Numerical study on condensation of moist jet in Laval nozzle

-

摘要:

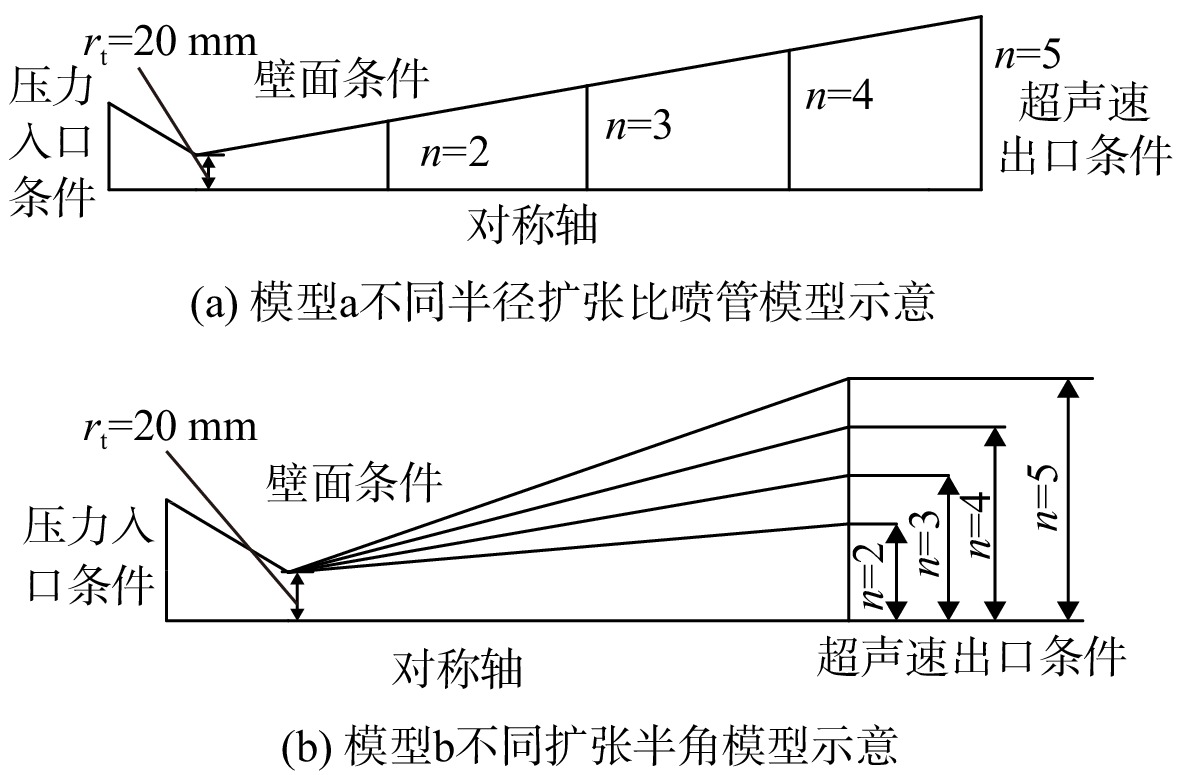

为明确拉瓦尔喷管内流动凝结效应以及喷管几何条件、水蒸气含量等因素对凝结状态的影响,采用综合了流动控制方程、相变成核模型和粒子生长模型的欧拉离散相计算方法,对扩张比分别为2、3、4、5和水蒸气含量分别为10%、30%、50%、70%、90%、100%的模型进行数值计算分析。计算结果表明:水蒸气凝结对喷管内的流场参数具有显著影响,水蒸气凝结释放潜热,流场温度明显高于不考虑凝结效应的模型状态;随着扩张比增大,轴线上喷管出口处液滴半径增随着喷管扩张半角增大,轴线上液滴出现位置更靠近喉部,轴线上喷管出口处液滴半径增大;随着水蒸气含量增大,轴线上液滴出现位置更靠近喉部,水蒸气含量与液滴粒径之间表现为非线性关系。

Abstract:The Eulerian dispersed phase method combining the flow governing equations, nucleation model and droplet growth model was adopted to clarify the influence of condensation on the flow field, and the influence of nozzle geometry and gas humidity on the condensation state. The models with nozzle radius ratio of 2, 3, 4, 5 and gas humidities of 10%, 30%, 50%, 70%, 90%, 100% were numerically simulated. The results showed that the influences of condensation effect no the flow field were obvious and the temperature of condensation flow field was higher than non-condensation condition because of the latent heat released by vapor condensation. With the increase of the nozzle radius ratio, the droplet radius at the exit of nozzle axis increased. The droplet appeared closer to the throat and the droplet radius at the exit of axis was larger with the increase of nozzle half angle. The relationship between gas humidity and droplet size was nonlinear, and the droplets appeared closer to throat with higher gas humidity.

-

表 1 喷管入口条件设置

Table 1. Initial parameters of nozzle inlet

模型编号 rin/mm n xin/mm rt/mm xout/mm $ \theta $/(°) h/% Tin/K pin/MPa a 50 2 50 20 113.43 10 50 500 3 50 3 50 20 226.85 10 50 500 3 50 4 50 20 340.28 10 50 500 3 50 5 50 20 453.70 10 50 500 3 b 50 2 50 20 226.85 5 50 500 3 50 3 50 20 226.85 10 50 500 3 50 4 50 20 226.85 14.8 50 500 3 50 5 50 20 226.85 19.4 50 500 3 表 2 计算初始条件

Table 2. Initial conditions

模型 Tin/K pin/Pa 来流组分 低压条件 354.6 2.5×104 水蒸气 高压条件 544 3.2×106 水蒸气 表 3 出口处压强、温度、水蒸气含量及液滴半径

Table 3. Pressure, temperature, water vapor content and droplet radius at the outlet

h/% pe/Pa T/K psat/Pa he/% r/µm 10 40800.43 282.78 1196.91 2.34 1.135 20 42929.58 310.86 6527.35 11.49 1.310 30 59895.79 352.14 45461.3 21.64 1.422 40 79429.08 373.38 102126.5 32.20 1.505 50 56972.7 351.07 43515.3 43.14 1.777 60 56821.61 354.23 49473.6 54.12 1.845 70 56868.73 357.96 57373.3 65.34 1.740 80 67629.17 371.90 96857.2 76.66 1.701 90 56401.84 361.59 66048.7 88.26 1.697 100 66114.21 375.41 109738.7 100 1.747 -

[1] WEGENER P P. Condensation phenomena in nozzles[J]. Progress in Astronautics and Rocketry,1964,15: 701-724. [2] HILL P G. Condensation of water vapour during supersonic expansion in nozzles[J]. Journal of Fluid Mechanics,1966,25(3): 593-620. doi: 10.1017/S0022112066000284 [3] 孙皖,徐涛,刘秀芳,等. 凝结相变对低温风洞雷诺数试验的影响[J]. 航空动力学报,2020,35(9): 1893-1899.SUN Wan,XU Tao,LIU Xiufang,et al. Effect of condensation phase transient on Reynold number test for cryogenic wind tunnel[J]. Journal of Aerospace Power,2020,35(9): 1893-1899. (in Chinese) [4] FRANCESCO G,FEDERICO M,ADRIANO M. CFD modelling of the condensation inside a cascade of steam turbine blades: comparison with an experimental test case[J]. Energy Procedia,2017,126: 730-737. doi: 10.1016/j.egypro.2017.08.306 [5] NAGIB ELMEKAWY A M,ALI M E H H. Computational modeling of non-equilibrium condensing steam flows in low-pressure steam turbines[J]. Results in Engineering,2020,5: 100065.1-100065.11. [6] 汤永智, 刘中良, 武洪强, 等. 蒸汽喷射器混合过程中凝结流态的可视化研究[J]. 工程热物理学报, 2019, 40(10): 2364-2372.TANG Yongzhi, LIU Zhongliang, WU Hongqiang, et al. Visualization study on the condensation flow regime in the mixing process of steam ejector[J]. Journal of Engineering Thermophysics, 2019, 40(10): 2364-2372. (in Chinese) [7] 杨文, 曹学文, 赵联祁, 等. 超声速旋流分离器内天然气液化过程研究[J]. 石油机械, 2015, 43(5): 87-91, 100.YANG Wen, CAO Xuewen, ZHAO Lianqi, et al. Study on natural gas liquefaction process within supersonic cyclone separator[J]. China Petroleum Machinery, 2015, 43(5): 87-91, 100. (in Chinese) [8] 杨文,曹学文,徐晓婷,等. 高速膨胀天然气凝结流动特性[J]. 石油学报(石油加工),2016,32(1): 73-81.YANG Wen,CAO Xuewen,XU Xiaoting,et al. Flow and condensation characteristics of natural gas with high speed expansion[J]. Acta Petrolei Sinica (Petroleum Processing Section),2016,32(1): 73-81. (in Chinese) [9] 曹学文,边江,靳学堂,等. 三组分气体超声速凝结过程数值模拟与实验研究[J]. 石油学报(石油加工),2019,35(1): 99-110.CAO Xuewen,BIAN Jiang,JIN Xuetang,et al. Numerical simulation and experimental study on supersonic condensation process of ternary mixture[J]. Acta Petrolei Sinica (Petroleum Processing Section),2019,35(1): 99-110. (in Chinese) [10] PAOLI R,SHARIFF K. Contrail modeling and simulation[J]. Annual Review of Fluid Mechanics,2016,48(1): 393-427. doi: 10.1146/annurev-fluid-010814-013619 [11] DALIN P,PERMINOV V,PERTSEV N,et al. Optical studies of rocket exhaust trails and artificial noctilucent clouds produced by Soyuz rocket launches[J]. Journal of Geophysical Research:Atmospheres,2013,118(14): 7850-7863. doi: 10.1002/jgrd.50549 [12] 李健兵,高航,王涛,等. 飞机尾流的散射特性与探测技术综述[J]. 雷达学报,2017,6(6): 653-672.LI Jianbing,GAO Hang,WANG Tao,et al. A survey of the scattering characteristics and detection of aircraft wake vortices[J]. Journal of Radars,2017,6(6): 653-672. (in Chinese) [13] 尚德敏,姜宝成,陈安斌,等. 燃油添加剂对喷气飞行器凝结尾迹的隐身作用[J]. 哈尔滨工业大学学报,1994,26(4): 24-27.SHANG Demin,JIANG Baocheng,CHEN Anbin,et al. Stealth function of jet aircraft’s condensation trail made of fuel additive[J]. Journal of Harbin Institute of Technology,1994,26(4): 24-27. (in Chinese) [14] YANG Yan,WALTHER J H,YAN Yuying,et al. CFD modeling of condensation process of water vapor in supersonic flows[J]. Applied Thermal Engineering,2017,115: 1357-1362. doi: 10.1016/j.applthermaleng.2017.01.047 [15] 杨勇,于欢,沈胜强,等. 水蒸气跨声速流动中非平衡相变与激波的耦合作用[J]. 工程热物理学报,2013,34(7): 1347-1351. doi: 10.1007/s10765-013-1494-zYANG Yong,YU Huan,SHEN Shengqiang,et al. Coupling effect of shock and non-equilibrium phase change of transonic steam flow[J]. Journal of Engineering Thermophysics,2013,34(7): 1347-1351. (in Chinese) doi: 10.1007/s10765-013-1494-z [16] KUNG R T V,CIANCIOLO L,MYER J A. Solar scattering from condensation in Apollo translunar injection plume[J]. AIAA Journal,1975,13(4): 432-437. doi: 10.2514/3.49725 [17] DYKAS S,MAJKUT M,SMOŁKA K,et al. Comprehensive investigations into thermal and flow phenomena occurring in the atmospheric air two-phase flow through nozzles[J]. International Journal of Heat and Mass Transfer,2017,114: 1072-1085. doi: 10.1016/j.ijheatmasstransfer.2017.06.131 [18] MOSES C A,STEIN G D. On the growth of steam droplets formed in a Laval nozzle using both static pressure and light scattering measurements[J]. Journal of Fluids Engineering,1978,100(3): 311-322. doi: 10.1115/1.3448672 [19] BAKHTAR F,ZIDI K. Nucleation phenomena in flowing high-pressure steam: experimental results[J]. Proceedings of the Institution of Mechanical Engineers: Part A Journal of Power Engineering,1989,203(3): 195-200. doi: 10.1243/PIME_PROC_1989_203_027_02 [20] BAKHTAR F,ZIDI K. Nucleation phenomena in flowing high-pressure steam: Part Ⅱ theoretical analysis[J]. Proceedings of the Institution of Mechanical Engineers: Part A Journal of Power and Energy,1990,204(4): 233-242. doi: 10.1243/PIME_PROC_1990_204_032_02 [21] EDATHOL J,BREZGIN D,ARONSON K,et al. Prediction of non-equilibrium homogeneous condensation in supersonic nozzle flows using Eulerian-Eulerian models[J]. International Journal of Heat and Mass Transfer,2020,152: 119451. doi: 10.1016/j.ijheatmasstransfer.2020.119451 [22] WEN Chuang,KARVOUNIS N,WALTHER J H,et al. Non-equilibrium condensation of water vapour in supersonic flows with shock waves[J]. International Journal of Heat and Mass Transfer,2020,149: 119109. doi: 10.1016/j.ijheatmasstransfer.2019.119109 [23] 刘光照,朱亚男. 晶体成核理论[J]. 人工晶体,1981,10(2): 1-34.LIU Guangzhao,ZHU Yanan. Crystal nucleation theory[J]. Journal of Synthetic Crystals,1981,10(2): 1-34. (in Chinese) [24] GYARMATHY G. The spherical droplet in gaseous carrier streams: review and synthesis[J]. Multiphase Science and Technology,1982,1(1/2/3/4): 99-279. [25] YOUNG J. Spontaneous condensation of steam in supersonic nozzles[J]. Physicochemical Hydrodynamics,1982,3(1): 57-82. [26] LAÍN S,ALIOD R. Study on the Eulerian dispersed phase equations in non-uniform turbulent two-phase flows: discussion and comparison with experiments[J]. International Journal of Heat and Fluid Flow,2000,21(3): 374-380. doi: 10.1016/S0142-727X(00)00023-0 [27] GERBER A G,KERMANI M J. A pressure based Eulerian-Eulerian multi-phase model for non-equilibrium condensation in transonic steam flow[J]. International Journal of Heat and Mass Transfer,2004,47(10/11): 2217-2231. [28] MOORE M J, WALTERS P T, CRANE R I, et al. Predicting the fog fog-drop size in wet- stream turbines[C]// Proceedings of the IMechE Conference on Heat and Fluid Flow in Steam and Gas Trubine Plant, London: IMechE, 1973: 101-109. -

下载:

下载: