A self-similarity heat sink with the structure of deflector hole

-

摘要:

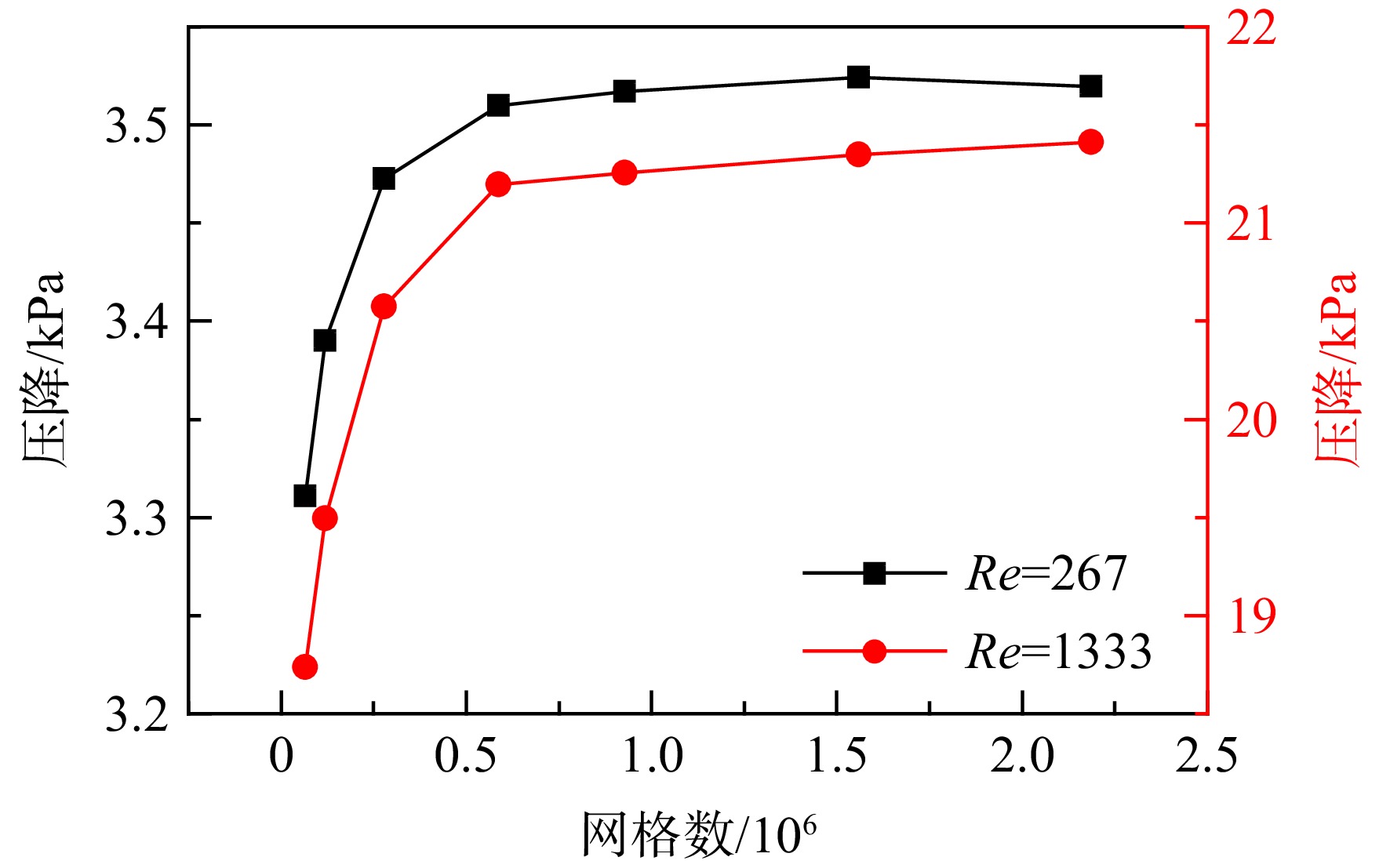

自相似微通道热沉(SSHS)具有结构紧凑、散热性能强、可扩展性好等特点,可应用于高发热电子芯片的散热。为克服自相似热沉内部的流动分配不均,进一步提高散热性能,提出一种具有导流孔结构的自相似微通道热沉。使用数值计算方法验证该结构设计的有效性。结果表明:具有导流孔结构的自相似微通道热沉内流体垂直冲击溢流道起到强化换热作用。计算单元入口流量在0.58~1.44 kg/h时,相比原型SSHS,改进型SSHS流量分配均匀性大幅改善,加热面最高温度降低10 K,加热底面温度分布均匀性提高57%,同时进出口压降降低约10.4%。在改进型基础上对射流孔尺寸进行了进一步结构优化,与改进型相比以更大的进出口压降(提高约16.5%)为代价,取得了更好的流动分配均匀性及散热性能。

-

关键词:

- 自相似微通道热沉(SSHS) /

- 导流孔 /

- 流动分配 /

- 散热均匀性 /

- 数值计算

Abstract:Self-similarity heat sink (SSHS) has the advantages of compact structure design, prominent heat transfer performance and extendibility, which can be applied in cooling the electronic chips. A new SSHS with the structure of deflector hole was proposed to overcome the maldistribution and improve the overall heat transfer performance. Numerical simulation was carried out to validate the new structure design of the SSHS. For the SSHS with the structure of deflector hole, the coolant was distributed to the deflector holes, subsequently impinged the bottom of the overflow channels, which enhanced the heat transfer of the SSHS. Comparison between the original and optimized SSHS was carried out with respect to flow distribution uniformity, heat transfer capacity and heat dissipation uniformity. For the mass flow rate covering 0.58−1.44 kg/h, the optimized SSHS had a better flow distribution uniformity, the maximum temperature on the heating surface was reduced by 10 K, the heat dissipation uniformity was increased by 57%, and average pressure drop was reduced by 10.4% compared with the original SSHS. The geometric dimensions of the deflector holes were further optimized, and better flow distribution and overall heat dissipation performance were achieved with the sacrifice of increasing the pressure drop of 16.5% compared with the optimized SSHS.

-

-

[1] MUDAWAR I. Assessment of high-heat-flux thermal management schemes[J]. IEEE Transactions on Components and Packaging Technologies,2001,24(2): 122-141. doi: 10.1109/6144.926375 [2] KANDLIKAR S G,BAPAT A V. Evaluation of jet impingement,spray and microchannel chip cooling options for high heat flux removal[J]. Heat Transfer Engineering,2007,28(11): 911-923. doi: 10.1080/01457630701421703 [3] WANG Yuan,WANG Zhenguo. An overview of liquid-vapor phase change,flow and heat transfer in mini- and micro-channels[J]. International Journal of Thermal Sciences,2014,86: 227-245. doi: 10.1016/j.ijthermalsci.2014.07.005 [4] 唐巍,孙立成,刘洪涛,等. 分流式微通道热沉强化传热性能数值分析[J]. 电子科技大学学报,2018,47(6): 864-868. TANG Wei,SUN Licheng,LIU Hongtao,et al. A numerical analysis of the enhanced performance in heat transfer of a manifold micro-channel heat sink[J]. Journal of University of Electronic Science and Technology of China,2018,47(6): 864-868. (in Chinese TANG Wei, SUN Licheng, LIU Hongtao, et al . A numerical analysis of the enhanced performance in heat transfer of a manifold micro-channel heat sink[J]. Journal of University of Electronic Science and Technology of China,2018 ,47 (6 ):864 -868 . (in Chinese)[5] KIM Y H,CHUN W C,KIM J T,et al. Forced air cooling by using manifold microchannel heat sinks[J]. KSME International Journal,1998,12(4): 709-718. doi: 10.1007/BF02945732 [6] RYU J H,CHOI D H,KIM S J. Three-dimensional numerical optimization of a manifold microchannel heat sink[J]. International Journal of Heat and Mass Transfer,2003,46(9): 1553-1562. doi: 10.1016/S0017-9310(02)00443-X [7] TANG Wei,SUN Licheng,LIU Hongtao,et al. Improvement of flow distribution and heat transfer performance of a self-similarity heat sink with a modification to its structure[J]. Applied Thermal Engineering,2017,121: 163-171. doi: 10.1016/j.applthermaleng.2017.04.051 [8] BRIGHENTI F,KAMARUZAMAN N,BRANDNER J J. Investigation of self-similar heat sinks for liquid cooled electronics[J]. Applied Thermal Engineering,2013,59(1/2): 725-732. [9] KAMARUZAMAN N B,BRIGHENTI F,BRANDNER J J,et al. Prediction of micro surface cooler performance for different rectangular type microchannels dimensions[J]. International Journal of Heat and Fluid Flow,2013,44: 644-651. doi: 10.1016/j.ijheatfluidflow.2013.09.005 [10] ESCHER W,MICHEL B,POULIKAKOS D. A novel high performance,ultra thin heat sink for electronics[J]. International Journal of Heat and Fluid Flow,2010,31(4): 586-598. doi: 10.1016/j.ijheatfluidflow.2010.03.001 [11] BOTELER L,JANKOWSKI N,MCCLUSKEY P,et al. Numerical investigation and sensitivity analysis of manifold microchannel coolers[J]. International Journal of Heat and Mass Transfer,2012,55(25/26): 7698-7708. [12] JANKOWSKI N R,EVERHART L,MORGAN B,et al. Comparing microchannel technologies to minimize the thermal stack and improve thermal performance in hybrid electric vehicles[C]//2007 IEEE Vehicle Power and Propulsion Conference. Arlington,US: IEEE,2008: 124-130. [13] SHARMA C S,SCHLOTTIG G,BRUNSCHWILER T,et al. A novel method of energy efficient hotspot-targeted embedded liquid cooling for electronics: an experimental study[J]. International Journal of Heat and Mass Transfer,2015,88: 684-694. doi: 10.1016/j.ijheatmasstransfer.2015.04.047 [14] ARIE M A,SHOOSHTARI A H,DESSIATOUN S V,et al. Numerical modeling and thermal optimization of a single-phase flow manifold-microchannel plate heat exchanger[J]. International Journal of Heat and Mass Transfer,2015,81: 478-489. doi: 10.1016/j.ijheatmasstransfer.2014.10.022 [15] KONG D,KIM Y,KANG M,et al. A holistic approach to thermal-hydraulic design of 3D manifold microchannel heat sinks for energy-efficient cooling[J]. Case Studies in Thermal Engineering,2021,28: 101583. doi: 10.1016/j.csite.2021.101583 [16] 黄名海,臧树升,葛冰,等. 热风洞中涡轮叶片温度场红外热像测量方法[J]. 航空动力学报,2014,29(11): 2679-2683. HUANG Minghai,ZANG Shusheng,GE Bing,et al. Method of infrared thermography measurement for temperature field of turbine vane in hot wind tunnel[J]. Journal of Aerospace Power,2014,29(11): 2679-2683. (in Chinese HUANG Minghai, ZANG Shusheng, GE Bing, et al . Method of infrared thermography measurement for temperature field of turbine vane in hot wind tunnel[J]. Journal of Aerospace Power,2014 ,29 (11 ):2679 -2683 . (in Chinese)[17] ZHOU Jianhong,CHEN Xuemei,ZHAO Qi,et al. Flow thermohydraulic characterization of hierarchical-manifold microchannel heat sink with uniform flow distribution[J]. Applied Thermal Engineering,2021,198: 117510. doi: 10.1016/j.applthermaleng.2021.117510 [18] PAN Yuhui,ZHAO Rui,NIAN Yongle,et al. Study on the flow and heat transfer characteristics of pin-fin manifold microchannel heat sink[J]. International Journal of Heat and Mass Transfer,2022,183: 122052. doi: 10.1016/j.ijheatmasstransfer.2021.122052 [19] GILMORE N,TIMCHENKO V,MENICTAS C. Manifold microchannel heat sink topology optimisation[J]. International Journal of Heat and Mass Transfer,2021,170: 121025. doi: 10.1016/j.ijheatmasstransfer.2021.121025 [20] 石宇,夏新林,陈学,等. 基于高温瞬态热响应的石英窗口导热系数反演[J]. 航空动力学报,2022,37(4): 755-764. SHI Yu,XIA Xinlin,CHEN Xue,et al. Inversion of thermal conductivity of quartz window based on transient thermal response at high temperature[J]. Journal of Aerospace Power,2022,37(4): 755-764. (in Chinese SHI Yu, XIA Xinlin, CHEN Xue, et al . Inversion of thermal conductivity of quartz window based on transient thermal response at high temperature[J]. Journal of Aerospace Power,2022 ,37 (4 ):755 -764 . (in Chinese) -

下载:

下载: