Uncertainty quantification of rotor blade dynamic strain reconstruction based on blade tip timing

-

摘要:

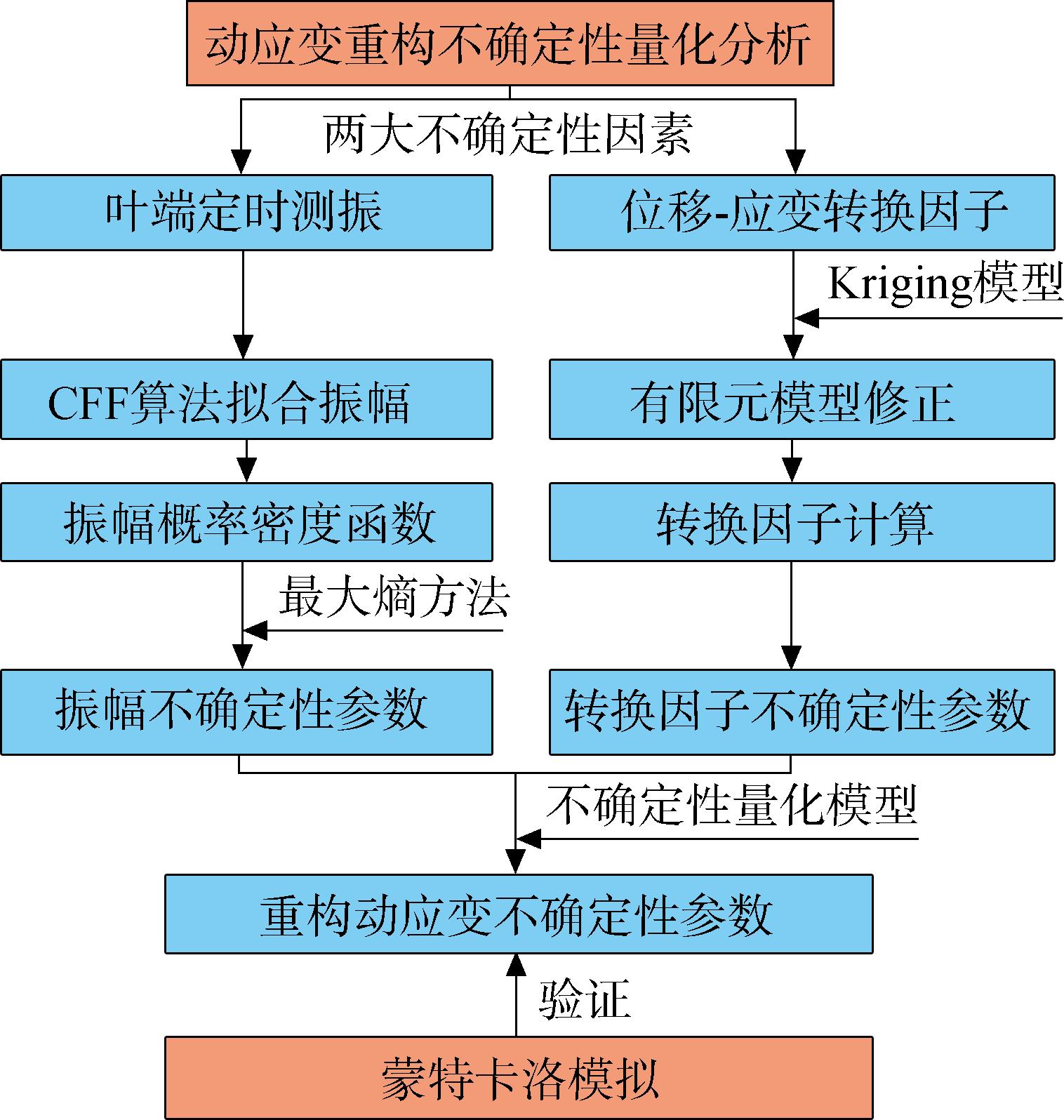

基于叶片非接触式动应变重构理论,开展动应变重构不确定性量化方法研究。基于方差合成定理建立重构叶片动应变不确定性量化分析模型;以模拟转子叶片为研究对象,开展旋转叶片叶端定时试验,利用周向傅里叶算法获取不同叶端定时传感器布局下的测点振幅,通过最大熵方法拟合振幅分布概率密度函数,确定叶端定时测振的不确定性参数;结合Kriging代理模型和试验共振频率数据对叶片有限元模型进行修正,获取关键测点位移⁃应变转换因子,并获取考虑共振转速以及测点位置不确定性的转换因子不确定性参数;获取重构动应变的均值、标准不确定度和包含区间,与应变片测量数据作对比。结果表明,除5号叶片

A 测点外,测量动应变均位于重构动应变的95%置信度下的包含区间内,且所有叶片的应变片测点动应变重构误差不超过15%。-

关键词:

- 叶端定时 /

- 动应变重构 /

- 不确定性量化 /

- 最大熵方法 /

- Kriging代理模型

Abstract:Based on the theory of blade non⁃contact dynamic strain reconstruction,research on the uncertainty quantification method of dynamic strain reconstruction was carried out.According to the variance composition theorem,a model of the blade reconstructed dynamic strain uncertainty for quantitative analysis was established.A simulated rotor blade was used as the research object,and the rotation experiment was carried out.The circumferential Fourier Fitting was used to obtain the amplitude of measuring point under different blade tip timing sensor layouts,and the maximum entropy method was adopted to fit the probability density function of the amplitude distribution,which could be used to determine the uncertainty parameters of the blade⁃tip⁃timing vibration measurement.The finite element model of the blade was modified by combining the Kriging proxy model and the resonant frequency of the test.The displacement⁃strain conversion factors of the key measuring points were obtained,and the uncertainty parameters of the conversion factor considering the uncertainty of the resonance speed and measuring point position were obtained.The mean value,standard uncertainty and inclusion interval of the reconstructed dynamic strain were obtained and compared with the measured data of the strain gauge.Results showed that except for the measuring point

A of No.5 blade,the measured dynamic strains were all within the 95% confidence interval of the reconstructed dynamic strain,and the dynamic strain reconstruction error of the strain gauges of all blades didn't exceed 15%. -

表 1 应变片在叶片上的位置

Table 1. Positions of the strain gauges on blades

叶片编号 应变片位置 1 A点、B点 2 A点、C点 3 A点、B点 4 A点、C点 5 A点、B点 表 2 叶片材料参数

Table 2. Material properties of the blade

参数 数值及详情 材料 GH4169 密度/ 8.24 弹性模量/GPa 195 泊松比 0.3 表 3 叶片静态固有频率

Table 3. Static natural frequency of the blade

阶次 固有频率/Hz 1阶 600.9 2阶 1 794.8 3阶 3 585.4 表 4 叶片振幅不确定性参数

Table 4. Uncertainty parameters of blade vibration amplitude

叶片编号 M1EO4 M1EO3 均值/μm 标准差 均值/μm 标准差 1 182.91 1.63 302.89 2.83 2 142.80 1.17 456.11 3.76 3 96.89 2.63 299.79 2.34 4 125.59 2.40 245.16 2.97 5 217.08 1.74 498.13 1.95 表 5 转子叶片共振转速及频率

Table 5. Rotor blade resonant rotational speed and frequency

工况 参数 叶片编号(试验) 仿真 1 2 3 4 5 M1EO4 转速/( ) 9 404 9 403 9 604 9 252 9 403 9 403 频率/Hz 627 627 640 617 627 626 M1EO3 转速/( ) 13 001 12 916 13 257 12 734 13 001 13 001 频率/Hz 650 646 663 637 650 648 表 6 固有频率方均根误差

Table 6. RMSE of natural frequency

叶片编号 方均根误差 M1EO4 M1EO3 3 0.54 0.55 4 0.44 0.45 表 7 固有频率修正结果

Table 7. Correction result of natural frequency

叶片编号 叶长/mm 固有频率/Hz 相对误差/% M1EO4 M1EO3 M1EO4 M1EO3 3 47.46 640.51 663.26 0.08 0.04 4 48.37 616.54 637.86 0.07 0.14 表 8 M1EO6处叶片固有频率对比

Table 8. Comparison of natural frequency under M1EO6

叶片编号 转速/( ) 固有频率/Hz 相对误差/% 试验 仿真 3 6 254 625 625.48 0.08 4 6 003 600 602.94 0.49 表 9 M1EO4下位移⁃应变转换因子不确定性参数

Table 9. Uncertainty parameters of displacement⁃strain conversion factor under M1EO4

叶片编号 均值/m-1 标准差 A点 B点 C点 A点 B点 C点 1,2,5 1.686 1.387 1.344 0.096 0 0.108 3 0.107 8 3 1.720 1.345 1.502 0.100 7 0.081 8 0.088 1 4 1.663 1.312 1.448 0.089 8 0.078 0 0.099 0 表 10 M1EO3下位移⁃应变转换因子不确定性参数

Table 10. Uncertainty parameters of displacement⁃strain conversion factor under M1EO3

叶片编号 均值/m⁃1 标准差 A点 B点 C点 A点 B点 C点 1,2,5 1.704 1.391 1.344 0.100 7 0.112 4 0.109 0 3 1.738 1.346 1.504 0.105 4 0.084 8 0.088 2 4 1.681 1.313 1.450 0.094 4 0.081 1 0.100 1 表 11 M1EO4下应变幅值及共振频率

Table 11. Strain amplitude and vibration frequency under M1EO4

叶片编号 位置点 频率/Hz 应变/10-6 1 A 625 308.60 B 625 263.50 2 A 625 263.29 C 625 213.84 4 A 616 220.43 C 616 166.67 5 A 625 418.70 B 625 260.31 表 12 M1EO3下应变幅值及共振频率

Table 12. Strain amplitude and vibration frequency under M1EO3

叶片编号 位置点 频率/Hz 应变/10-6 1 A 650 518.91 B 650 438.18 2 A 647 758.46 C 647 609.14 4 A 638 410.08 C 638 327.93 5 A 650 1034.56 B 650 652.26 表 13 M1EO4下处重构动应变不确定性参数

Table 13. Uncertainty parameter of reconstructed dynamic strain under M1EO4

叶片编号 位置点 应变均值/10-6 应变标准差 1 A 308.39 17.77 B 253.89 19.94 2 A 240.76 13.85 C 192.06 15.47 3 A 166.74 10.75 B 130.31 8.68 4 A 208.73 11.96 C 181.85 12.91 5 A 366.00 21.05 B 301.31 23.63 表 14 M1EO3下重构动应变不确定性参数

Table 14. Uncertainty parameter of reconstructed dynamic strain under M1EO3

叶片编号 位置点 应变均值/10-6 应变标准差 1 A 516.12 30.88 B 421.32 34.27 2 A 777.21 46.38 C 613.01 49.97 3 A 521.04 31.86 B 403.52 25.62 4 A 412.11 23.68 C 355.48 24.92 5 A 848.81 50.27 B 692.90 56.06 表 15 叶片动应变重构误差

Table 15. Dynamic strain reconstruction error of blades

叶片编号 位置点 相对误差/% M1EO4 M1EO3 1 A 0.07 0.54 B 3.65 3.85 2 A 8.56 2.47 C 10.19 0.64 4 A 5.31 0.50 C 9.11 8.40 5 A 12.59 17.95 B 15.75 6.23 -

[1] 王寿菊.国内外航空发动机企业信息化发展概述[J].内燃机与配件,2020,41(13):192⁃193.WANG Shouju.Overview of the development of informatization of domestic and foreign aero⁃engine enterprises[J].Internal Combustion Engine and Parts,2020,41(13):192⁃193.(in Chinese) [2] 徐海龙.旋转叶片裂纹的叶端定时非接触在线检测关键技术研究[D].长沙:国防科技大学,2018.XU Hailong.Research on key technology of crack detection in rotating blades by non‑contact online blade tip‑timing method[D].Changsha:National University of Defense Technology,2018.(in Chinese) [3] KNAPPETT D,GARCIA J.Blade tip timing and strain gauge correlation on compressor blades[J].Proceedings of the Institution of Mechanical Engineers:Part G Journal of Aerospace Engineering,2008,222(4):497⁃506. [4] ZHANG Xiaojie,WANG Yanrong,JIANG Xianghua,et al.Blade vibration stress determination method based on blade tip timing simulator and finite element method[J].Journal of Engineering for Gas Turbines and Power,2020,142(3):1‑16. [5] 段发阶,李刚,叶德超,等.基于叶尖定时的叶片动应力反演方法[J].纳米技术与精密工程,2016,14(3):161⁃166.DUAN Fajie,LI Gang,YE Dechao,et al.Method for inversing dynamic stress of blade based on tip⁃timing[J].Nano⁃technology and Precision Engineering,2016,14(3):161⁃166.(in Chinese) [6] 王维民,任三群,陈立芳,等.涡轮机叶片同步振动参数辨识方法研究(实验研究)[J].振动与冲击,2017,36(17):127‑133.WANG Weiming,REN Sanqun,CHEN Lifang,et al.Tests for synchronous vibration parametric identification method of a turbine's blades[J].Journal of Vibration and Shock,2017,36(17):127⁃133.(in Chinese) [7] 刘美茹,滕光蓉,肖潇,等.基于叶尖定时的航空发动机涡轮叶片振动测量[J].航空动力学报,2020,35(9):1954⁃1963.LIU Meiru,TENG Guangrong,XIAO Xiao,et al.Vibration measurement of turbine rotor blades of aero⁃engine based on blade tip⁃timing[J].Journal of Aerospace Power,2020,35(9):1954⁃1963.(in Chinese) [8] 刘美茹,朱靖,梁恩波,等.基于叶尖定时的航空发动机压气机叶片振动测量[J].航空动力学报,2019,34(9):1895⁃1904.LIU Meiru,ZHU Jing,LIANG Enbo,et al.Vibration measurement on compressor rotor blades of aero⁃engine based on tip⁃timing[J].Journal of Aerospace Power,2019,34(9):1895⁃1904.(in Chinese) [9] 徐海龙,杨拥民,胡海峰,等.基于压缩感知的叶端定时欠采样多频叶片振动盲重构研究[J].机械工程学报,2019,55(13):113⁃121.XU Hailong,YANG Yongmin,HU Haifeng,et al.Compressed sensing⁃based blind reconstruction of multi⁃frequency blade vibration from under⁃sampled BTT signals[J].Journal of Mechanical Engineering,2019,55(13):113⁃121.(in Chinese) [10] 敖春燕,乔百杰,刘美茹,等.基于非接触式测量的旋转叶片动应变重构方法[J].航空动力学报,2020,35(3):569⁃580.AO Chunyan,QIAO Baijie,LIU Meiru.Dynamic strain reconstruction method of rotating blades based on no⁃contact measurement[J].Journal of Aerospace Power,2020,35(3):569⁃580.(in Chinese) [11] SATISH TN,MURTHY R,SINGH AK.Analysis of uncertainties in measurement of rotor blade tip clearance in gas turbine engine under dynamic condition[J].Proceedings of the Institution of Mechanical Engineers:Part G Journal of Aerospace Engineering,2014,228(5):652⁃670. [12] PICKERING T M.Methods for validation of a turbomachinery rotor blade tip timing system[D].Blacksburg,Virginia,the United States of America:Virginia Tech,2014. [13] KAMARAJ A.Stress prediction in turbine blades under force excitation[D].San Diego,California,the United States of America:San Diego State University.2016. [14] 潘明昊.基于叶端定时测量的叶片多频振动稀疏重构方法[D].长沙:国防科技大学,2017.PAN Minghao.Sparse reconstruction of multi⁃frequency blade vibration spectrum by blade tip timing measurement[D].Changsha:National University of Defense Technology,2017.(in Chinese) [15] 许敬晖,乔百杰,滕光蓉,等.基于压缩感知的叶端定时信号参数辨识方法[J].航空学报,2021,42(5):524229⁃524239XU Jinghui,QIAO Baijie,TENG Guangrong,et al.Parameter identification of blade tip timing signal using compressed sensing[J].Acta Aeronauticaet Astronautica Sinica,2021,42(5):524229⁃524239.(in Chinese) [16] 吉利.基于响应面法的航天器有限元模型修正方法研究[D].哈尔滨:哈尔滨工业大学,2020.JI Li.Study of finite element model updating meth⁃od for spacecraft based on response surface method[D].Harbin:Harbin Institute of Technology,2020.(in Chinese) [17] 唐新姿,王喆,王效禹.多源不确定耦合下离心压气机叶轮气动稳健性[J].航空动力学报,2020,35(1):196⁃204.TANG Xinzi,WANG Zhe,WANG Xiaoyu.Aerodynamic robustness of centrifugal compressor impeller under multi⁃source uncertainty coupling[J].Journal of Aerospace Power,2020,35(1):196⁃204.(in Chinese) [18] DENG Zhongmin,GUO Zhaopu,ZHANG Xinjie.Interval model updating using perturbation method and radial basis function neural networks[J].Mechanical Systems and Signal Processing,2017,84:699⁃716. [19] HAMED H K,JOHN E M,KENNETH J B.Interval model updating with irreducible uncertainty using the Kriging predictor[J].Mechanical Systems and Signal Processing,2011,25(4):1204⁃1226. [20] MOHAMED M,PHILIP B,PETER R.A novel method for the determination of the change in blade tip timing probe sensing position due to steady movements[J].Mechanical Systems and Signal Processing,2019,126:686‑710. [21] 史进渊,杨宇,孙庆,等.机械零件振动的可靠性设计[J].振动工程学报,1999,4(4):117⁃122.SHI Jinyuan,YANG Yu,SUN Qing,et al.Reliability Design of Vibrating Machinery Part[J].Journal of Vibration Engineering,1999,4(4):117⁃122.(in Chinese) -

下载:

下载: