Optimization method of turbulent flamelet model in afterburner

-

摘要:

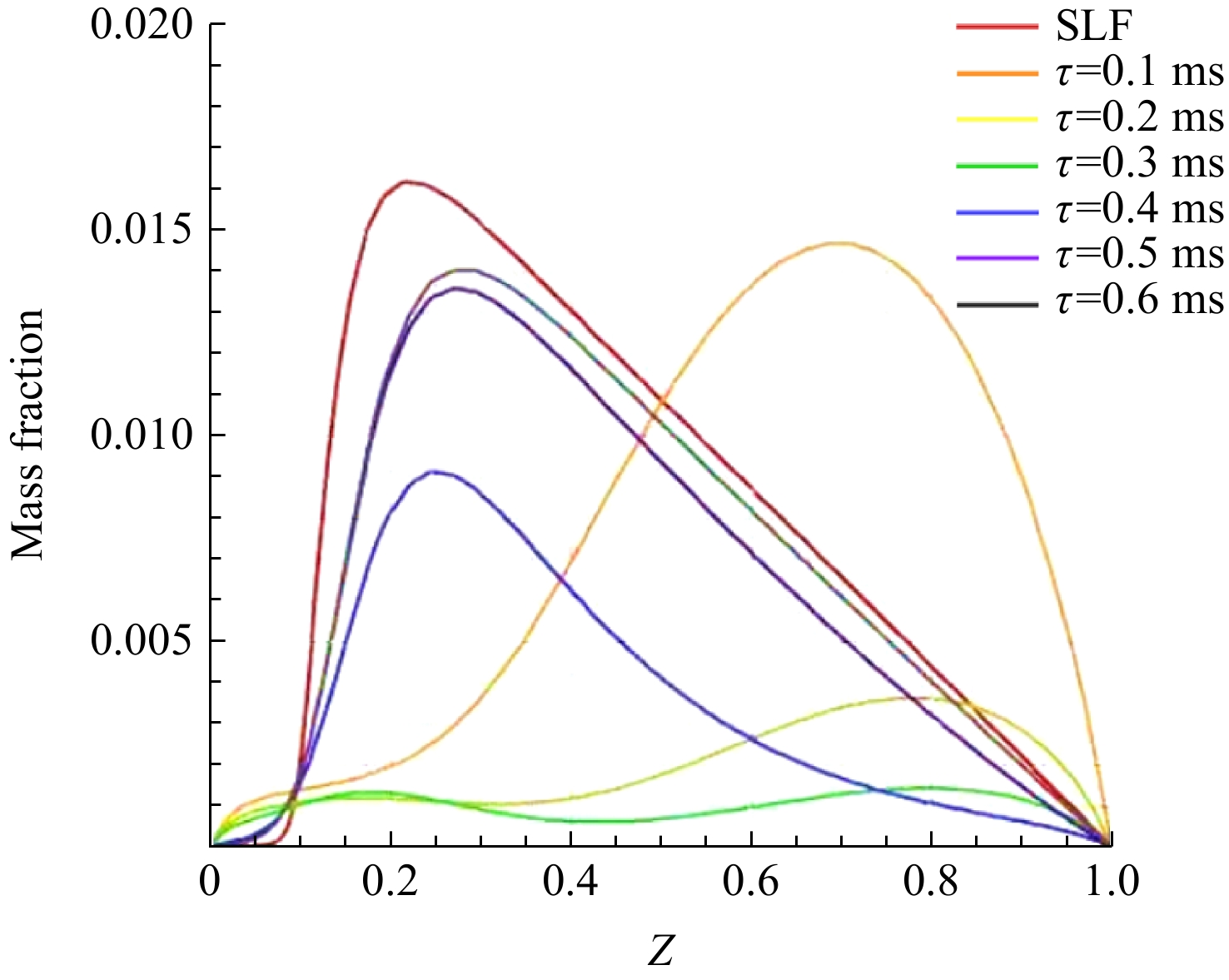

加力燃烧室中流速高、压力低、含氧量低,燃油喷射以直射式为主,常用燃烧模型多会高估其反应速率。火焰面类模型采用查表法处理标量场,计算速度较快,但较难调整反应速率。在稳态层流火焰面模型基础上,添加了非定常化学动力学的影响因素来调整反应速率;在试验数据基础上,建立火焰面反应时间尺度,优化火焰面数据库,改善了该类方法在高速、低压、贫氧和雾化差下的数值仿真精度。结果表明:该优化方法形成的火焰面数据库能够较好模拟加力燃烧室中燃油复杂化学反应过程;在本文计算结果验证中,能将温度分布模拟误差控制在15%以内,平均温度模拟误差控制在5%以内。

Abstract:In the afterburner with high flow rate high, low pressure, oxygen poverty, the direct fuel injection is predominent, and the combustion model usually overestimates the reaction rate of the afterburner. Table-searching method is used in flamelet models with the advantage of fast calculation, but it is difficult to adjust the reaction rate. Based on the steady laminar flamelet model, unsteady chemical kinetic factors were added to adjust the reaction rate. Based on the experimental data, the key geometric parameters were established. The flamelet database was optimized, and the numerical simulation accuracy of this method was improved under high speed, low pressure, oxygen poverty and poor atomization effect. The results showed that the flamelet database formed by this optimization method can better simulate the complex chemical reaction process in afterburner. According to the calculation results, the simulation error of temperature distribution can be controlled within 15%, and the simulation error of average temperature can be controlled within 5%.

-

工况 空气进口

速度/(m/s)空气进口

温度/K试验段

压力/MPa总油气比 1 109.26 700 0.06 0.0378 2 103.96 700 0.04 0.0370 3 149.57 700 0.03 0.0372 4 135.04 600 0.03 0.0375 5 161.60 800 0.03 0.0365 表 2 工况1、工况2数值模拟值与试验测量值对比表[18]

Table 2. Comparison table of numerical simulation value and experimental measurement value in working conditions 1 and 2[18]

工况 高度/

mm试验测量

温度/K数值模拟

温度/K温度偏差/

K偏差

百分比/%1 18 1358.72 1483.35 124.63 9.17 43 1325.14 1386.98 61.84 4.60 68 1322.86 1177.28 145.58 11.0 2 18 1411.15 1570.09 158.94 11.26 43 1431.10 1398.93 32.17 2.25 68 1334.89 1161.81 173.08 12.97 -

[1] 夏姣辉,杨谦,王慧汝,等. 涡扇发动机加力燃烧技术发展分析[J]. 航空动力,2020(4): 17-21.XIA Jiaohui,YANG Qian,WANG Huiru,et al. Development analysis to afterburner combustion technology of turbofan[J]. Aerospace Power,2020(4): 17-21. (in Chinese) [2] 张峥. 燃烧室燃油喷雾场特性研究[D]. 南京: 南京航空航天大学, 2009.ZHANG Zheng. Experiment study on fuel spray characteristics in model combustor[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2009. (in Chinese) [3] 王成冬. 小型涡喷发动机加力燃烧室燃烧特性研究及整机验证[D]. 合肥: 中国科学院大学, 2018.WANG Chengdong. Research on combustion characteristics of afterburner of small turbo-jet engine and validation of overall engine test[D]. Hefei: University of Chinese Academy of Sciences, 2018. (in Chinese) [4] 陆斌. 加力燃烧室波瓣强迫混合器掺混及燃烧特性研究[D]. 南京: 南京航空航天大学, 2017.LU Bin. Investigation on mixing and combustion performances of lobe forced mixer for the afterburner[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017. (in Chinese) [5] 刘雨辰. 加力用扇形喷嘴雾化特性试验研究[D]. 南京: 南京航空航天大学, 2019.LIU Yuchen. Experimental study on spray characteristics of atomizing fan nozzle for afterburner[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019. (in Chinese) [6] RAVICHANDRAN M,SAMPATH S,GANESAN V. Numerical analysis of two-ring flame stabilizer flows in aircraft afterburners[J]. Numerical Heat Transfer: Part A Applications,1995,28(1): 85-101. doi: 10.1080/10407789508913734 [7] 赵坚行,颜应文. 加力燃烧室热态流场的大涡模拟[J]. 工程热物理学报,2004,25(增刊): 237-239.ZHAO Jianxing,YAN Yingwen. Large-eddy simulation of turbulent reacting flows for the afterburner[J]. Journal of Engineering Thermophysics,2004,25(Suppl.): 237-239. (in Chinese) [8] 邵茂敏,颜应文,刘勇,等. 模型加力室大涡模拟的并行计算[J]. 航空动力学报,2006,21(3): 497-501. doi: 10.3969/j.issn.1000-8055.2006.03.011SHAO Maomin,YAN Yingwen,LIU Yong,et al. Parallel computing of flow field of a model afterburner[J]. Journal of Aerospace Power,2006,21(3): 497-501. (in Chinese) doi: 10.3969/j.issn.1000-8055.2006.03.011 [9] 章诚,叶桃红,陈义良,等. 三维加力燃烧室两相湍流燃烧的数值模拟[J]. 航空动力学报,2000,15(4): 397-400. doi: 10.3969/j.issn.1000-8055.2000.04.013ZHANG Cheng,YE Taohong,CHEN Yiliang,et al. Numerical simulation of two-phase turbulent combustion in a 3-D afterburner[J]. Journal of Aerospace Power,2000,15(4): 397-400. (in Chinese) doi: 10.3969/j.issn.1000-8055.2000.04.013 [10] 朱祚金,张孝春. 加力燃烧室单相燃烧模型及其应用[J]. 推进技术,1997,18(5): 36-40,45. doi: 10.3321/j.issn:1001-4055.1997.05.009ZHU Zuojin,ZHANG Xiaochun. Single phase combustion model and its application in a jet endine afterburner[J]. Journal of Propulsion Technology,1997,18(5): 36-40,45. (in Chinese) doi: 10.3321/j.issn:1001-4055.1997.05.009 [11] PETERS N. Laminar flamelet concepts in turbulent combustion[J]. Symposium (International) on Combustion,1988,21(1): 1231-1250 . doi: 10.1016/S0082-0784(88)80355-2 [12] MARBLE F E, BROADWELL J. The coherent flame model of non-premixed turbulent combustion[M]. Poston: Springer, 1977. [13] WILLIAMS F A. A review of some theoretical combustions of turbulent flame structure[C]//AGARD Conference Proceedings Ⅱ. Copenhagen: OPTICA, 1975: 1-25. [14] BERGLUND M,FUREBY C. LES of supersonic combustion in a scramjet engine model[J]. Proceedings of the Combustion Institute,2007,31(2): 2497-2504. doi: 10.1016/j.proci.2006.07.074 [15] GAMBA M, MUNGAL M G, HANSON R K. Ignition and near-wall burning in transverse hydrogen jets in super sonic crossflow[R]. AIAA-2011-319, 2011. [16] PIERCE C D,MOIN P. Progress-variable approach for large-eddy simulation of non-premixed turbulent combustion[J]. Journal of Fluid Mechanics,2004,504: 73-97. doi: 10.1017/S0022112004008213 [17] 金台. 超声速湍流燃烧多物理耦合的直接数值模拟[D]. 杭州: 浙江大学, 2015.JIN Tai. Direct numerical simulation of coupled multi-physics in supersonic turbulent combustion[D]. Hangzhou: Zhejiang University, 2015. (in Chinese) [18] HUANG Yakun, HE Xiaomin, ZHANG Huangwei, et al. Spark ignition and stability limits of spray kerosene flames under subatmospheric pressure conditions[J]. Aerospace Science and Technology, 2021, 114: 106734.1-106734.12. -

下载:

下载: