: 10.7652/xjtuxb202107007 [18] 赵静宇. 颗粒在平板气膜冷却壁面沉积机理研究[D]. 西安: 西北工业大学, 2017.ZHAO Jingyu. Investigations of particle deposition mechanism on the flat plate wall with film cooling holes[D]. Xi’an: Northwestern Polytechnical University, 2017. (in Chinese) [19] BRACH R M,DUNN P F. A mathematical model of the impact and adhesion of microsphers[J]. Aerosol Science and Technology,1992,16(1): 51-64. doi: 10.1080/02786829208959537 [20] EL-BATSH H, HASELBACHER H. Numerical investigation of the effect of ash particle deposition on the flow field through turbine cascades[C]//Proceedings of ASME Turbo Expo. Amsterdam: ASME, 2002: 1035-1043. [21] SINHA A K,BOGARD D G,CRAWFORD M E. Film-cooling effectiveness downstream of a single row of holes with variable density ratio[J]. Journal of Turbomachinery,1991,113(3): 442-449. doi: 10.1115/1.2927894 [22] AI Weiguo,FLETCHER T H. Computational analysis of conjugate heat transfer and particulate deposition on a high pressure turbine vane[J]. Journal of Turbomachinery,2012,134(4): 041020. doi: 10.1115/1.4003716 -

下载:

下载: