Development and application of virtual flight balance measurement device for aircraft with lateral jet

-

摘要:

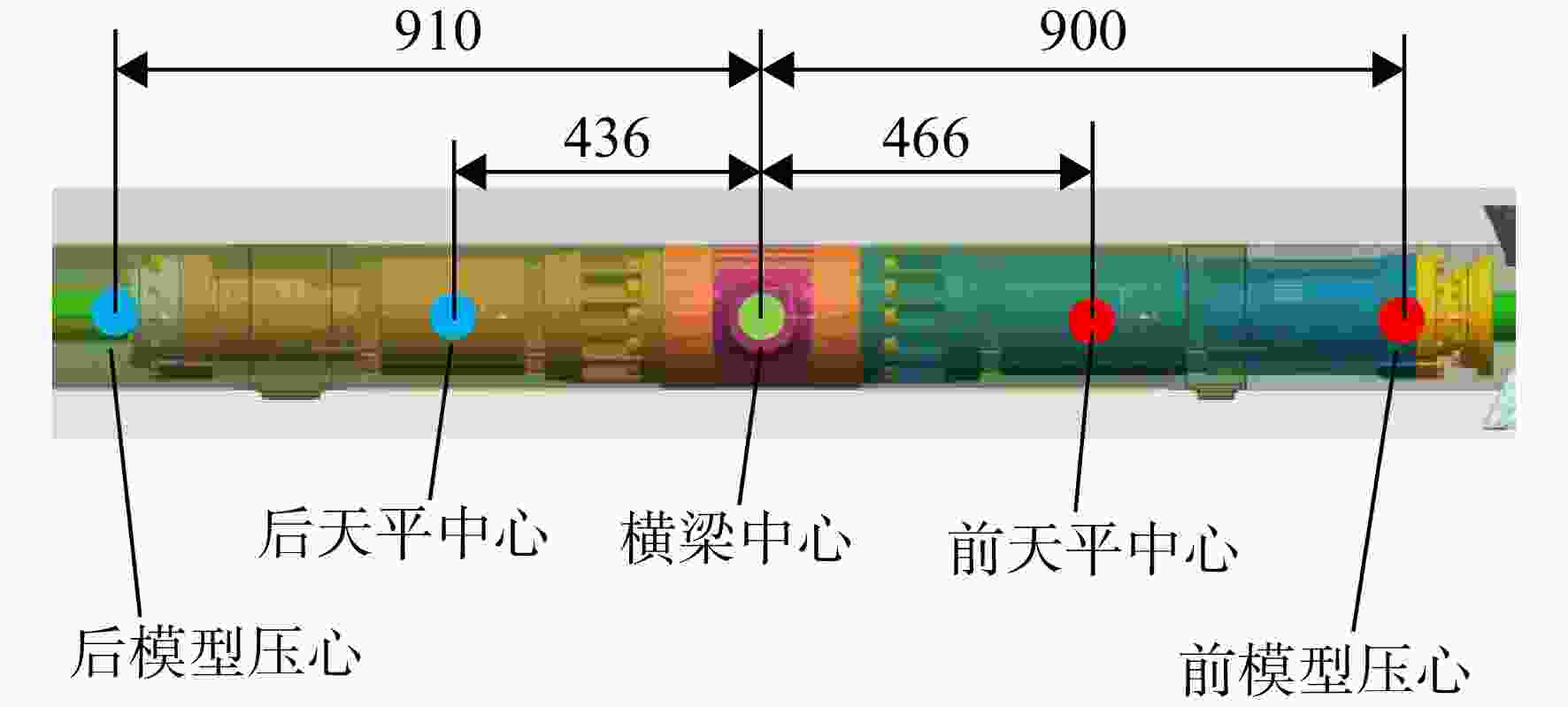

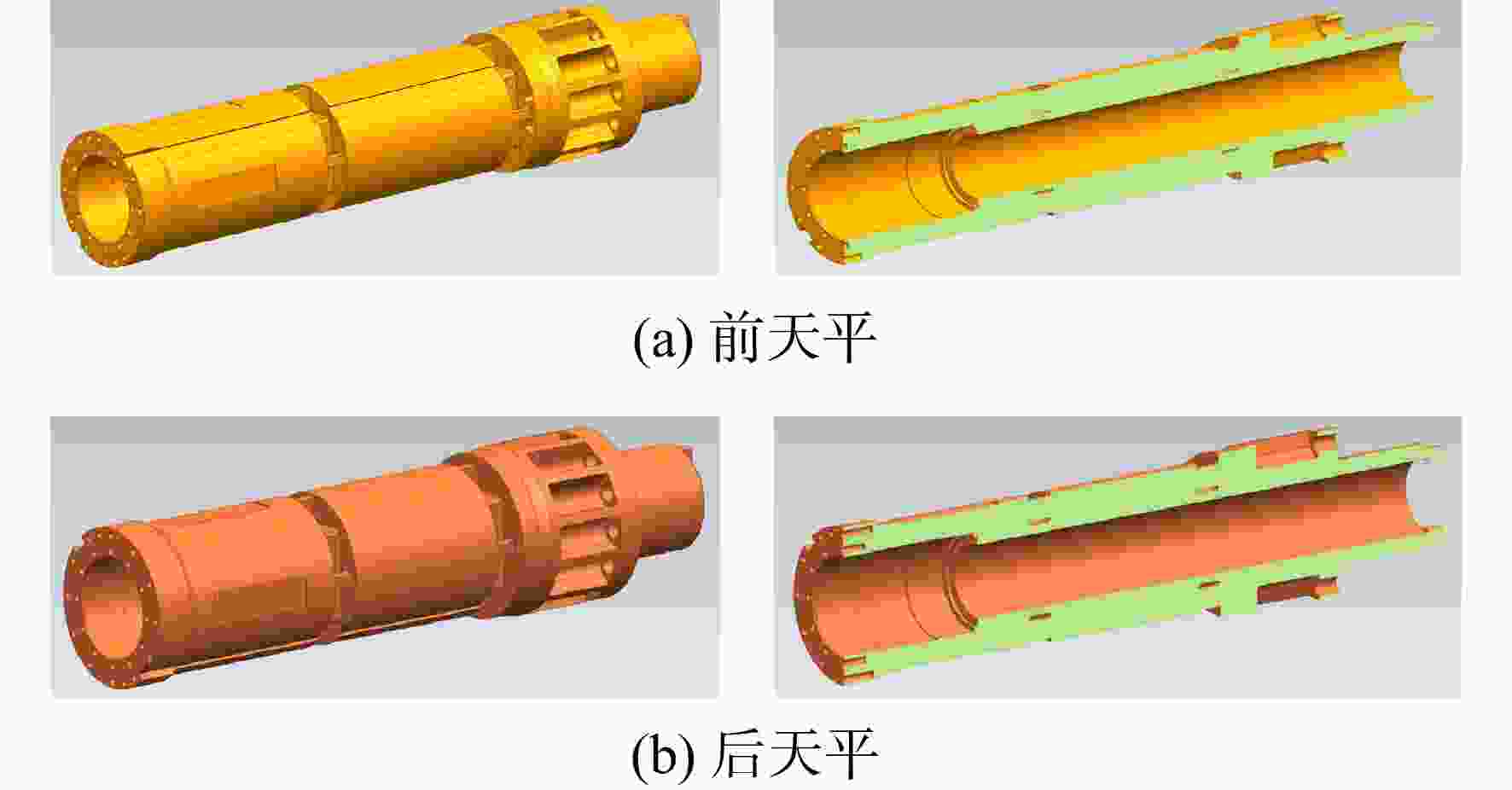

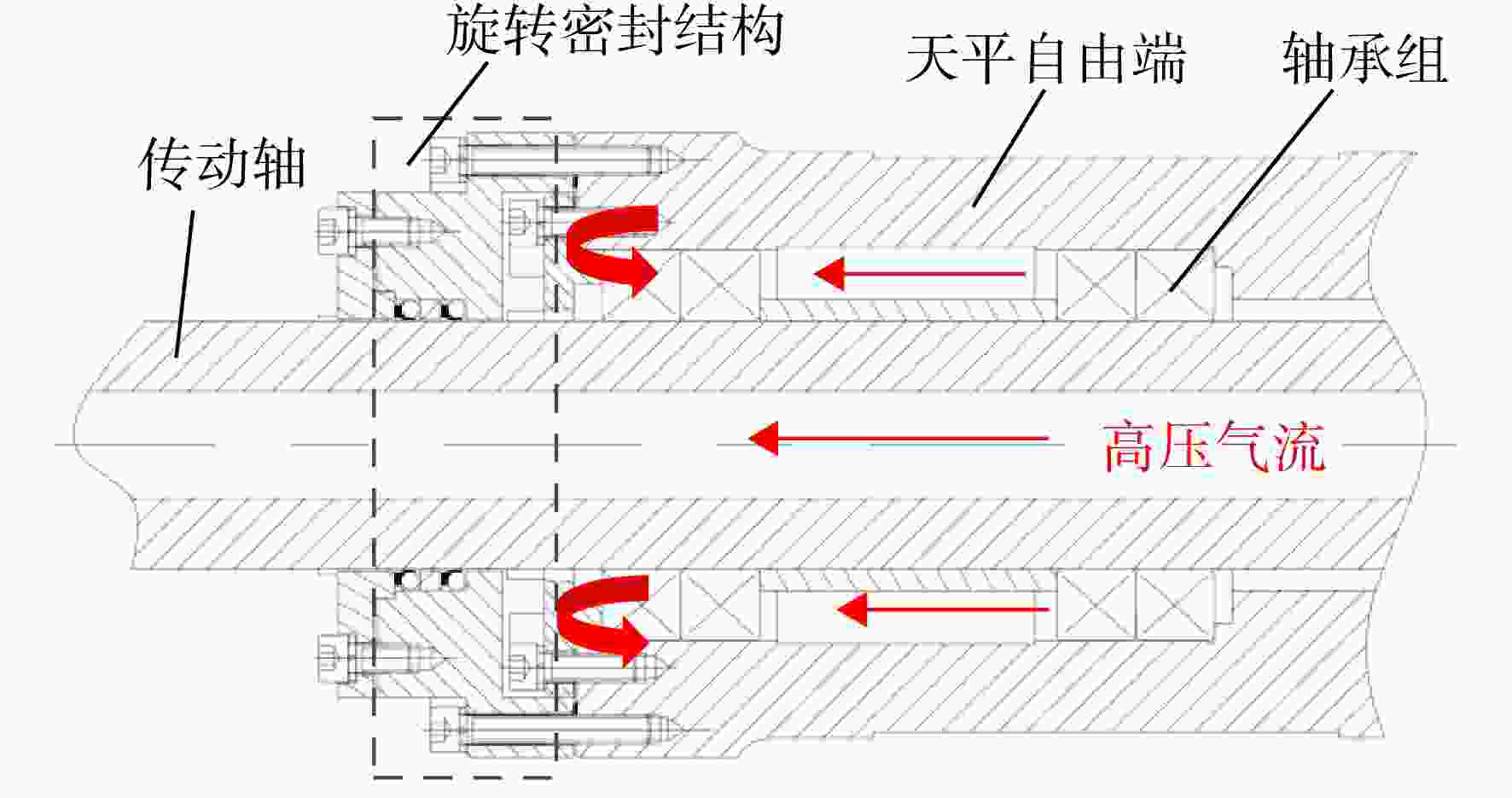

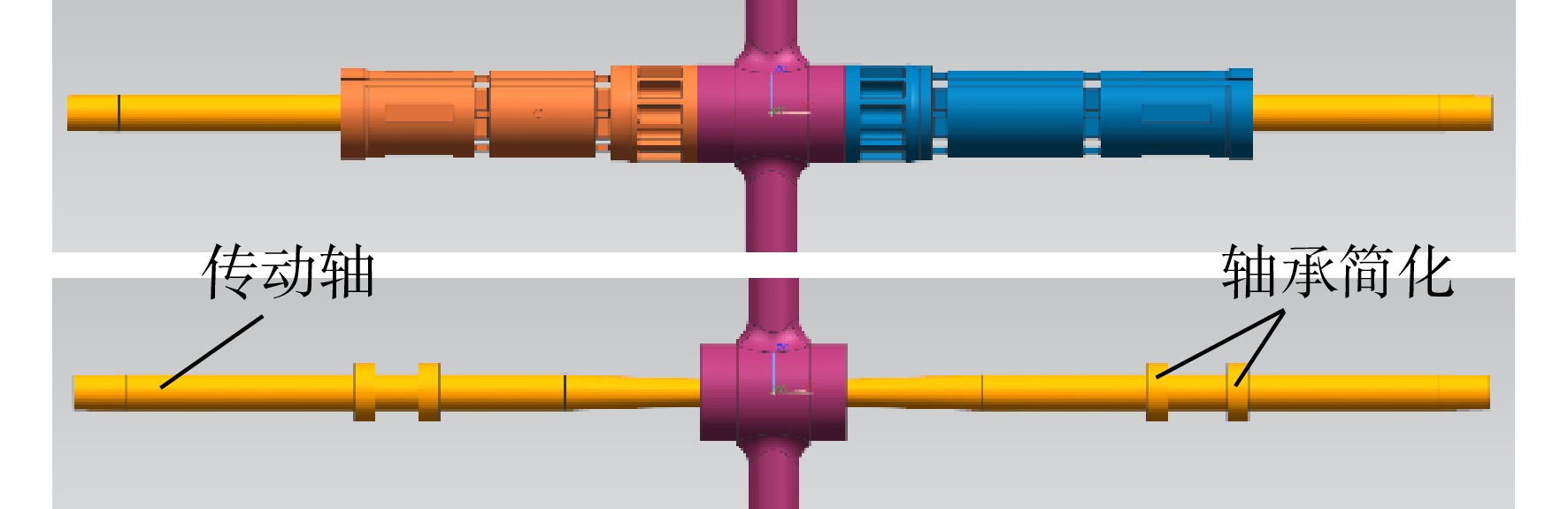

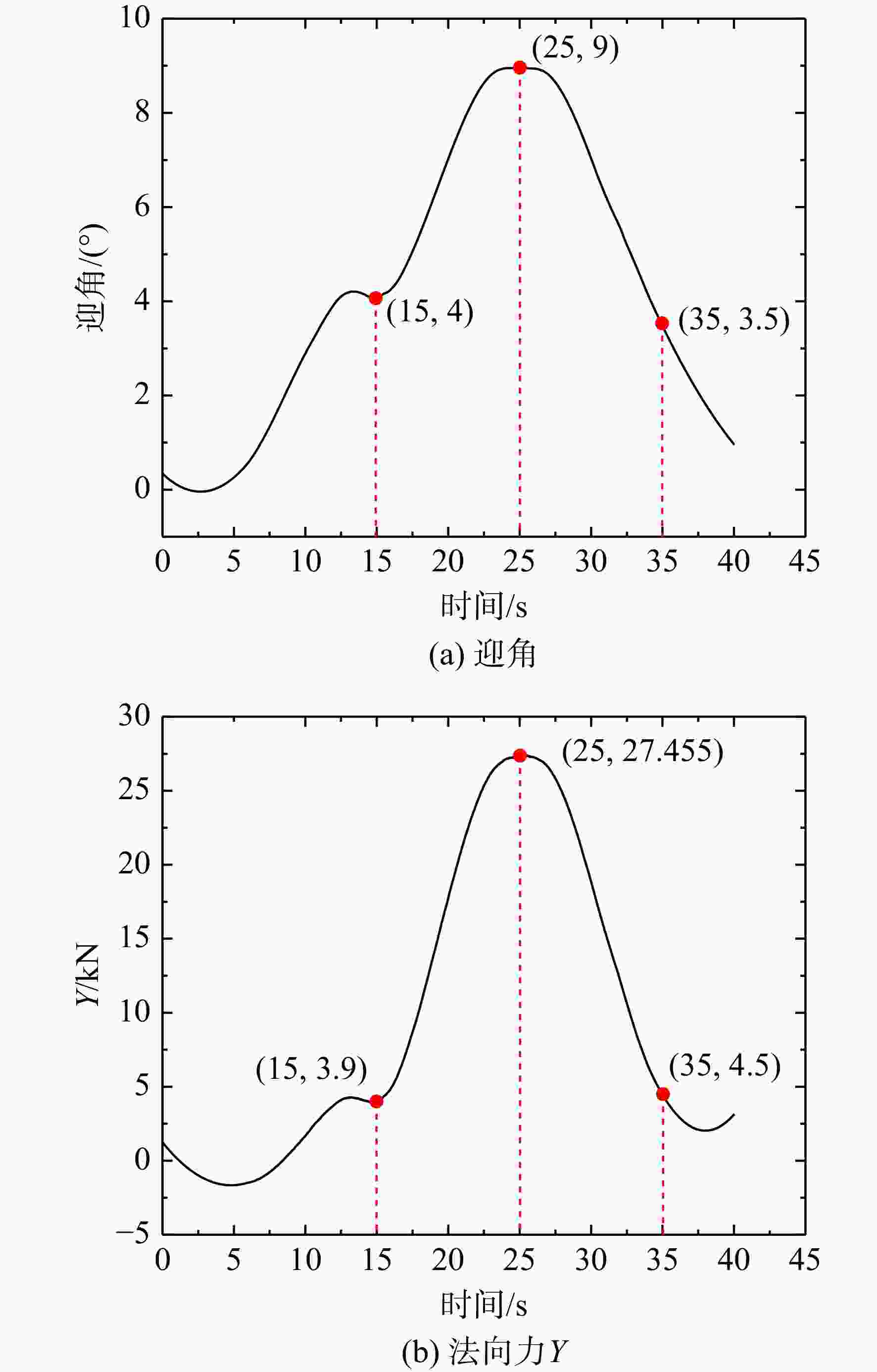

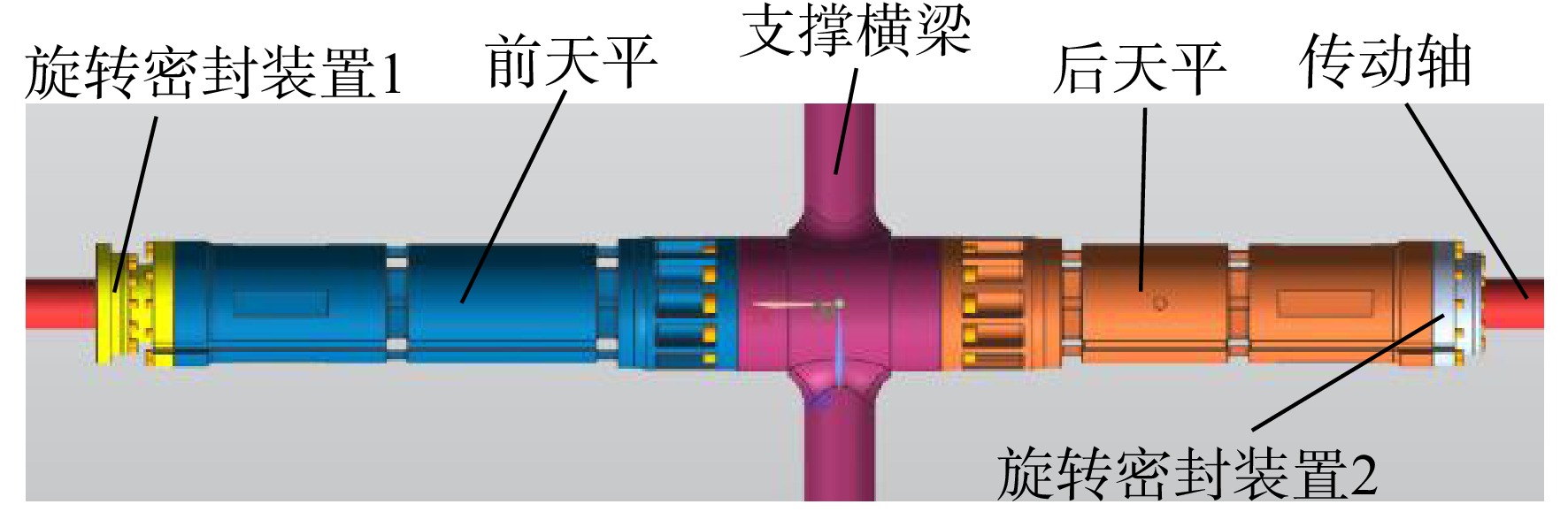

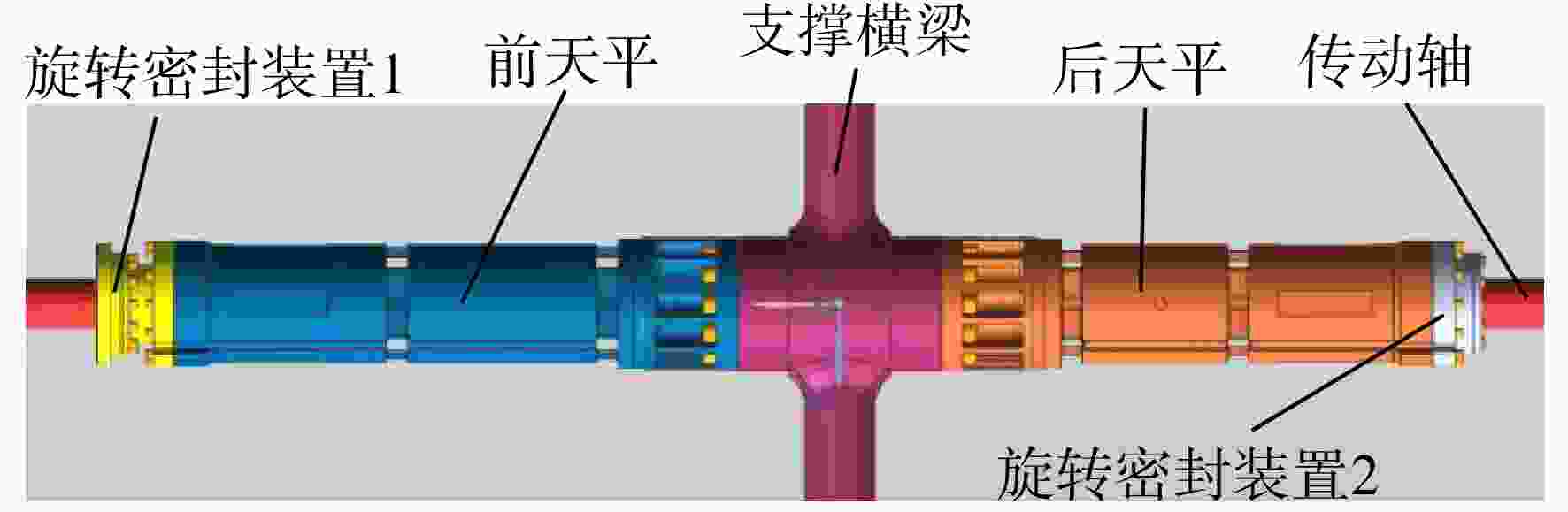

为满足某带横向喷流效应飞行器的虚拟飞行风洞试验需求,采用两台独立的4分量天平、传动轴及支撑横梁等组成测力装置同时分别测量前/后两段模型的气动载荷。通过有限元软件计算每台天平的灵敏度,传动轴对天平的干扰以及高压气体对天平的影响,结果表明:传动轴对天平力分量基本无影响,对俯仰力矩干扰约2.5%,对偏航力矩干扰约8%,压力对前天平的影响小于2%,对后天平的影响小于9%。基于每台天平的静态校准公式,生成了适用于测力装置的气动载荷计算方法,通过模拟加载验证了计算方法的准确性。最后,通过风洞试验检验了带横向喷流效应的虚拟飞行天平测力装置的整体性能。静态校准和风洞试验数据表明:静态校准数据与有限元分析结果基本一致,测力装置性能稳定、测值准确,满足风洞虚拟飞行试验研究要求。

Abstract:To meet the requirements of virtual flight wind tunnel testing for aircraft with lateral jet, the measurement device composed of two independent four-component wind tunnel balances, transmission shaft and supporting crossbeam, etc, was applied to respectively measure the aerodynamic loads of the front/rear two parts model at the same time. By finite element software, the sensitivity of each balance, the interference of transmission shaft and the influence of high-pressure gas on balance were analyzed. The results showed that the transmission shaft had little effect on the force component of the balance, the interference on the pitch moment was about 2.5% and that on the yaw moment was 8%, the impact of pressure on the front balance was less than 2% and that on the rear balance was less than 9%. Based on the static calibration formula of each balance, an aerodynamic load calculation method suitable for measurement device was generated. The correctness of the method was verified through simulated loading. Finally, the performance of the measurement device for aircraft with lateral jet was verified through the wind tunnel tests. The results of static calibration and wind tunnel tests showed that static calibration data were consistent with finite element analysis results, the measurement device had stable performance and accurate measurement values, so it can meet the requirements of virtual flight test research.

-

Key words:

- virtual flight /

- lateral jet /

- wind tunnel balance /

- finite element analysis /

- static calibration /

- wind tunnel test

-

表 1 模型载荷

Table 1. Load of model

名称 Y/N Mz/(N·m) Z/N My/(N·m) 前模型 17100 15300 9900 9000 后模型 18900 17100 11700 10800 表 2 天平设计载荷

Table 2. Design load of balance

名称 Y/N Mz/(N·m) Z/N My/(N·m) 前天平 17100 7610 9900 4406 后天平 18900 8975 11700 5558 表 3 设计载荷作用下,法向力Y和俯仰力矩Mz分量贴片区域的平均应变

Table 3. Average strain of Y and Mz component in paste area under design load

10−6 位置 法向力Y 俯仰力矩Mz M1 M2 M1 M2 L5 L6 L7 L8 L1 L2 L3 L4 L5 L6 L7 L8 L1 L2 L3 L4 前天平 189 189 −188 −188 −198 −198 198 198 −520 −518 517 516 −540 −539 540 539 后天平 162 162 −162 −162 −173 −173 171 171 −586 −586 587 587 −618 −618 613 612 表 4 设计载荷作用下,侧向力Z和偏航力矩My分量贴片区域的平均应变

Table 4. Average strain of Z and My component in paste area under design load

10−6 位置 侧向力Z 偏航力矩My M5 M6 M5 M6 L13 L14 L15 L16 L9 L10 L11 L12 L13 L14 L15 L16 L9 L10 L11 L12 前天平 147 −148 147 −148 −153 154 −153 154 400 −401 400 −402 417 −419 417 −419 后天平 132 −133 132 −133 −129 135 −129 135 474 −478 474 −479 469 −484 468 −484 表 5 设计载荷作用下,各分量电桥信号理论输出值

Table 5. Theoretical output of each bridge under design load

mV 位置 分量 UY UMz UZ UMy 前天平 UY 7.6413 0.1878 UMz 0.4300 20.9025 UZ 5.9510 −0.1186 UMy −0.341 16.1872 后天平 UY 6.6860 0.2002 UMz 0.5755 24.0566 UZ 5.2948 0.0100 UMy 0 19.0671 表 6 设计载荷及内压力作用下,法向力Y和俯仰力矩Mz分量贴片区域的平均应变

Table 6. Average strain of Y and Mz component in paste area under design load and internal pressure

10−6 位置 法向力Y 俯仰力矩Mz M1 M2 M1 M2 L5 L6 L7 L8 L1 L2 L3 L4 L5 L6 L7 L8 L1 L2 L3 L4 前天平 107 107 −270 −270 −302 −301 94 94 −603 −600 435 434 −644 −643 437 436 后天平 73 73 −252 −252 −282 −282 63 63 −675 −675 498 497 −727 −728 505 504 表 7 设计载荷及内压力作用下,侧向力Z和偏航力矩My分量贴片区域的平均应变

Table 7. Average strain of Z and My component in paste area under design load and internal pressure

10−6 位置 侧向力Z 偏航力矩My M5 M6 M5 M6 L13 L14 L15 L16 L9 L10 L11 L12 L13 L14 L15 L16 L9 L10 L11 L12 前天平 22 −274 22 −274 −304 2 −304 2 275 −528 275 −526 266 −571 266 571 后天平 0 −266 0 −266 −264 −6 −264 −6 343 −611 343 −612 333 −625 333 −625 表 8 设计载荷及内压力作用下,各分量电桥信号理论输出值

Table 8. Theoretical output of each bridge under design load and internal pressure

mV 位置 分量 UY UMz UZ UMy 前天平 UY 7.6364 0.1829 UMz 0.4350 20.9173 UZ 5.9460 −0.1038 UMy −0.3460 16.2020 后天平 UY 6.7060 0.2002 UMz 0.5955 24.0666 UZ 5.24472 0.0801 UMy −0.0350 19.1422 表 9 设计载荷作用下,带传动轴状态天平各分量贴片区域平均应变

Table 9. Average strain of each component of balance with transmission shaft under design load

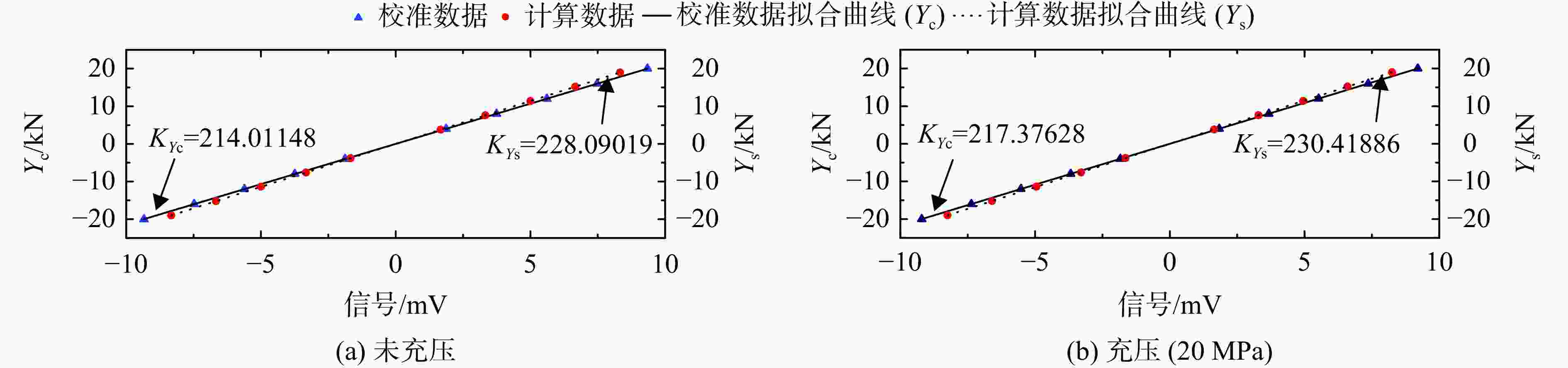

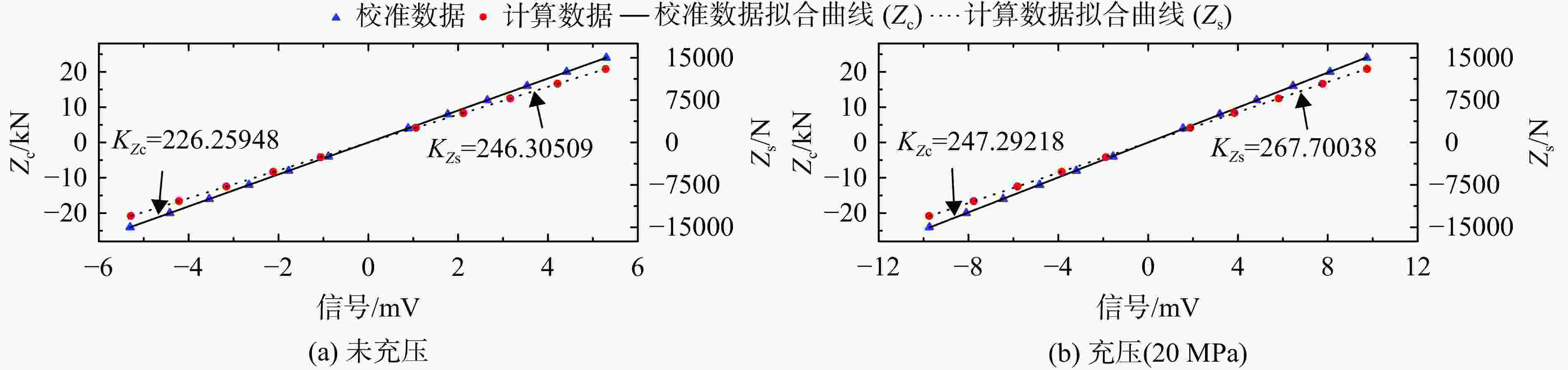

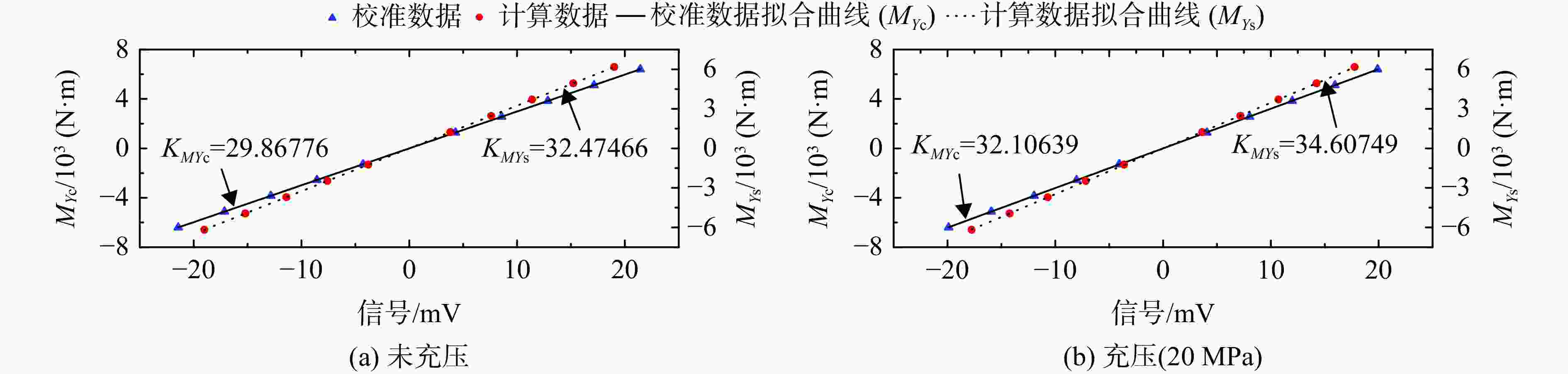

10−6 位置 法向力Y 俯仰力矩Mz 侧向力Z 偏航力矩My 前天平 194 516 148 380 后天平 168 585 132 436 表 10 前天平充压/未充压校准结果

Table 10. Calibration results of front balance with/without pressure

参数 未充压 充压(20 MPa) 力分量/N 力矩分量/(N·m) 力分量/N 力矩分量/(N·m) 法向力Y 侧向力Z 俯仰力矩Mz 偏航力矩My 法向力Y 侧向力Z 俯仰力矩Mz 偏航力矩My 设计载荷 17100 9900 7610 4406 17100 9900 7610 4406 校准载荷 18000 5760 6400 4800 18000 5760 6400 4800 供桥电压/V 9.8853 9.8853 9.8853 9.8853 9.8853 9.8853 9.8853 9.8853 综合加载误差/% 0.11 0.13 0.10 0.12 0.13 0.13 0.12 0.12 综合加载重复性误差/% 0.01 0.01 0.01 0.01 0.02 0.03 0.03 0.02 表 11 后天平充压/未充压校准结果

Table 11. Calibration results of rear balance with/without pressure

参数 未充压 充压(20 MPa) 力分量/N 力矩分量/(N·m) 力分量/N 力矩分量/(N·m) 法向力Y 侧向力Z 俯仰力矩Mz 偏航力矩My 法向力Y 侧向力Z 俯仰力矩Mz 偏航力矩My 设计载荷 18900 11700 8975 5558 18900 11700 8975 5558 校准载荷 23040 21600 6400 6400 23040 21600 6400 6400 供桥电压/V 10.009 10.009 10.009 10.009 10.009 10.009 10.009 10.009 综合加载误差/% 0.12 0.13 0.12 0.13 0.14 0.15 0.12 0.13 综合加载重复性误差/% 0.01 0.01 0.01 0.01 0.02 0.02 0.01 0.02 -

[1] 赖江,赵忠良,李玉平,等. 导弹模型后体横向喷流干扰特性[J]. 航空动力学报,2019,34(2): 469-478. LAI Jiang,ZHAO Zhongliang,LI Yuping,et al. Transverse jet interaction characteristics on rear section of missile model[J]. Journal of Aerospace Power,2019,34(2): 469-478. (in ChineseLAI Jiang, ZHAO Zhongliang, LI Yuping, et al. Transverse jet interaction characteristics on rear section of missile model[J]. Journal of Aerospace Power, 2019, 34(2): 469-478. (in Chinese) [2] SRIVASTAVA B,SRIVASTAVA B. Lateral jet control of a supersonic missile-CFD predictions and comparison to force and moment measurements[R]. AIAA1997-639,1997. [3] SRIVASTAVA B. Lateral jet control of a supersonic missile: computational and experimental comparisons[J]. Journal of Spacecraft and Rockets,1998,35(2): 140-146. doi: 10.2514/2.3321 [4] 陈洪,刘李涛,巫朝君. 8 m×6 m风洞大尺度模型进气道和喷流试验技术[J]. 空气动力学学报,2017,35(6): 875-878. CHEN Hong,LIU Litao,WU Chaojun. Inlet and jet test techniques for large scale model in 8 m×6 m low speed wind tunnel[J]. Acta Aerodynamica Sinica,2017,35(6): 875-878. (in ChineseCHEN Hong, LIU Litao, WU Chaojun. Inlet and jet test techniques for large scale model in 8 m×6 m low speed wind tunnel[J]. Acta Aerodynamica Sinica, 2017, 35(6): 875-878. (in Chinese) [5] 李建强,李耀华,郭旦平,等. 2.4米跨声速风洞推力矢量试验技术[J]. 空气动力学学报,2016,34(1): 20-26. LI Jianqiang,LI Yaohua,GUO Danping,et al. The thrust vectoring experiment technique in the 2.4 m×2.4 m transonic wind tunnel[J]. Acta Aerodynamica Sinica,2016,34(1): 20-26. (in ChineseLI Jianqiang, LI Yaohua, GUO Danping, et al. The thrust vectoring experiment technique in the 2.4 m×2.4 m transonic wind tunnel[J]. Acta Aerodynamica Sinica, 2016, 34(1): 20-26. (in Chinese) [6] MCWATERS M. F-35 conventional mode jet-effects testing methodology[R]. AIAA2015-2404,2015. [7] 赵忠良,吴军强,李浩,等. 高机动导弹气动/运动/控制耦合的风洞虚拟飞行试验技术[J]. 空气动力学学报,2016,34(1): 14-19. ZHAO Zhongliang,WU Junqiang,LI Hao,et al. Wind tunnel based virtual flight testing of aerodyanmics,flight dynamics and flight control for high maneuver missle[J]. Acta Aerodynamica Sinica,2016,34(1): 14-19. (in ChineseZHAO Zhongliang, WU Junqiang, LI Hao, et al. Wind tunnel based virtual flight testing of aerodyanmics, flight dynamics and flight control for high maneuver missle[J]. Acta Aerodynamica Sinica, 2016, 34(1): 14-19. (in Chinese) [8] 赵忠良,吴军强,李浩,等. 2.4 m跨声速风洞虚拟飞行试验技术研究[J]. 航空学报,2016,37(2): 504-512. ZHAO Zhongliang,WU Junqiang,LI Hao,et al. Investigation of virtual flight testing technique based on 2.4 m transonic wind tunnel[J]. Acta Aeronautica et Astronautica Sinica,2016,37(2): 504-512. (in ChineseZHAO Zhongliang, WU Junqiang, LI Hao, et al. Investigation of virtual flight testing technique based on 2.4 m transonic wind tunnel[J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(2): 504-512. (in Chinese) [9] 李浩,赵忠良,范召林. 风洞虚拟飞行试验模拟方法研究[J]. 实验流体力学,2011,25(6): 72-76. LI Hao,ZHAO Zhongliang,FAN Zhaolin. Simulation method for wind tunnel based virtual flight testing[J]. Journal of Experiments in Fluid Mechanics,2011,25(6): 72-76. (in Chinese doi: 10.3969/j.issn.1672-9897.2011.06.014LI Hao, ZHAO Zhongliang, FAN Zhaolin. Simulation method for wind tunnel based virtual flight testing[J]. Journal of Experiments in Fluid Mechanics, 2011, 25(6): 72-76. (in Chinese) doi: 10.3969/j.issn.1672-9897.2011.06.014 [10] 李浩. 风洞虚拟飞行试验相似准则和模拟方法研究[D]. 四川 绵阳: 中国空气动力研究与发展中心,2012. LI Hao. Study on the similarity criteria and simulation method of the wind tunnel based virtual flight testing[D]. Mianyang Sichuan: China Aerodynamics Research and Development Center,2012. (in ChineseLI Hao. Study on the similarity criteria and simulation method of the wind tunnel based virtual flight testing[D]. Mianyang Sichuan: China Aerodynamics Research and Development Center, 2012. (in Chinese) [11] RATLIFF C L,MARQUART E J. Bridging the gap between ground and flight tests: virtual flght testing (VIF)[R]. AIAA-1995-3875,1995. [12] RATLIFF C,MARQUART E. An assessment of a potential test technique: virtual flight testing (VFT) [R]. AIAA95-3472,1995. [13] LAWRENCE F,MILLS B. Status update of the AEDC wind tunnel virtual flight testing development program[R]. AIAA2002-0168,2002. [14] MAGILL J. Design of a wire suspension system for dynamic testing in AEDC 16T[R]. Reno,US: 41st Aerospace Sciences Meeting and Exhibit,2003. [15] MAGILL J C,CATALDI P,MORENCY J R,et al. Demonstration of a wire suspension for wind-tunnel virtual flight testing[J]. Journal of Spacecraft and Rockets,2009,46(3): 624-633. doi: 10.2514/1.39188 [16] PATTINSON J,LOWENBERG M H,GOMAN M G. A multi-degree-of freedom rig for wind tunnel determination of dynamic data[R]. AIAA-2009-5727,2009. [17] GRISHIN I,KHRABROV A,KOLINKO A,et al. Wind tunnel investigation of critical flight regimes using dy-namically scaled actively controlled model in 3 DOF gimbal[R]. St Petersburg,Russia: 29th Congress of the International Council of the Aeronautical Sciences,2014. [18] 向光伟,谢斌,赵忠良,等. 2.4 m×2.4 m跨声速风洞虚拟飞行试验天平研制[J]. 实验流体力学,2014,28(1): 65-69. XIANG Guangwei,XIE Bin,ZHAO Zhongliang,et al. Development of virtual flight test balance for 2.4 m×2.4 m transonic wind tunnel[J]. Journal of Experiments in Fluid Mechanics,2014,28(1): 65-69. (in Chinese doi: 10.11729/syltlx20130015XIANG Guangwei, XIE Bin, ZHAO Zhongliang, et al. Development of virtual flight test balance for 2.4 m×2.4 m transonic wind tunnel[J]. Journal of Experiments in Fluid Mechanics, 2014, 28(1): 65-69. (in Chinese) doi: 10.11729/syltlx20130015 [19] 郭林亮,祝明红,傅澔,等. 一种低速风洞虚拟飞行试验装置的建模与仿真[J]. 空气动力学学报,2017,35(5): 708-717,726. GUO Linliang,ZHU Minghong,FU Hao,et al. Modeling and simulation for a low speed wind tunnel virtual flight test rig[J]. Acta Aerodynamica Sinica,2017,35(5): 708-717,726. (in ChineseGUO Linliang, ZHU Minghong, FU Hao, et al. Modeling and simulation for a low speed wind tunnel virtual flight test rig[J]. Acta Aerodynamica Sinica, 2017, 35(5): 708-717, 726. (in Chinese) [20] 张石玉,赵俊波,付增良,等. 类F-16飞行器风洞虚拟飞行试验研究[J]. 实验流体力学,2020,34(1): 49-54,86. ZHANG Shiyu,ZHAO Junbo,FU Zengliang,et al. Wind tunnel based virtual flight testing research of F-16 fighter[J]. Journal of Experiments in Fluid Mechanics,2020,34(1): 49-54,86. (in ChineseZHANG Shiyu, ZHAO Junbo, FU Zengliang, et al. Wind tunnel based virtual flight testing research of F-16 fighter[J]. Journal of Experiments in Fluid Mechanics, 2020, 34(1): 49-54, 86. (in Chinese) [21] 王延灵,卜忱,王建锋,等. 8 m低速风洞虚拟飞行试验技术研究[J]. 飞行力学,2021,39(5): 71-76,94. WANG Yanling,BU Chen,WANG Jianfeng,et al. Investigation of virtual flight test technique based on 8 m low speed wind tunnel[J]. Flight Dynamics,2021,39(5): 71-76,94. (in ChineseWANG Yanling, BU Chen, WANG Jianfeng, et al. Investigation of virtual flight test technique based on 8 m low speed wind tunnel[J]. Flight Dynamics, 2021, 39(5): 71-76, 94. (in Chinese) [22] 苗磊,李耀华,李建强,等. 某飞行器推力矢量试验测力装置研制[J]. 航空动力学报,2020,35(12): 2521-2531. MIAO Lei,LI Yaohua,LI Jianqiang,et al. Development of force measuring device for an aircraft thrust vectoring test[J]. Journal of Aerospace Power,2020,35(12): 2521-2531. (in ChineseMIAO Lei, LI Yaohua, LI Jianqiang, et al. Development of force measuring device for an aircraft thrust vectoring test[J]. Journal of Aerospace Power, 2020, 35(12): 2521-2531. (in Chinese) [23] 罗华云,赖传兴,王月贵,等. 喷管模型试验器六分量天平校准技术[J]. 航空动力学报,2013,28(1): 67-73. LUO Huayun,LAI Chuanxing,WANG Yuegui,et al. Six-component balance calibration technology for nozzle model testing facility[J]. Journal of Aerospace Power,2013,28(1): 67-73. (in ChineseLUO Huayun, LAI Chuanxing, WANG Yuegui, et al. Six-component balance calibration technology for nozzle model testing facility[J]. Journal of Aerospace Power, 2013, 28(1): 67-73. (in Chinese) [24] AIAA. Calibration and use of internal strain gage balances with application to wind tunnel testing: AIAA R-091-2003[S]. Reston,US: AIAA,2003. [25] AIAA. Calibration and use of internal strain gage balances with application to wind tunnel testing: AIAA R-091A-2020[S]. Reston,US: AIAA,2020. [26] 苗磊,李建强,李耀华,等. 风洞天平静态校准与使用状态一致性研究[J]. 中国测试,2020,46(8): 158-164. MIAO Lei,LI Jianqiang,LI Yaohua,et al. Study on consistency between static calibration and service state of wind tunnel balance[J]. China Measurement & Test,2020,46(8): 158-164. (in Chinese doi: 10.11857/j.issn.1674-5124.2019010027MIAO Lei, LI Jianqiang, LI Yaohua, et al. Study on consistency between static calibration and service state of wind tunnel balance[J]. China Measurement & Test, 2020, 46(8): 158-164. (in Chinese) doi: 10.11857/j.issn.1674-5124.2019010027 -

下载:

下载: