Experimental investigation on friction and wear characteristics of brush seal bristle

-

摘要:

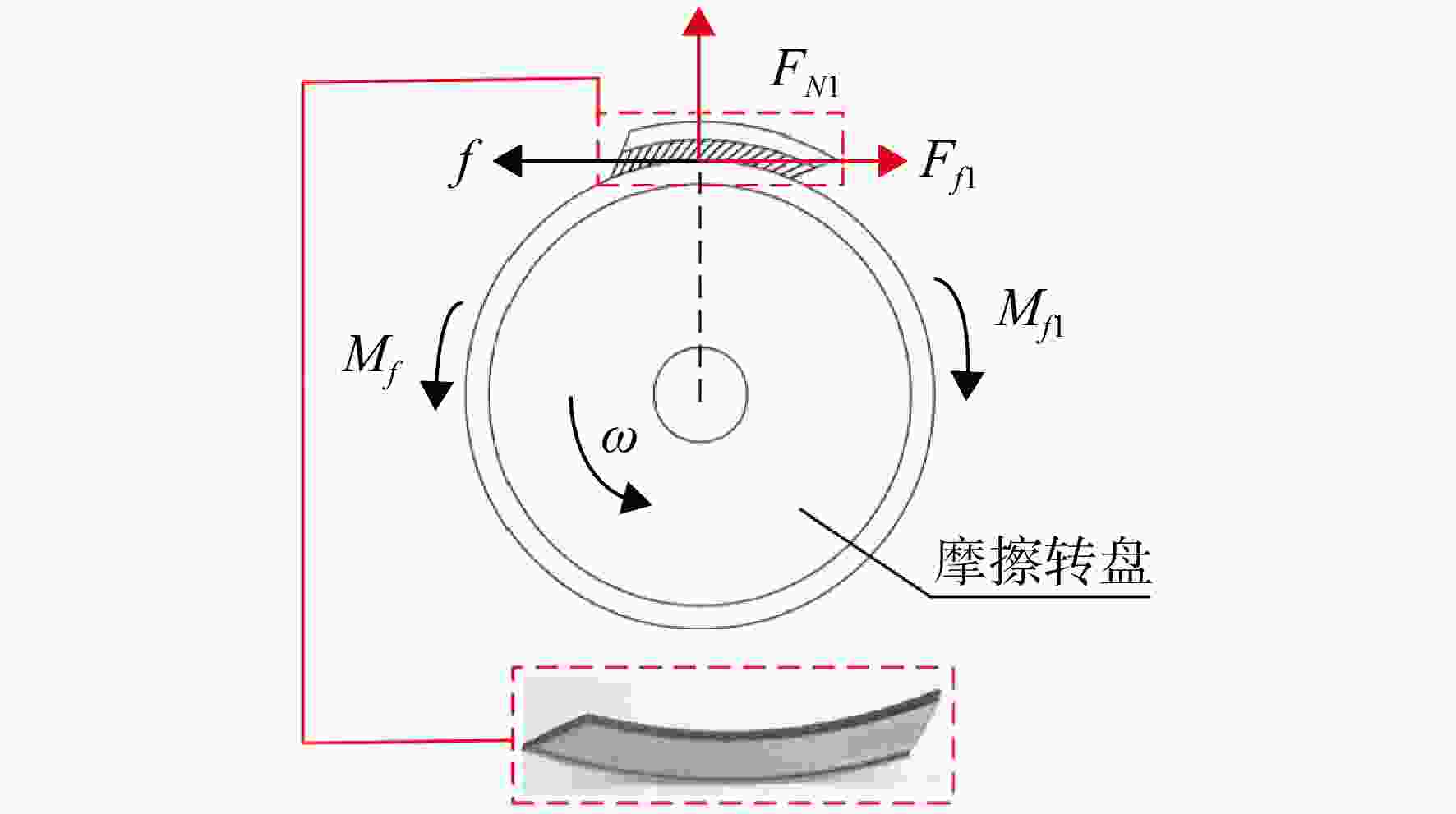

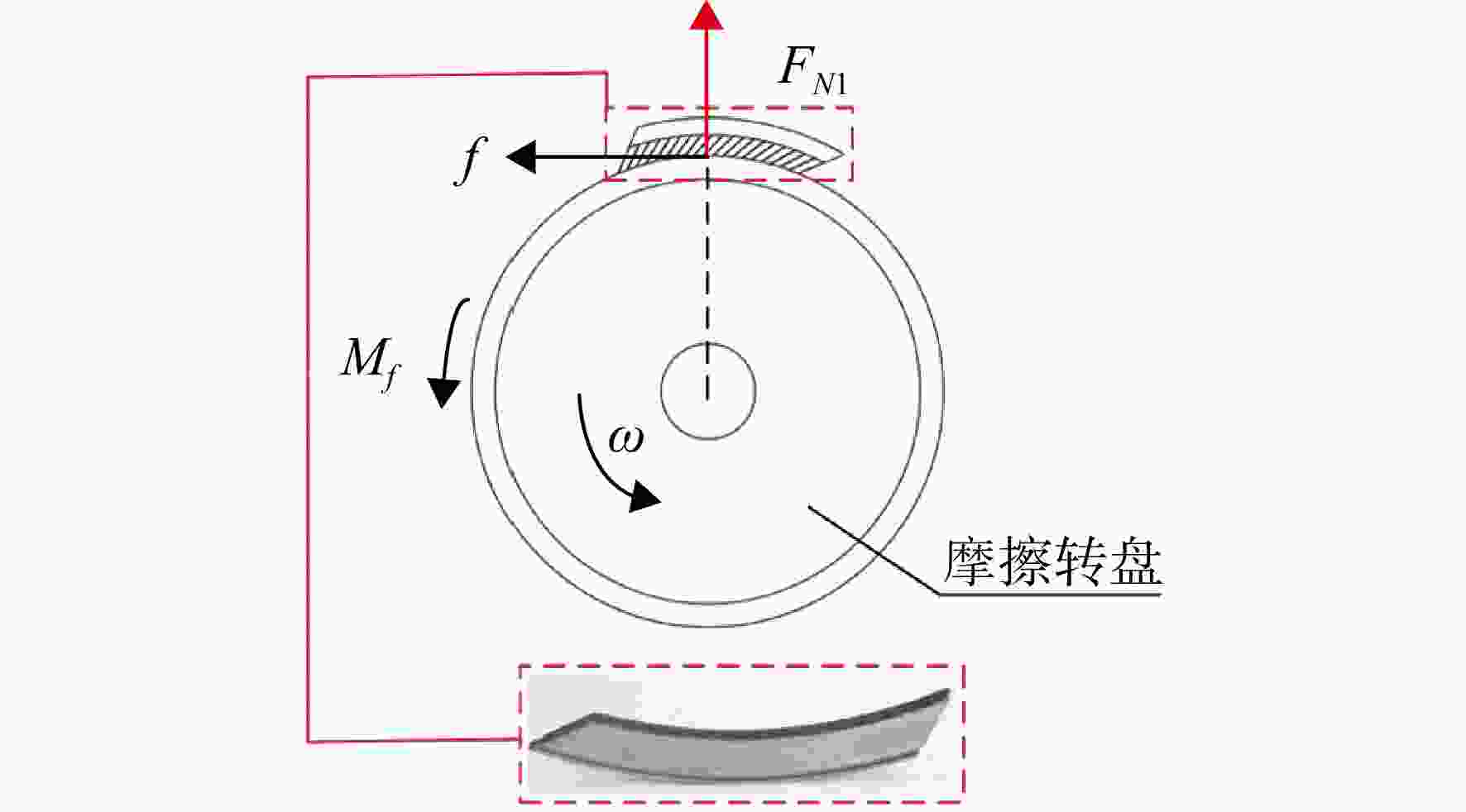

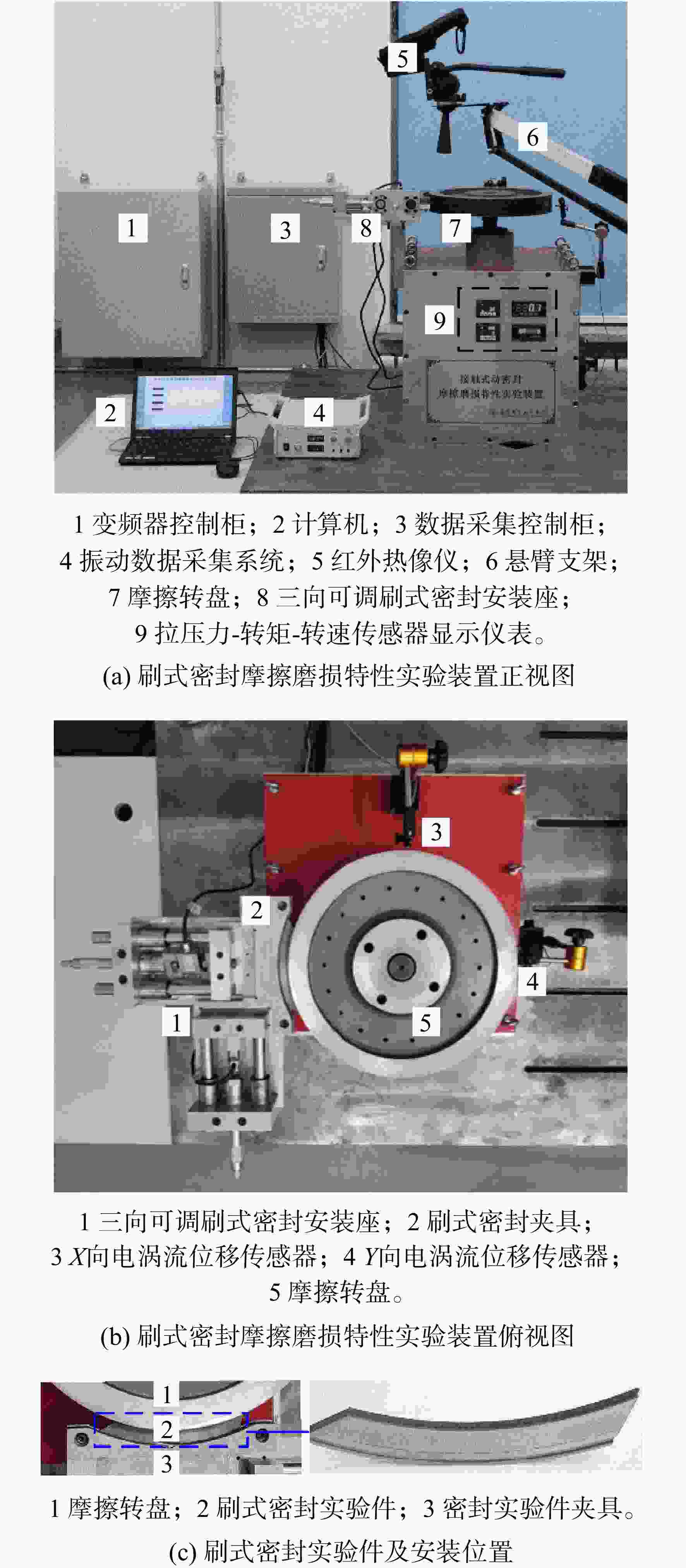

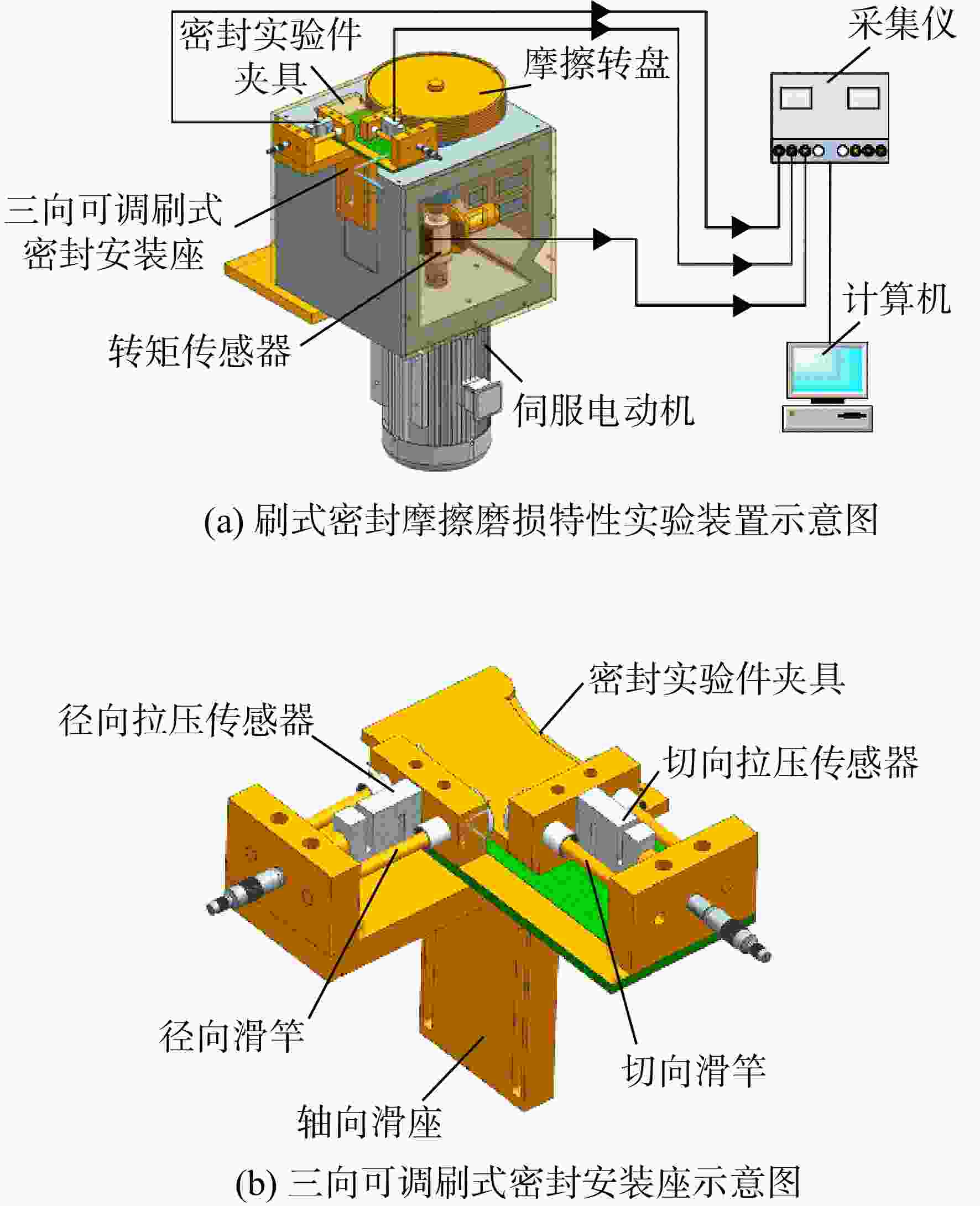

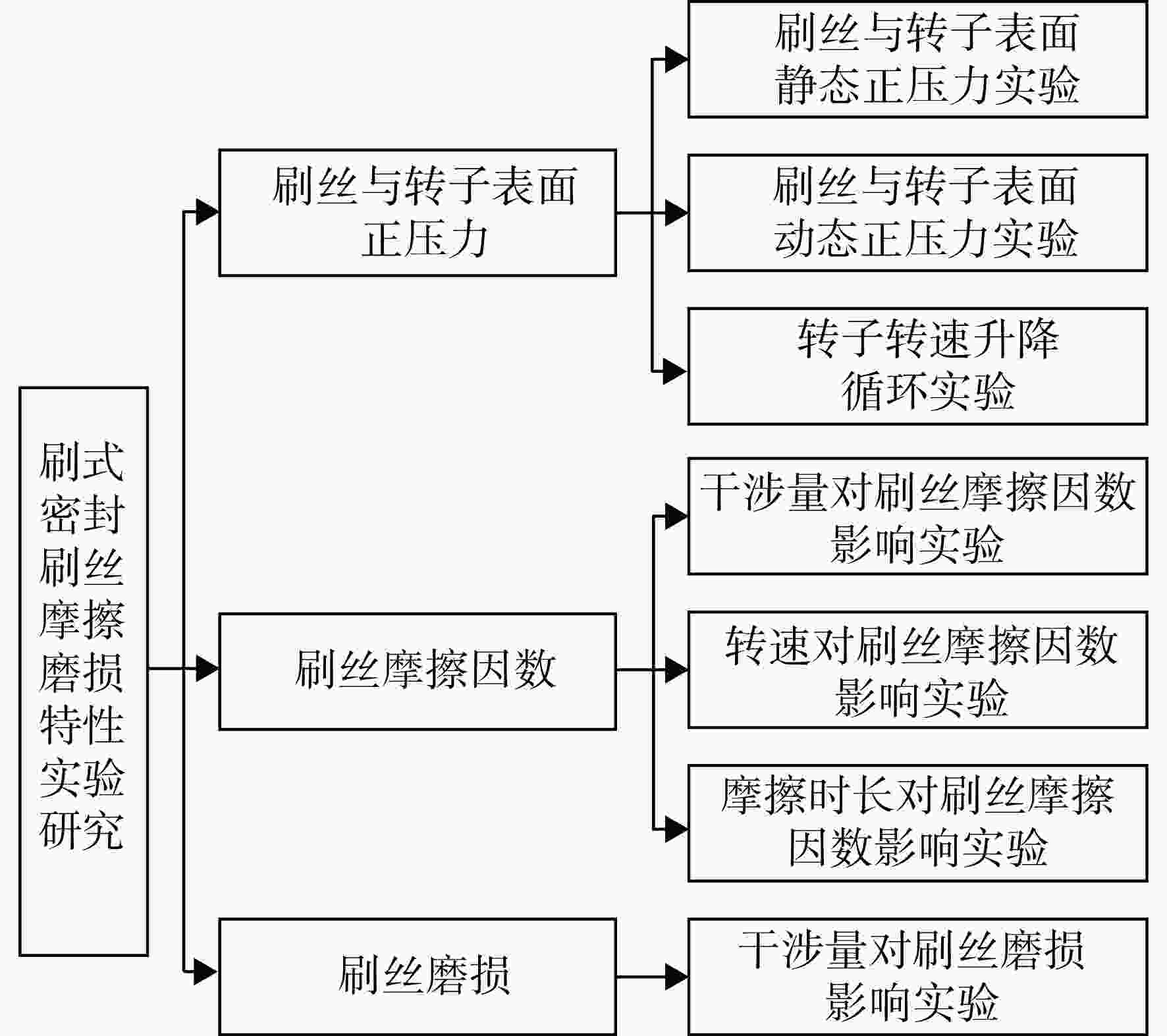

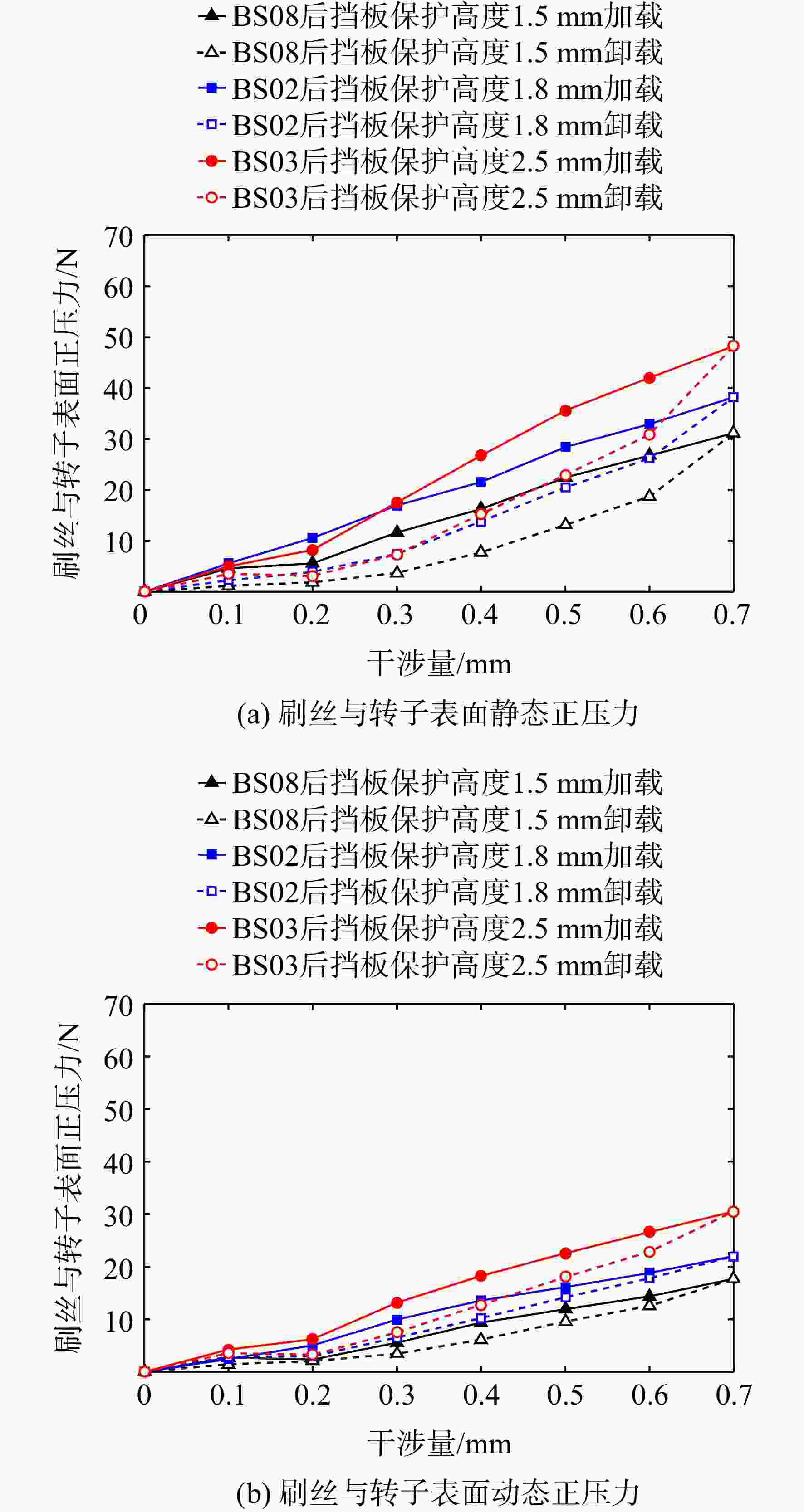

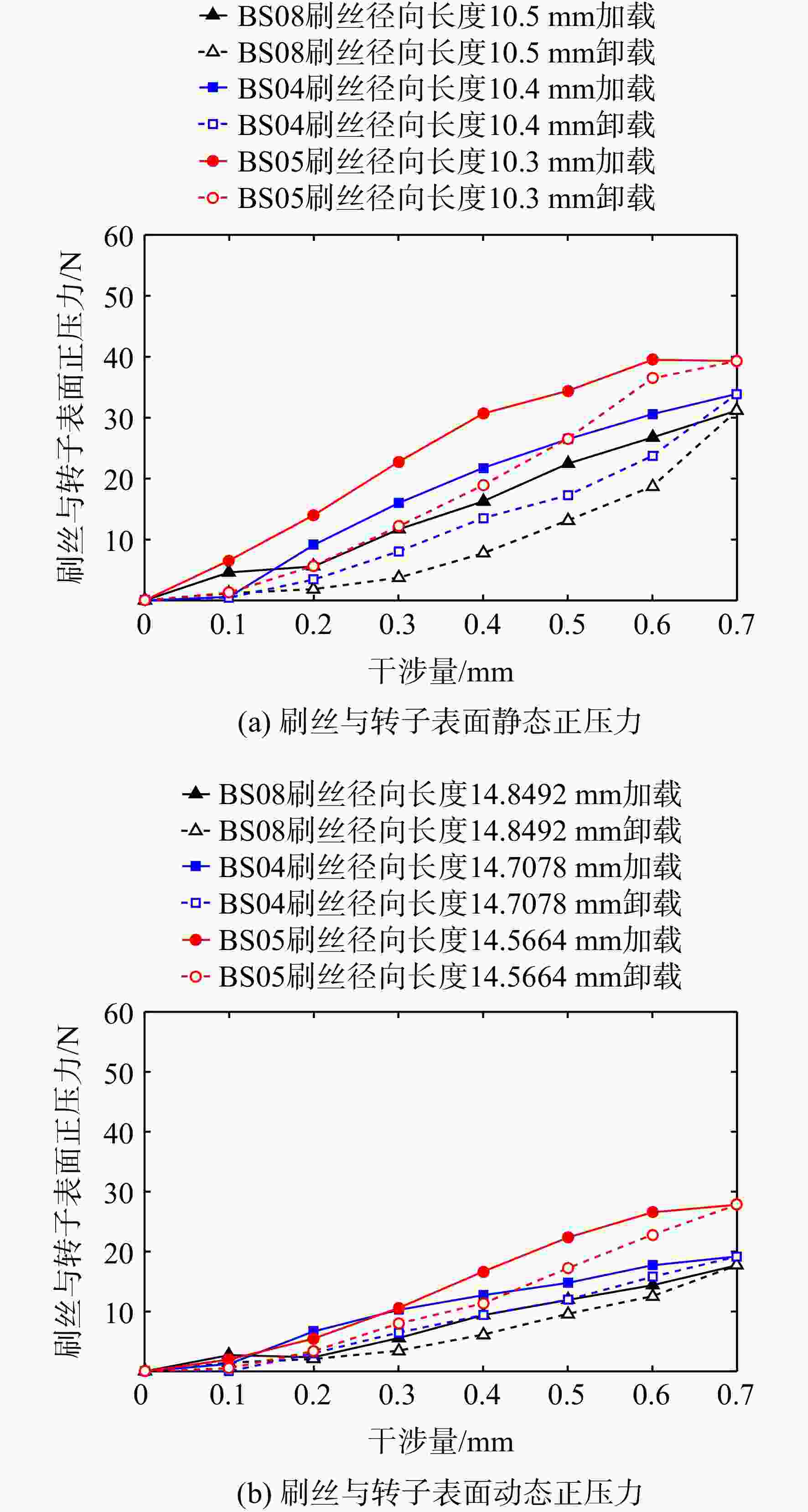

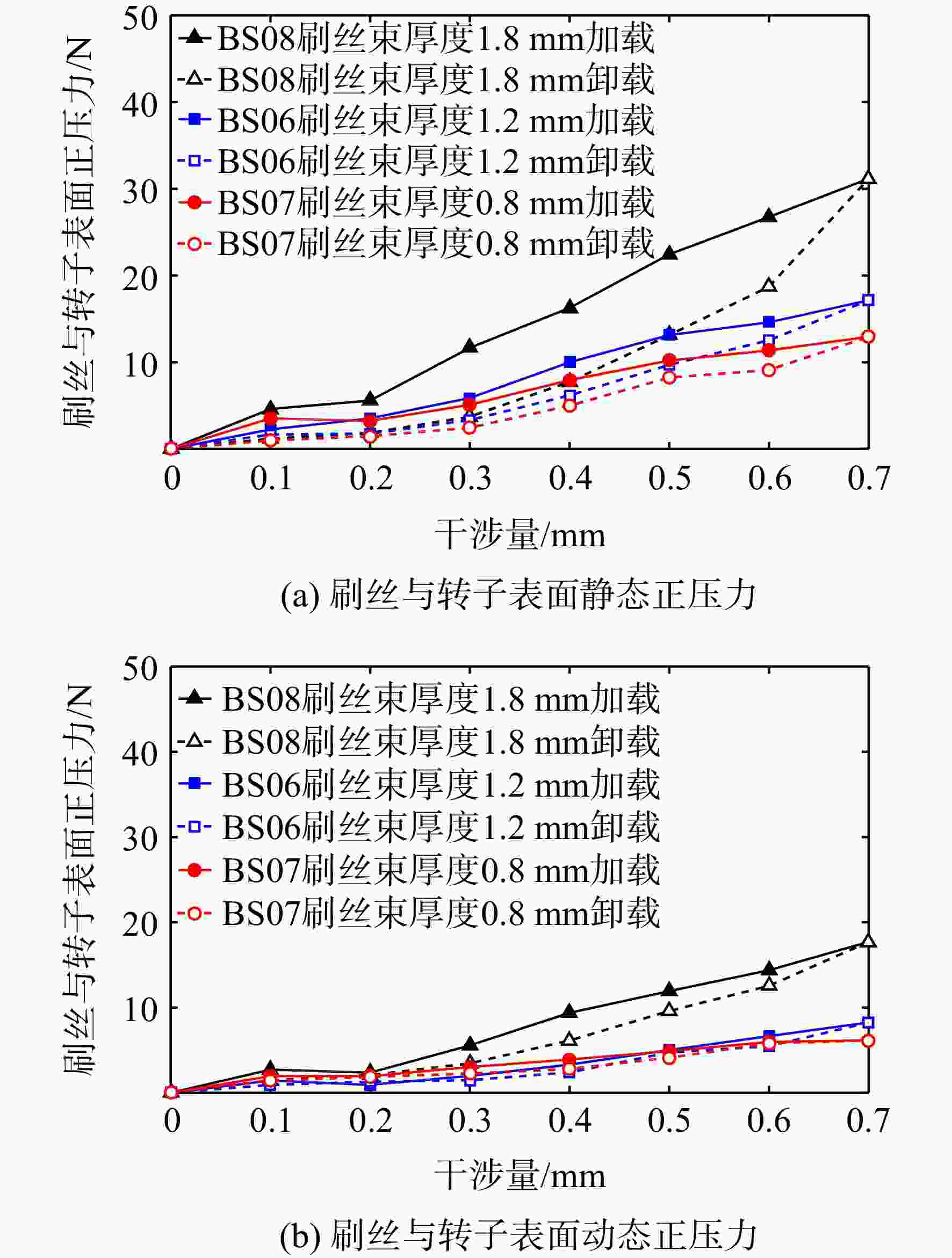

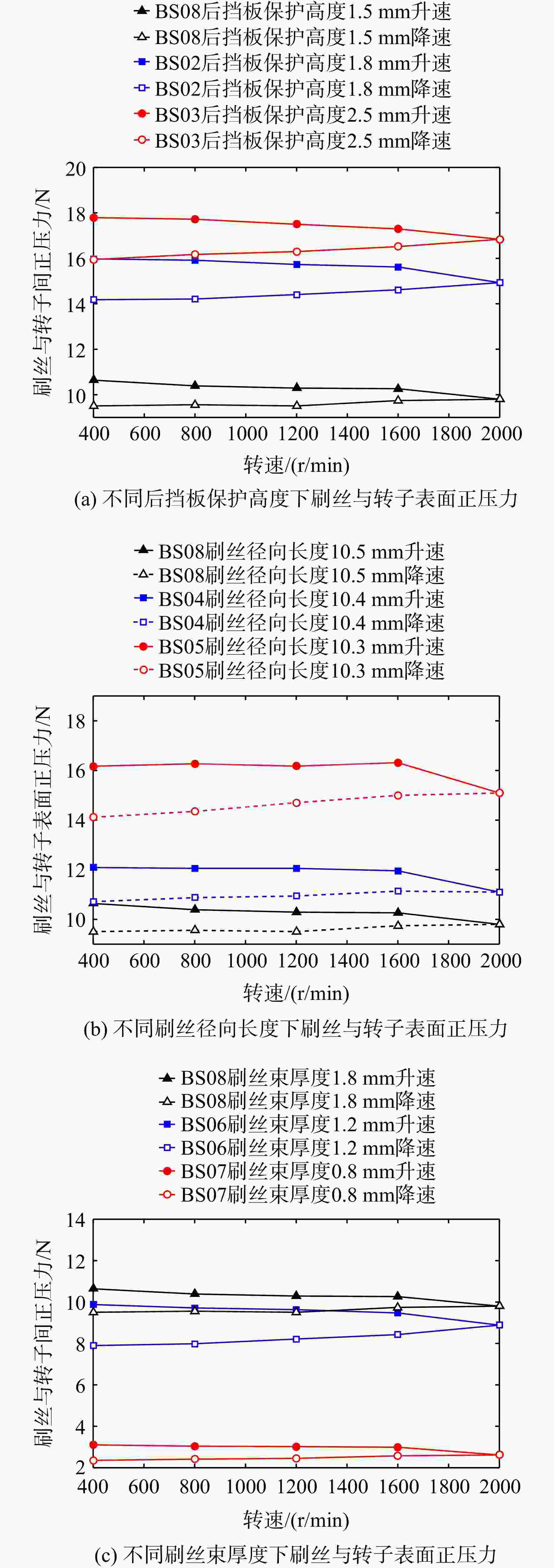

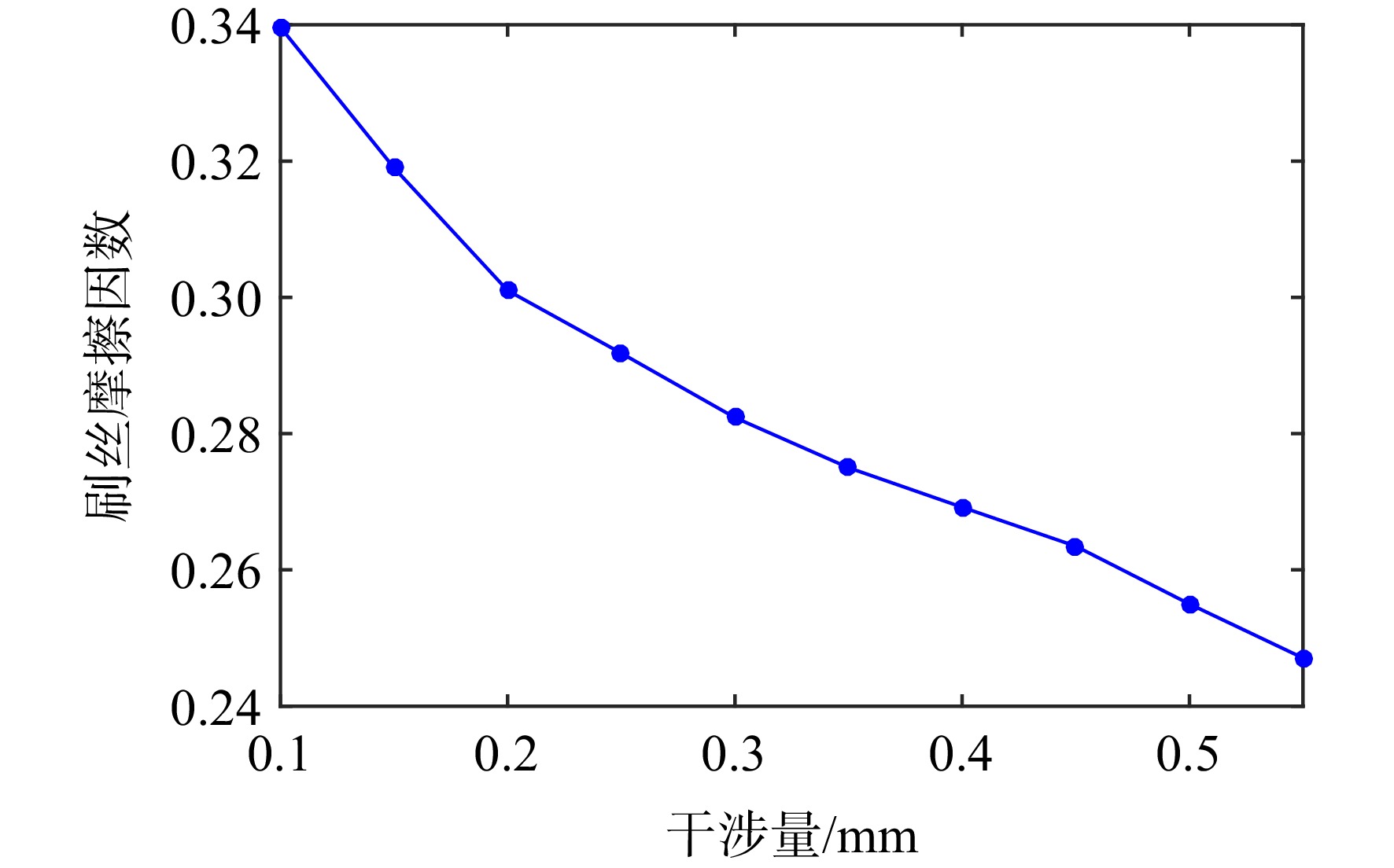

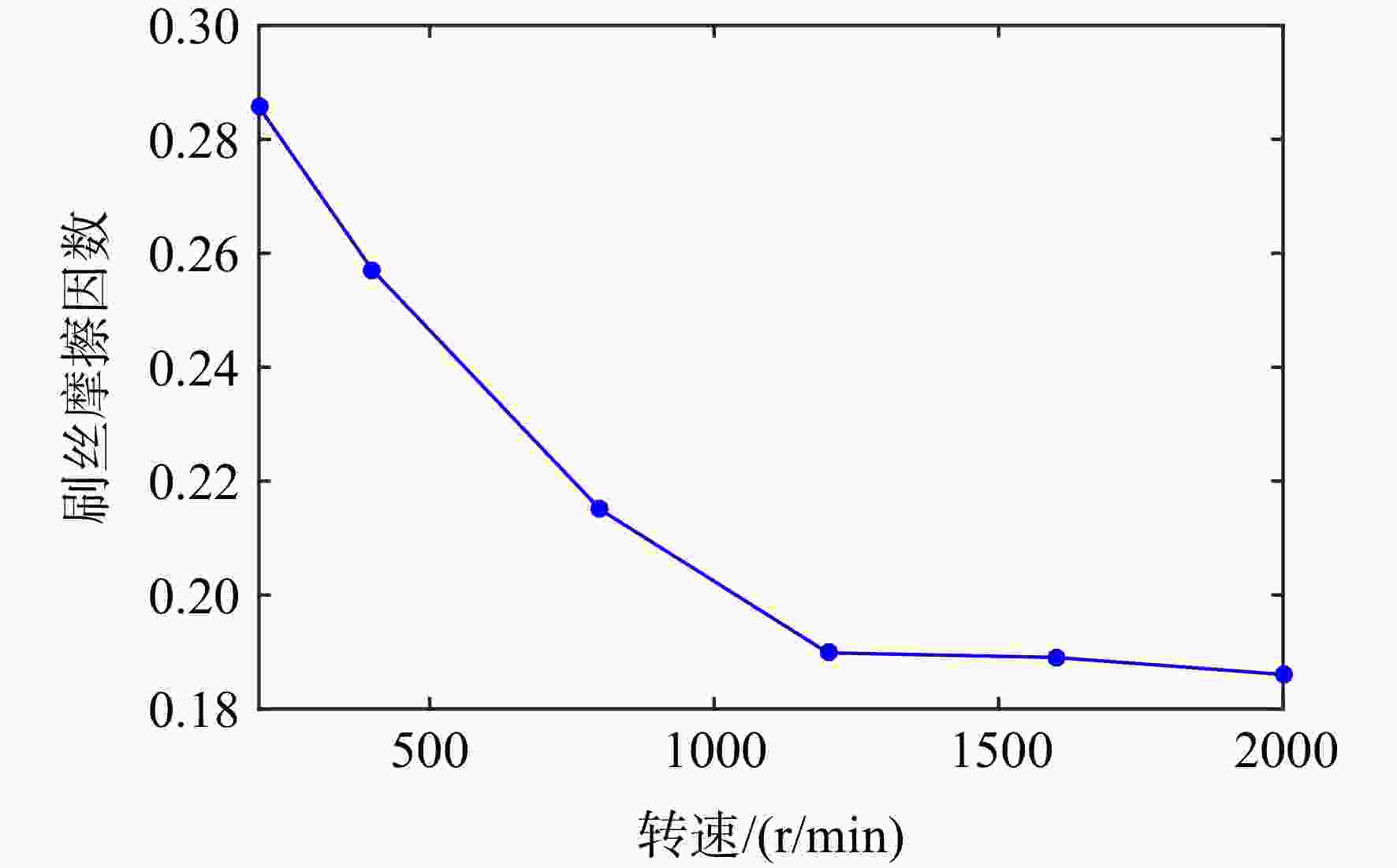

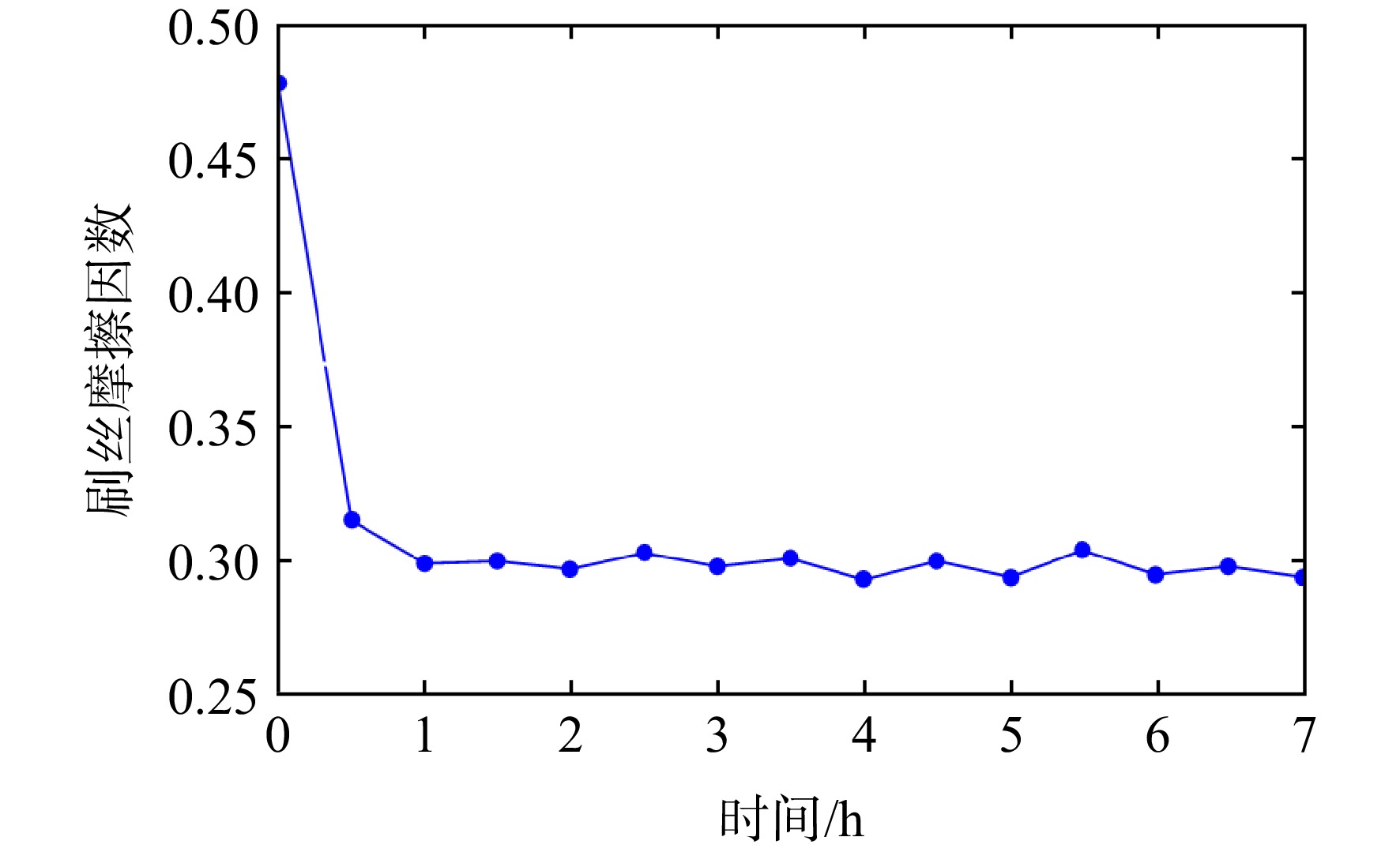

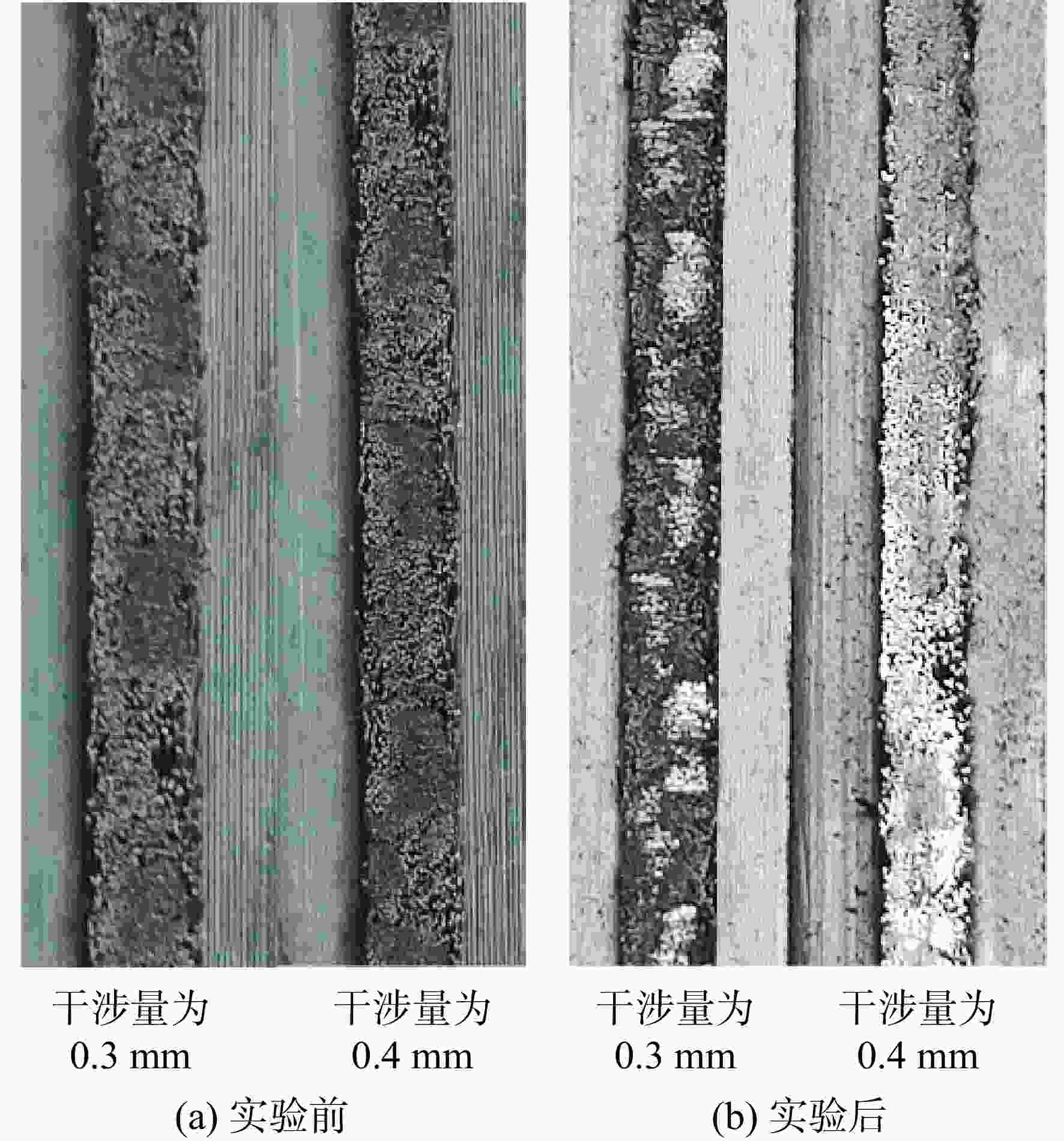

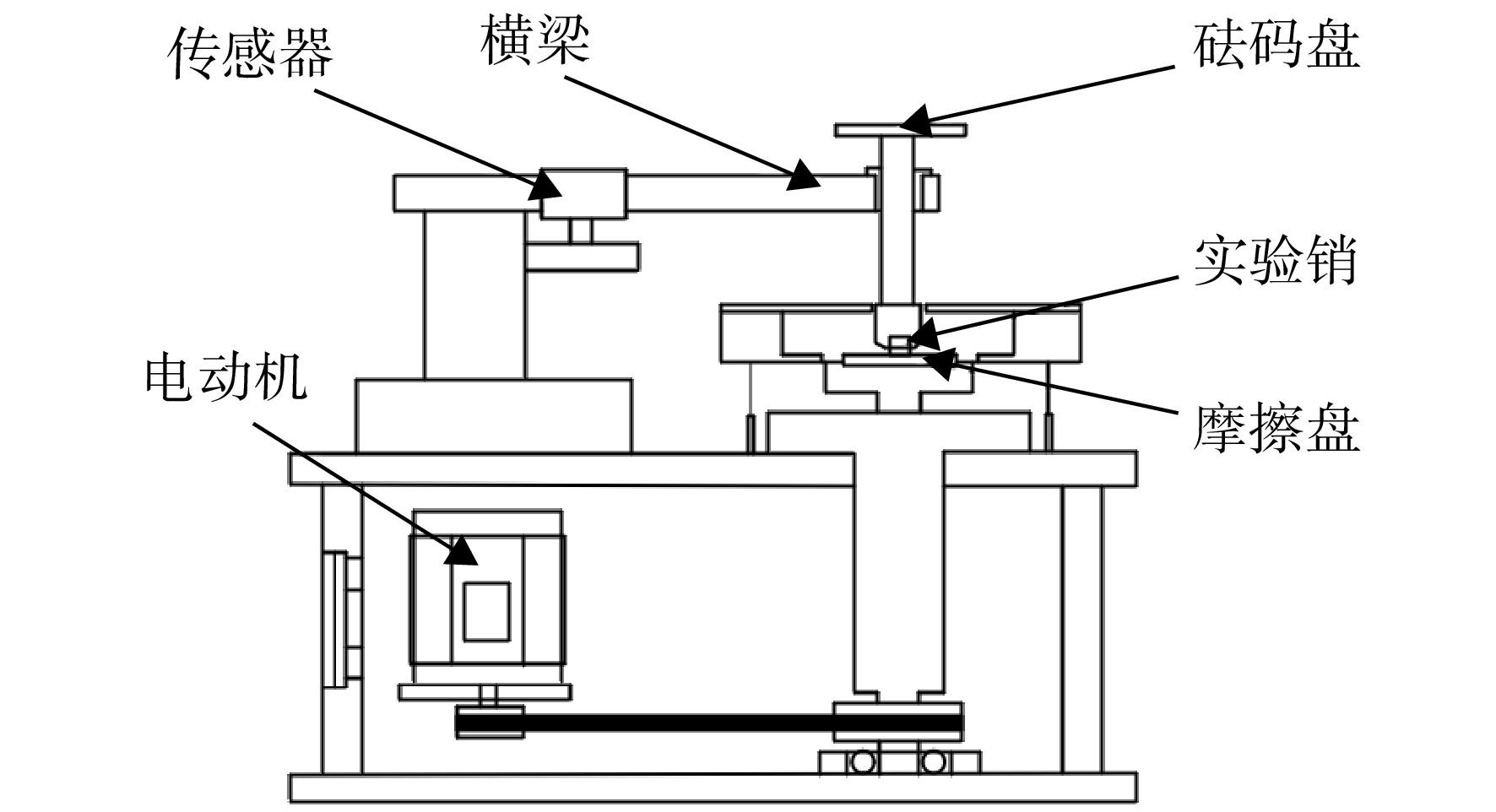

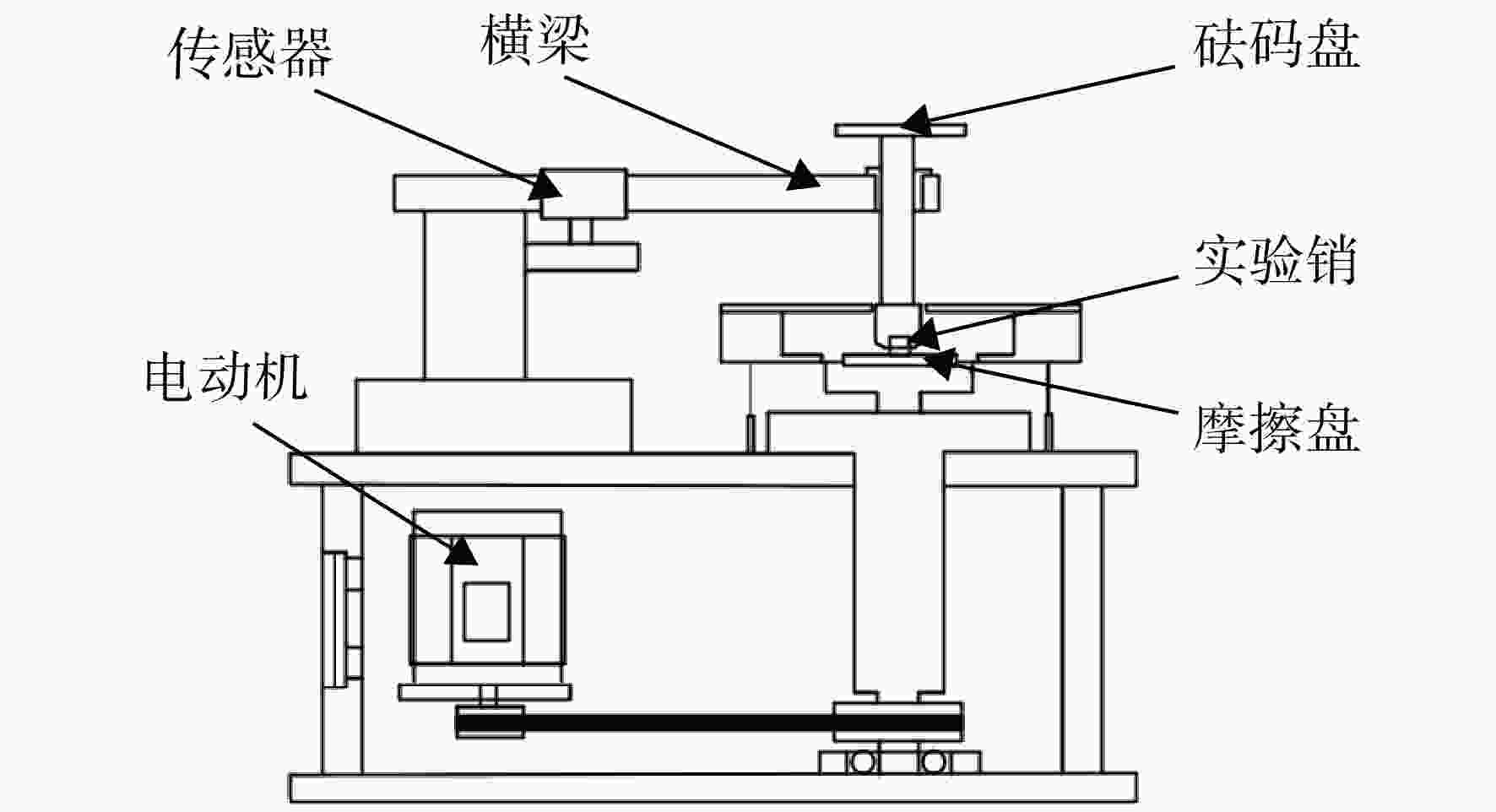

建立了基于柱面圆周摩擦的直接测力法与间接转矩法两种刷式密封摩擦因数实验识别模型,设计搭建了刷式密封摩擦磨损特性实验装置,设计加工了8种不同结构参数的刷式密封实验件,实验对比分析了两种摩擦因数识别模型的实验结果,研究了结构参数对刷丝与转子表面正压力影响、工况参数对刷丝摩擦因数影响、干涉量对刷丝磨损影响。结果表明:直接测力法与间接转矩法测得的刷丝摩擦因数彼此相差较小,直接测力法稳定性优于间接转矩法。刷式密封刷丝与转子表面静态和动态正压力均随后挡板保护高度的增加而增大,随刷丝径向长度的增加而减小,随刷丝束厚度的增加而增大;相同干涉量下,静态正压力大于动态正压力;刷式密封刷丝与转子表面正压力在干涉加载阶段大于干涉卸载阶段,在转速升高阶段大于转速降低阶段,刷丝表现出滞后效应。刷式密封刷丝摩擦因数随刷丝与转子间干涉量的增加而降低,随转子转速的增加而降低;随摩擦时长增加,摩擦因数在磨损初期先迅速降低,之后基本保持稳定。刷式密封刷丝磨损量随刷丝与转子间干涉量的增加而增大,刷丝与转子间干涉量由0.3 mm增加至0.4 mm时,刷丝磨损量增大了296.66%。

Abstract:Two brush seal friction coefficient experimental identification models were established based on cylindrical circumferential friction, direct force measurement and indirect torque method, an experimental device for friction and wear characteristics of brush seals was designed and built, and eight brush seal test pieces with different structural parameters were designed and processed. The experimental results of two kinds of friction coefficient identification models were compared and analyzed, and the influence of structural parameters on the positive pressure of the brush bristle and rotor surface, the influence of working conditions on the friction coefficient of the brush bristle, and the influence of interference on the wear of the brush bristle were studied. The research results showed that the friction coefficients of brush bristle measured by the direct force measurement method and the indirect torque method were less different from each other, and the stability of the direct force measurement method was better than that of the indirect torque method. Both the static and dynamic positive pressures on the surface of the brush seal and the rotor increased with the increase of the protection height of the baffle, decreased with the increase of the radial length of the brush, and increased with the increase of the thickness of the brush pack; at the same interference under the condition of measurement, the static positive pressure was greater than the dynamic positive pressure; the positive pressure of the brush seal filament and the rotor surface was greater in the interference loading phase than in the interference unloading phase, and the speed increase phase was greater than the speed reduction phase, the brush filament exhibited a hysteresis effect. The friction coefficient of the brush seal bristle decreased with the increase of the interference between the brush bristle and the rotor, and also decreased with the increase of the rotor speed; with the increase of the friction time, the friction coefficient decreased rapidly at the initial stage of wear, and then kept basically stable. The wear amount of the brush bristle of the brush seal increased with the increase of the interference between the brush bristle and the rotor. When the interference between the brush bristle and the rotor increased from 0.3 mm to 0.4 mm, the wear amount of the brush bristle increased by 296.66%.

-

Key words:

- brush seal /

- positive pressure /

- friction coefficient /

- wear extent /

- wear surface morphology

-

表 1 刷式密封实验件结构参数表

Table 1. Structure parameter table of the brush seal experimental piece

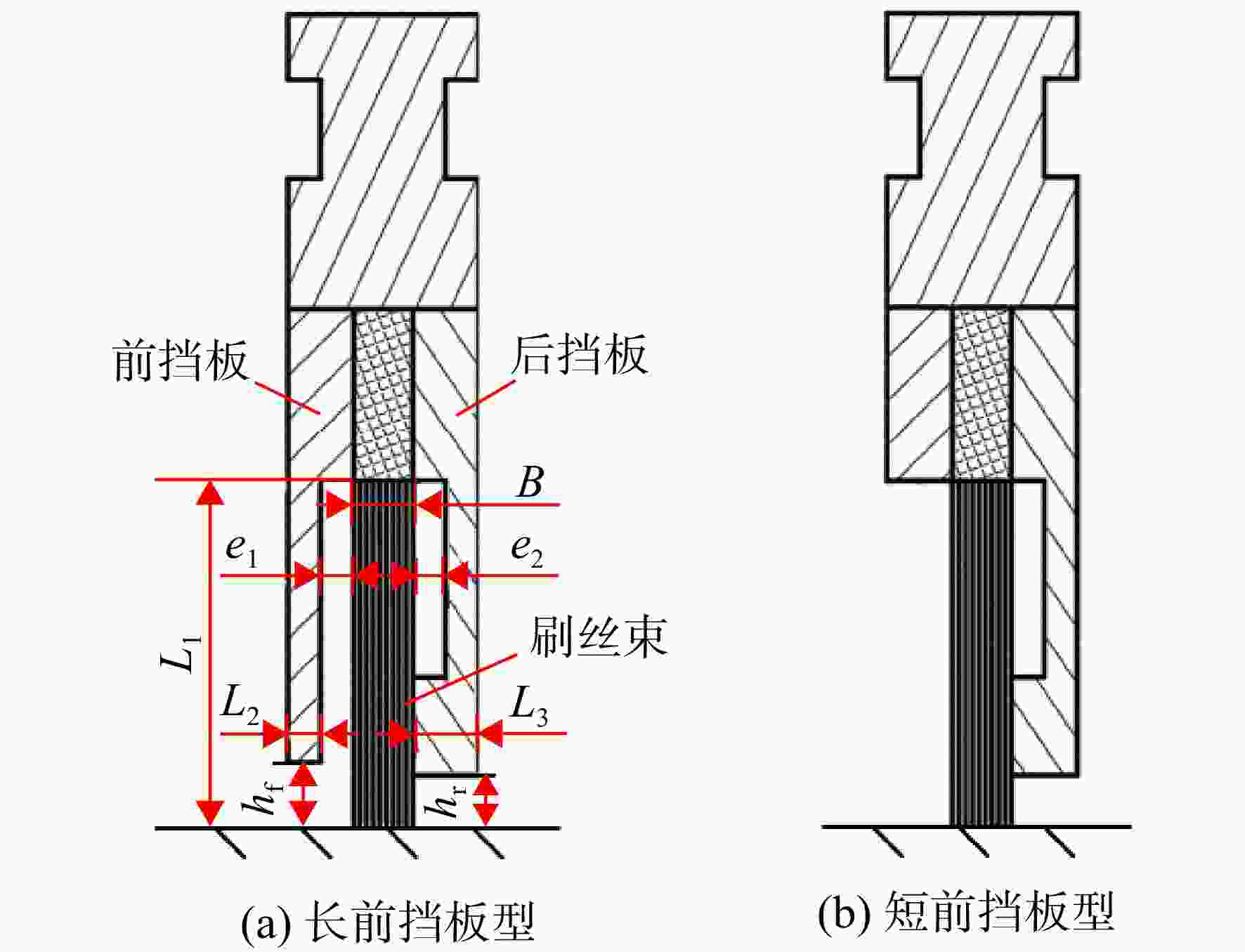

结构参数 数值 刷丝直径d/mm 0.08 刷丝束轴向厚度B/mm 0.8,1.2,1.8 刷丝径向长度L1/mm 10.3,10.4,10.5 前挡板轴向厚度L2/mm 1.0 后挡板轴向厚度L3/mm 2.0 前挡板与刷丝间距离e1/mm 1.0 后挡板压力腔宽度e2/mm 1.0 前挡板保护高度hf/mm 1.9 后挡板保护高度hr/mm 1.5,1.8,2.5 周向倾角θ/(°) 45 表 2 刷式密封实验件编号及主要参数表

Table 2. Brush seal experiment part number and main parameter table

mm 长前

挡板短前挡板 主要参数 基本型 后挡板保护高度 刷丝径向长度 刷丝束厚度 BS01 BS08 BS02 BS03 BS04 BS05 BS06 BS07 后挡板保护高度hr 1.5 1.5 1.8 2.5 1.5 1.5 1.5 1.5 刷丝束厚度B 1.8 1.8 1.8 1.8 1.8 1.8 1.2 0.8 刷丝径向长度L1 10.5 10.5 10.5 10.5 10.4 10.3 10.5 10.5 表 3 不同干涉量下磨损前后实验件质量对比

Table 3. Comparison of the quality of the experimental parts before and after wear under different interference

g 刷丝与转子间干涉量 BS01-干涉0.3 mm BS01-干涉0.4 mm 磨损前 163.9104 163.0175 磨损后 163.7517 162.3880 磨损量 0.1587 0.6295 -

[1] 杜春华,吉洪湖,胡娅萍,等. 刷式封严磨损特性及其对泄漏影响的试验研究[J]. 推进技术,2017,38(11): 2597-2605. DU Chunhua,JI Honghu,HU Yaping,et al. Experimental investigation on wearing characteristics and effects on leakage of brush seal[J]. Journal of Propulsion Technology,2017,38(11): 2597-2605. (in Chinese DU Chunhua, JI Honghu, HU Yaping, et al . Experimental investigation on wearing characteristics and effects on leakage of brush seal[J]. Journal of Propulsion Technology,2017 ,38 (11 ):2597 -2605 . (in Chinese)[2] 李军,李志刚,张元桥,等. 刷式密封技术的研究进展[J]. 航空发动机,2019,45(2): 74-84. LI Jun,LI Zhigang,ZHANG Yuanqiao,et al. Research progress of brush seal technology[J]. Aeroengine,2019,45(2): 74-84. (in Chinese LI Jun, LI Zhigang, ZHANG Yuanqiao, et al . Research progress of brush seal technology[J]. Aeroengine,2019 ,45 (2 ):74 -84 . (in Chinese)[3] CHUPP R E,DOWLER C A. Performance characteristics of brush seals for limited-life engines[J]. Journal of Engineering for Gas Turbines and Power,1993,115(2): 390-396. doi: 10.1115/1.2906721 [4] FELLENSTEIN J A,DELLACORTE C. A new tribological experimental for candidate brush seal materials evaluation[J]. Tribology Transactions,1996,39(1): 173-179. doi: 10.1080/10402009608983517 [5] FELLENSTEIN J A,DELLACORTE C,MOORE K D,et al. High temperature brush seal tuft experimentaling of metallic bristles versus chrome carbide[R]. AIAA-1996-2908,1996. [6] FELLENSTEIN J A,DELLACORTE C,MOORE K D,et al. High temperature brush seal tuft experimentaling of selected nickel-chrome and cobalt-chrome superalloys[R]. AIAA-1997-2634,1997. [7] RABEN M,FRIEDRICHS J,HELMIS T,et al. Brush seals used in steam environments-chronological wear development and the impact of different seal designs[J]. Journal of Engineering for Gas Turbines and Power,2016,138(5): 051901. doi: 10.1115/1.4031531 [8] CRUDGINGTON P,BOWSHER A,WALIA J,et al. Bristle angle effects on brush seal contact pressures[R]. AIAA-2009-5168,2009. [9] STANGO R J,ZHAO H,SHIA C Y. Analysis of contact mechanics for rotor-bristle interference of brush seal[J]. Journal of Tribology,2003,125(2): 414-421. doi: 10.1115/1.1510879 [10] DURAN E T,AKSIT M F,OZMUSUL M. CAE based brush seal characterization for stiffness and stress levels[R]. ASME Paper GT2015-44068,2015. [11] DURAN E T,AKSIT M F,OZMUSUL M. Brush seal free state stiffness analyses,experimentals and inspection on dynamic effects[R]. ASME Paper GT2015-44069,2015. [12] 孙晓萍. 刷式密封性能和耐久性试验研究[J]. 航空发动机,2002(3): 37-41. SUN Xiaoping. Experimental investigation of performance and durability of brush seal[J]. Aeroengine,2002(3): 37-41. (in Chinese SUN Xiaoping . Experimental investigation of performance and durability of brush seal[J]. Aeroengine,2002 (3 ):37 -41 . (in Chinese)[13] 孙晓萍,李卫东,刘晓远. 刷式密封设计与试验研究[J]. 航空发动机,2005(2): 17-19. SUN Xiaoping,LI Weidong,LIU Xiaoyuan. Design and experimental of brush seal[J]. Aeroengine,2005(2): 17-19. (in Chinese SUN Xiaoping, LI Weidong, LIU Xiaoyuan . Design and experimental of brush seal[J]. Aeroengine,2005 (2 ):17 -19 . (in Chinese)[14] 曹广州,吉洪湖,纪国剑. 刷式封严初期使用特性的实验和数值研究[J]. 推进技术,2010,31(4): 478-482,489. CAO Guangzhou,JI Honghu,JI Guojian. Experimental and numerical study on the leakage characteristics of brush seals at the early stage of operating[J]. Journal of Propulsion Technology,2010,31(4): 478-482,489. (in Chinese CAO Guangzhou, JI Honghu, JI Guojian . Experimental and numerical study on the leakage characteristics of brush seals at the early stage of operating[J]. Journal of Propulsion Technology,2010 ,31 (4 ):478 -482, 489 . (in Chinese)[15] 周坤,潘君,王晓燕,等. 后挡板结构对刷式密封泄漏特性影响实验研究[J]. 推进技术,2020,41(12): 2834-2839. ZHOU Kun,PAN Jun,WANG Xiaoyan,et al. Experimental investigation for effects of back plate structure on leakage characteristics of brush seal[J]. Journal of Propulsion Technology,2020,41(12): 2834-2839. (in Chinese ZHOU Kun, PAN Jun, WANG Xiaoyan, et al . Experimental investigation for effects of back plate structure on leakage characteristics of brush seal[J]. Journal of Propulsion Technology,2020 ,41 (12 ):2834 -2839 . (in Chinese)[16] 李朋飞,胡娅萍,陈文洋,等. 减压腔宽度对刷式密封泄漏特性和滞后效应的影响[J]. 航空动力学报,2020,35(7): 1473-1481. LI Pengfei,HU Yaping,CHEN Wenyang,et al. Influence of axial wide of pressure relief chamber on leakage characteristics and hysteresis of brush seals[J]. Journal of Aerospace Power,2020,35(7): 1473-1481. (in Chinese LI Pengfei, HU Yaping, CHEN Wenyang, et al . Influence of axial wide of pressure relief chamber on leakage characteristics and hysteresis of brush seals[J]. Journal of Aerospace Power,2020 ,35 (7 ):1473 -1481 . (in Chinese)[17] 孙丹,杜宸宇,刘永泉,等. 刷式密封刷丝变形与振动特性实验[J]. 航空学报,2020,41(10): 68-78. SUN Dan,DU Chenyu,LIU Yongquan,et al. Experiment on bristle deflection and oscillation characteristics of brush seals[J]. Acta Aeronautica et Astronautica Sinica,2020,41(10): 68-78. (in Chinese SUN Dan, DU Chenyu, LIU Yongquan, et al . Experiment on bristle deflection and oscillation characteristics of brush seals[J]. Acta Aeronautica et Astronautica Sinica,2020 ,41 (10 ):68 -78 . (in Chinese)[18] 孙丹,杜宸宇,刘永泉,等. 基于ALE流固耦合方法的刷式密封刷丝接触变形特性理论与试验研究[J]. 机械工程学报,2020,56(9): 170-180. SUN Dan,DU Chenyu,LIU Yongquan,et al. Theoretical and experimental investigation on the bristle contact deflections characteristics of brush seals based on ALE fluid-structure interaction method[J]. Journal of Mechanical Engineering,2020,56(9): 170-180. (in Chinese doi: 10.3901/JME.2020.09.170 SUN Dan, DU Chenyu, LIU Yongquan, et al . Theoretical and experimental investigation on the bristle contact deflections characteristics of brush seals based on ALE fluid-structure interaction method[J]. Journal of Mechanical Engineering,2020 ,56 (9 ):170 -180 . (in Chinese) doi: 10.3901/JME.2020.09.170[19] 杜春华,吉洪湖,胡娅萍,等. 低前挡板型小尺寸刷式封严泄漏特性的试验[J]. 航空动力学报,2017,32(2): 298-305. DU Chunhua,JI Honghu,HU Yaping,et al. Experimental investigation on leakage characteristics of small size brush seal with low front plate[J]. Journal of Aerospace Power,2017,32(2): 298-305. (in Chinese DU Chunhua, JI Honghu, HU Yaping, et al . Experimental investigation on leakage characteristics of small size brush seal with low front plate[J]. Journal of Aerospace Power,2017 ,32 (2 ):298 -305 . (in Chinese)[20] 何立东,袁新,尹新. 刷式密封研究的进展[J]. 中国电机工程学报,2001(12): 29-33, 54. HE Lidong,YUAN Xin,YIN Xin. The advance in the investegation of brush seal[J]. Proceedings of the CSEE,2001(12): 29-33, 54. (in Chinese HE Lidong, YUAN Xin, YIN Xin . The advance in the investegation of brush seal[J]. Proceedings of the CSEE,2001 (12 ):29 -33, 54 . (in Chinese)[21] 刘笑笑,任先京,章德铭,等. 刷式密封转子涂层材料研究[J]. 热喷涂技术,2011,3(4): 49-52. LIU Xiaoxiao,REN Xianjing,ZHANG Deming,et al. Research of the coating material on brush seal rotor surface[J]. Thermal Spray Technology,2011,3(4): 49-52. (in Chinese LIU Xiaoxiao, REN Xianjing, ZHANG Deming, et al . Research of the coating material on brush seal rotor surface[J]. Thermal Spray Technology,2011 ,3 (4 ):49 -52 . (in Chinese)[22] 朱宗举. 刷式密封的设计与应用[J]. 燃气轮机技术,2005(3): 68-72. [23] 牛少鹏. NiCr/Cr3C2-BaF2·CaF2自润滑涂层制备与性能研究[D]. 长沙: 中南大学,2013. NIU Shaopeng. Study on preparation and properties of NiCr/Cr3C2-BaF2·CaF2Self-lubricating coating[D]. Changsha: Central South University,2013. (in ChineseNIU Shaopeng. Study on preparation and properties of NiCr/Cr3C2-BaF2·CaF2Self-lubricating coating[D]. Changsha: Central South University, 2013. (in Chinese) [24] 李莉平,白洪金. 一种高温摩擦磨损试验机: CN103364296B[P]. 2015-11-18. [25] 谢新良. 氧化铝涂层高温摩擦磨损性能研究[D]. 沈阳: 东北大学,2014. XIE Xinliang. Friction and wear properties of aluminum oxide coatings under high temperature[D]. Shenyang: Northeastern University,2014. (in ChineseXIE Xinliang. Friction and wear properties of aluminum oxide coatings under high temperature[D]. Shenyang: Northeastern University, 2014. (in Chinese) [26] 张甜甜. 航空发动机高温固体润滑涂层材料的制备与性能研究[D]. 北京: 中国科学院大学,2017. ZHANG Tiantian. Preparation and investigation of coatings with self-lubricating and wear-resistant properties used ai elevated temperatures in turbo-engines[D]. Beijing: University of Chinese Academy of Sciences,2017. (in ChineseZHANG Tiantian. Preparation and investigation of coatings with self-lubricating and wear-resistant properties used ai elevated temperatures in turbo-engines[D]. Beijing: University of Chinese Academy of Sciences, 2017. (in Chinese) -

下载:

下载: