Fusion algorithm of multi design points for turboshaft-turbofan variable cycle engine scheme design

-

摘要:

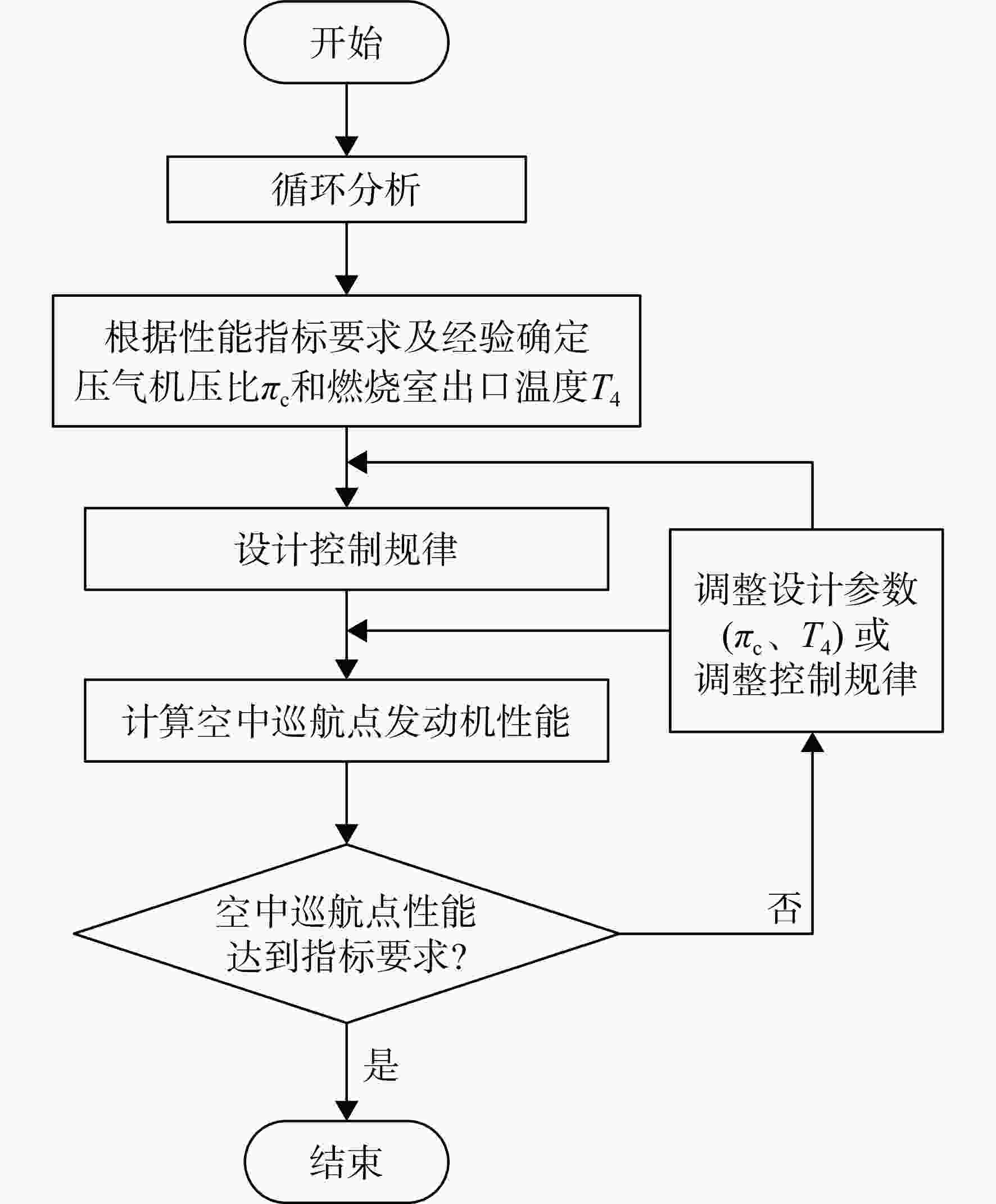

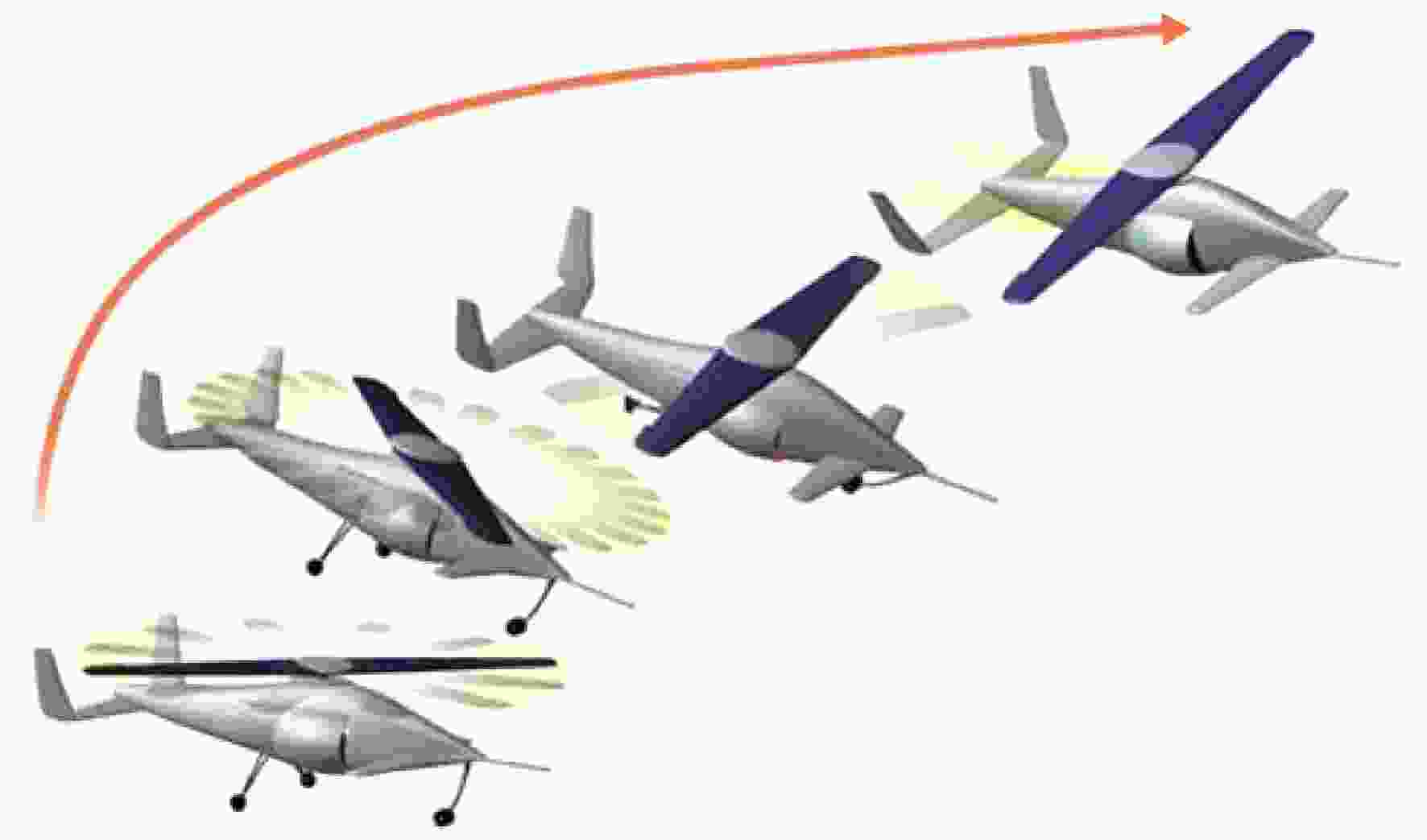

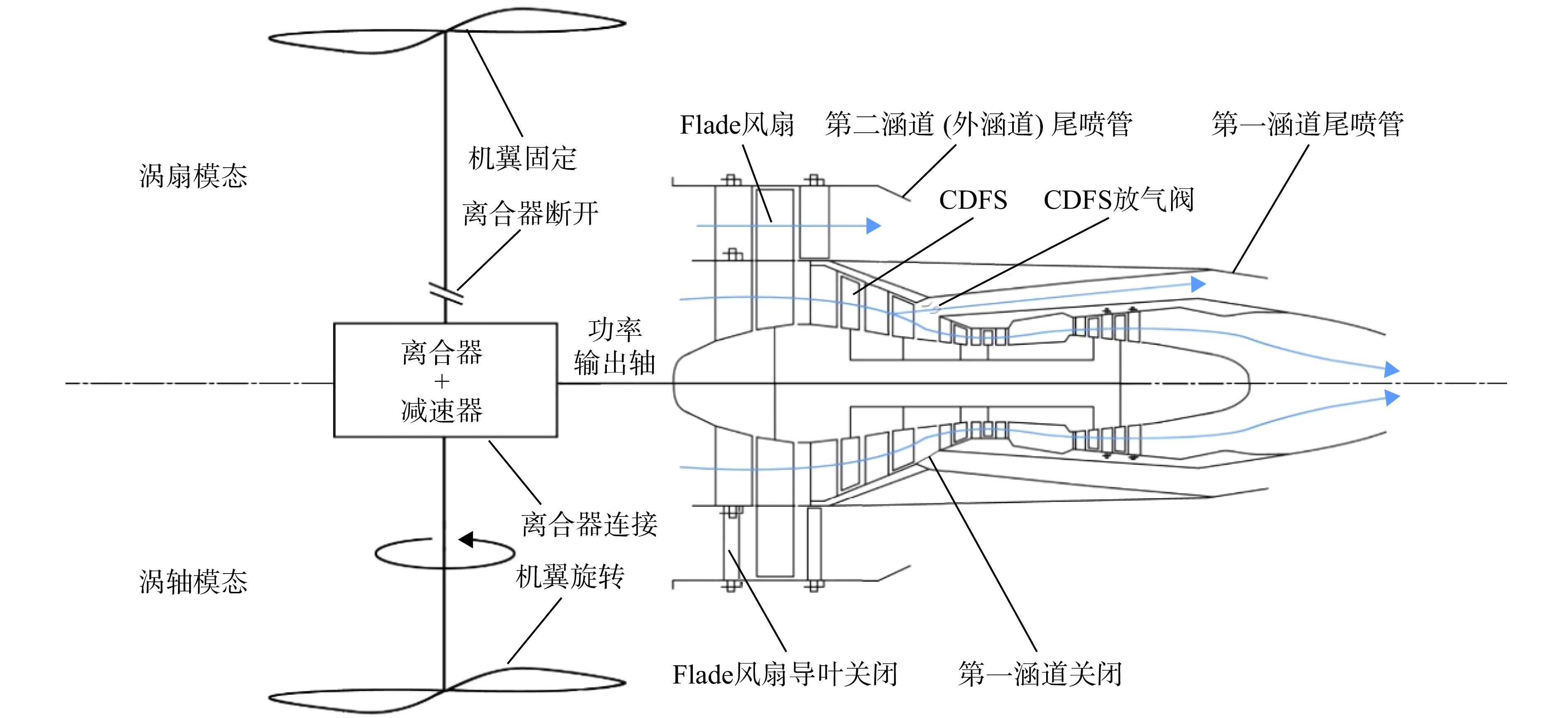

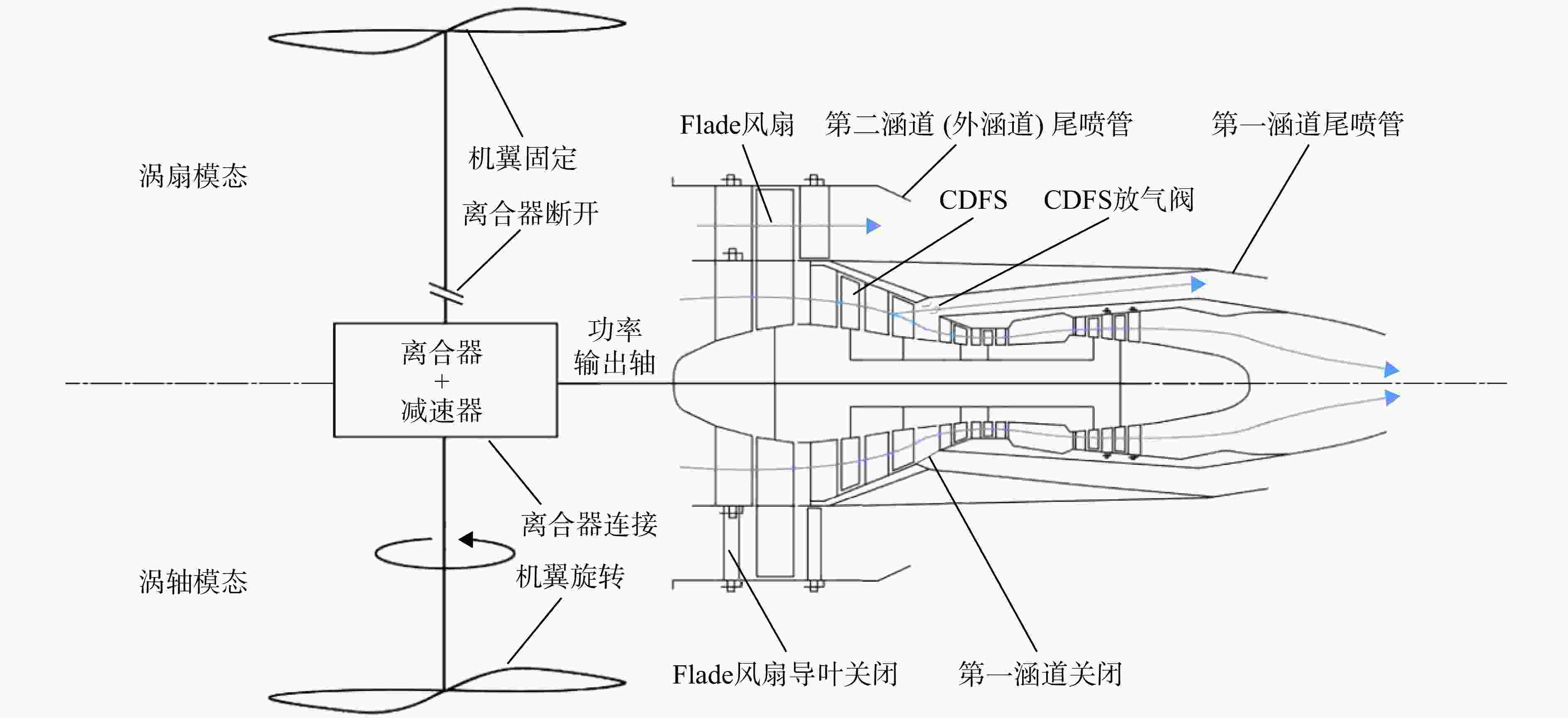

针对有涡轴和涡扇两种工作模态的涡轴-涡扇变循环发动机,提出了其方案设计的多设计点融合算法。以涡喷发动机为例,对发动机多设计点设计的融合算法模型的建立方法进行了介绍; 建立了涡轴-涡扇变循环发动机的多设计点融合算法模型;确定涡轴-涡扇变循环发动机的典型工况点包括高空巡航涡扇模态工况点、地面涡轴模态工况点及转模态工况点,完成发动机方案设计;最后以各典型工况点处飞行器对发动机的性能需求为多设计点融合算法的输入条件,与常规方法得到的参数进行对比验证,结果差异在1%以内。所提出的多设计点融合算法可为变循环发动机总体方案设计提供借鉴。

-

关键词:

- 涡轴-涡扇变循环发动机 /

- 多设计点 /

- 融合算法 /

- 垂直起降高速巡航飞行器 /

- 发动机方案设计

Abstract:A fusion algorithm of multi design points (FAMDP) was proposed for the design of turboshaft-turbofan variable cycle engine (TSFVCE) with two operating modes, including: turboshaft mode and turbofan mode. A turbojet engine was taken as an example to introduce the establishment of a FAMDP model. The FAMDP model for the TSFVCE was established. The typical operating points of the TSFVCE, including high-altitude cruise turbofan mode operating points, ground turboshaft mode oper-ating points, and modal conversion operating points, were determined, and the design of the engine scheme was completed. The performance requirements of the aircraft for the TSFVCE at each typical operating point were used as input for the FAMDP. Compared with the parameters obtained by conventional methods, the results showed a difference of less than 1%. The fusion algorithm of multi design points proposed can provide a reference for the overall design of variable cycle engines.

-

表 1 涡轴-涡扇变循环发动机设计点参数

Table 1. Design point parameters of turboshaft-turbofan variable cycle engine

部件 参数 数值 进气道 空气流量Wa /(kg/s) 118.02 Flade内涵风扇 增压比πf 1.48 Flade外涵风扇 增压比πFlade 1.98 导叶角度αFlade/(°) 0.0 CDFS 增压比πCDFS 1.53 导叶角度αCDFS/(°) −5.0 高压压气机 增压比πc 6.9 燃烧室 出口总温T4/K 1469.16 外涵道 第一涵道比γ1 0.11 第二涵道比γ2 3.0 注:Flade外涵风扇导叶角度为0°时表示导叶处于完全打开状 态,−90.0°时表示导叶处于完全关闭状态,外涵流道不再有 空气流入。 表 2 涡轴-涡扇变循环发动机设计点总体性能

Table 2. Overall performance of turboshaft-turbofan variable cycle engine

性能参数 数值 发动机地面推力Fn/daN 2574.9 单位推力Fs/(daN/(kg/s)) 21.82 耗油率ζ/(kg/(daN·h)) 0.8005 表 3 各限制参数设计点处取值和最大限制值

Table 3. Value and the maximum limit value of each limiting parameter at the design point

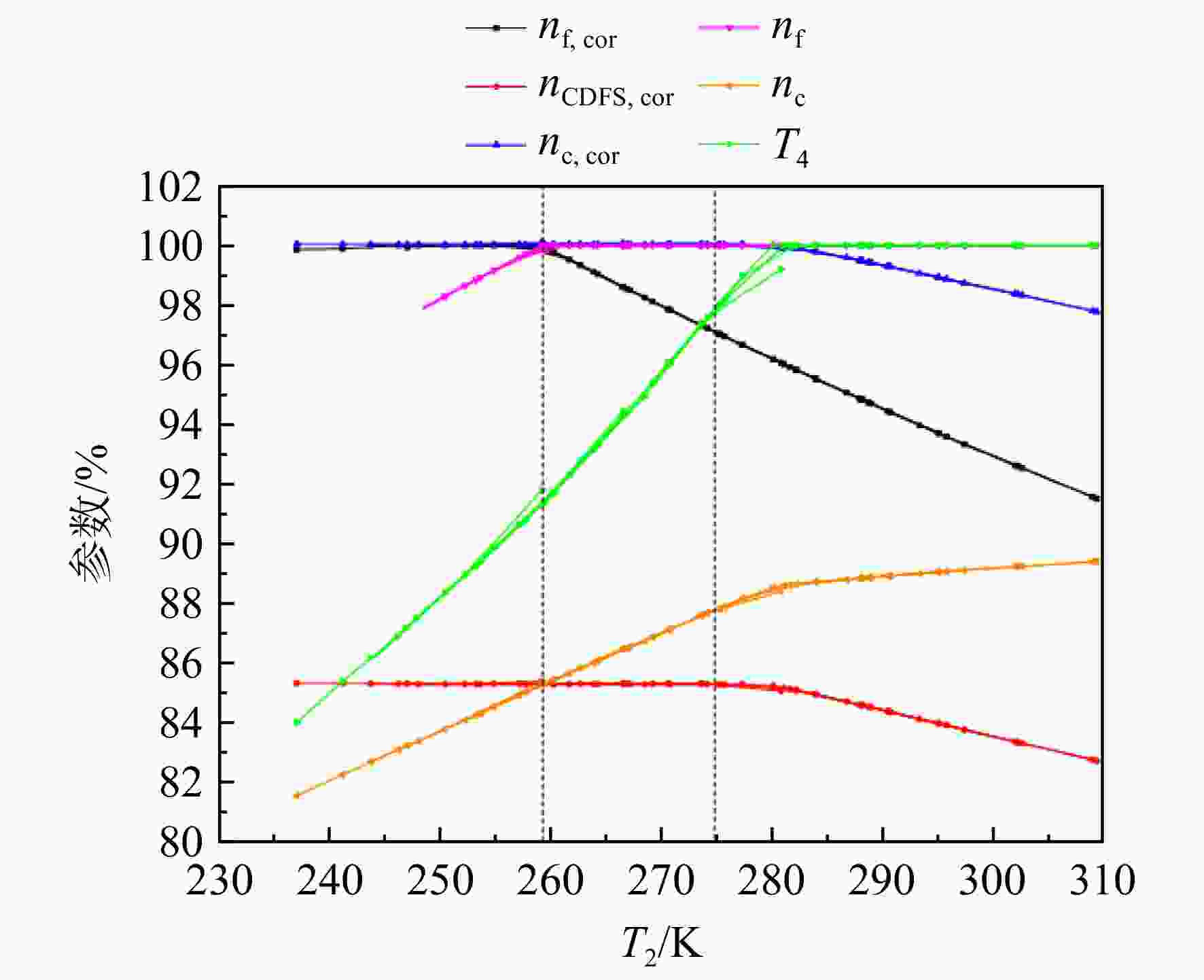

限制参数 设计点取值 限制值 低压转子物理百分比转速nf 100.0 100.0 低压转子相对换算转速nf,cor 1.0 1.0 高压转子物理百分比转速nc 85.42 100.0 低压转子相对换算转速nc,cor 1.00 1.00 燃烧室出口温度T4/K 1469.2 1600.0 表 4 涡轴-涡扇变循环发动机各设计点处相关参数

Table 4. Relevant parameters at each design point of the turboshaft-turbofan variable cycle engine

部件 参数 H=9 km,Ma=0.8 H=0 km,Ma=0 H=0.5 km,Ma=0 进气道 空气换算流量/(kg/s) 118.03 61.26 155.3 Flade内涵风扇 物理百分比转速 100.0 100.0 100.0 增压比 1.48 1.499 1.499 Flade外涵风扇 增压比 1.98 1.34 导叶角度/(°) 0.0 −90.0 −52.0 CDFS 增压比 1.53 1.53 1.53 导叶角度/(°) −5.0 −4.9 −4.9 高压压气机 物理百分比转速 85.42 90.0 89.51 增压比 6.9 6.76 6.77 燃烧室 出口总温/K 1469.16 1560.7 1546.87 涵道比 第一涵道比 0.11 0.11 0.11 第二涵道比 3.0 1.676 性能参数 推力/daN 2574.9 3334.0 单位推力/(daN/(kg/s)) 21.82 21.46 涡扇模态耗油率/(kg/(daN·h)) 0.8005 1.278 功率/kW 16500.0 12000.0 单位功率/(kW/(kg/s)) 269.35 77.26 涡轴模态耗油率/(kg/(kW·h)) 0.2754 0.355 表 5 涡轴-涡扇变循环发动机性能设计要求

Table 5. Performance design requirements of the turboshaft-turbofan variable cycle engine

参数 H=9 km,Ma=0.8 H=0 km,Ma=0 H=0.5 km,Ma=0 推力/daN 2574.9 3334.0 涡扇模态耗油率/(kg/(daN·h)) 0.8005 1.278 功率/kW 16500.0 12000.0 涡轴模态耗油率/(kg/(kW·h)) 0.2754 0.355 表 6 涡轴-涡扇变循环发动机部件参数

Table 6. Engine component parameters of turboshaft-turbofan variable cycle engine

部件 参数 H=9 km,Ma=0.8 H=0 km,Ma=0 H=0.5 km,Ma=0 进气道 空气流量/(kg/s) 118.74 61.48 156.5 Flade内涵风扇 物理百分比转速 100.0 100.0 100.0 增压比 1.48 1.499 1.499 Flade外涵风扇 增压比 1.98 1.34 导叶角度/(°) 0 −90.0 −52.2 CDFS 增压比 1.53 1.53 1.53 导叶角度/(°) −5.0 −4.9 −4.9 高压压气机 物理百分比转速 85.7 90.1 89.53 增压比 6.92 6.77 6.77 燃烧室 出口总温/K 1470.0 1561.4 1547.2 涵道比 第一涵道比 0.11 0.11 0.11 第二涵道比 3.0 1.677 -

[1] 邓阳平,高正红,詹浩. 鸭式旋翼/机翼飞机的技术发展及其关键技术[J]. 飞行力学,2006,24(3): 1-4. DENG Yangping,GAO Zhenghong,ZHAN Hao. Development and key technologies of the CRW[J]. Flight Dynamics,2006,24(3): 1-4. (in Chinese DENG Yangping, GAO Zhenghong, ZHAN Hao . Development and key technologies of the CRW[J]. Flight Dynamics,2006 ,24 (3 ):1 -4 . (in Chinese)[2] 张啸迟,万志强,章异嬴,等. 旋翼固定翼复合式垂直起降飞行器概念设计研究[J]. 航空学报,2016,37(1): 179-192. ZHANG Xiaochi,WAN Zhiqiang,ZHANG Yiying,et al. Conceptual design of rotary wing and fixed wing compound VTOL aircraft[J]. Acta Aeronautica et Astronautica Sinica,2016,37(1): 179-192. (in Chinese ZHANG Xiaochi, WAN Zhiqiang, ZHANG Yiying, et al . Conceptual design of rotary wing and fixed wing compound VTOL aircraft[J]. Acta Aeronautica et Astronautica Sinica,2016 ,37 (1 ):179 -192 . (in Chinese)[3] BELLIN A I,BROOKS A. Status report: DARPA/NASA convertible turbofan/turboshaft engine program[R]. ASME Paper 83-GT-196,1983. [4] ABDALLA K L,BROOKS A. TF34 convertible engine system technology program[R]. Anaheim,CA,US: NASA Technical Reports Server 82A40521,1982. [5] NEITZEL R E,HIRSCHKRON R,VINSON P W. Studies of convertible turboshaft/turbofan engines for high-speed rotorcraft[J]. Journal of Aircraft,1985,22(4): 296-302. doi: 10.2514/3.45123 [6] GARVIN E L,SLOSS T,RESS R,et al. Revolutionary concepts for multi-mode adaptive advanced cycle gas turbine engine[R]. Cincinnati,Ohio,US: 2018 Joint Propulsion Conference,2018. [7] 陈玉春,贾琳渊,任成,等. 涡轴涡扇组合循环发动机: CN206694149U[P]. 2018-06-19. [8] REN Cheng,CHEN Yuchun,JIA Linyuan,et al. Variable compression component interpolation method for turbine engine[C]//2018 9th International Conference on Mechanical and Aerospace Engineering. Piscataway,US: IEEE,2018: 162-167. [9] REN Cheng,CHEN Yuchun,JIA Linyuan,et al. The performance simulation of the conversion process of a double-mode turbo engine[C]//2022 13th International Conference on Mechanical and Aerospace Engineering. Piscataway,US: IEEE,2022: 65-70. [10] SIELEMANN M,COÏC C,HÜBEL M,et al. Introduction to multi-point design strategies for aero engines[R]. ASME Paper GT2020-14912,2020. [11] SCHUTTE J,TAI J,MAVRIS D. Multi design point cycle design incorporation into the environmental design space[R]. AIAA 2012-3812,2012. [12] 郑华雷,王召广,蔡建兵,等. 航空发动机多设计点热力循环分析方法的构建及应用[J]. 燃气涡轮试验与研究,2019,32(5): 8-14. ZHENG Hualei,WANG Zhaoguang,CAI Jianbing,et al. Construction and application of multi-design point method to perform thermodynamic cycle analysis for aero-engine[J]. Gas Turbine Experiment and Research,2019,32(5): 8-14. (in Chinese doi: 10.3969/j.issn.1672-2620.2019.05.002 ZHENG Hualei, WANG Zhaoguang, CAI Jianbing, et al . Construction and application of multi-design point method to perform thermodynamic cycle analysis for aero-engine[J]. Gas Turbine Experiment and Research,2019 ,32 (5 ):8 -14 . (in Chinese) doi: 10.3969/j.issn.1672-2620.2019.05.002[13] 郑华雷,苏志敏,黄兴,等. 基于多设计点方法的陶瓷基材料涡桨发动机热力循环分析[J]. 推进技术,2021,42(1): 1-9. ZHENG Hualei,SU Zhimin,HUANG Xing,et al. Thermal cycle analysis of turboprop with ceramic matrix composite based on multiple design points approach[J]. Journal of Propulsion Technology,2021,42(1): 1-9. (in Chinese ZHENG Hualei, SU Zhimin, HUANG Xing, et al . Thermal cycle analysis of turboprop with ceramic matrix composite based on multiple design points approach[J]. Journal of Propulsion Technology,2021 ,42 (1 ):1 -9 . (in Chinese)[14] 郑华雷,蔡建兵,黄兴. 基于多设计点方法的涡轴发动机热力循环分析[J]. 航空发动机,2023,49(1): 41-46. ZHENG Hualei,CAI Jianbing,HUANG Xing. Turboshaft thermodynamic cycle analysis based on multi-design point method[J]. Aeroengine,2023,49(1): 41-46. (in Chinese doi: 10.13477/j.cnki.aeroengine.2023.01.005 ZHENG Hualei, CAI Jianbing, HUANG Xing . Turboshaft thermodynamic cycle analysis based on multi-design point method[J]. Aeroengine,2023 ,49 (1 ):41 -46 . (in Chinese) doi: 10.13477/j.cnki.aeroengine.2023.01.005[15] 任成,贾琳渊,卜贤坤,等. 涡轴-涡扇变循环发动机方案及性能匹配设计研究[J/OL]. 推进技术, (2023-07-25) [2023-07-28]. https://link.cnki.net/doi/10.13675/j.cnki.tjjs.2212021. REN Cheng,JIA Linyuan,BU Xiankun,et al. Design and study on scheme and performance matching of turboshaft-turbofan variable cycle engine[J/OL]. Journal of Propulsion Technology, (2023-07-25)[2023-07-28]. https://link.cnki.net/doi/10.13675/j.cnki.tjjs.2212021. (in ChineseREN Cheng, JIA Linyuan, BU Xiankun, et al. Design and study on scheme and performance matching of turboshaft-turbofan variable cycle engine[J/OL]. Journal of Propulsion Technology, (2023-07-25)[2023-07-28]. https://link.cnki.net/doi/10.13675/j.cnki.tjjs.2212021. (in Chinese) [16] 陈敏,唐海龙. 基于通用核心机的航空发动机派生设计技术研究[C]//第六届空天动力联合会议暨中国航天第三专业信息网第四十二届技术交流会暨2021航空发动机技术发展高层论坛论文集(第一册). 成都:中国科协航空发动机产学联合体,2022: 69-76. [17] 张少锋,陈玉春,李夏鑫,等. 中小型核心机派生发动机设计研究[J]. 航空工程进展,2019,10(6): 826-835. ZHANG Shaofeng,CHEN Yuchun,LI Xiaxin,et al. Research on design of medium-small core-derived engine[J]. Advances in Aeronautical Science and Engineering,2019,10(6): 826-835. (in Chinese ZHANG Shaofeng, CHEN Yuchun, LI Xiaxin, et al . Research on design of medium-small core-derived engine[J]. Advances in Aeronautical Science and Engineering,2019 ,10 (6 ):826 -835 . (in Chinese)[18] 温泉,马宁,南希. 航空发动机风扇/压气机技术发展趋势[J]. 航空动力,2020(2): 42-46. WEN Quan,MA Ning,NAN Xi. Development trend of aero engine fan and compressor technology[J]. Aerospace Power,2020(2): 42-46. (in Chinese WEN Quan, MA Ning, NAN Xi . Development trend of aero engine fan and compressor technology[J]. Aerospace Power,2020 (2 ):42 -46 . (in Chinese)[19] 刘永泉,刘太秋,季路成. 航空发动机风扇/压气机技术发展的若干问题与思考[J]. 航空学报,2015,36(8): 2563-2576. LIU Yongquan,LIU Taiqiu,JI Lucheng. Some problems and thoughts in the development of aero-engine fan/compressor[J]. Acta Aeronautica et Astronautica Sinica,2015,36(8): 2563-2576. (in Chinese LIU Yongquan, LIU Taiqiu, JI Lucheng . Some problems and thoughts in the development of aero-engine fan/compressor[J]. Acta Aeronautica et Astronautica Sinica,2015 ,36 (8 ):2563 -2576 . (in Chinese)[20] 任成. 涡轮组合循环发动机一体化及总体性能设计[D]. 西安: 西北工业大学,2018. REN Cheng. Turbine combined cycle engine integration and overall performance design[D]. Xi’an: Northwestern Polytechnical University,2018. (in ChineseREN Cheng. Turbine combined cycle engine integration and overall performance design[D]. Xi’an: Northwestern Polytechnical University, 2018. (in Chinese) [21] 陈玉春,徐思远,杨云铠,等. 改善航空发动机特性计算收敛性的方法[J]. 航空动力学报,2008,23(12): 2242-2248. CHEN Yuchun,XU Siyuan,YANG Yunkai,et al. Research on the method to solve convergence problem in aero turbo-engine performance computation[J]. Journal of Aerospace Power,2008,23(12): 2242-2248. (in Chinese CHEN Yuchun, XU Siyuan, YANG Yunkai, et al . Research on the method to solve convergence problem in aero turbo-engine performance computation[J]. Journal of Aerospace Power,2008 ,23 (12 ):2242 -2248 . (in Chinese) -

下载:

下载: