Influence of trailing edge designs of squealer tips on aerodynamic performance of high-pressure turbine

-

摘要:

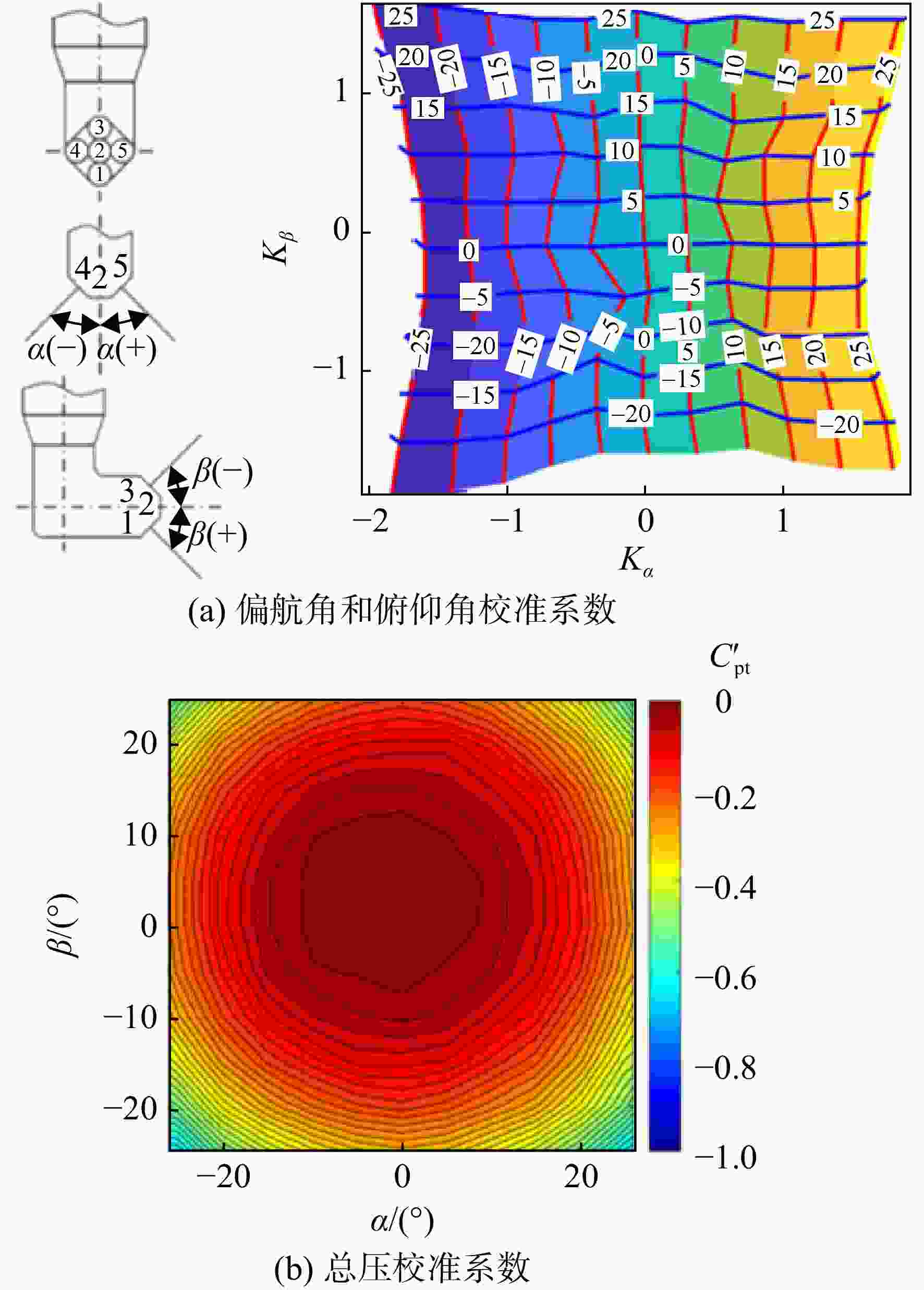

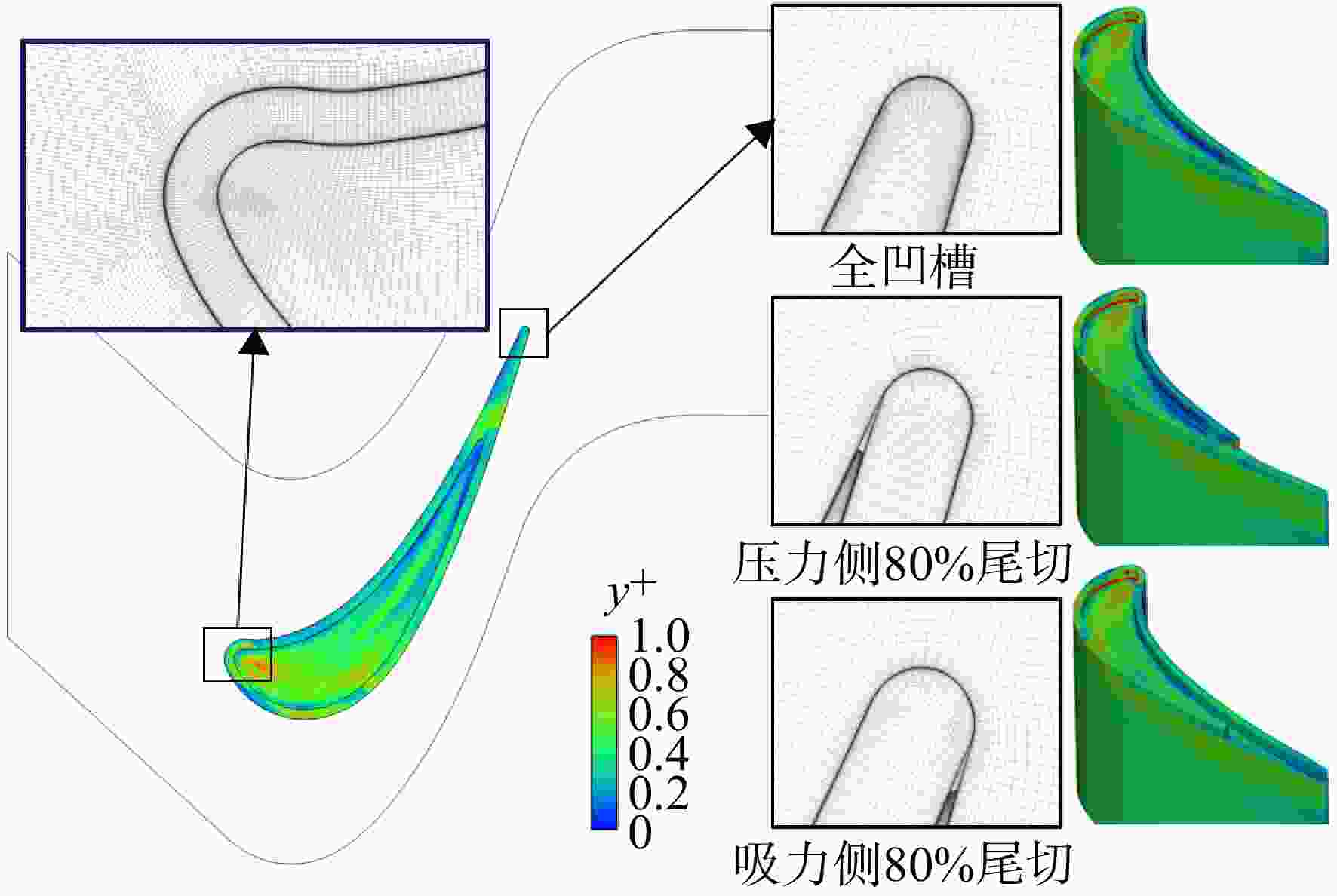

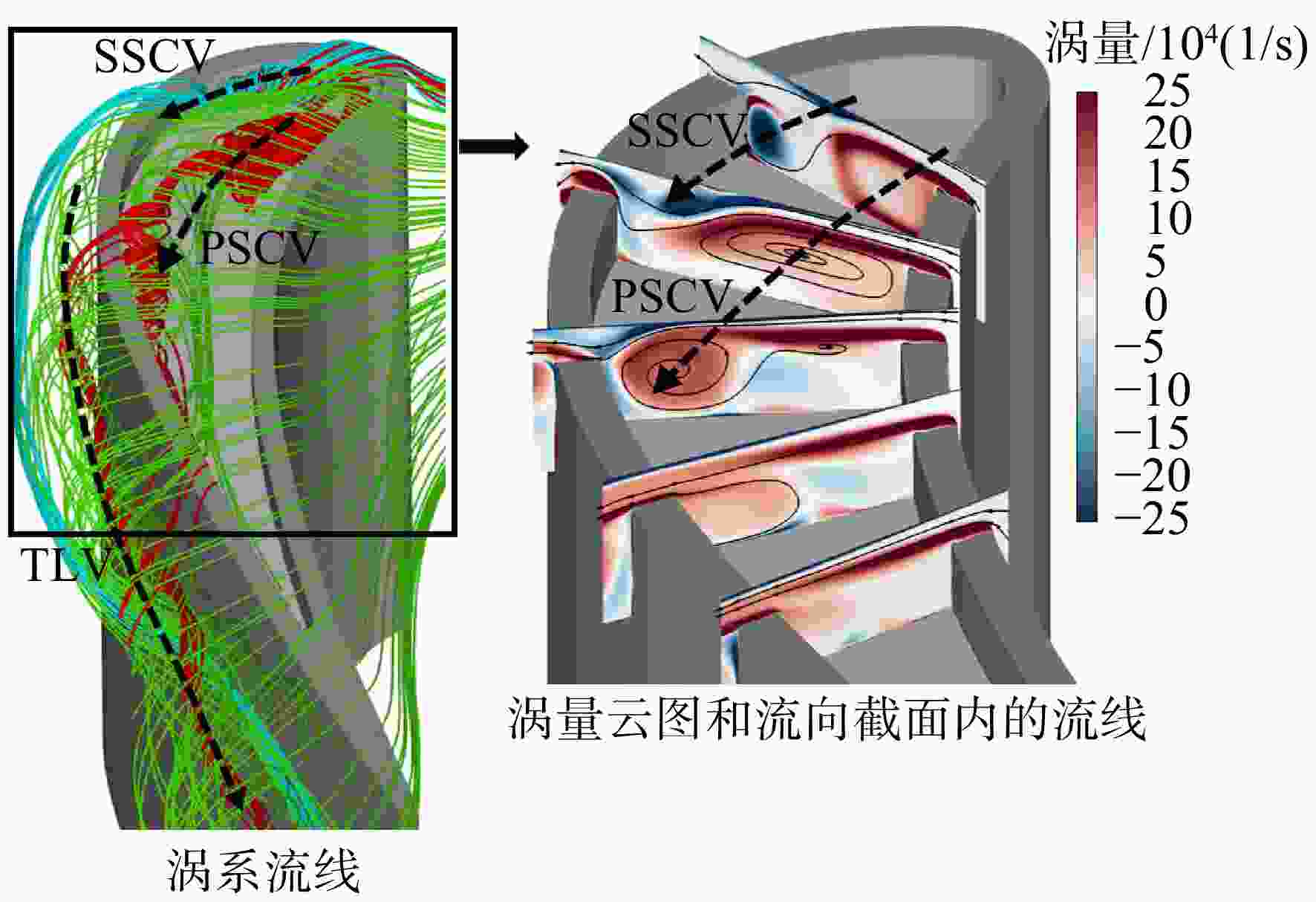

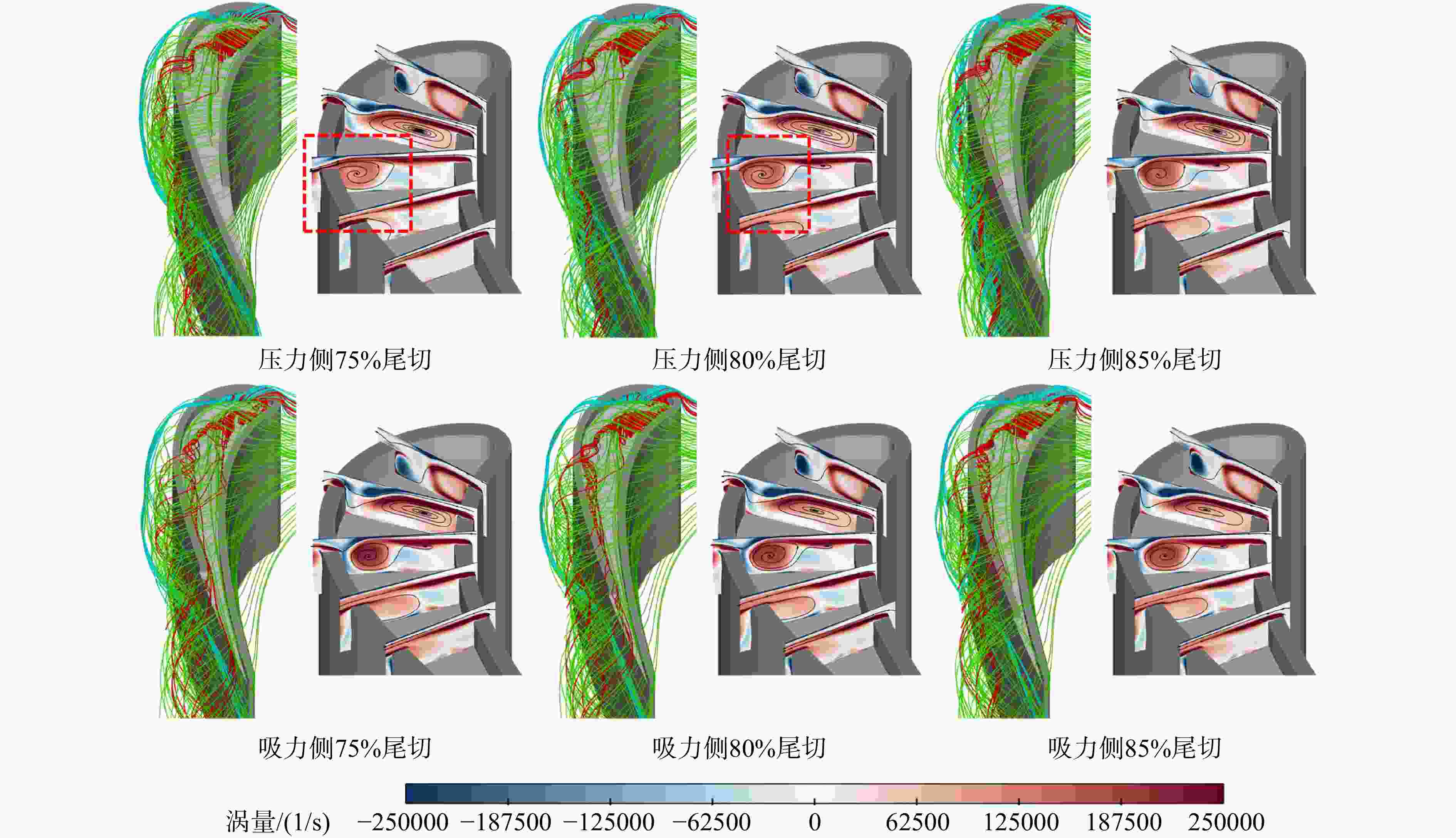

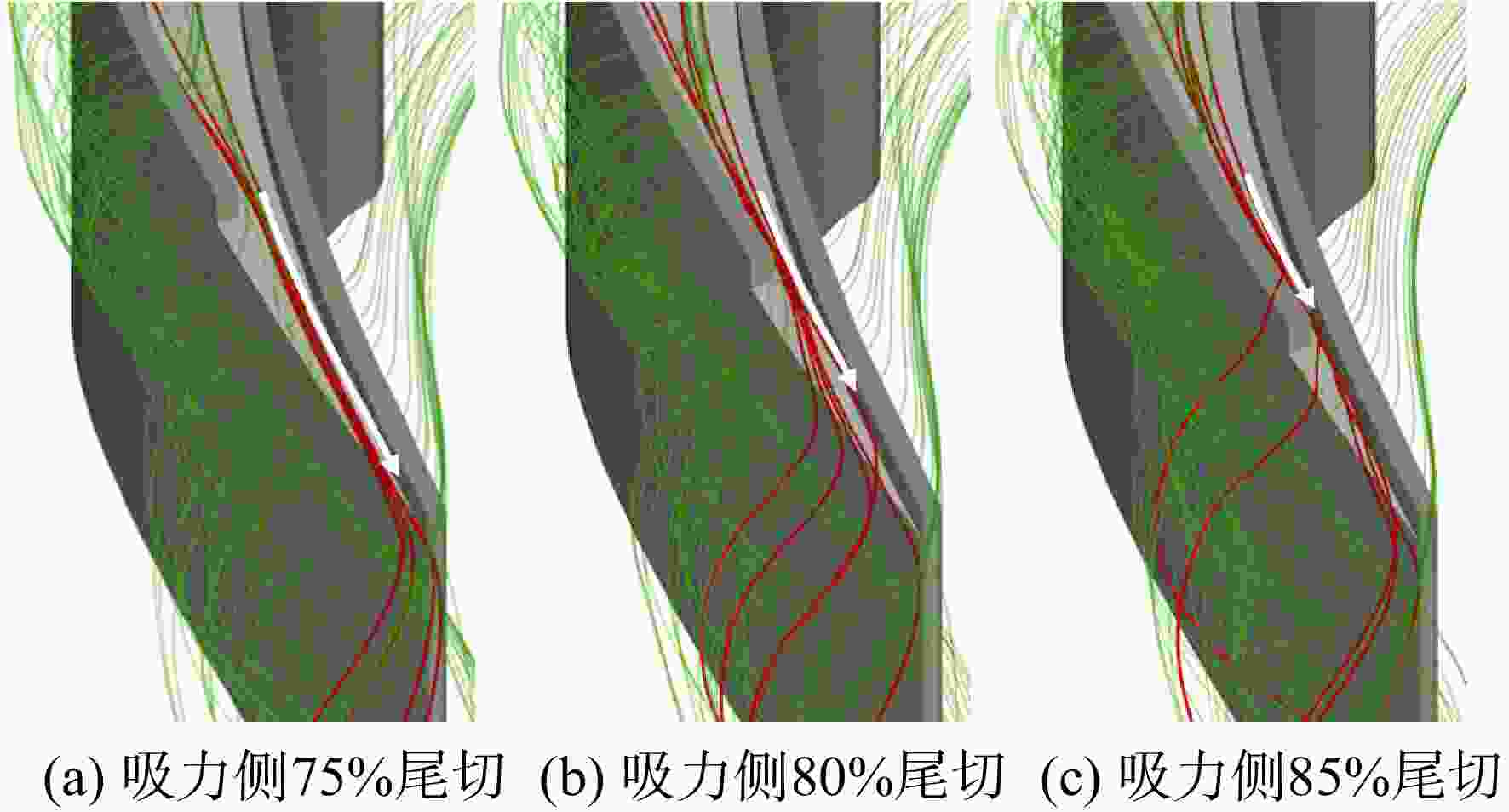

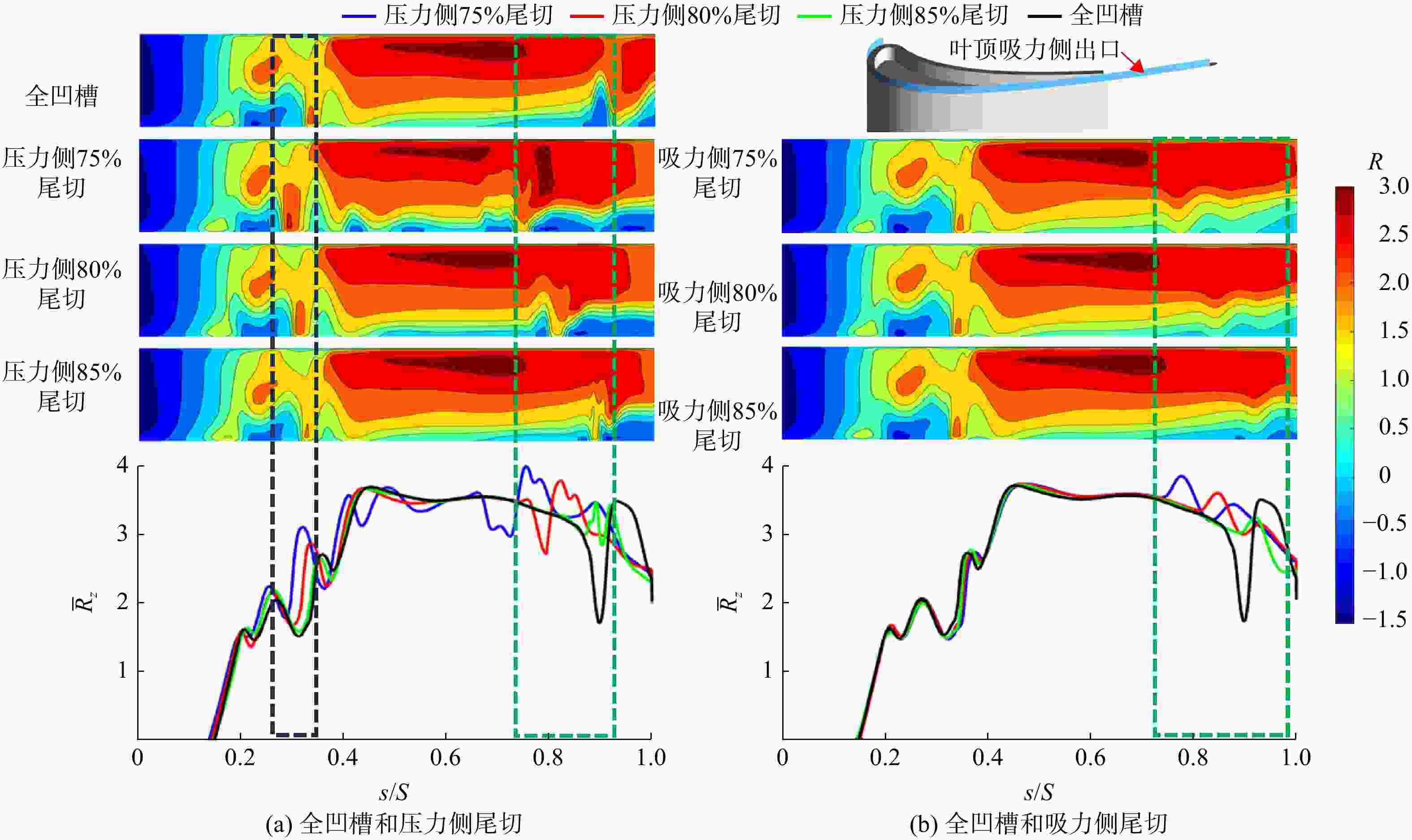

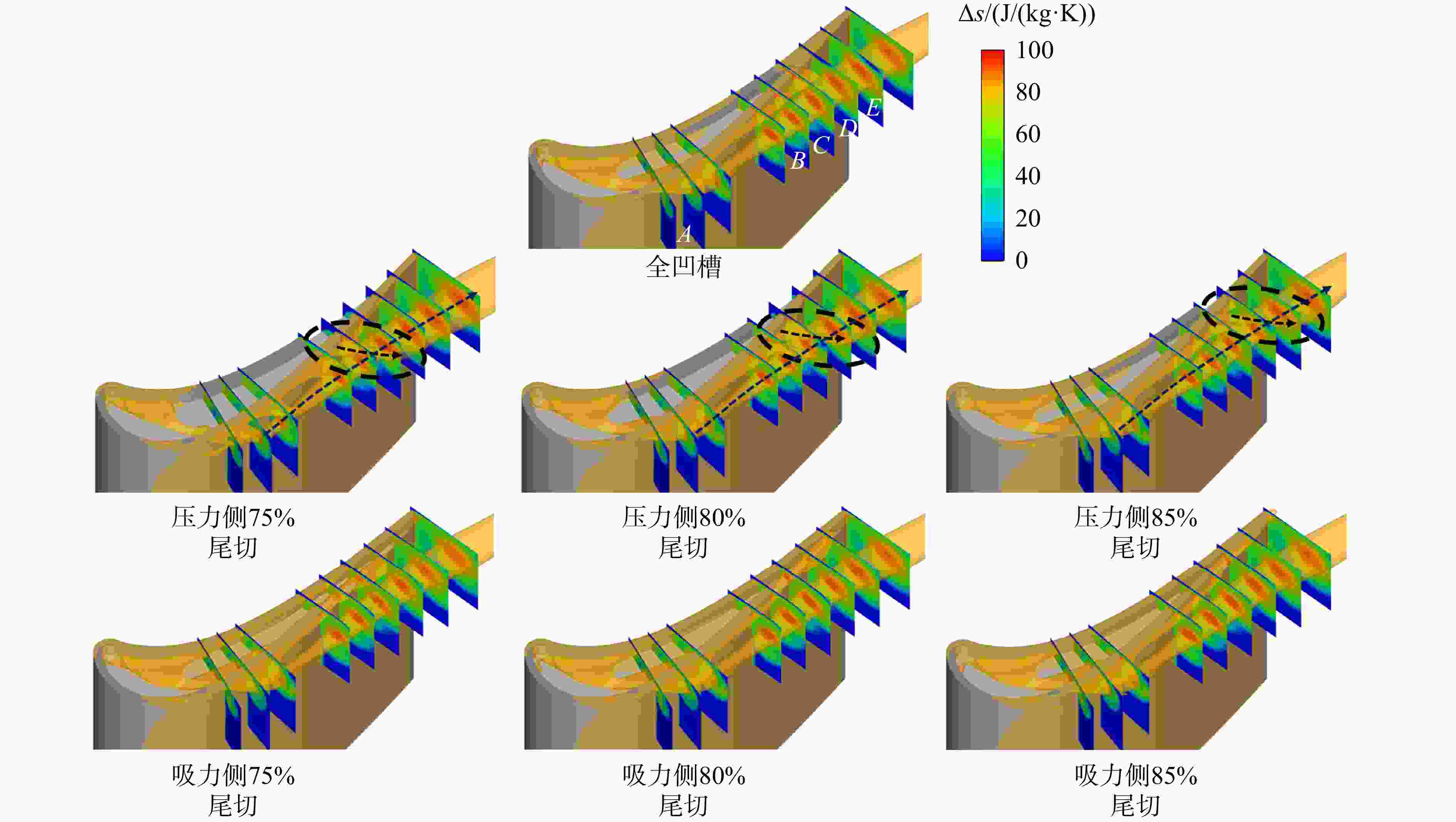

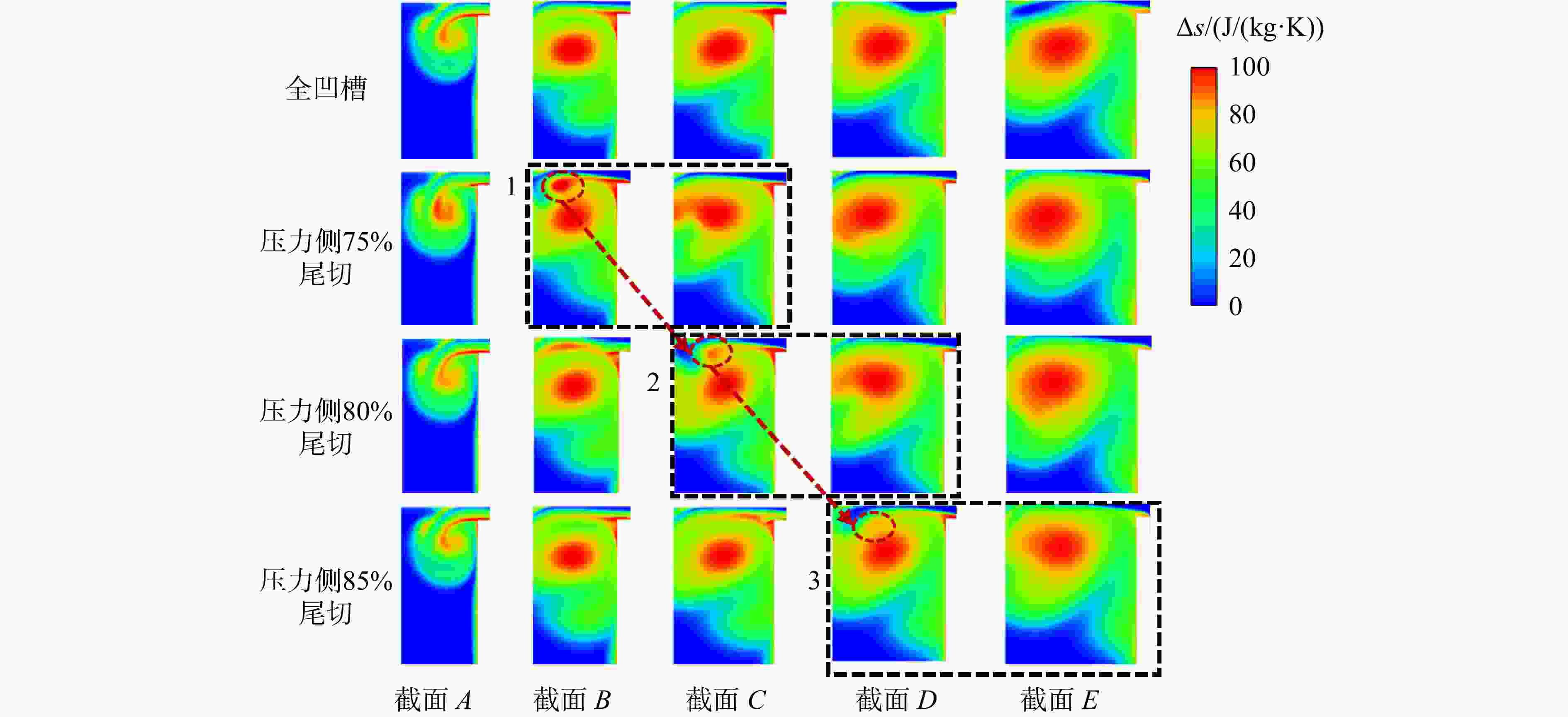

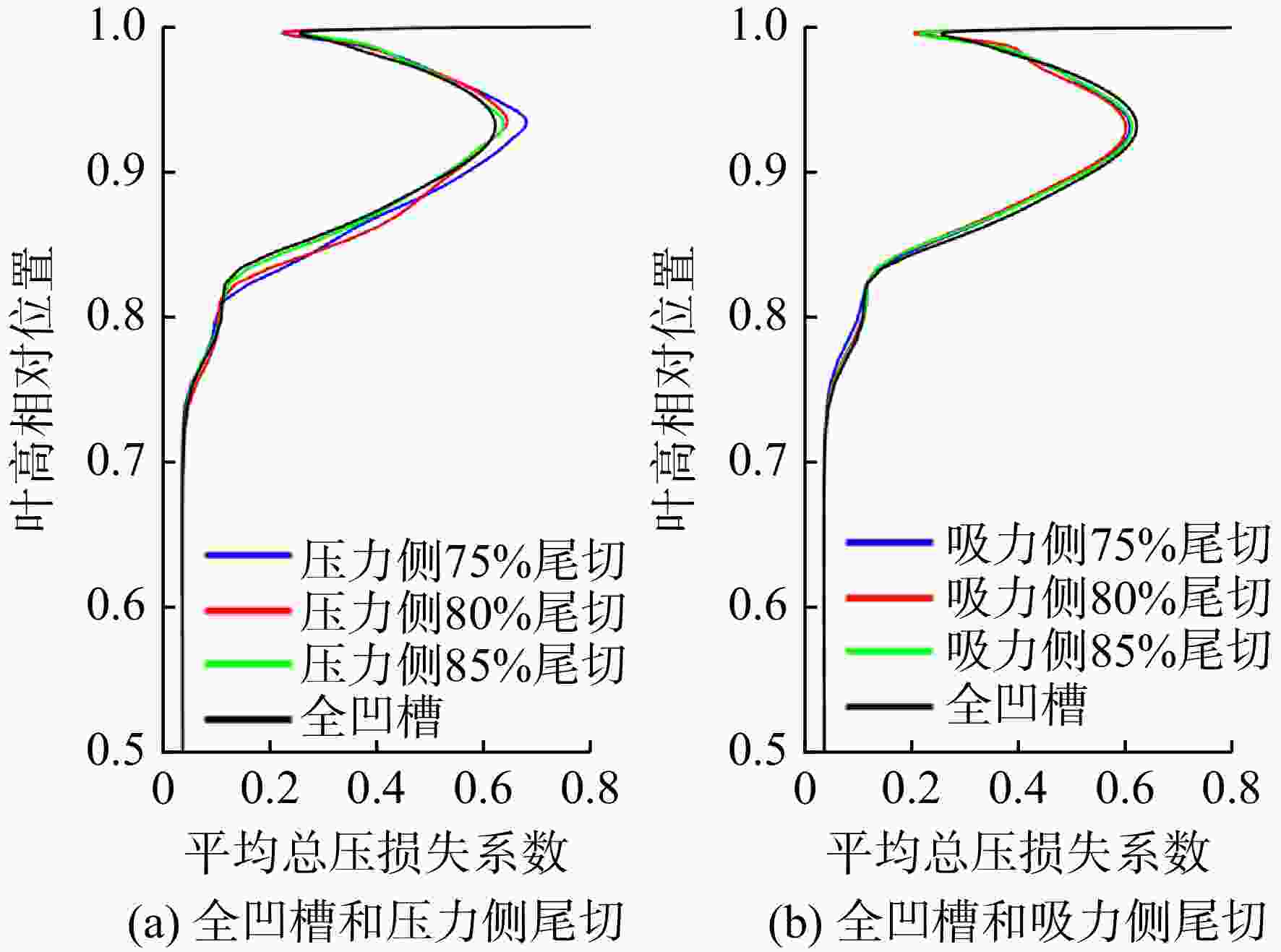

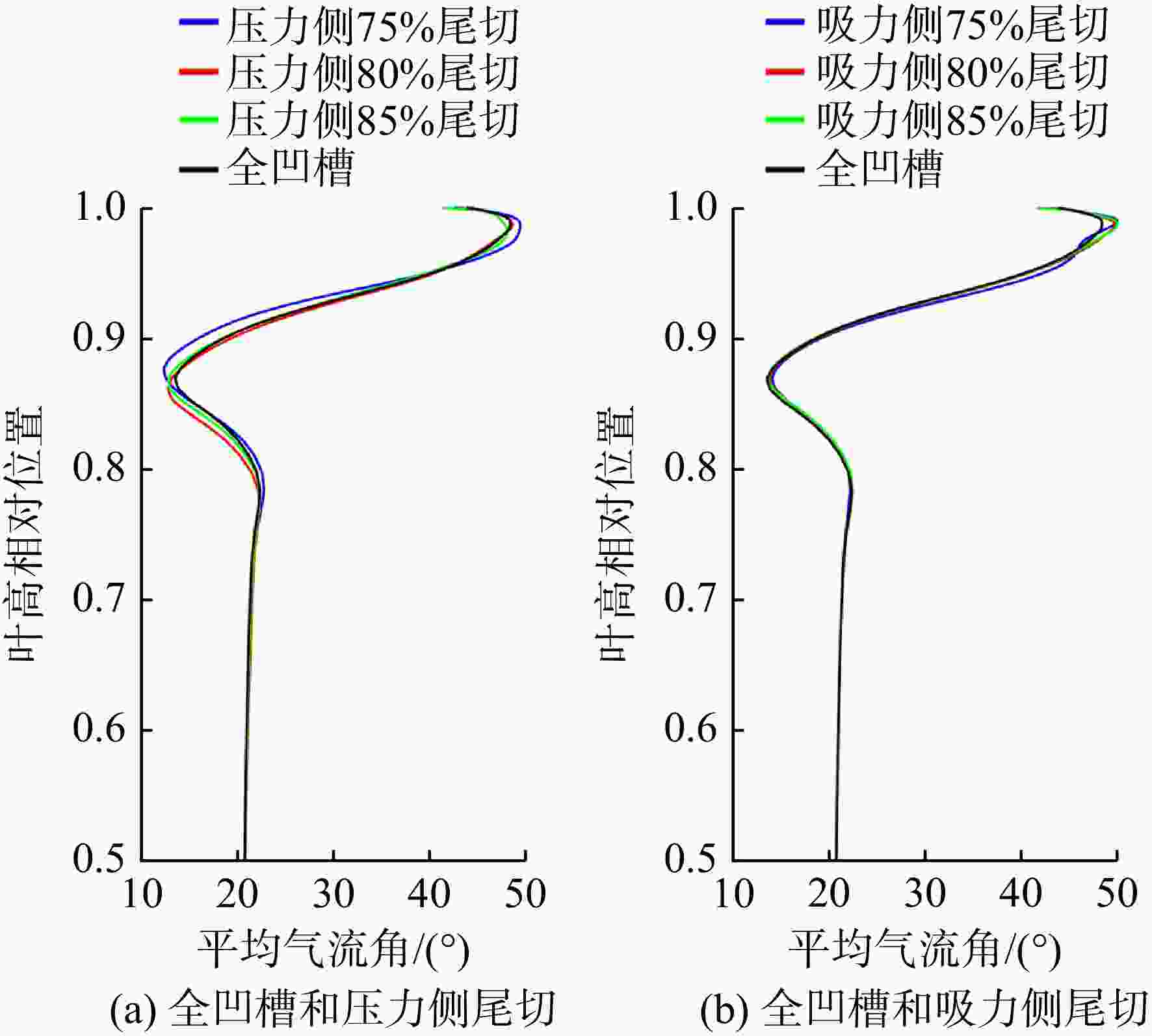

针对凹槽叶尖,设计全凹槽、压力侧尾切、吸力侧尾切尾缘构型,研究不同尾缘构型及尾切位置对叶尖流动机理及气动性能影响规律。结果表明:压力侧尾切叶尖会导致凹槽涡泄漏位置前移,并且在吸力侧叶尖相应位置附近形成尾切涡,从而导致尾缘下游总压损失增大,最多增加了7.1%;吸力侧尾切叶尖凹槽内流动从切除位置流出而非横跨吸力侧肋边泄漏,总压损失相对减小,最多减小了4.6%。相较于全凹槽叶尖构型和压力侧尾切构型,吸力侧尾切构型具有更优的气动性能。

Abstract:In this article, full cavity squealer tip and several pressure side and suction side cutback blade tips were designed, their detailed flow field and aerodynamic performance were compared with full cavity squealer tip numerically, including vortices inside cavity and flows around blade tip trailing edge, differences in tip leakage flow rate, downstream total pressure loss and entropy rise. The result indicated that pressure side cutback designs caused the cavity vortex leak earlier compared with full cavity tip, a small vortex formed at cut region leading to increase in total pressure loss of 7.1% at most; flow inside cavity left at cut region for suction side cutback designs instead of crossing over cavity wall, downstream total pressure loss was relatively smaller, with the reduction of 4.6% at most. Compared with full cavity and pressure side cutback squealer tip, suction side cutback designs have better aerodynamic performance.

-

表 1 试验边界条件

Table 1. Experimental boundary conditions

参数 数值 进口总压 $ {p}_{\mathrm{i}\mathrm{n}}^{*} $/Pa 140 000 进口总温 $ {T}_{\mathrm{i}\mathrm{n}}^{*} $/K 328 出口静压 $ {p}_{\mathrm{i}\mathrm{n}} $/Pa 101 325 出口马赫数 0.65 进口雷诺数(基于叶片轴向弦长) 306 000 进口湍流度/% 5 -

[1] BUNKER R S. A review of turbine blade tip heat transfer[J]. Annals of the New York Academy of Sciences,2001,934(1): 64-79. doi: 10.1111/j.1749-6632.2001.tb05843.x [2] BUNKER R S. Axial turbine blade tips: function,design,and durability[J]. Journal of Propulsion and Power,2006,22(2): 271-285. doi: 10.2514/1.11818 [3] YAMAMOTO A. Interaction mechanisms between tip leakage flow and the passage vortex in a linear turbine rotor cascade[J]. Journal of Turbomachinery,1988,110(3): 329-338. doi: 10.1115/1.3262201 [4] 王大磊,朴英,陈美宁. 高压涡轮转子间隙泄漏流动的非定常特征研究[J]. 航空动力学报,2012,27(11): 2569-2576. WANG Dalei,PIAO Ying,CHEN Meining. Study of unsteady tip leakage flow characteristic in high pressure turbine stage[J]. Journal of Aerospace Power,2012,27(11): 2569-2576. (in Chinese WANG Dalei, PIAO Ying, CHEN Meining . Study of unsteady tip leakage flow characteristic in high pressure turbine stage[J]. Journal of Aerospace Power,2012 ,27 (11 ):2569 -2576 . (in Chinese)[5] 魏佐君,段文华,乔渭阳,等. 涡轮转子叶尖泄漏涡涡核稳定性及控制[J]. 航空动力学报,2018,33(9): 2139-2149. WEI Zuojun,DUAN Wenhua,QIAO Weiyang,et al. Analysis and control of tip-leakage vortex core stability of turbine rotor[J]. Journal of Aerospace Power,2018,33(9): 2139-2149. (in Chinese WEI Zuojun, DUAN Wenhua, QIAO Weiyang, et al . Analysis and control of tip-leakage vortex core stability of turbine rotor[J]. Journal of Aerospace Power,2018 ,33 (9 ):2139 -2149 . (in Chinese)[6] ANTO K,XUE S,NG W F,et al. Effects of tip clearance gap and exit Mach number on turbine blade tip and near-tip heat transfer[R]. ASME GT-2013-94345,2013. [7] COULL J D,ATKINS N R. The influence of boundary conditions on tip leakage flow[J]. Journal of Turbomachinery,2015,137(6): 061005. doi: 10.1115/1.4028796 [8] KRISHNABABU S K,NEWTON P J,DAWES W N,et al. Aerothermal investigations of tip leakage flow in axial flow turbines: Part I: effect of tip geometry and tip clearance gap[J]. Journal of Turbomachinery,2009,131(1): 011006. doi: 10.1115/1.2950068 [9] 高杰,郑群,张曦,等. 涡轮叶顶泄漏涡非定常破碎特性分析[J]. 推进技术,2016,37(2): 242-249. GAO Jie,ZHENG Qun,ZHANG Xi,et al. Analysis of unsteady breakdown characteristics of tip leakage vortex in turbines[J]. Journal of Propulsion Technology,2016,37(2): 242-249. (in Chinese GAO Jie, ZHENG Qun, ZHANG Xi, et al . Analysis of unsteady breakdown characteristics of tip leakage vortex in turbines[J]. Journal of Propulsion Technology,2016 ,37 (2 ):242 -249 . (in Chinese)[10] TALLMAN J,LAKSHMINARAYANA B. Numerical simulation of tip leakage flows in axial flow turbines,with emphasis on flow physics: part Ⅰ effect of tip clearance height[J]. Journal of Turbomachinery,2001,123(2): 314-323. doi: 10.1115/1.1368881 [11] 傅力宏,张雪辉,陈海生,等. 涡轮叶顶泄漏控制研究进展[J]. 工程热物理学报,2023,44(5): 1177-1198. FU Lihong,ZHANG Xuehui,CHEN Haisheng,et al. Research progress of turbine tip leakage control[J]. Journal of Engineering Thermophysics,2023,44(5): 1177-1198. (in Chinese FU Lihong, ZHANG Xuehui, CHEN Haisheng, et al . Research progress of turbine tip leakage control[J]. Journal of Engineering Thermophysics,2023 ,44 (5 ):1177 -1198 . (in Chinese)[12] AZAD G S,HAN J C,BOYLE R J. Heat transfer and flow on the squealer tip of a gas turbine blade[J]. Journal of Turbomachinery,2000,122(4): 725-732. doi: 10.1115/1.1311284 [13] KWAK J S,HAN J C. Heat transfer coefficient and film-cooling effectiveness on the squealer tip of a gas turbine blade[R]. ASME GT2002-30555,2002. [14] COULL J D,ATKINS N R,HODSON H P. High efficiency cavity winglets for high pressure turbines[R]. ASME GT2014-25261,2014. [15] ZOU Zhengping,SHAO Fei,LI Yiran,et al. Dominant flow structure in the squealer tip gap and its impact on turbine aerodynamic performance[J]. Energy,2017,138: 167-184. doi: 10.1016/j.energy.2017.07.047 [16] HEYES F J G,HODSON H P,DAILEY G M. The effect of blade tip geometry on the tip leakage flow in axial turbine cascades[J]. Journal of Turbomachinery,1992,114(3): 643-651. doi: 10.1115/1.2929188 [17] 李伟,乔渭阳,许开富,等. 涡轮叶尖镶嵌肋条对泄漏流场的影响[J]. 航空动力学报,2008,23(8): 1523-1529. LI Wei,QIAO Weiyang,XU Kaifu,et al. Influence of squealer tip on tip leakage flow in axial turbine[J]. Journal of Aerospace Power,2008,23(8): 1523-1529. (in Chinese LI Wei, QIAO Weiyang, XU Kaifu, et al . Influence of squealer tip on tip leakage flow in axial turbine[J]. Journal of Aerospace Power,2008 ,23 (8 ):1523 -1529 . (in Chinese)[18] CAMCI C,DEY D,KAVURMACIOGLU L. Tip leakage flows near partial squealer rims in an axial flow turbine stage[R]. ASME GT2003-38979,2003. [19] LEE S W,LEE S E. Tip gap flow characteristics in a turbine cascade equipped with pressure-side partial squealer rims[J]. International Journal of Heat and Fluid Flow,2014,50: 369-377. doi: 10.1016/j.ijheatfluidflow.2014.09.008 [20] KIM J H,LEE S Y,CHUNG J T. Numerical analysis of the aerodynamic performance & heat transfer of a transonic turbine with a partial squealer tip[J]. Applied Thermal Engineering,2019,152: 878-889. doi: 10.1016/j.applthermaleng.2019.02.066 [21] 王掩刚,刘波,姜健,等. 涡轮叶片尾缘开缝喷气的数值模拟和试验研究[J]. 航空动力学报,2006,21(3): 474-479. WANG Yangang,LIU Bo,JIANG Jian,et al. Experiment and numerical simulation investigation of turbine blade with trailing edge ejection[J]. Journal of Aerospace Power,2006,21(3): 474-479. (in Chinese WANG Yangang, LIU Bo, JIANG Jian, et al . Experiment and numerical simulation investigation of turbine blade with trailing edge ejection[J]. Journal of Aerospace Power,2006 ,21 (3 ):474 -479 . (in Chinese)[22] LU S,MA H,ZHANG Q,et al. Cutback squealer tip trailing edge cooling performance[J]. International Journal of Heat and Mass Transfer,2020,154: 119632. doi: 10.1016/j.ijheatmasstransfer.2020.119632 [23] CHENG Fengna,ZHANG Jingzhou,ZHANG Jingyang,et al. Effect of cutbacks on tip leakage flow and film-cooling effectiveness of a turbine blade tip under relative moving condition[J]. Transactions of the Japan Society for Aeronautical and Space Sciences,2021,64(6): 293-303. doi: 10.2322/tjsass.64.293 [24] LU S,ZHANG Q,HE L. A high-speed disk rotor rig design for tip aerothermal research[J]. Journal of Turbomachinery,2022,144(5): 051002. doi: 10.1115/1.4052603 [25] JIANG H,PENG X,XIE W,et al. Development of a large-scale high-speed linear cascade rig for turbine blade tip heat transfer study[J]. Aerospace,2022,9(11): 695. doi: 10.3390/aerospace9110695 [26] XIE W,LU S,JIANG H,et al. Interaction mechanism of transonic squealer tip cooling with the effect of high-speed relative casing motion[J]. Journal of Turbomachinery,2023,145(8): 081016. doi: 10.1115/1.4062278 [27] DENTON J D. Loss mechanisms in turbomachines[J]. Journal of Turbomachinery,1993,115(4): 621-656. doi: 10.1115/1.2929299 -

下载:

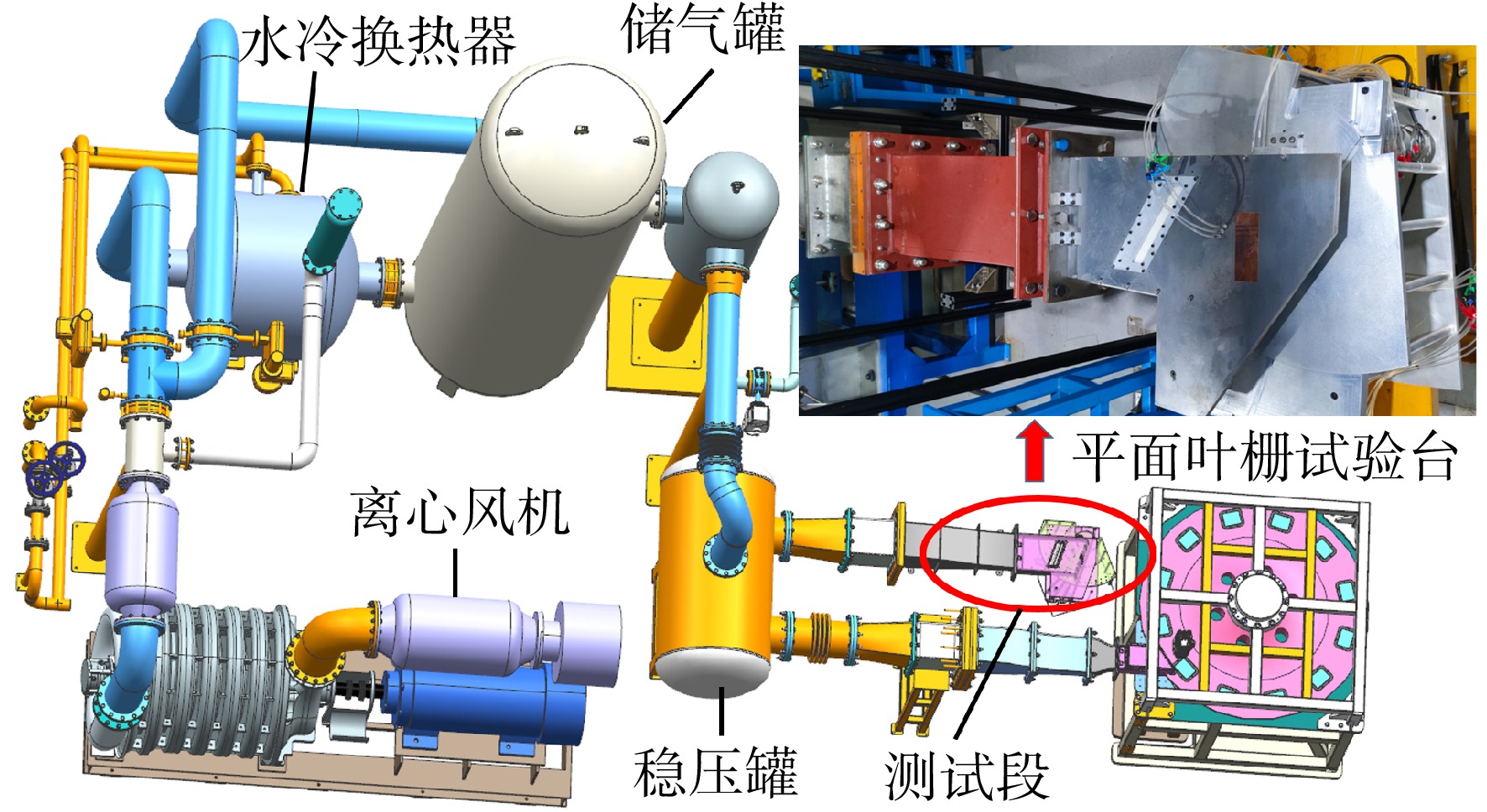

下载: