Virtual fatigue test technology of aero-engine turbine joint structure

-

摘要:

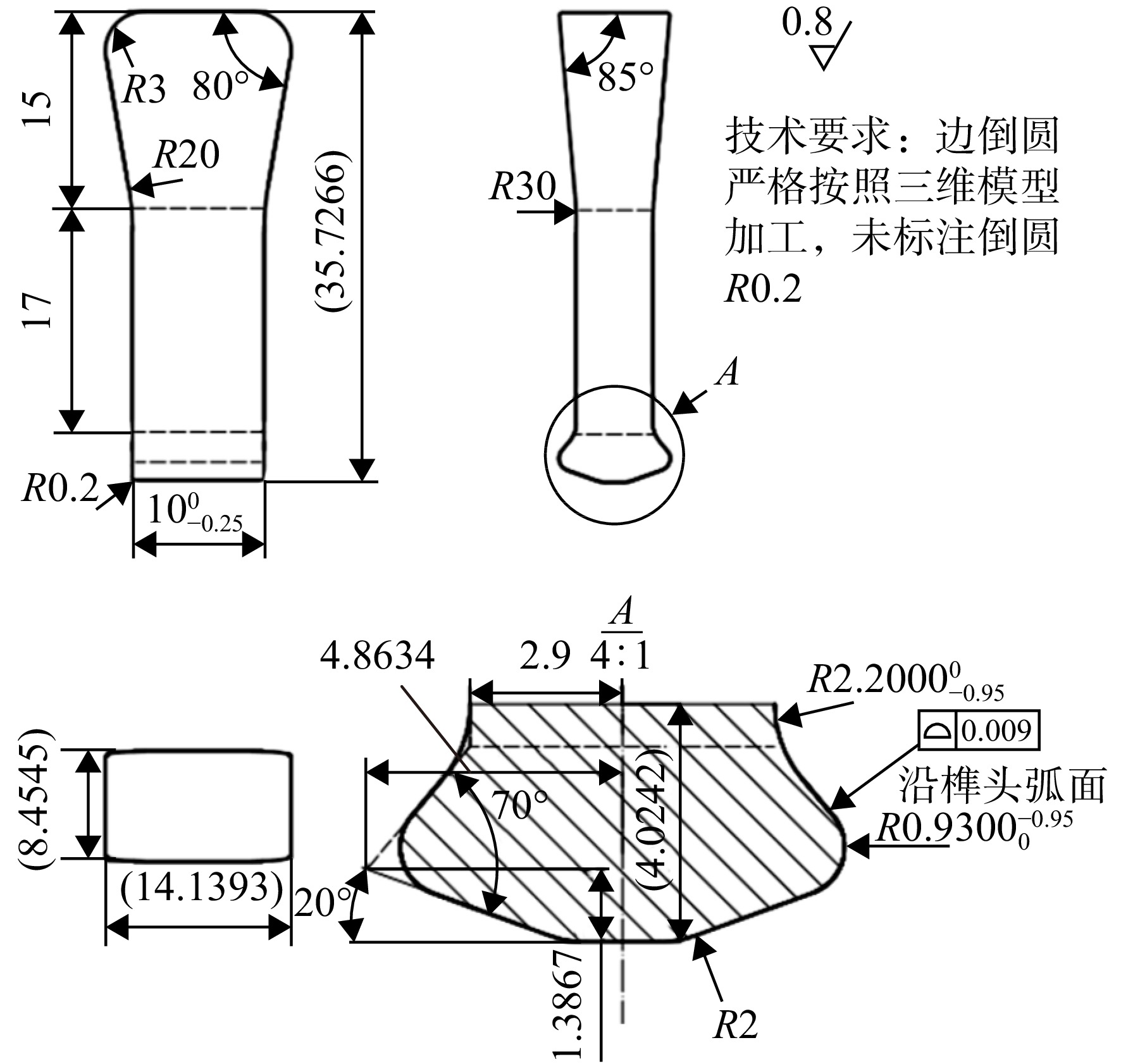

为解决航空发动机涡轮榫接结构疲劳试验成本高、周期长,且试验过程状态难以实时监控等问题,开展了涡轮榫接结构疲劳的虚拟试验技术研究。通过涡轮榫接结构模拟件的疲劳试验获取载荷-位移数据,构建NARX(nonlinear auto regressive model with exogenous inputs)神经网络模型,开展位移初步预测;在此基础上采用Kalman滤波引入实测数据对预测状态进行修正,实现疲劳虚拟试验位移的实时预测和更新且预测误差均小于5%;最后,基于3D MAX和Unity 3D平台,构建高度保真的涡轮榫接结构数字模型和虚拟环境,实现涡轮榫接结构疲劳虚拟试验过程的直观展示以及数据可视化。

Abstract:To solve the problems of high cost, long cycle and difficulty in monitoring in real time the test status of the fatigue test of aero-engine turbine joint structure, the virtual fatigue test technology was studied. The fatigue test of turbine joint structure was carried out to obtain load-displacement data, which were used to construct the NARX (nonlinear auto regressive model with exogenous inputs) neural network to carry out preliminary displacement prediction. On that basis, Kalman filtering was used to correct the predicted state with the measured data, and real-time prediction and updating of virtual fatigue test displacement were realized with the prediction error less than 5%. Finally, based on 3D MAX and Unity 3D, a high-fidelity digital model and virtual environment of the turbine joint structure were constructed to realize the visual display and data visualization of virtual fatigue test process of turbine joint structure.

-

Key words:

- turbine joint /

- virtual test /

- neural network /

- Kalman filtering /

- visualization

-

表 1 材料参数

Table 1. Material parameters

参数 数值 DD412 GH4720Li 温度$T$/℃ 20 600 800 23 600 800 密度$\rho $/(kg/m3) 8930 8140 弹性模量$E$/MPa 129.9 114.5 101.4 225 190 164 泊松比$\nu $ 0.365 0.417 0.435 0.345 0.37 0.39 表 2 试验件低周疲劳寿命数据

Table 2. Low cycle fatigue life data of test pieces

试验编号 疲劳寿命/循环 试验编号 疲劳寿命/循环 1 43315 6 119041 2 22301 7 76771 3 35850 8 81621 4 32721 9 146961 5 52891 10 63812 -

[1] 申秀丽,张野,龙丹,等. 涡轮榫接结构多层次设计优化方法[J]. 航空动力学报,2015,30(12): 2824-2832. SHEN Xiuli,ZHANG Ye,LONG Dan,et al. Multi-level design and optimization of turbine joint structure[J]. Journal of Aerospace Power,2015,30(12): 2824-2832. (in ChineseSHEN Xiuli, ZHANG Ye, LONG Dan, et al. Multi-level design and optimization of turbine joint structure[J]. Journal of Aerospace Power, 2015, 30(12): 2824-2832. (in Chinese) [2] SKELLEY M,LANGHAM T,PETERS W. Integrated test and evaluation for the 21st century[R]. AIAA2004-6873,2004. [3] WATERS D. Integrating modeling and simulation with test and evaluation activities[R]. AIAA2004-6800,2004. [4] 吕颂. 基于PLM工业软件的工程科研虚拟试验技术研究[J]. 中国设备工程,2020(5): 224-226. LÜ Song. Research on virtual experiment technology of engineering scientific research based on PLM industrial software[J]. China Plant Engineering,2020(5): 224-226. (in ChineseLÜ Song. Research on virtual experiment technology of engineering scientific research based on PLM industrial software[J]. China Plant Engineering, 2020(5): 224-226. (in Chinese) [5] WETTER M. Co-simulation of building energy and control systems with the Building Controls Virtual Test Bed[J]. Journal of Building Performance Simulation,2011,4(3): 185-203. doi: 10.1080/19401493.2010.518631 [6] JIANG Zhenhua,DOUGAL R A,LIU Shengyi. Application of VTB in design and testing of satellite electrical power systems[J]. Journal of Power Sources,2003,122(1): 95-108. doi: 10.1016/S0378-7753(03)00360-4 [7] 段建国,徐欣. 虚拟试验技术及其应用现状综述[J]. 上海电气技术,2015,8(3): 1-12. DUAN Jianguo,XU Xin. Overview of present status of virtual experimental technique and its application[J]. Journal of Shanghai Electric Technology,2015,8(3): 1-12. (in ChineseDUAN Jianguo, XU Xin. Overview of present status of virtual experimental technique and its application[J]. Journal of Shanghai Electric Technology, 2015, 8(3): 1-12. (in Chinese) [8] DATAR M,STANCIULESCU I,NEGRUT D. A co-simulation environment for high-fidelity virtual prototyping of vehicle systems[J]. International Journal of Vehicle Systems Modelling and Testing,2012,7(1): 54. doi: 10.1504/IJVSMT.2012.045308 [9] 何西波,王则力,王智勇. 虚拟试验技术在结构热试验中的应用[J]. 强度与环境,2016,43(1): 60-64. HE Xibo,WANG Zeli,WANG Zhiyong. The application of virtual test technology in thermal test[J]. Structure & Environment Engineering,2016,43(1): 60-64. (in ChineseHE Xibo, WANG Zeli, WANG Zhiyong. The application of virtual test technology in thermal test[J]. Structure & Environment Engineering, 2016, 43(1): 60-64. (in Chinese) [10] SCHILDERS W H A,VAN DER VORST H A,ROMMES J. Model order reduction: theory,research aspects and applications[M]. Berlin,Germany: Springer,2008. [11] YOU S,GAO X S,NELSON A. Breaking the testing pyramid with virtual testing and hybrid simulation[J]. Fatigue of Aircraft Structures,2019,2019(11): 1-10. doi: 10.2478/fas-2019-0001 [12] DOMINICZAK K,RZĄDKOWSKI R,RADULSKI W,et al. Online prediction of temperature and stress in steam turbine components using neural networks[J]. Journal of Engineering for Gas Turbines and Power,2016,138(5): 052606. doi: 10.1115/1.4031626 [13] 赵晨. 动态神经网络在量化投资预测中的应用[D]. 上海: 复旦大学,2014. ZHAO Chen. Application of dynamic neural network in quantitative investment forecast[D]. Shanghai: Fudan University,2014. (in ChineseZHAO Chen. Application of dynamic neural network in quantitative investment forecast[D]. Shanghai: Fudan University, 2014. (in Chinese) [14] 李岩峰. 基于动态神经网络的接触器寿命预测模型研究[D]. 沈阳: 沈阳工业大学,2021. LI Yanfeng. Research on the life prediction model of contactor based on dynamic neural network[D]. Shenyang: Shenyang University of Technology,2021. (in ChineseLI Yanfeng. Research on the life prediction model of contactor based on dynamic neural network[D]. Shenyang: Shenyang University of Technology, 2021. (in Chinese) [15] 吴耀,李文钧,姜华,等. 基于动态Kalman滤波的多传感数据融合算法研究[J]. 物联网技术,2015,5(1): 27-29. WU Yao,LI Wenjun,JIANG Hua,et al. Research on multi-sensor data fusion algorithm based on dynamic Kalman filter[J]. Internet of Things Technologies,2015,5(1): 27-29. (in ChineseWU Yao, LI Wenjun, JIANG Hua, et al. Research on multi-sensor data fusion algorithm based on dynamic Kalman filter[J]. Internet of Things Technologies, 2015, 5(1): 27-29. (in Chinese) [16] 李群力,傅妍芳. 基于Kalman滤波的数据融合研究[J]. 计算机仿真,2007,24(8): 299-302. LI Qunli,FU Yanfang. Multi-sonar data fusion using Kalman filter[J]. Computer Simulation,2007,24(8): 299-302. (in ChineseLI Qunli, FU Yanfang. Multi-sonar data fusion using Kalman filter[J]. Computer Simulation, 2007, 24(8): 299-302. (in Chinese) [17] DUAN Jianguo,MA Tianyu,ZHANG Qinglei,et al. Design and application of digital twin system for the blade-rotor test rig[J]. Journal of Intelligent Manufacturing,2023,34(2): 753-769. doi: 10.1007/s10845-021-01824-w [18] 吴琪. 基于Unity 3D的车间虚拟现实系统研究与实现[D]. 武汉: 华中科技大学,2020. WU Qi. Research and implementation of a workshop virtual reality system based on unity 3D[D]. Wuhan: Huazhong University of Science and Technology,2020. (in ChineseWU Qi. Research and implementation of a workshop virtual reality system based on unity 3D[D]. Wuhan: Huazhong University of Science and Technology, 2020. (in Chinese) -

下载:

下载: