Analysis and verification of the quasi-dynamic model for the three-point contact ball bearing

-

摘要:

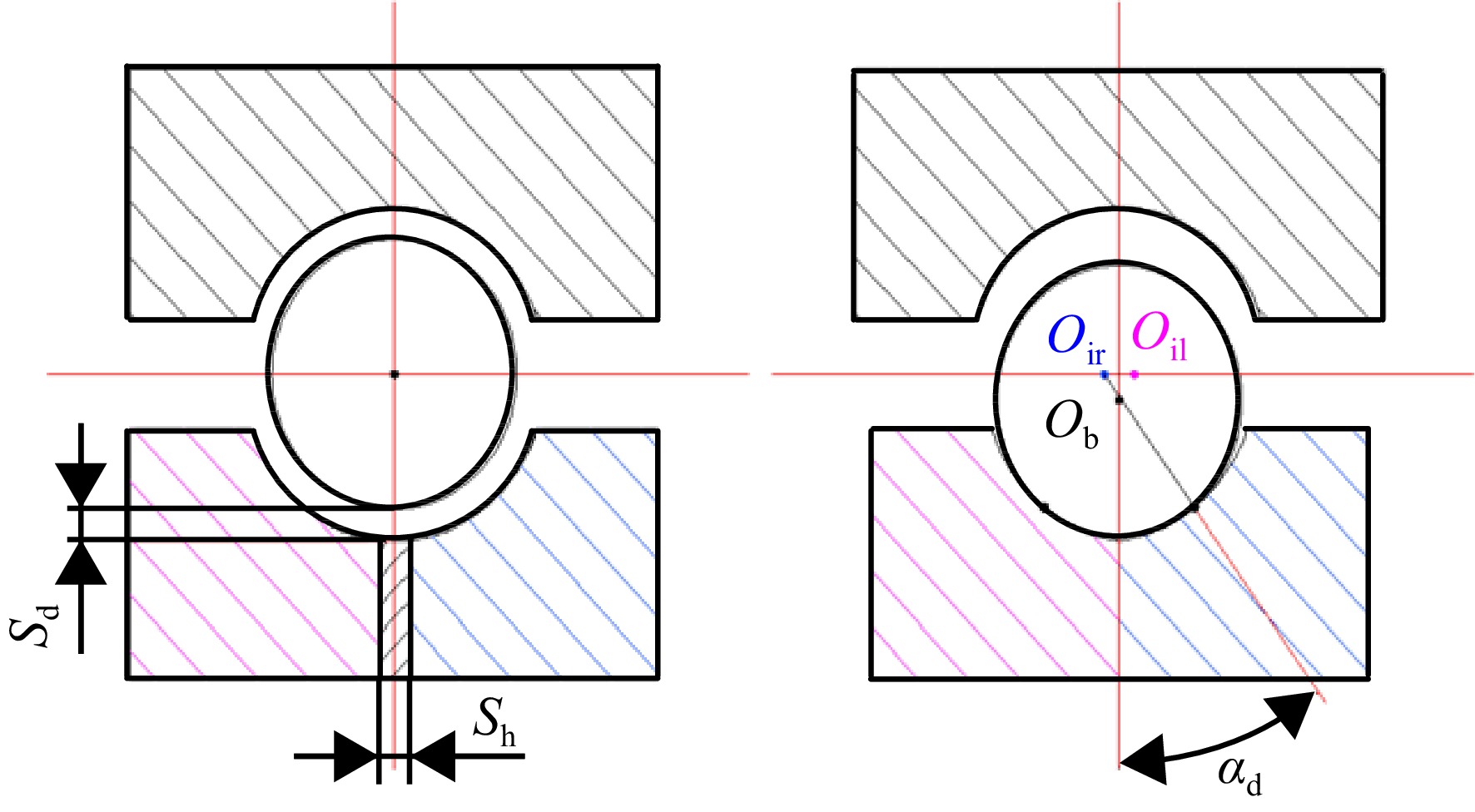

为定量预测与规避双半内圈角接触球轴承三点接触现象,降低轴承异常磨损风险,采用牛顿-欧拉矢量力学方法,结合该轴承结构与受载特点,对双半内圈角接触球轴承内部元件相对位置与速度关系进行了描述,综合考虑轴承各元件相互作用力、运动惯性力、陀螺力矩以及润滑油对轴承元件施加的流体拖动力与挤压力,建立了考虑三点接触情况的双半内圈角接触球轴承拟动态性能分析模型,并完成轴承非线性方程组求解算法优化,且通过与国外成熟软件计算结果和保持架转速试验结果对比,验证了所建立模型的准确性,研究表明,所建立的双半内圈角接触球轴承分析方法对内部接触角分布和应力分布的预测误差小于12%,对于最大接触应力的预测误差小于2%,且对接触痕迹的预测较为准确,对于保持架实际转速的预测误差小于10%,可用于双半内圈角接触球轴承设计优化。

-

关键词:

- 双半内圈角接触球轴承 /

- 三点接触特性 /

- 接触应力 /

- 接触痕迹 /

- 保持架转速试验.

Abstract:In order to predict the three-point contact phenomenon and reduce the risk of abnormal wear, with the help of Newton-Euler vectorial mechanics, combining with the force and structure features, relative location and velocity relationship of internal element of the arched inner race ball bearing were described, the force of bearing parts, inertia force, gyroscopic torque, fluid drag force and extrusion force were considered in process of the arched inner race ball bearing quasi-dynamic modeling considering the three-point contact condition, the optimization of algorithm for solving nonlinear equations of the model was completed, and the accuracy of the model was validated by comparing with foreign mature software and test of the cage rotational speed. The results indicated that the proposed model had a maximum error of 12% for contact angle and contact stress distribution, and a maximum error of 2% for maximum contact stress, and also had high precision for the contact traces prediction, at the same time, the model had a maximum error of 10% for the cage rotational speed by the test validation, so that the model can be used for improving optimization design of the arched inner race ball bearing.

-

表 1 轴承主要参数

Table 1. Main design parameters of bearing

参数 数值 节圆直径/mm 140 轴承内径/mm 100 轴承外径/mm 180 滚珠直径/mm 19.05 滚珠数目 18 垫片角/(°) 20 初始接触角/(°) 25 内圈沟曲率系数 0.54 外圈沟曲率系数 0.52 保持架内径/mm 130.1 保持架外径/mm 146.3 表 2 轴承材料参数

Table 2. Material parameters of bearing

参数 数值 密度/(kg/m3) 7800 泊松比 0.3 弹性模量/GPa 209 表 3 轴承工况

Table 3. Working condition of bearing

参数 数值 内圈转速/(r/min) 20000 径向载荷/N 6000 轴向载荷/N 1112 表 4 试验轴承结构参数

Table 4. Main parameters of tested bearing

参数 数值 节圆直径/mm 165 轴承内径/mm 130 轴承外径/mm 200 滚珠直径/mm 24.606 滚珠个数 17 垫片角/(°) 25 初始接触角/(°) 25 内圈沟曲率系数 0.525 外圈沟曲率系数 0.515 引导间隙/mm 0.6 兜孔间隙/mm 1.594 引导方式 外引导 -

[1] HALPIN J D,TRAN A N. An analytical model of four-point contact rolling element ball bearings[J]. Journal of Tribology,2016,138(3): 031404. doi: 10.1115/1.4033134 [2] LIN Bo,DUAN Molong,OKWUDIRE C E,et al. A simplified analytical model of rolling/sliding behavior and friction in four-point-contact ball bearings and screws[R]. IMECE2017-72486,2017. [3] AGUIRREBEITIA J,AVILÉS R,FERNÁNDEZ DE BUSTOS I,et al. Calculation of general static load-carrying capacity for the design of four-contact-point slewing bearings[J]. Journal of Mechanical Design,2010,132(6): 66-68. [4] AGUIRREBEITIA J,ABASOLO M,AVILÉS R,et al. General static load-carrying capacity for the design and selection of four contact point slewing bearings: finite element calculations and theoretical model validation[J]. Finite Elements in Analysis and Design,2012,55: 23-30. doi: 10.1016/j.finel.2012.02.002 [5] 李杰,田拥胜,张华良,等. 考虑轴向力影响的三点接触球轴承刚度特性研究[J]. 推进技术,2018,39(2): 419-425. LI Jie,TIAN Yongsheng,ZHANG Hualiang,et al. Research on stiffness behavior of three point contact ball bearing in consideration of axial load[J]. Journal of Propulsion Technology,2018,39(2): 419-425. (in ChineseLI Jie, TIAN Yongsheng, ZHANG Hualiang, et al. Research on stiffness behavior of three point contact ball bearing in consideration of axial load[J]. Journal of Propulsion Technology, 2018, 39(2): 419-425. (in Chinese) [6] 王道全. 双半内圈三点接触球轴承的几何分析[J]. 轴承,1988(2): 2-8,63. WANG Daoquan. A geometrical analysis on three point contact ball bearing with two-piece inner ring[J]. Bearing,1988(2): 2-8,63. (in ChineseWANG Daoquan. A geometrical analysis on three point contact ball bearing with two-piece inner ring[J]. Bearing, 1988(2): 2-8, 63. (in Chinese) [7] 白广忱,迟大华,齐毓霖. 双半内圈三点接触球轴承的负荷分布[J]. 哈尔滨建筑工程学院学报,1994,27(2): 90-94. BAI Guangchen,CHI Dahua,QI Yulin. Load distribution of three-point contact ball bearing with double half inner rings[J]. Journal of Harbin University of Civil Engineering and Architecture,1994,27(2): 90-94. (in ChineseBAI Guangchen, CHI Dahua, QI Yulin. Load distribution of three-point contact ball bearing with double half inner rings[J]. Journal of Harbin University of Civil Engineering and Architecture, 1994, 27(2): 90-94. (in Chinese) [8] MA Shuaijun,HE Gaobo,YAN Ke,et al. Structural optimization of ball bearings with three-point contact at high-speed[J]. International Journal of Mechanical Sciences,2022,229: 107494. doi: 10.1016/j.ijmecsci.2022.107494 [9] LEBLANC A,NELIAS D. Ball motion and sliding friction in a four-contact-point ball bearing[J]. Journal of Tribology,2007,129(4): 801-808. doi: 10.1115/1.2768079 [10] 刘鲁,赵聪,冯小川,等. 角接触球轴承在高速大载荷工况下滑油中断耐受能力分析[J]. 航空动力学报,2021,36(11): 2430-2436. LIU Lu,ZHAO Cong,FENG Xiaochuan,et al. Analysis of oil-off tolerance of angular contact ball bearing under condition of high speed and heavy load[J]. Journal of Aerospace Power,2021,36(11): 2430-2436. (in ChineseLIU Lu, ZHAO Cong, FENG Xiaochuan, et al. Analysis of oil-off tolerance of angular contact ball bearing under condition of high speed and heavy load[J]. Journal of Aerospace Power, 2021, 36(11): 2430-2436. (in Chinese) [11] 万长森. 滚动轴承的分析方法[M]. 北京: 机械工业出版社,1987. WAN Changsen. Analysis method of rolling bearing[M]. Beijing: China Machine Press,1987. (in ChineseWAN Changsen. Analysis method of rolling bearing[M]. Beijing: China Machine Press, 1987. (in Chinese) [12] 张文虎. 圆柱滚子轴承动力学仿真及半物理试验研究[D]. 西安: 西北工业大学,2017: 60-80. ZHANG Wenhu. Study on the dynamics simulation and semi-physical experiment of cylindrical roller bearing[D]. Xi’an: Northwestern Polytechnical University,2017: 60-80. (in ChineseZHANG Wenhu. Study on the dynamics simulation and semi-physical experiment of cylindrical roller bearing[D]. Xi’an: Northwestern Polytechnical University, 2017: 60-80. (in Chinese) [13] 王燕霜. 航空润滑油流变特性及其对润滑性能影响的研究[D]. 哈尔滨: 哈尔滨工业大学,2006: 30-39. WANG Yanshuang. Study on rheological characteristics of aviation lubricating oil and its influence on lubrication performance[D]. Harbin: Harbin Institute of Technology,2006: 30-39. (in ChineseWANG Yanshuang. Study on rheological characteristics of aviation lubricating oil and its influence on lubrication performance[D]. Harbin: Harbin Institute of Technology, 2006: 30-39. (in Chinese) [14] YAN Ke,WANG Yatai,ZHU Yongsheng,et al. Investigation on heat dissipation characteristic of ball bearing cage and inside cavity at ultra high rotation speed[J]. Tribology International,2016,93: 470-481. doi: 10.1016/j.triboint.2015.09.030 [15] 温保岗. 角接触球轴承保持架动力学特性及其试验研究[D]. 大连: 大连理工大学,2017: 20-30. WEN Baogang. Theoretical and experimental investigation of cage dynamics in angular contact ball bearing[D]. Dalian: Dalian University of Technology,2017: 20-30. (in ChineseWEN Baogang. Theoretical and experimental investigation of cage dynamics in angular contact ball bearing[D]. Dalian: Dalian University of Technology, 2017: 20-30. (in Chinese) [16] 叶振环. 航空发动机高速滚动轴承动力学行为研究[D]. 哈尔滨: 哈尔滨工业大学,2013: 30-40. YE Zhenhuan. Research on dynamic behavior of high-speed rolling bearings in aeroengines[D]. Harbin: Harbin Institute of Technology,2013: 30-40. (in ChineseYE Zhenhuan. Research on dynamic behavior of high-speed rolling bearings in aeroengines[D]. Harbin: Harbin Institute of Technology, 2013: 30-40. (in Chinese) [17] 刘秀海. 高速滚动轴承动力学分析模型与保持架动态性能研究[D]. 大连: 大连理工大学,2011: 40-45. LIU Xiuhai. Dynamics analysis model of high-speed rolling bearings and dynamic performance of cages[D]. Dalian: Dalian University of Technology,2011: 40-45. (in ChineseLIU Xiuhai. Dynamics analysis model of high-speed rolling bearings and dynamic performance of cages[D]. Dalian: Dalian University of Technology, 2011: 40-45. (in Chinese) [18] 崔立. 航空发动机高速滚动轴承及转子系统的动态性能研究[D]. 哈尔滨: 哈尔滨工业大学,2008: 33-3. CUI Li. Research on dynamic performances of high-speed rolling bearing and rotor system of aeroengine[D]. Harbin: Harbin Institute of Technology,2008: 33-3. (in ChineseCUI Li. Research on dynamic performances of high-speed rolling bearing and rotor system of aeroengine[D]. Harbin: Harbin Institute of Technology, 2008: 33-3. (in Chinese) -

下载:

下载: