Twin⁃duct matching mechanism in fan booster under different bypass working conditions

-

摘要:

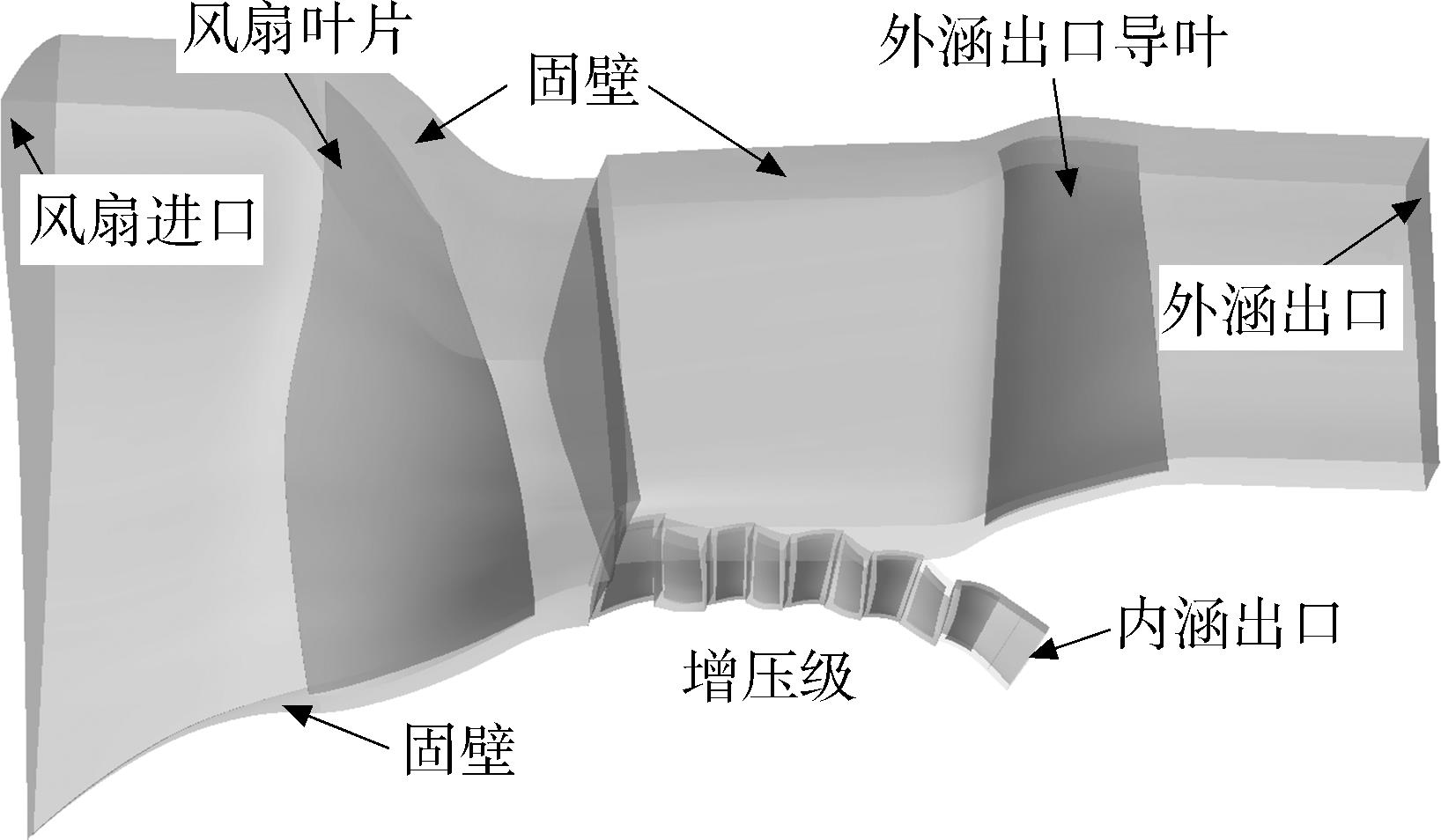

针对某型民机大涵道比风扇增压级,在不同外涵工况下开展数值计算,旨在研究风扇增压级双涵性能匹配规律和相应机理。通过分析计算结果,掌握了外涵工况对内涵特性的影响规律:当外涵工况从近堵点移向近喘点的过程中,内涵的流量、总压比、效率逐渐增大,且内涵稳定裕度呈持续增大的变化规律。同时也在获取内涵特性时,掌握了外涵气动性能的变化规律,在不同外涵工况下阐明了内涵逼喘过程中双涵气动性能的相互匹配机理取决于风扇的总压比‑流量特性和内外涵流量再分配机制的共同作用。

Abstract:Numerical research on a high‑bypass‑ratio fan booster of a civil‑aircraft engine was conducted under different bypass working conditions,with the aim of understanding the twin‑duct matching rule and corresponding matching mechanism.By analysis of the numerical results,it was understood that as the bypass working condition changed from the near choke point to the near surge point,the mass flow,pressure ratio and efficiency increased and the core surge margin first climbed up and then declined.In the process of acquiring core characteristics,the change law of bypass aerodynamic performance was mastered.Furthermore,during the forced surge process of the core,the twin‑duct matching mechanism was subject to the combined actions of the fan characteristic of pressure ratio and mass flow and the redistribution of mass flow between the core and bypass.

-

表 1 各工况分隔线位置及内涵逼喘过程的流量变化

Table 1. Locations of dividing lines and variations in mass flow during the forced surge process of the core under different working conditions

外涵工况 中间点 工作点 近堵点 内外涵分隔线相对位置/% 内涵工作点 17.86 16.45 15.35 内涵近喘点 16.94 15.08 14.71 额外流向外涵流量/% 0.56 0.81 0.41 内涵流量相对变化量/% -1.15 -1.43 -0.52 外涵流量相对变化量/% -3.16 0.31 0.48 风扇流量相对变化量/% -4.31 -1.12 -0.04 -

[1] 陈懋章,刘宝杰.风扇/压气机气动设计技术发展趋势——用于大型客机的大涵道比涡扇发动机[J].航空动力学报,2008,23(6):961⁃975.CHEN Maozhang,LIU Baojie.Fan/compressor aero design trend and challenge on the development of high bypass ratio turbofan[J].Journal of Aerospace Power,2008,23(6):961⁃975.(in Chinese) [2] 陈云永,杨小贺,卫飞飞.大涵道比风扇设计技术发展趋势[J].航空学报,2017,38(9):27⁃34.CHEN Yunyong,YANG Xiaohe,WEI Feifei,et al.Development trend of high bypass ratio turbofans design technology[J].Acta Aeronautica et Astronautica Sinica,2017,38(9):27⁃34.(in Chinese) [3] RITI S.Fifty years of civil aero gas turbines[J].Aircraft Engineering and Aerospace Technology,1996,68(4):3⁃19. [4] DAWES W N.Multi⁃blade row Navier⁃Stokes simulations of fan⁃bypass configurations[R].ASME Paper 91⁃GT⁃148,1991. [5] 赵永辉.涡扇发动机风扇及内外涵道匹配的数值分析[D].北京:中国科学院工程热物理研究所,2005.ZHAO Yonghui.Numerical analysis on matching between internal and external bypass and fan of aero⁃engine[D].Beijing:Institute of Engineering Thermophysics,Chinese Academy of Sciences,2005.(in Chinese) [6] BRILLIANT L,BALAMUCKI S,BUERGER G,et al.Application of multistage CFD analysis to low pressure compressor design[R].ASME Paper GT2004⁃54263,2004. [7] ADAMCZYK J J.Aerodynamic analysis of multistage turbomachinery flows in support of aerodynamic design[J].Journal of Turbomachinery,2000,122:189⁃217. [8] HORLOCK J H,DENTON J D.A review of some early design practice using computational fluid dynamics and a current perspective[J].Journal of Turbomachinery,2005,127:5‑13. [9] 李晓娟,金海良,桂幸民.风扇/增压级内外涵联算的特性数值模拟[J].航空动力学报,2009,24(12):2719⁃2726.LI Xiaojuan,JIN Hailiang,GUI Xingmin.Performance numerical investigation of double‑channel fan/compressor[J].Journal of Aerospace Power,2009,24(12):2719⁃2726.(in Chinese) [10] 李晓娟,桂幸民.风扇/增压级设计与非设计性能数值模拟[J].推进技术,2005,26(6):522⁃525.LI Xiaojuan,GUI Xingmin.Numerical simulation of fan/compressor design and off⁃design performance[J].Journal of Propulsion Technology,2005,26(6):522⁃525.(in Chinese) [11] 万科,朱芳,金东海,等.周向平均方法在某风扇/增压级分析中的应用[J].航空学报,2014,35(1):132⁃140.WAN Ke,ZHU Fang,JIN Donghai,et al.Application of circumferentially averaged method in fan/booster[J].Acta Aeronautica et Astronautica Sinica,2014,35(1):132⁃140.(in Chinese) [12] 万科,杨小贺,丁建国.风扇/增压级端区流动优化设计研究[J].燃气轮机技术,2018,31(4):53⁃58.WAN Ke,YANG Xiaohe,DING Jianguo.Optimization design and research of endwall flow in high⁃bypass⁃ratio fan/booster[J].Gas Turbine Technology,2018,31(4):53⁃58.(in Chinese) [13] 刘晓锋,刘世文,杨小贺,等.某大涵道比风扇轮毂型线数值计算[J].航空发动机,2018,44(4):26⁃33.LIU Xiaofeng,LIU Shiwen,YANG Xiaohe,et al.Numerical calculation of hub⁃shape contouring on a high bypass ratio engine fan[J].Aeroengine,2018,44(4):26⁃33.(in Chinese) [14] 丁建国,胡骏.某掠形跨声风扇设计与数值模拟[J].航空动力学报,2007,22(1):54⁃59.DING Jianguo,HU Jun.Design and numerical simulation of a transonic swept fan[J].Journal of Aerospace Power,2007,22(1):54⁃59.(in Chinese) [15] 赵威程.大涵道比风扇、增压级三维设计及性能研究[D].哈尔滨:哈尔滨工程大学,2018.ZHAO Weicheng.The three⁃dimensional design and performance investigation on high bypass ratio fan and booster[D].Harbin:Harbin Engineering University,2018.(in Chinese) [16] 李晓娟,桂幸民.风扇/增压级带间隙三维粘性流场数值模拟[J].北京航空航天大学学报,2006,32(1):4⁃7.LI Xiaojuan,GUI Xingmin.Numerical simulation of three dimension viscous flow of fan/compressor with tip clearance[J].Journal of Beijing University of Aeronautics and Astronautics,2006,32(1):4⁃7.(in Chinese) [17] 陈云永,万科,杨小贺,等.大涵道比风扇/增压级叶尖间隙影响研究[J].航空学报,2017,38(9):190⁃197.CHEN Yunyong,WAN Ke,YANG Xiaohe,et al.Influence of tip clearance on high⁃bypass⁃ratio fan/booster[J].Acta Aeronautica et Astronautica Sinica,2017,38(9):190⁃197.(in Chinese) [18] 顾明浩,桂幸民.低雷诺数效应对某型风扇的性能影响及改进方案研究[J].航空动力学报,2004,19(4):438⁃443.GU Minghao,GUI Xingmin.Low⁃Re number effects on the performance of some fans and the modified design[J].Journal of Aerospace Power,2004,19(4):438⁃443.(in Chinese) [19] 桂幸民,李晓娟.基于低雷诺数条件的风扇/增压级气动设计[J].燃气涡轮试验与研究,2007,20(3):18⁃22.GUI Xingmin,LI Xiaojuan.Aerodynamic design of fan/compressor operated at low Reynolds number[J].Gas Turbine Experiment and Research,2007,20(3):18⁃22.(in Chinese) [20] 朱芳,陈云永,卫飞飞,等.某民用大涵道比涡扇发动机风扇缩尺试验件气动性能数值仿真[J].航空动力学报,2013,28(7):1539⁃1548.ZHU Fang,CHEN Yunyong,WEI Feifei,et al.Numerical simulation of aerodynamic performance of scaled fan of a civil high⁃bypass⁃ratio turbofan engine[J].Journal of Aerospace Power,2013,28(7):1539⁃1548.(in Chinese) [21] 郑覃,杨小贺,叶俊,等.内涵工况对风扇增压级双涵匹配的影响[J].航空学报,2022,43(7):184⁃199.ZHENG Tan,YANG Xiaohe,YE Jun,et al.Influence of various core working conditions on twin⁃duct matching in fan booster[J].Acta Aeronautica et Astronautica Sinica,2022,43(7):184⁃199.(in Chinese) -

下载:

下载: