Mechanism of stability improvement with slot casing treatment in counter-rotating compressor

-

摘要:

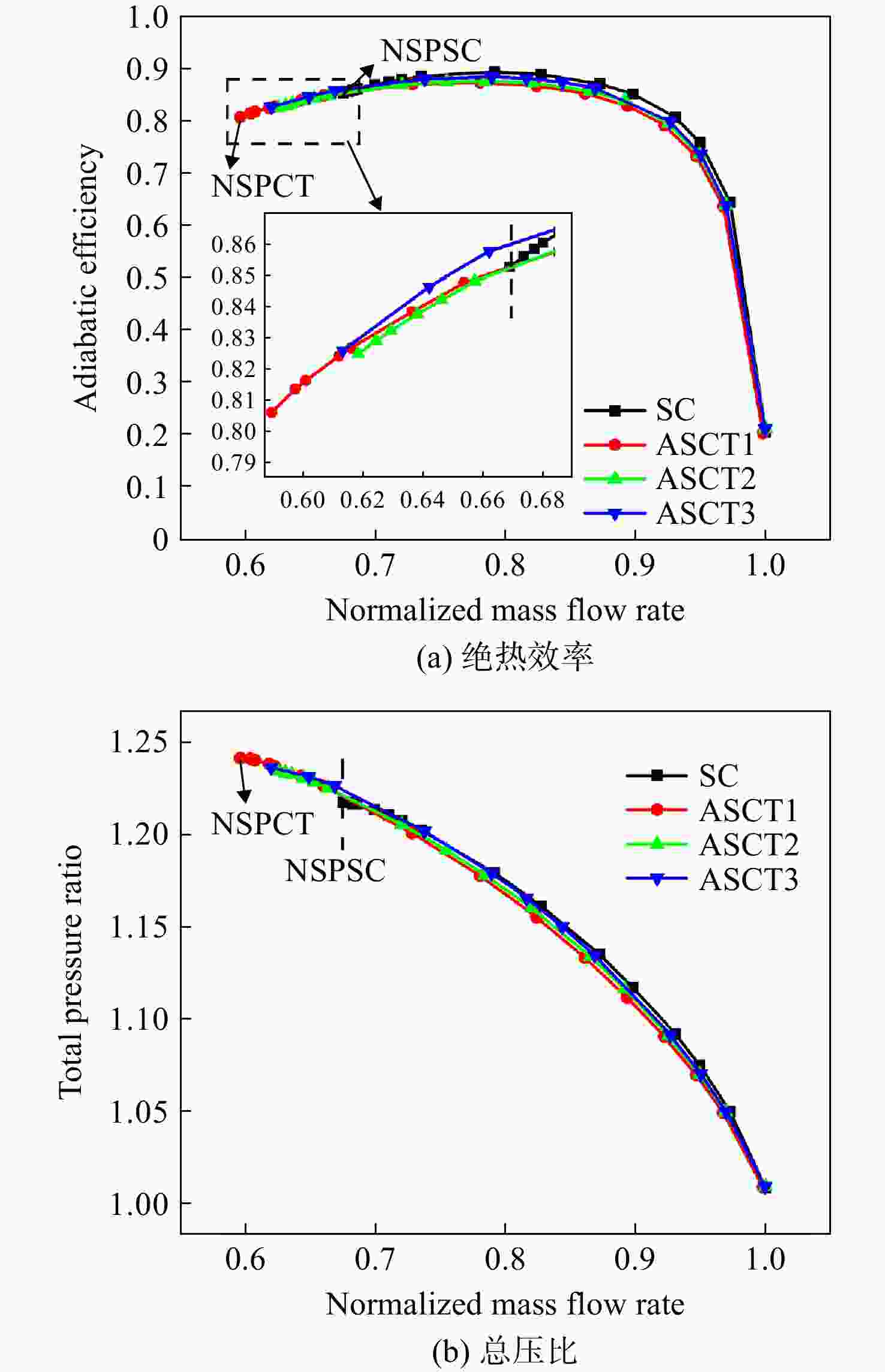

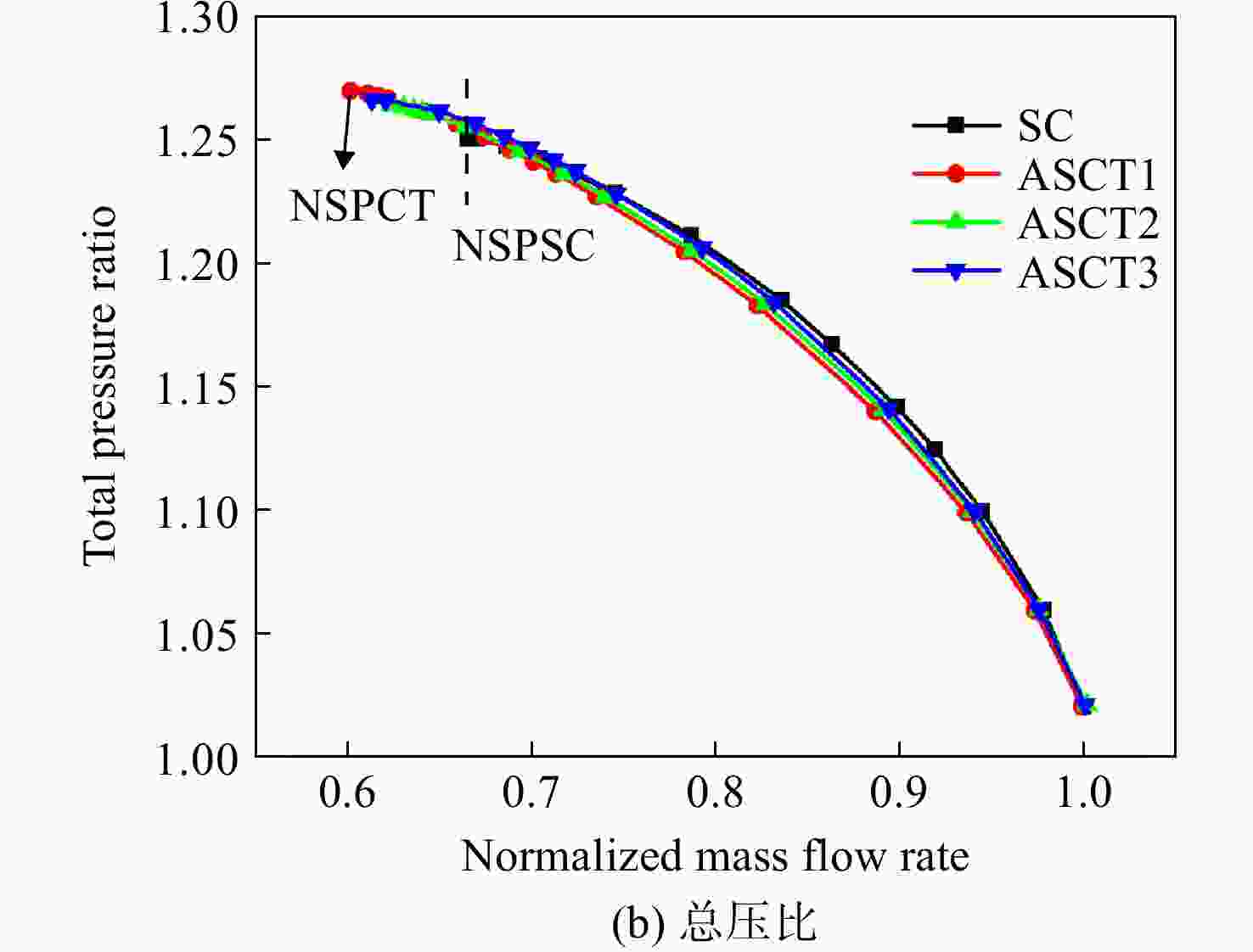

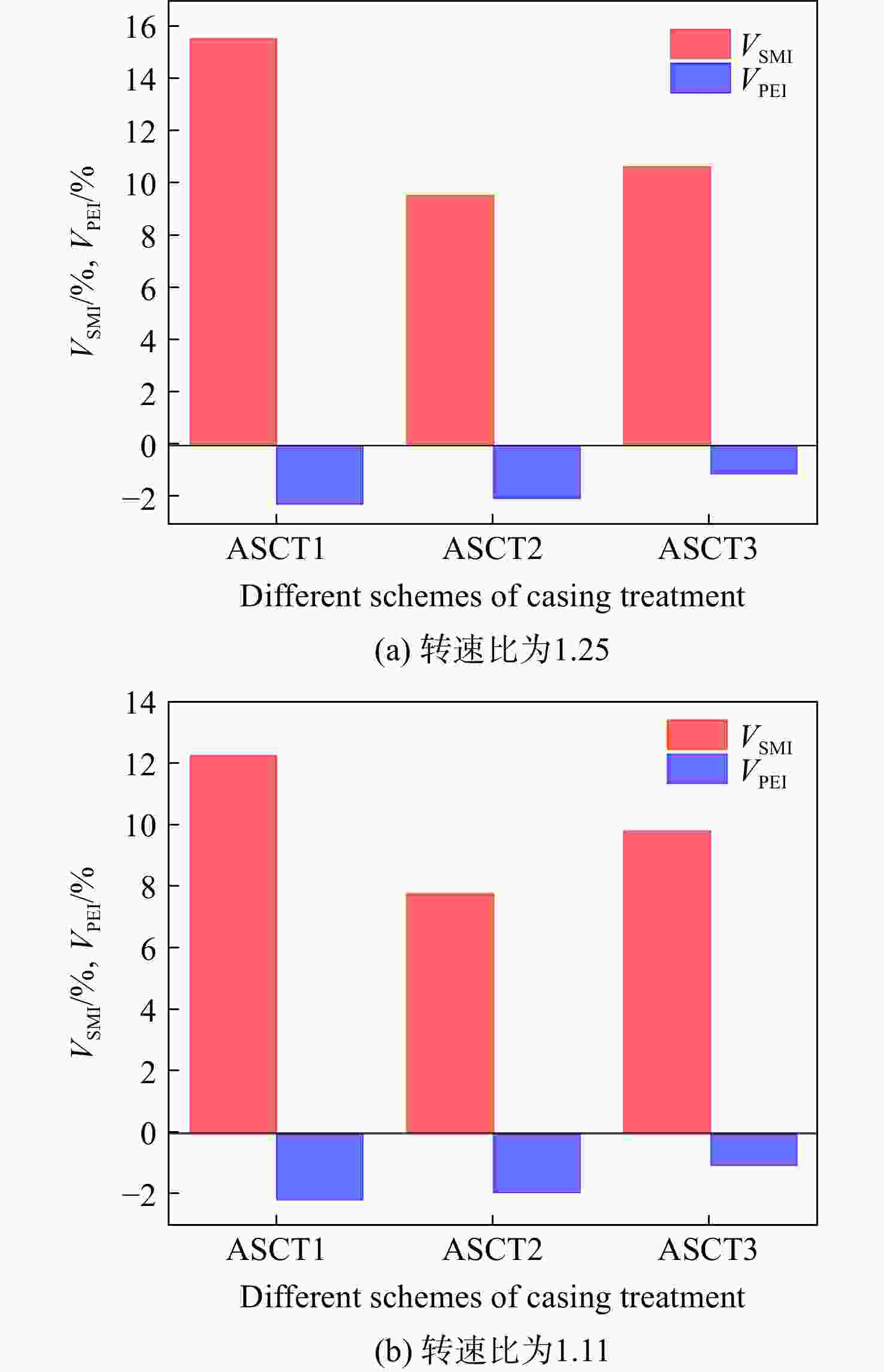

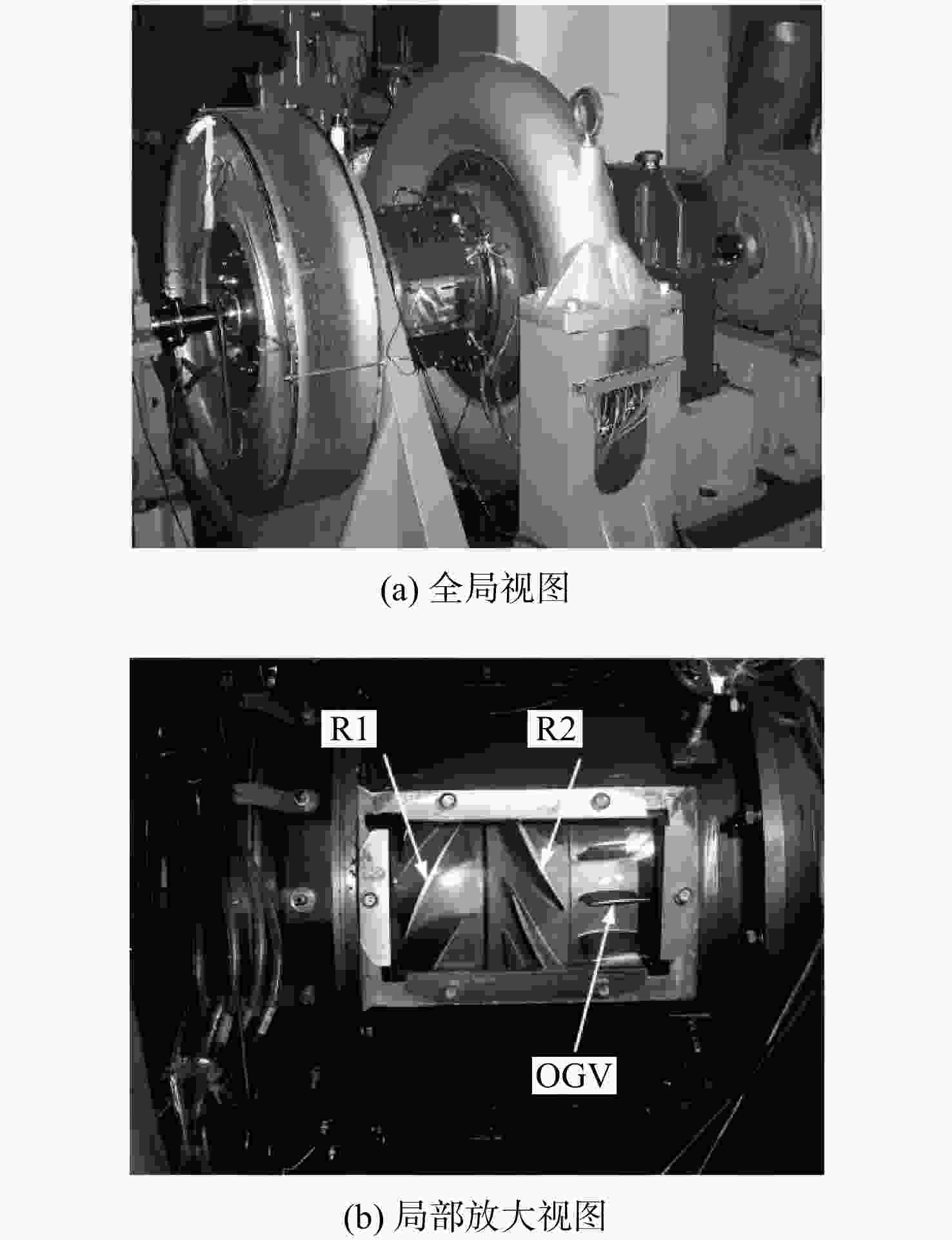

为探索缝式机匣处理在对转压气机中的适用性,采用数值模拟的方法研究了缝式机匣处理对对转压气机气动性能和稳定裕度的影响。通过分析缝式机匣处理对压气机总体性能和叶尖流场的影响,以揭示缝式机匣处理在对转压气机中的扩稳机理。研究表明:缝式机匣处理可以提高对转压气机的失速裕度,机匣处理的轴向位置对对转压气机的气动性能和失速裕度有显著的影响。随着机匣处理的前移,对转压气机峰值效率的亏损逐渐减小,而失速裕度改善程度相差不大。机匣处理缝的抽吸和射流效应减弱了转子R2叶顶通道的堵塞程度,通过抑制叶尖泄漏流和二次泄漏流的发展以推迟失速的发生,进而实现扩稳。此外,缝式机匣处理时可能改变该对转压气机的最先失速级,同时也证明了缝式机匣处理在变工况下扩稳的有效性。

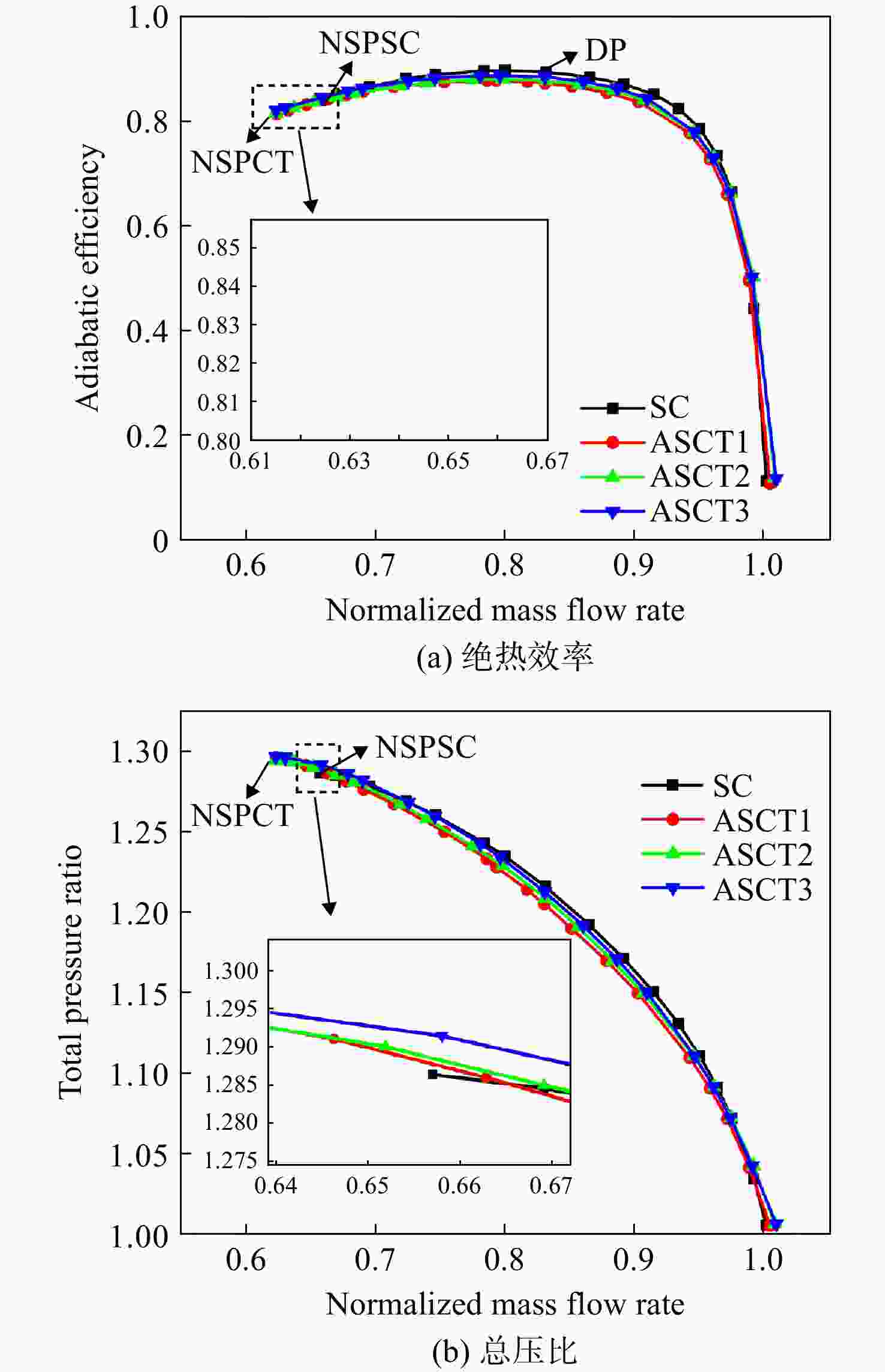

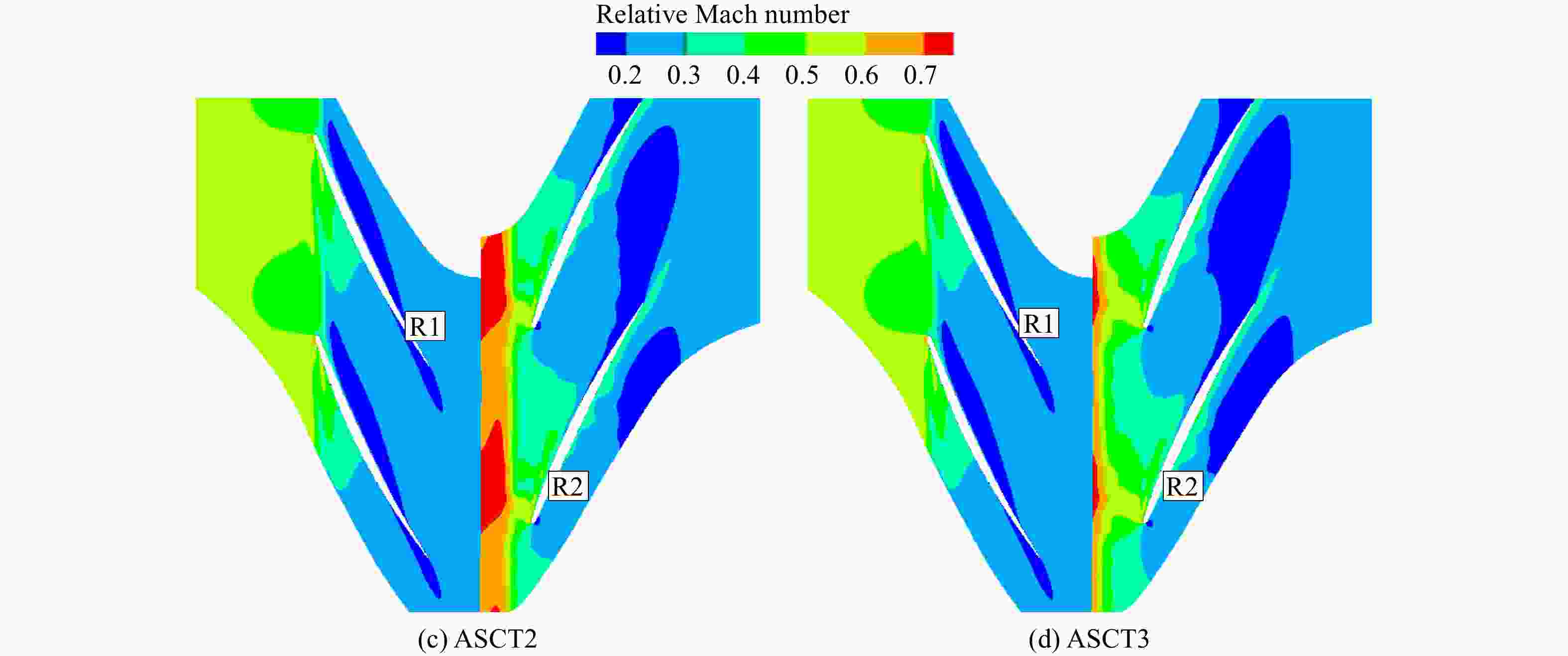

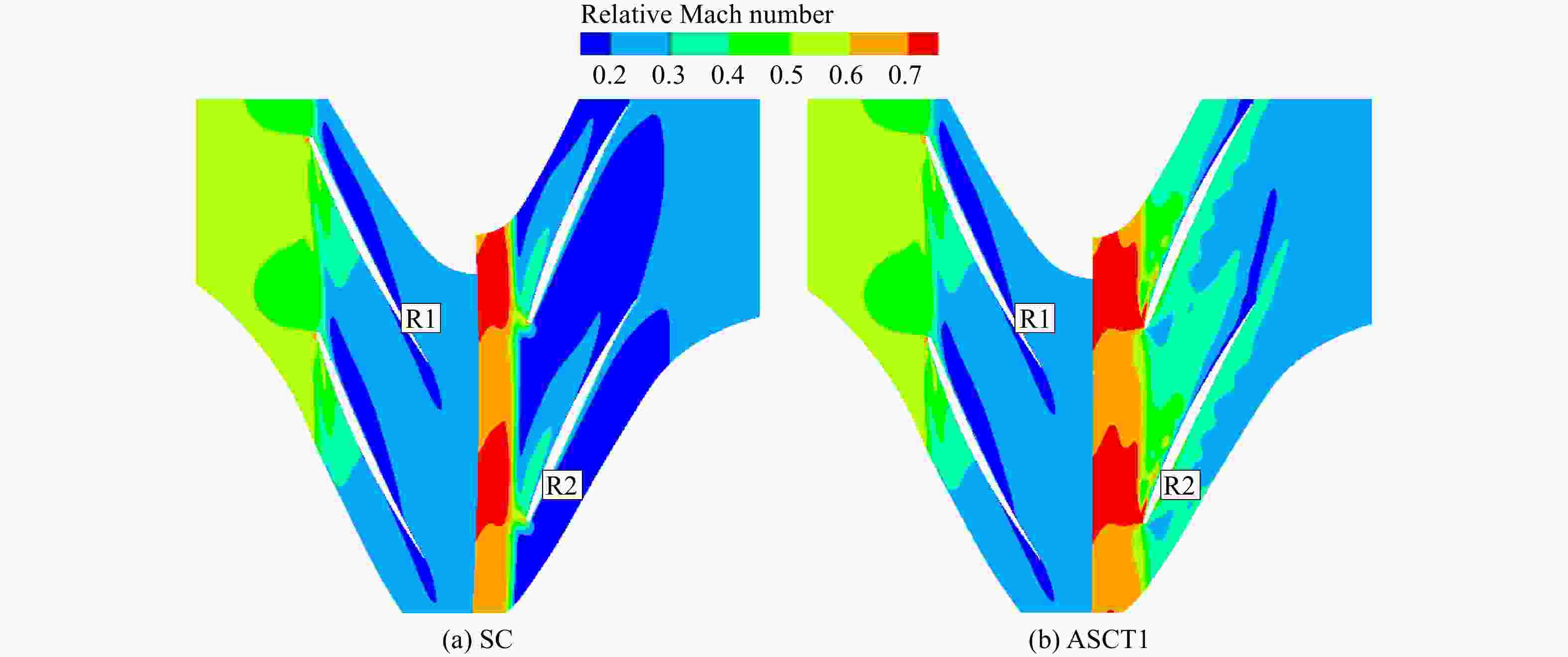

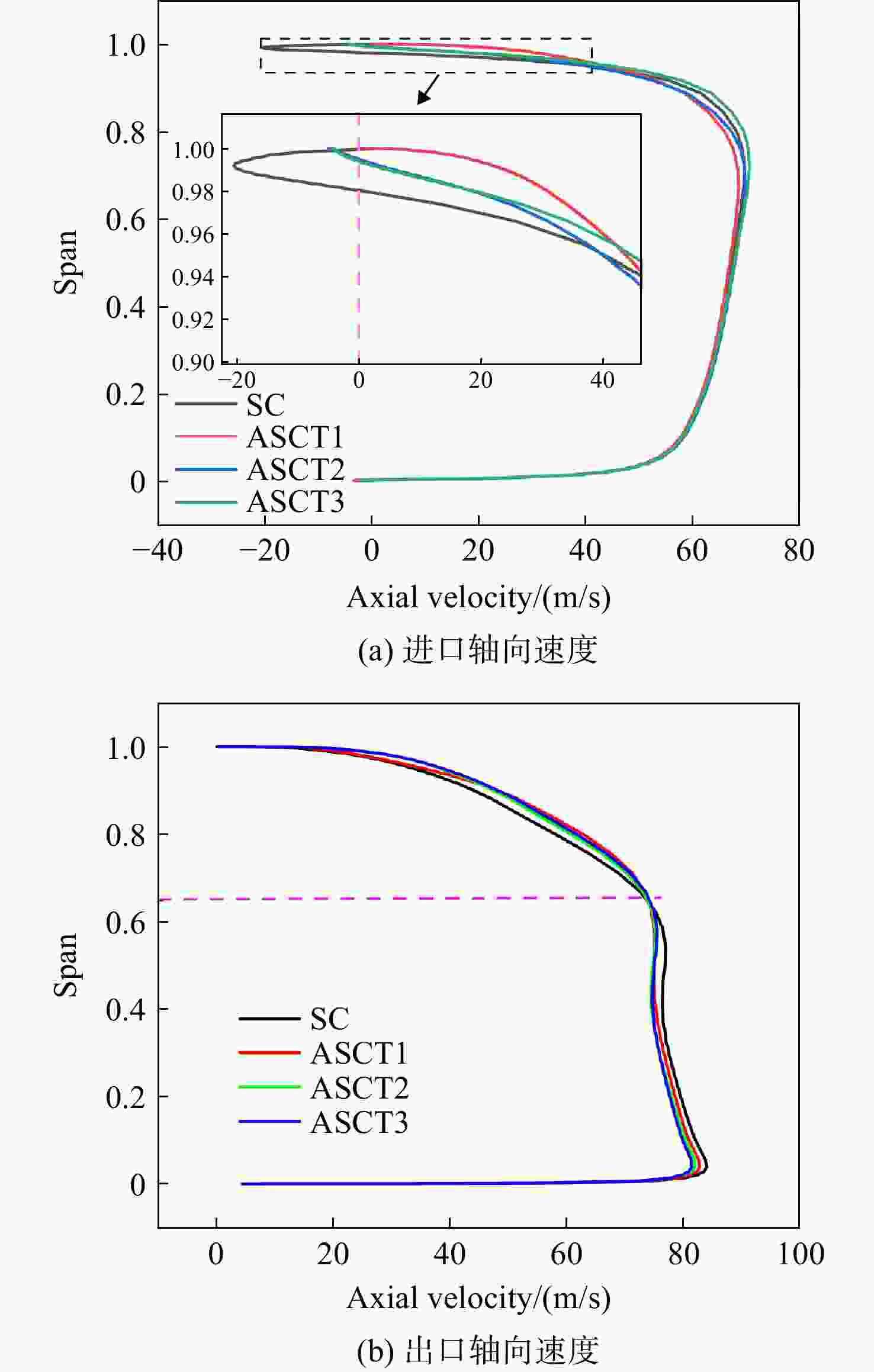

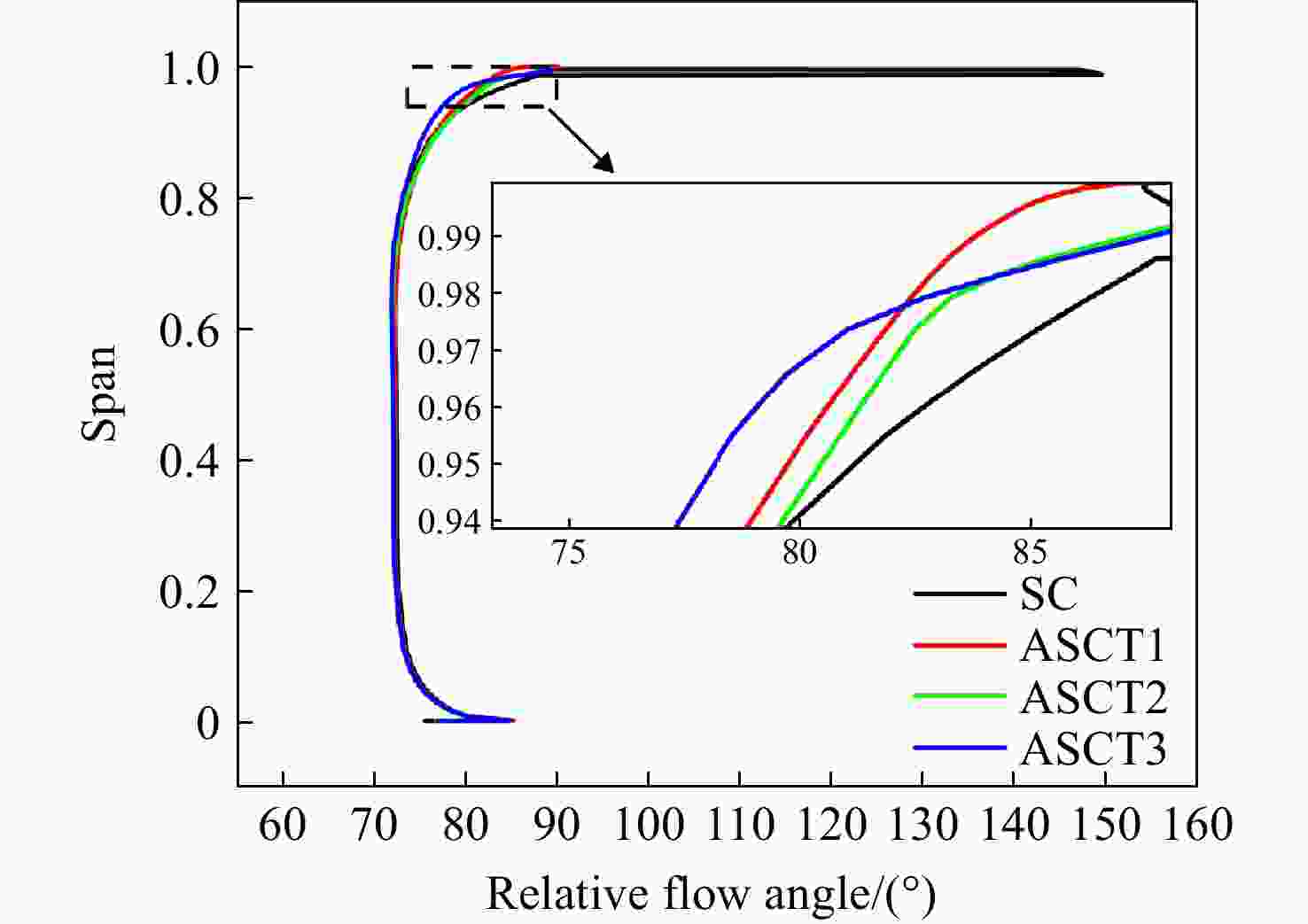

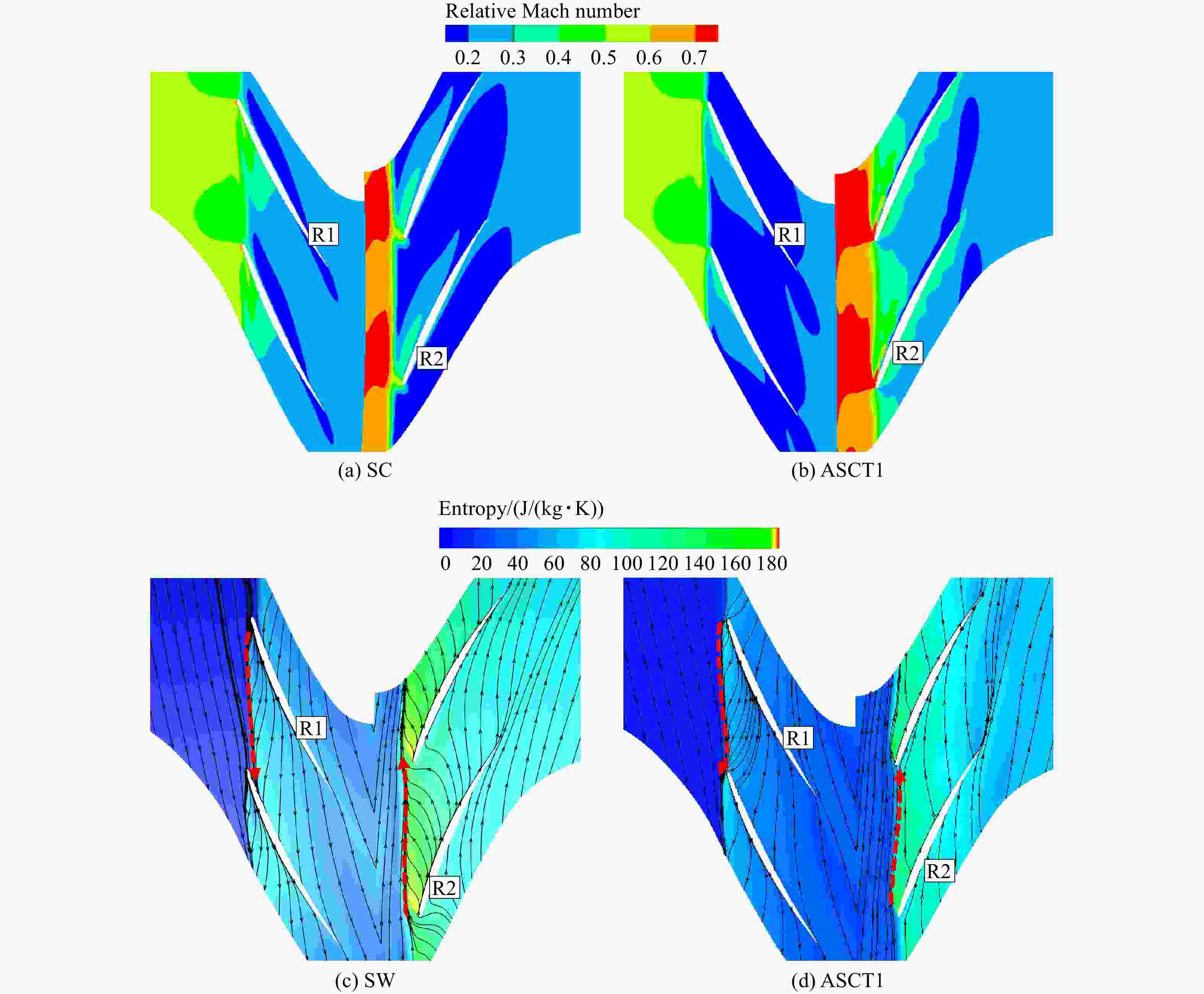

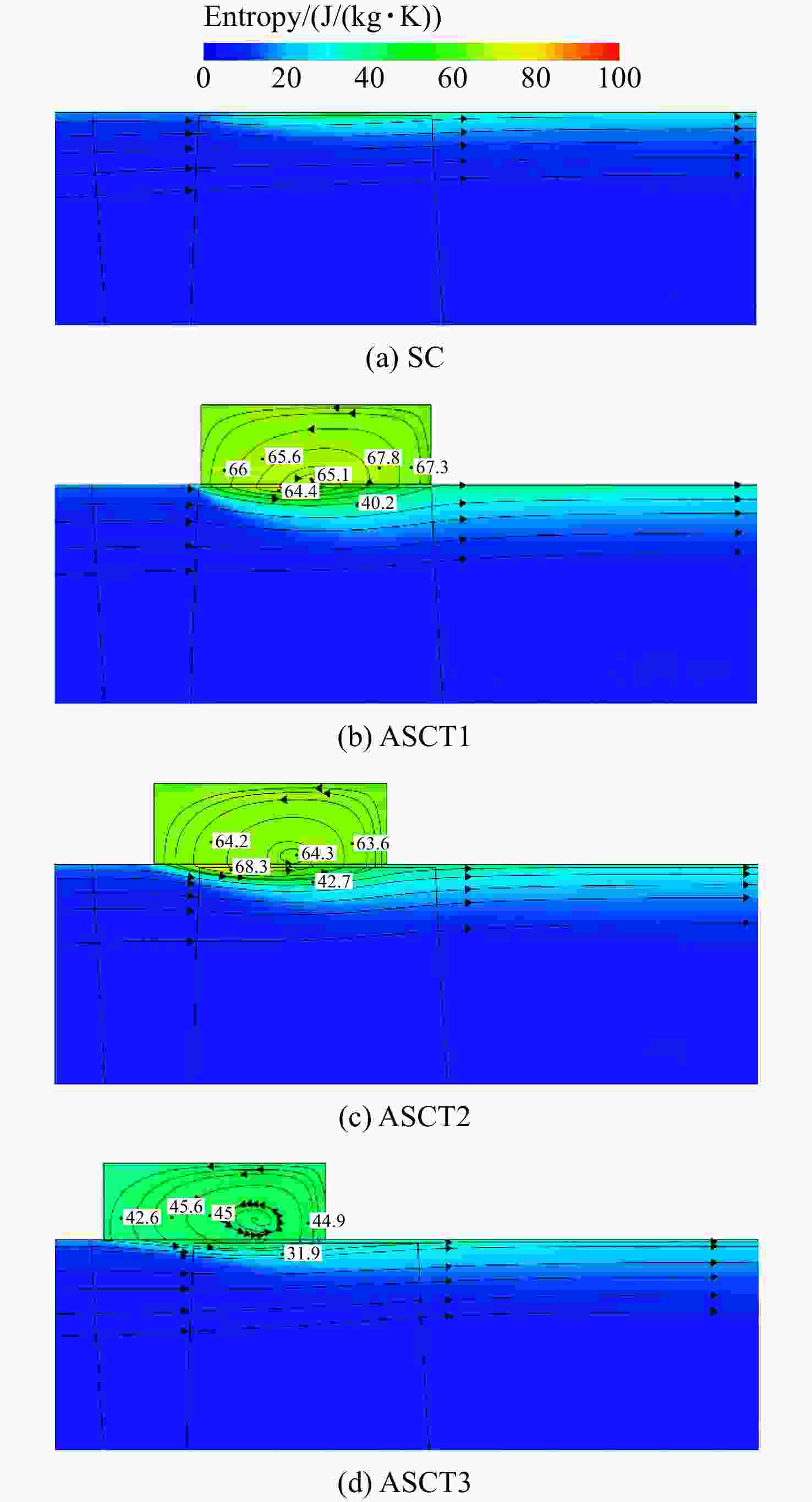

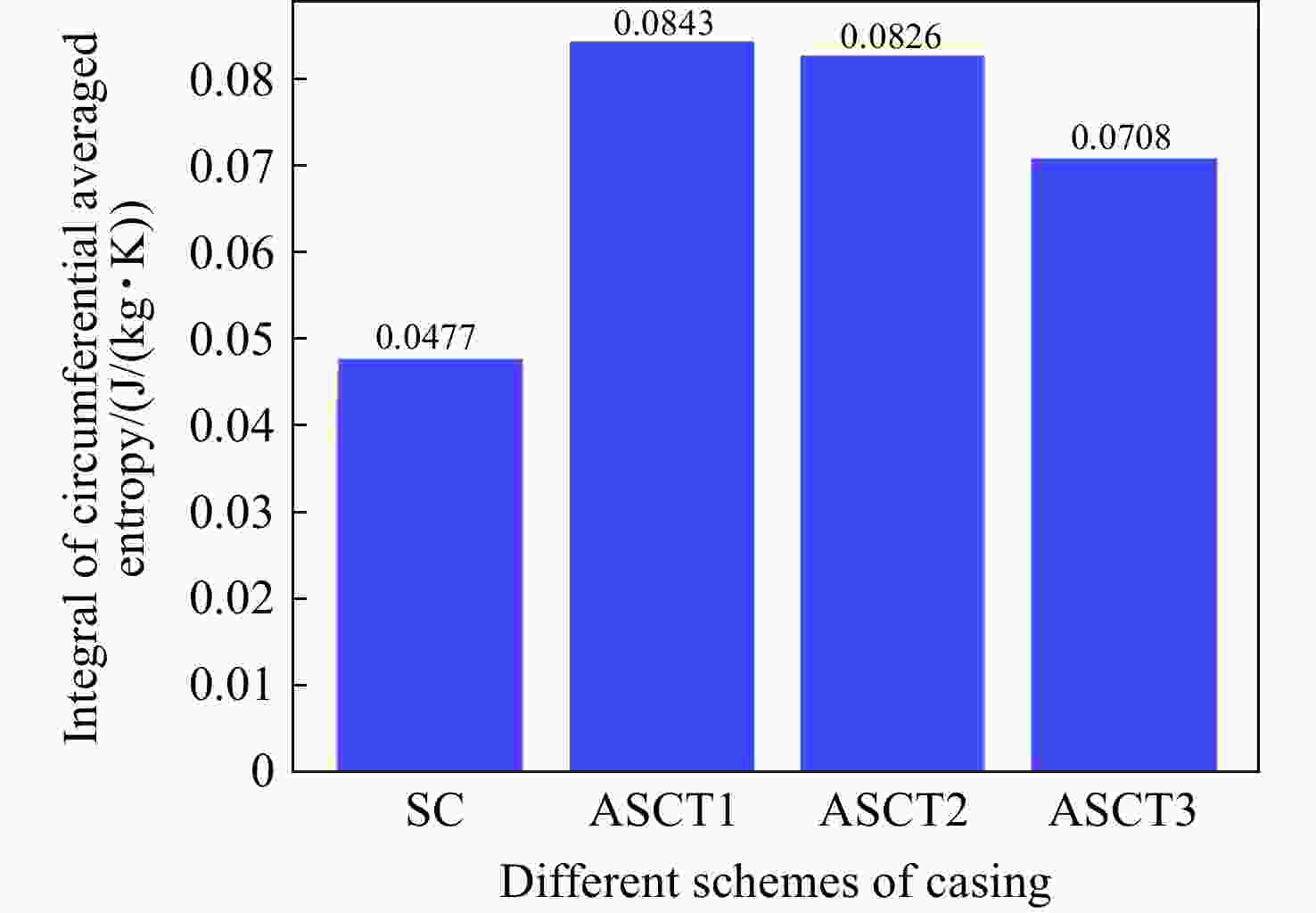

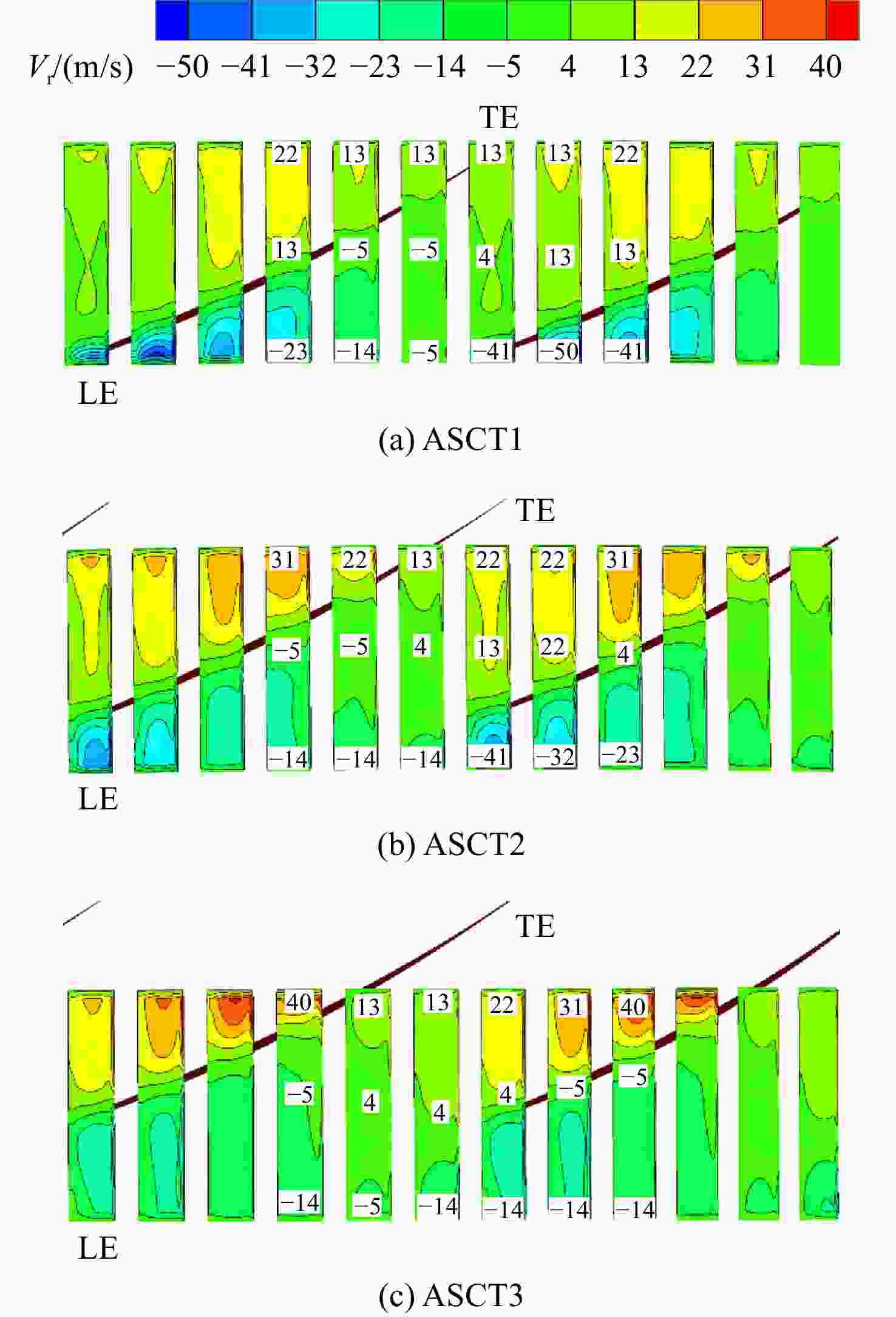

Abstract:In order to explore the applicability of slot casing treatment in counter-rotating compressors, the effects of slot casing treatment on the aerodynamic performance and stability margin of a counter-rotating compressor were investigated by numerical simulation. The effect of the slot casing treatment on overall performance of the compressor and tip flow field was analyzed to reveal the stall margin improvement mechanism of the slot casing treatment in the counter-rotating compressor. The study showed that the slot casing treatment can improve the stability margin of the counter-rotating compressor, and the axial position of the casing treatment had a significant impact on the aerodynamic performance and stability margin of the counter-rotating compressor. With the forward movement of the casing treatment, the peak efficiency loss of the counter-rotating compressor gradually decreased, while the stall margin improvement was not much different. The combined effect of bleed and injection of the slots slowed down the degree of blockage in the rotor R2 blade tip passage, and achieved stability improvement by suppressing the development of tip leakage flow and secondary leakage flow. In addition, the slot casing treatment may change the first stall stage of this counter-rotating compressor, demonstrating the effectiveness of slot casing treatment in the expansion of stability under variable operating conditions.

-

表 1 转子的主要设计参数

Table 1. Main design parameters of the rotors

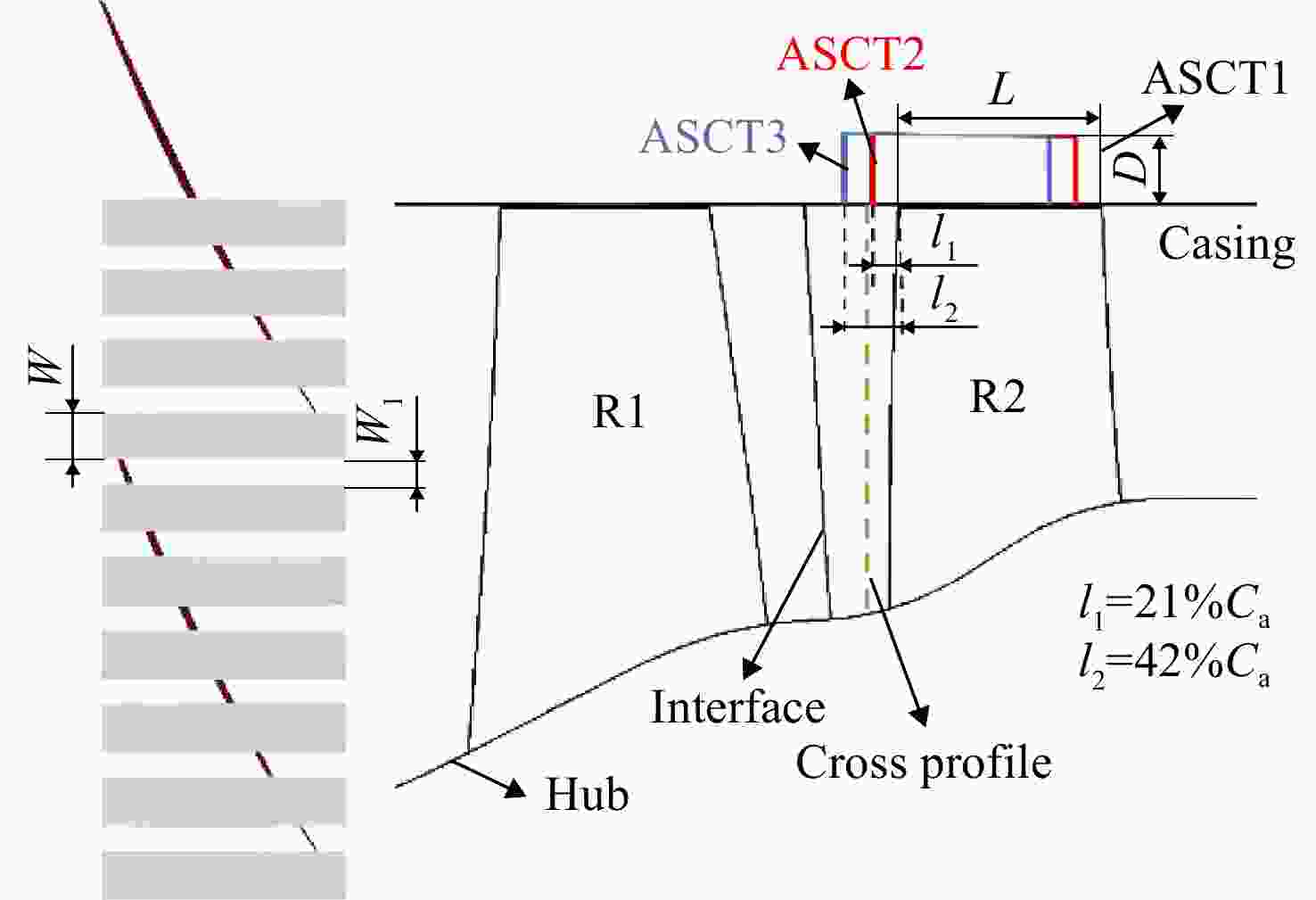

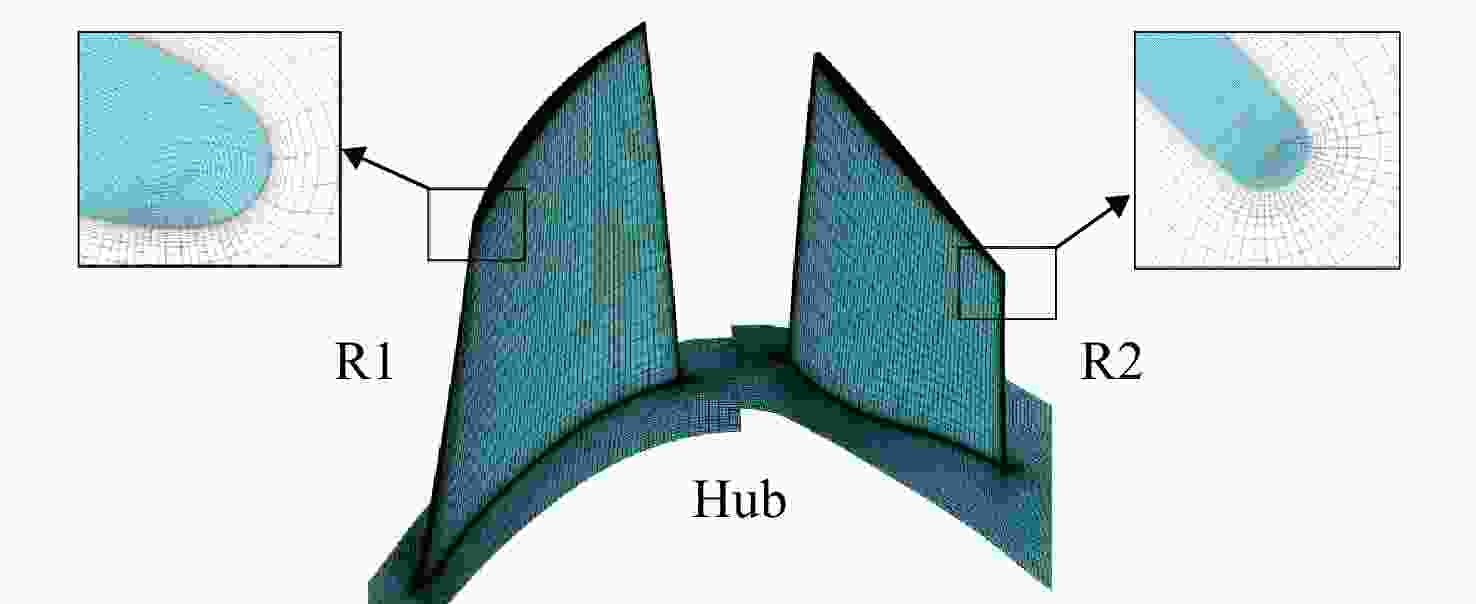

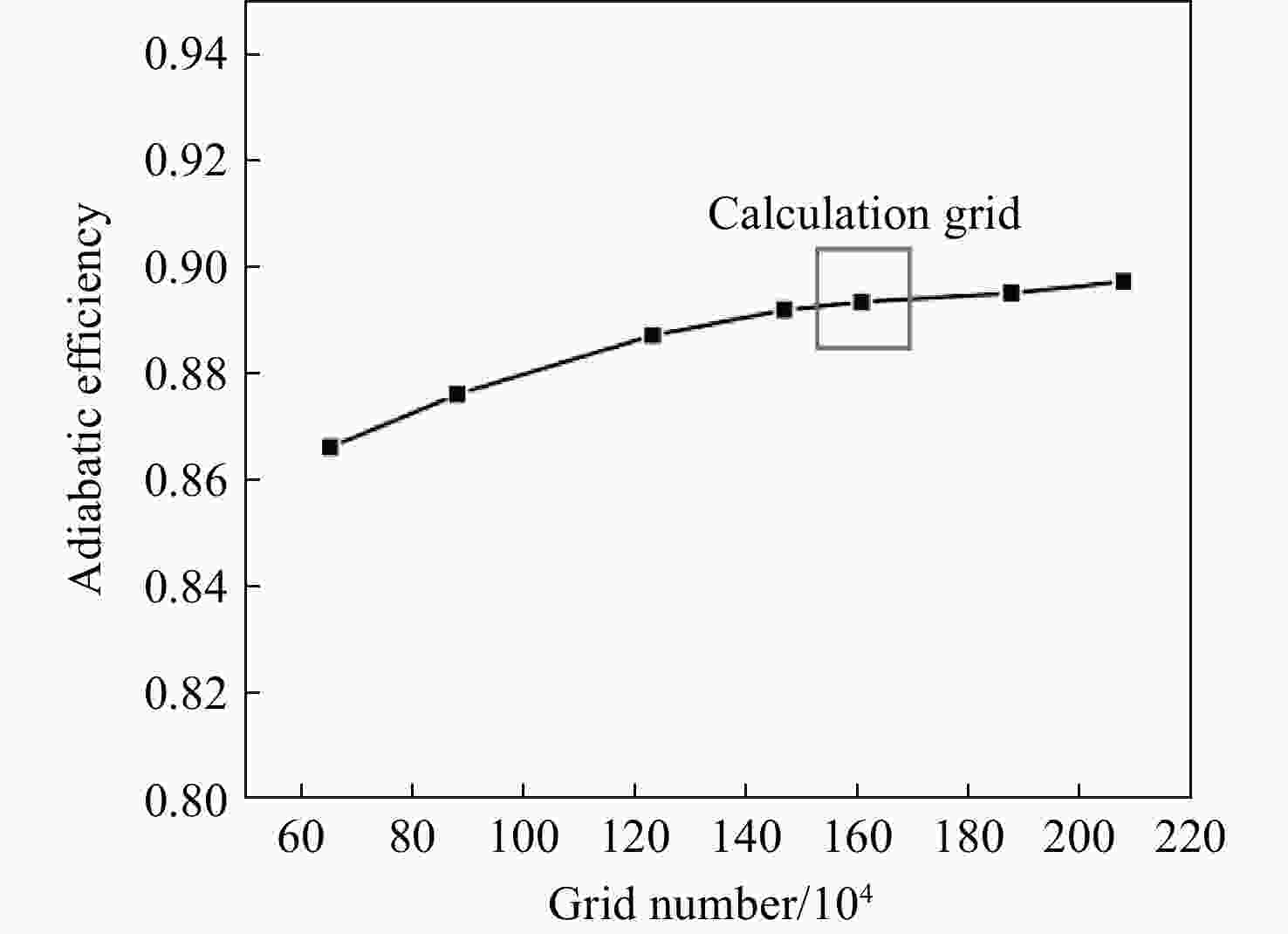

设计参数 转子1(R1) 转子2(R2) 转速N/(r/min) 8000 −8000 叶片数n 19 20 叶顶间隙τ/mm 0.5 0.5 叶尖弦长C/m 0.0832 0.0769 叶尖速度Utip/(m/s) 167.6 167.6 进口轮毂比 0.485 0.641 表 2 缝式机匣处理几何参数

Table 2. Geometry parameters of slot casing treatment

参数 缝式机匣处理类型 ASCT1 ASCT2 ASCT3 缝长(L/Ca)/% 100 100 100 缝宽W/mm 7.4 7.4 7.4 缝深D/mm 12 12 12 缝数(单通道缝数)m 6 6 6 中心偏移度 0 0.21 0.42 W/W1 2/1 2/1 2/1 表 3 缝式机匣处理扩稳效果评估

Table 3. Evaluation of stability expansion effect of slot casing treatment

机匣类型 MSMF/(kg/s) VSMI/% VPEI/% ASCT1 4.81 6.23 −2.15 ASCT2 4.806 6.15 −1.82 ASCT3 4.807 6.29 −0.99 -

[1] JOLY M, VERSTRAETE T, PANIAGUA G. Full design of a highly loaded and compact contra-rotating fan using multidisciplinary evolutionary optimization[R]. ASME Paper GT2013-94433,2013. [2] MISTRY C,PRADEEP A M. Effect of variation in axial spacing and rotor speed combinations on the performance of a high aspect ratio contra-rotating axial fan stage[J]. Journal of Power and Energy,2013,227(2): 138-146. doi: 10.1177/0957650912467453 [3] MANAS M P,PRADEEP A M. Stall inception mechanisms in a contra-rotating fan operating at different speed combinations[J]. Journal of Power and Energy,2019,234(8): 1014-1052. [4] KERREBROCK J L,EPSTEIN A H,MERCHANT A A,et al. Design and test of an aspirated counter-rotating fan[J]. Journal of Turbomachinery,2008,130(2): 293-302. [5] MEYER T, KNOBLOCH K, LINDEN J. Hot-wire measurements in a high speed counter rotating turbo fan rig[R]. ASME Paper GT2010-22569,2010. [6] CHEN Y Y,LIU B,XUAN Y,et al. A study of speed ratio affecting the performance of a contra-rotating axial compressor[J]. Journal of Aerospace Engineering,2008,222(7): 985-991. [7] 高丽敏,苗芳,李瑞宇,等. 动/动干涉效应对叶片非定常负荷的影响[J]. 航空学报,2014,35(7): 1874-1881. doi: 10.7527/S1000-6893.2013.0509GAO Limin,MIAO Fang,LI Ruiyu,et al. Effect of rotor/rotor interactions on blades unsteady loading[J]. Acta Aeronautica et Astronautica Sinica,2014,35(7): 1874-1881. (in Chinese) doi: 10.7527/S1000-6893.2013.0509 [8] MAO X,LIU B,ZHAO H. Effects of tip clearance size on the unsteady flow behaviors and performance in a counter-rotating axial flow compressor[J]. Journal of Aerospace Engineering,2017,233(3): 1059-1070. [9] YUE S,WANG Y,WEI L,et al. Experimental investigation on the development process of large-scale low-speed stall disturbance in contra-rotating compressor[J]. Journal of Thermal Science,2020,29(5): 1282-1291. doi: 10.1007/s11630-020-1341-z [10] GAO L, LI X, JIAN X, et al. The effect of speed ratio on the first rotating stall stage in contra-rotating compressor[R]. ASME Paper GT2012-68802,2012. [11] 刘波,茅晓晨,张鹏,等. 对转压气机叶尖间隙效应对其性能影响的研究[J]. 推进技术,2016,37(5): 815-825.LIU Bo,MAO Xiaochen,ZHANG Peng,et al. Research on effects of tip clearance on performance of a contra-rotating compressor[J]. Journal of Propulsion Technology,2016,37(5): 815-825. (in Chinese) [12] 徐强仁,刘智远,马英群,等. 高负荷对转压气机尾迹涡对叶顶泄漏流的影响[J]. 工程热物理学报,2020,41(4): 822-828.XU Qiangren,LIU Zhiyuan,MA Yingqun,et al. The impact of wake vortices on the tip clearance flow in a high-load counter-rotating compressor[J]. Journal of Engineering Thermophysics,2020,41(4): 822-828. (in Chinese) [13] MOORE R D. Effect of casing treatment on overall and blade element performance of a compressor rotor[R]. NASA TN D-6538,1971. [14] OSBORN W M, LEWIS G E, HEIDELBERG L J. Effect of several porous casing treatments on stall limit and on overall performance of an axial flow compressor rotor[R]. NASA TN D-6537,1971. [15] 卢新根,楚武利,朱俊强,等. 轴流压气机机匣处理研究进展及评述[J]. 力学进展,2006,36(2): 222-232. doi: 10.3321/j.issn:1000-0992.2006.02.006LU Xingen,CHU Wuli,ZHU Junqiang,et al. A review of studies on casing treatment of axial-flow compressor[J]. Advance in Mechanics,2006,36(2): 222-232. (in Chinese) doi: 10.3321/j.issn:1000-0992.2006.02.006 [16] MÜLLER M W, SCHIFFER H P, VOGES M, et al. Investigation of passage flow features in a transonic compressor rotor with casing treatments[R].ASME Paper GT2011-45364,2011. [17] WILKE I, KAU H P. A numerical investigation of the flow mechanisms in a HPC front stage with axial slots[R].ASME Paper GT 2003-38481,2003. [18] WILKE I, BRIGNOLE G, AKAU H P. Numerically aided design of a high-efficient casing treatment for a transonic compressor[R].ASME Paper GT2005-68993,2005. [19] 张皓光,楚武利,吴艳辉. 缝式处理机匣轴向位置对压气机特性影响的机理[J]. 航空动力学报,2011,26(1): 92-98. doi: 10.13224/j.cnki.jasp.2011.01.013ZHANG Haoguang,CHU Wuli,WU Yanhui. Mechanism of influences of axial positions of axial skewed slot casing treatment on a compressor performance[J]. Journal of Aerospace Power,2011,26(1): 92-98. (in Chinese) doi: 10.13224/j.cnki.jasp.2011.01.013 [20] ZHOU X,ZHAO Q,CUI W,et al. Investigation on axial effect of slot casing treatment in a transonic compressor[J]. Applied Thermal Engineering,2017,126: 53-69. doi: 10.1016/j.applthermaleng.2017.07.165 [21] BRIGNOLE G A, DANNER F, KAU H P. Time resolved simulation and experimental validation of the flow in axial slot casing treatments for transonic axial compressors[R].ASME Paper GT2008-50593,2008. [22] DJEGHRI N, VO H D, YU H. Parametric study for lossless casing treatment on a mixed-flow compressor rotor[R].ASME Paper GT2015-42750,2015. [23] ZHANG H G,ZHANG X D,WU Y H,et al. Flow mechanism of affecting an axial flow compressor performance and stability with cross-blade slot casing treatments[J]. Journal of Power and Energy,2019,233(1): 17-36. doi: 10.1177/0957650918772620 [24] KUANG H,CHU S W,ZHANG H,et al. Flow mechanism for stall margin improvement via axial slot casing treatment on a transonic axial compressor[J]. Journal of Applied Fluid Mechanics,2017,10(2): 703-712. doi: 10.18869/acadpub.jafm.73.239.27047 [25] PUNDHIR D S,SHARMA P B,CHAUDHARY K K. Effect of casing treatment on aerodynamic performance of a contrarotating axial compressor stage[J]. Journal of Power and Energy,1990,204(11): 47-55. [26] MAO X,LIU B,ZHAO H. Numerical analysis of the circumferential grooves casing treatment in a counter-rotating axial flow compressor[J]. Applied Thermal Engineering,2017,130: 29-39. [27] MAO X,LIU B,TANG T,et al. The Impact of casing groove location on the flow instability in a counter-rotating axial flow compressor[J]. Aerospace Science and Technology,2018,76: 250-259. doi: 10.1016/j.ast.2018.01.037 [28] 李晓军,高丽敏,谢建,等. 双级对转压气机的失速机理[J]. 航空动力学报,2013,28(1): 188-194.LI Xiaojun,GAO Limin,XIE Jian,et al. Rotating stall mechanism of dual-stage contra-rotating compressor[J]. Journal of Aerospace Power,2013,28(1): 188-194. (in Chinese) [29] GREITZER E M,NIKKANEN J P,HADDAD D E,et al. A Fundamental criterion for the application of rotor casing treatment[J]. Journal of Fluids Engineering,1979,101(2): 237-243. doi: 10.1115/1.3448945 [30] ZHANG S, CHU W, YANG J. Effect of axial short slot casing treatment and its center deviation on stability of a transonic axial flow compressor[R].ASME Paper GT2020-14588,2020. [31] MA N, NAN X, LIN F. Numerical study on effects of axial-slot casing treatment on peak efficiency of axial compressors[R].ASME Paper GT2016-56554,2016. [32] 张皓光, 谭锋, 安康, 等. 进口畸变下缝式机匣处理改善轴流压气机性能的研究[J].推进技术,2018,39(1):46-58.ZHANG Haoguang, TAN Feng, AN Kang, et al. Investigation of performance improvement for axial flow compressor with slots casing treatment with inlet distortion[J]. Journal of Propulsion Technology,2018,39(1):46-58. (in Chinese) [33] BA D,ZHANG Q,LI Z,et al. Design optimization of axial slot casing treatment in a highly-loaded mixed-flow compressor[J]. Aerospace Science and Technology,2020,107: 106262.1-106262.12. [34] 郭彦超,高丽敏,杨冠华,等. 对转压气机中自循环机匣处理扩稳机理的研究[J]. 航空动力学报,2022,37(1): 191-203. doi: 10.13224/j.cnki.jasp.20210009GUO Yanchao,GAO Liming,YANG Guanhua,et al. Study on the mechanism of stability improvement of the self-circulating casing treatment in a counter-rotating compressor[J]. Journal of Aerospace Power,2022,37(1): 191-203. (in Chinese) doi: 10.13224/j.cnki.jasp.20210009 [35] GAO L,LI R,MIAO F,et al. Unsteady investigation on tip flow field and rotating stall in counter-rotating axial compressor[J]. Journal of Engineering for Gas Turbines and Power,2015,137(7): 072603.1-072603.11. -

下载:

下载: