Unsteady effect on casing treatment in counter-rotating axial flow compressor

-

摘要:

为探究不同形式的机匣处理扩稳机理和损失产生区别,以某两级对转压气机(CRAC)为研究对象,通过非定常数值模拟方法开展了自循环机匣处理(SRCT)和轴向槽机匣处理(ASCT)扩稳机理的研究。结果表明:SRCT和ASCT在近失速点均显著提高失速裕度和总压比,在峰值效率点附近增加效率损失;机匣处理通过作用于叶顶泄漏流和抑制压力势流减弱转子间动-动干涉效应;机匣处理槽内流场与转子相对位置相关,转子周期性的扫掠机匣处理槽增加了轴向槽内流动的非定常性,机匣处理槽内流动掺混是效率下降的主要原因。

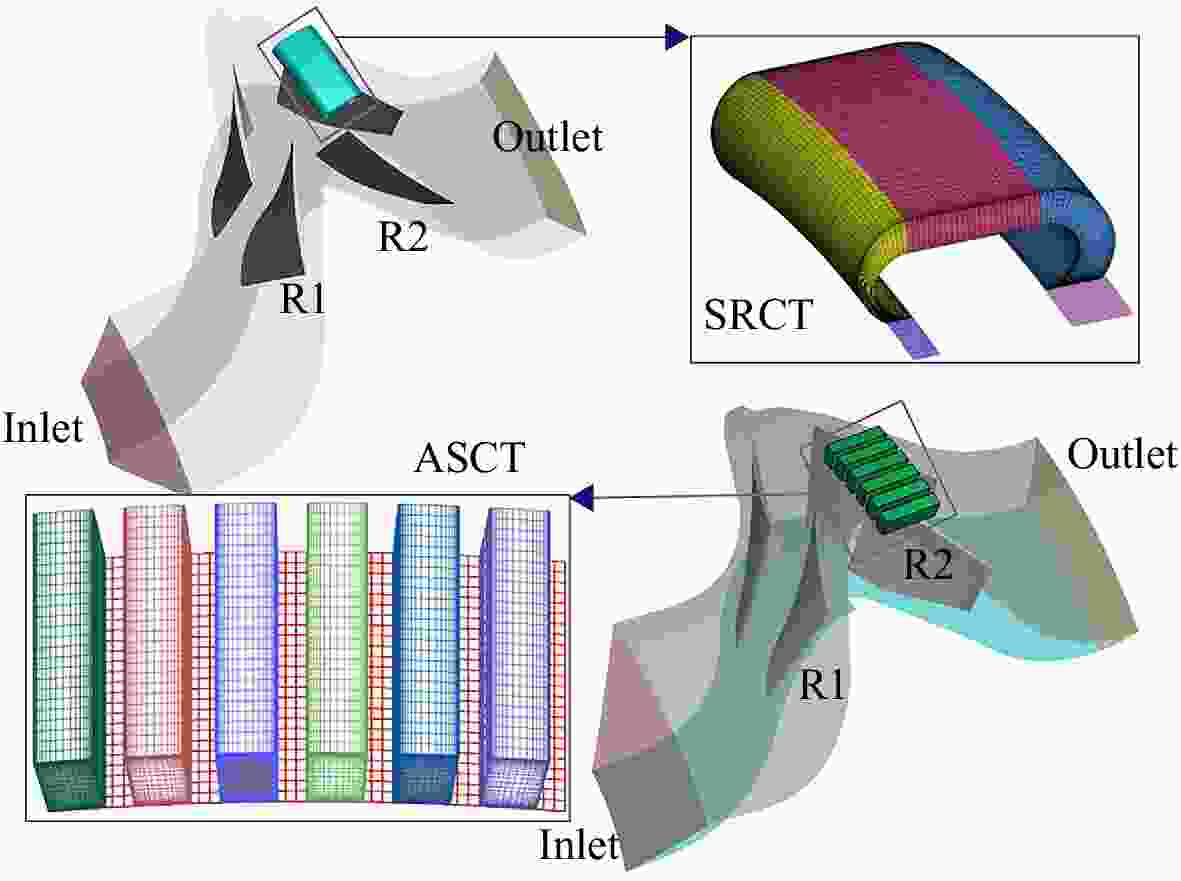

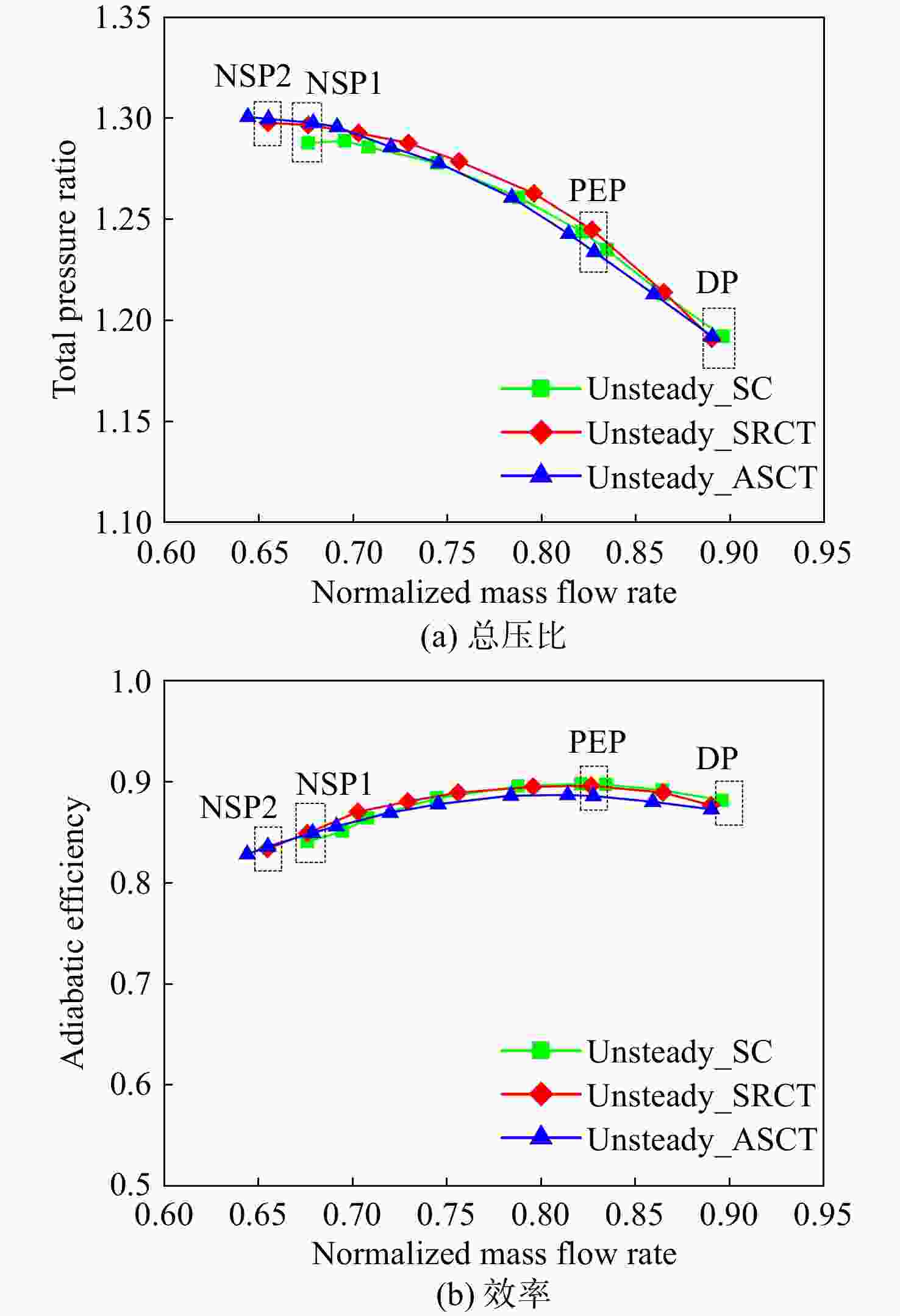

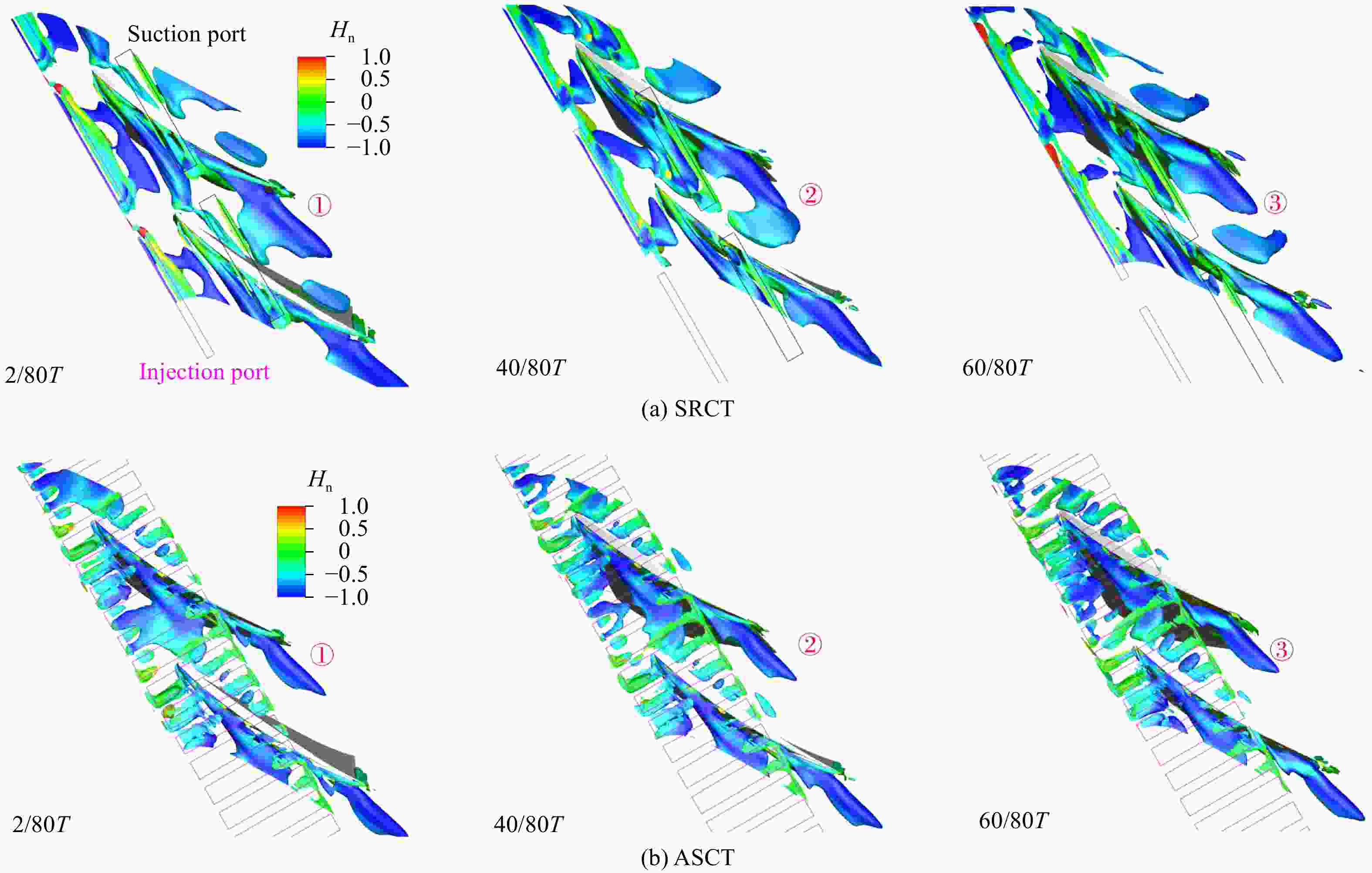

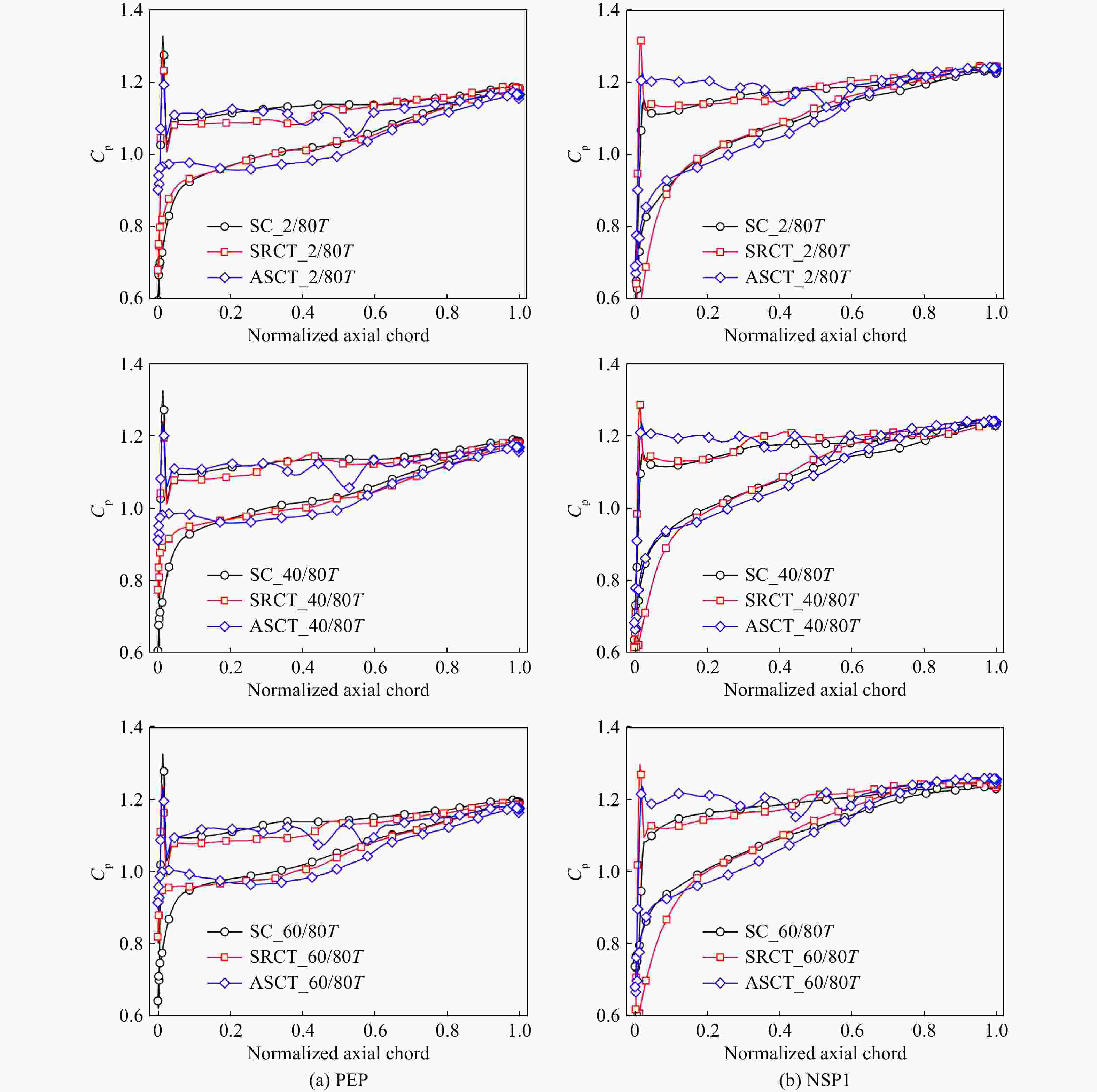

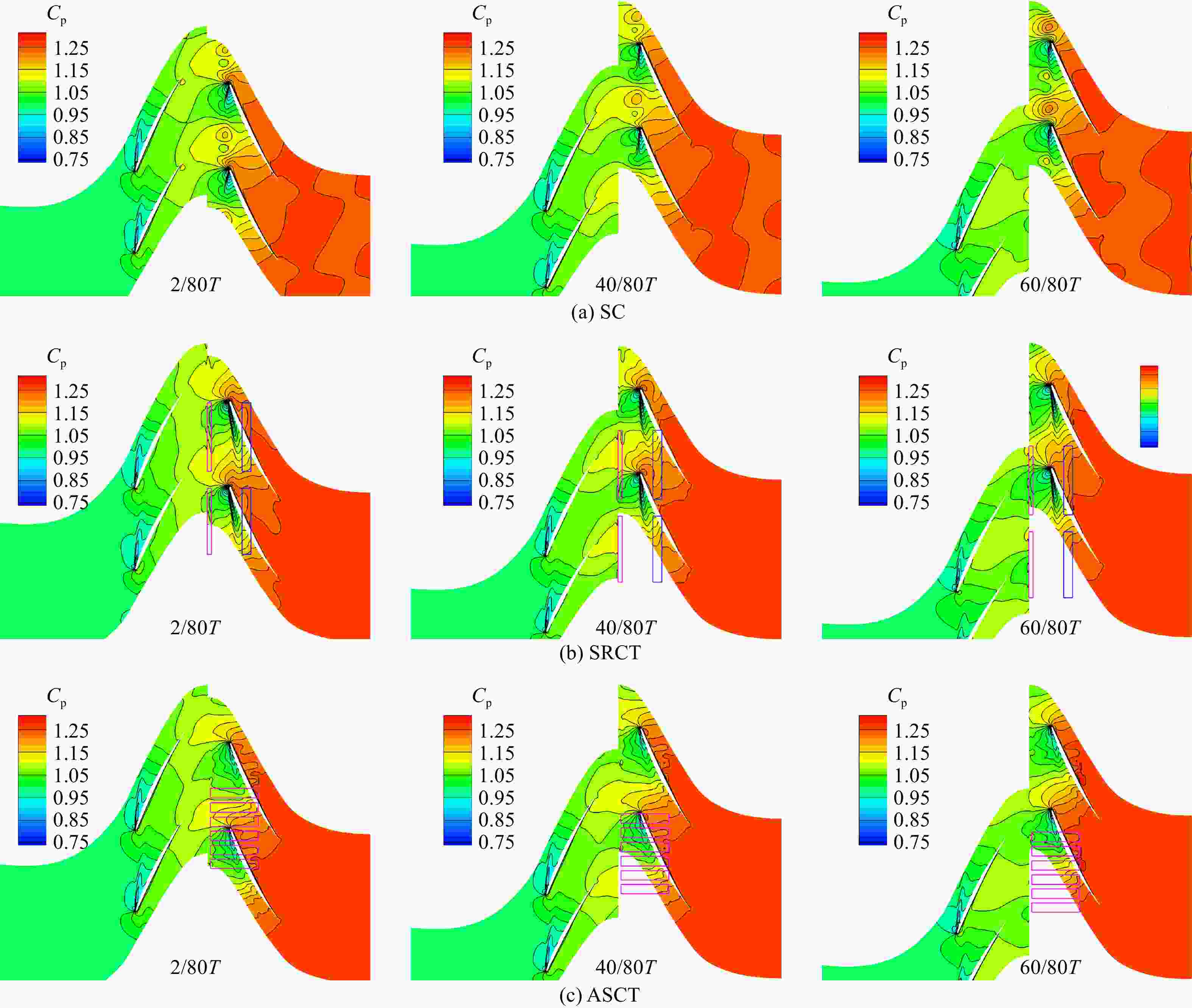

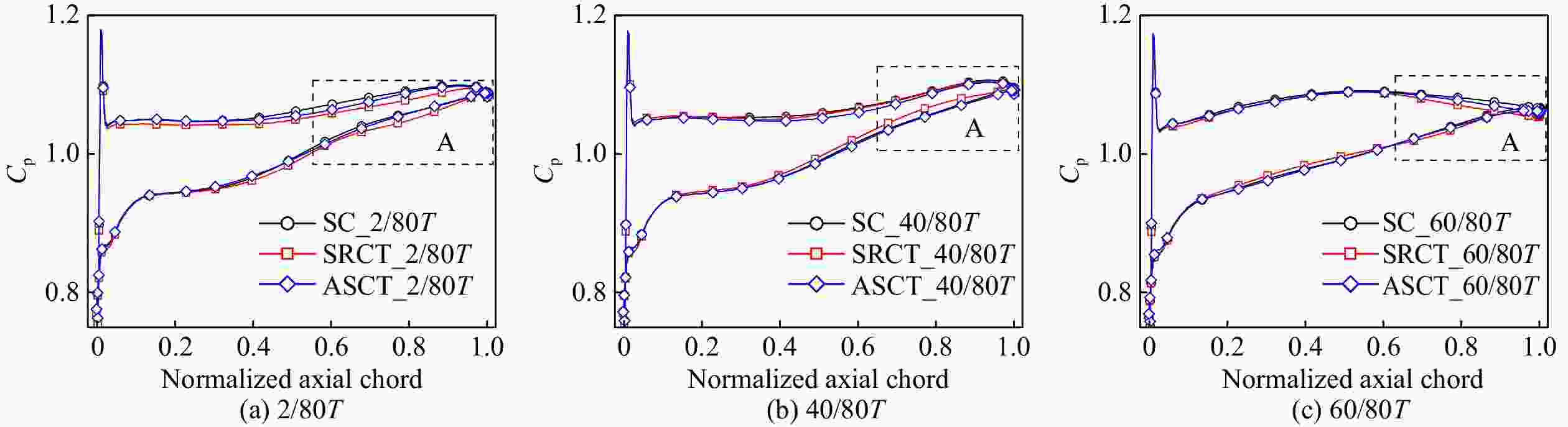

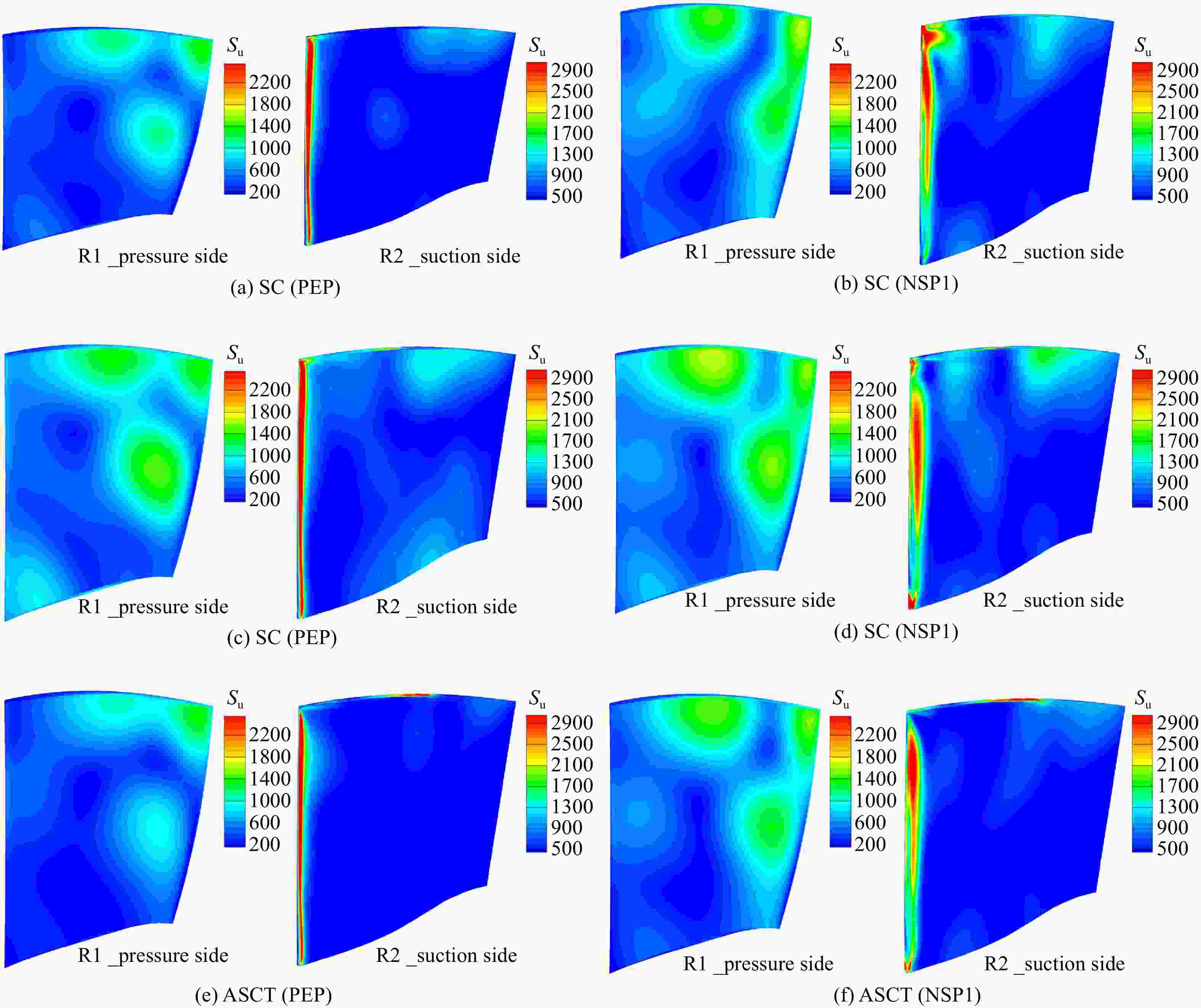

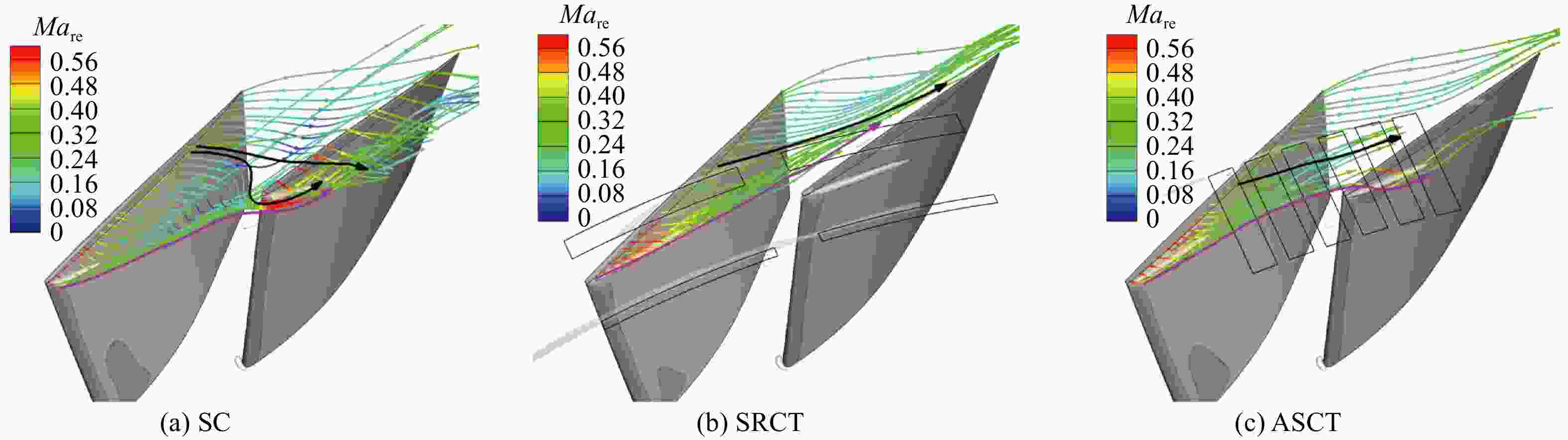

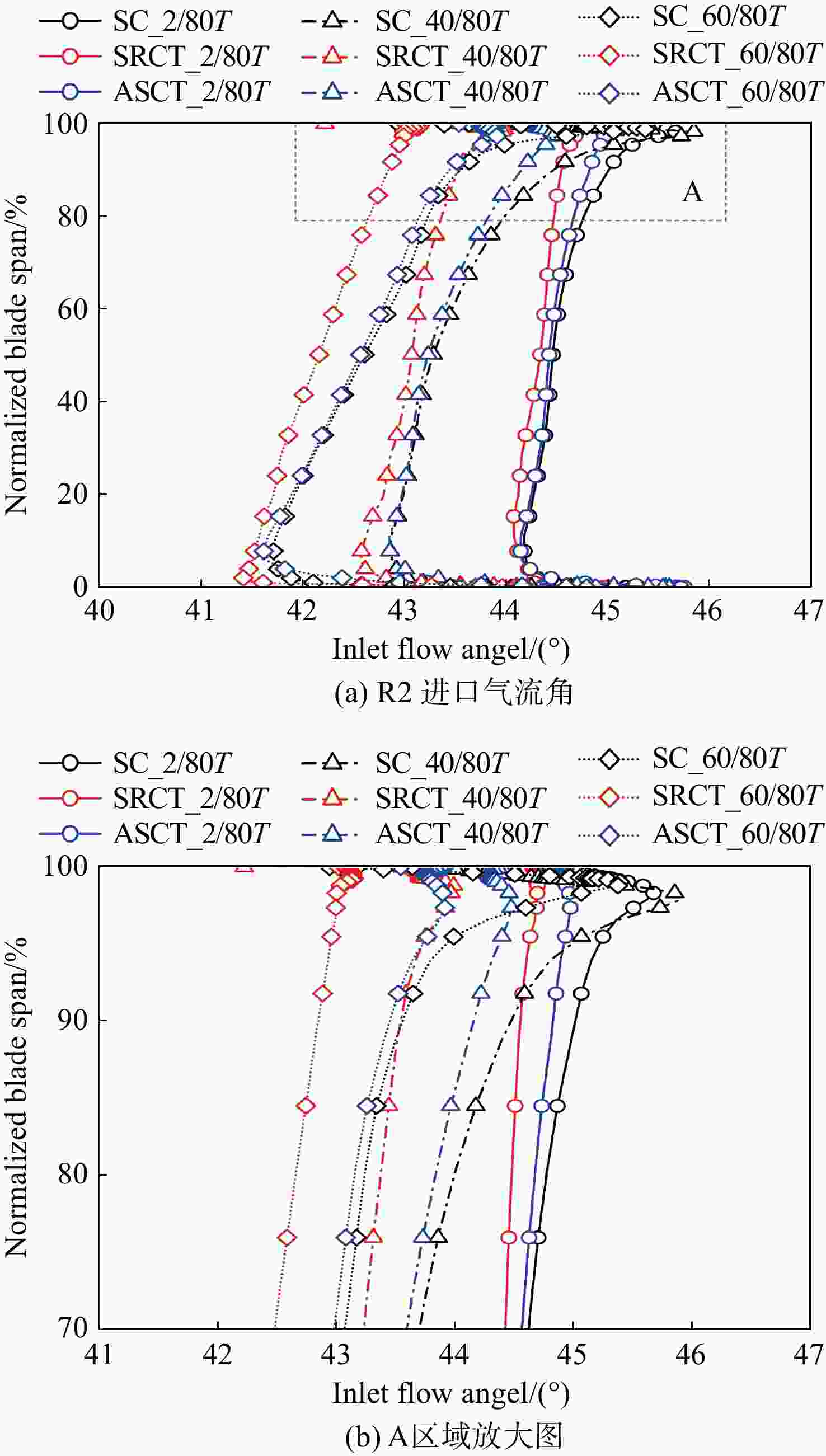

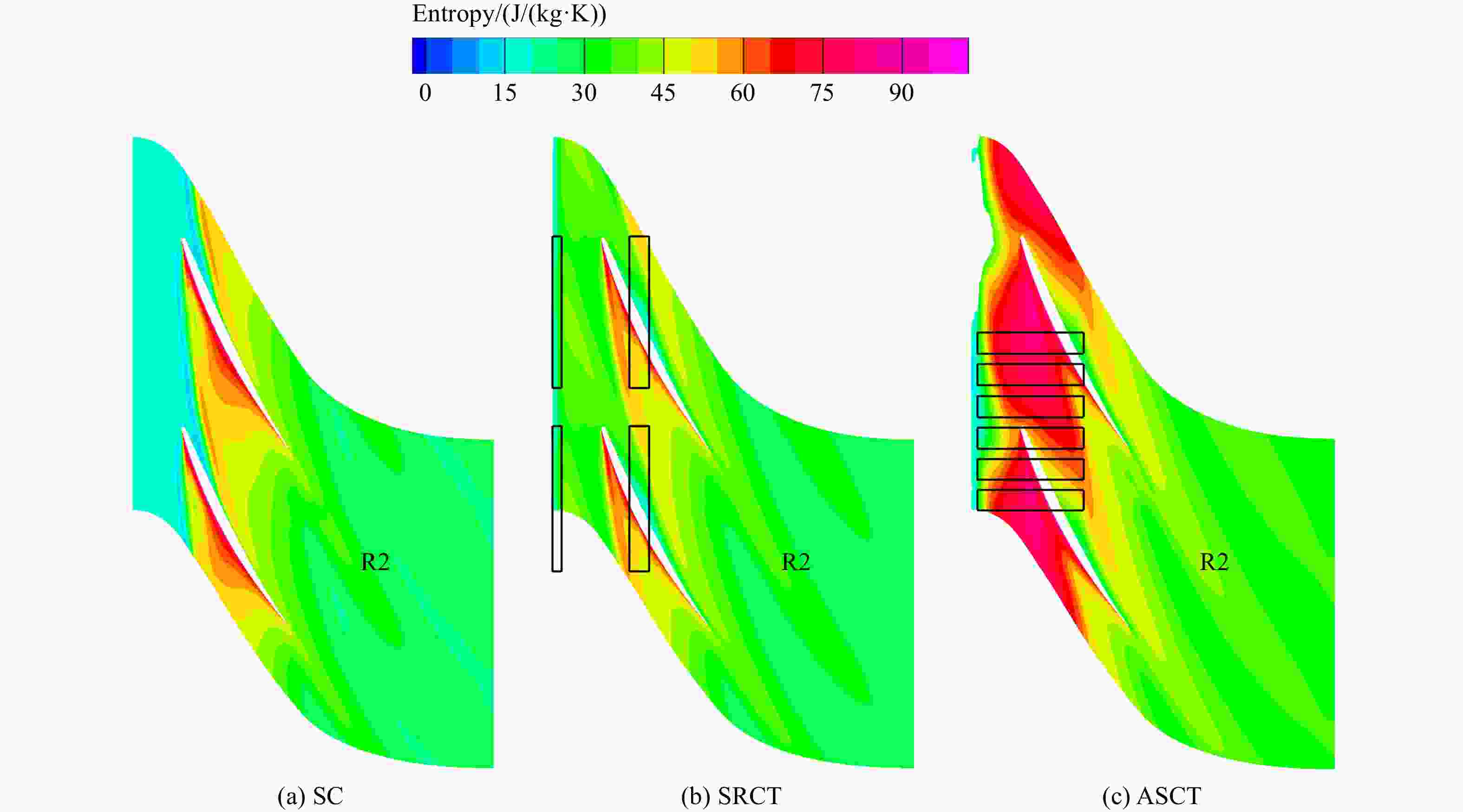

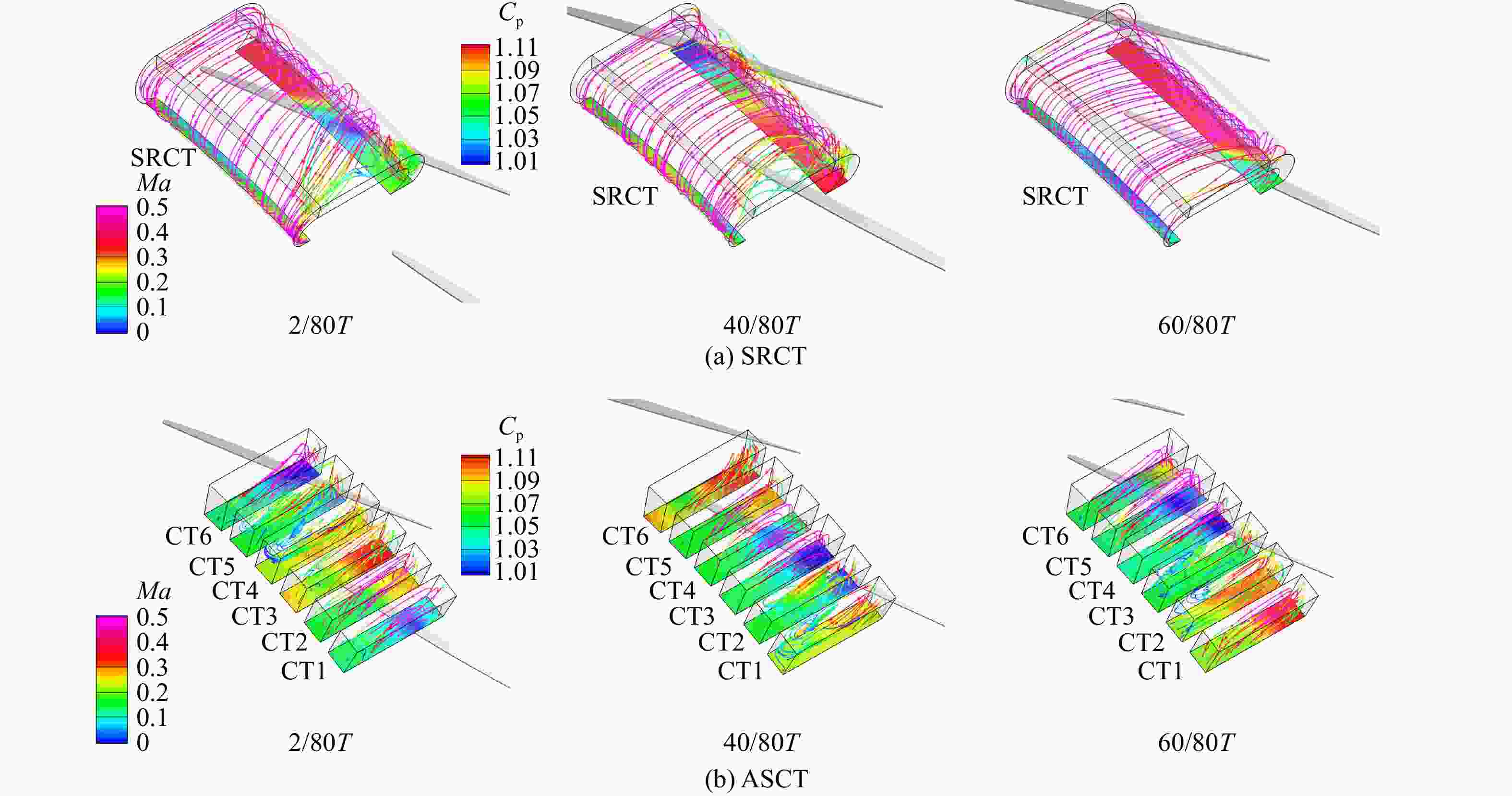

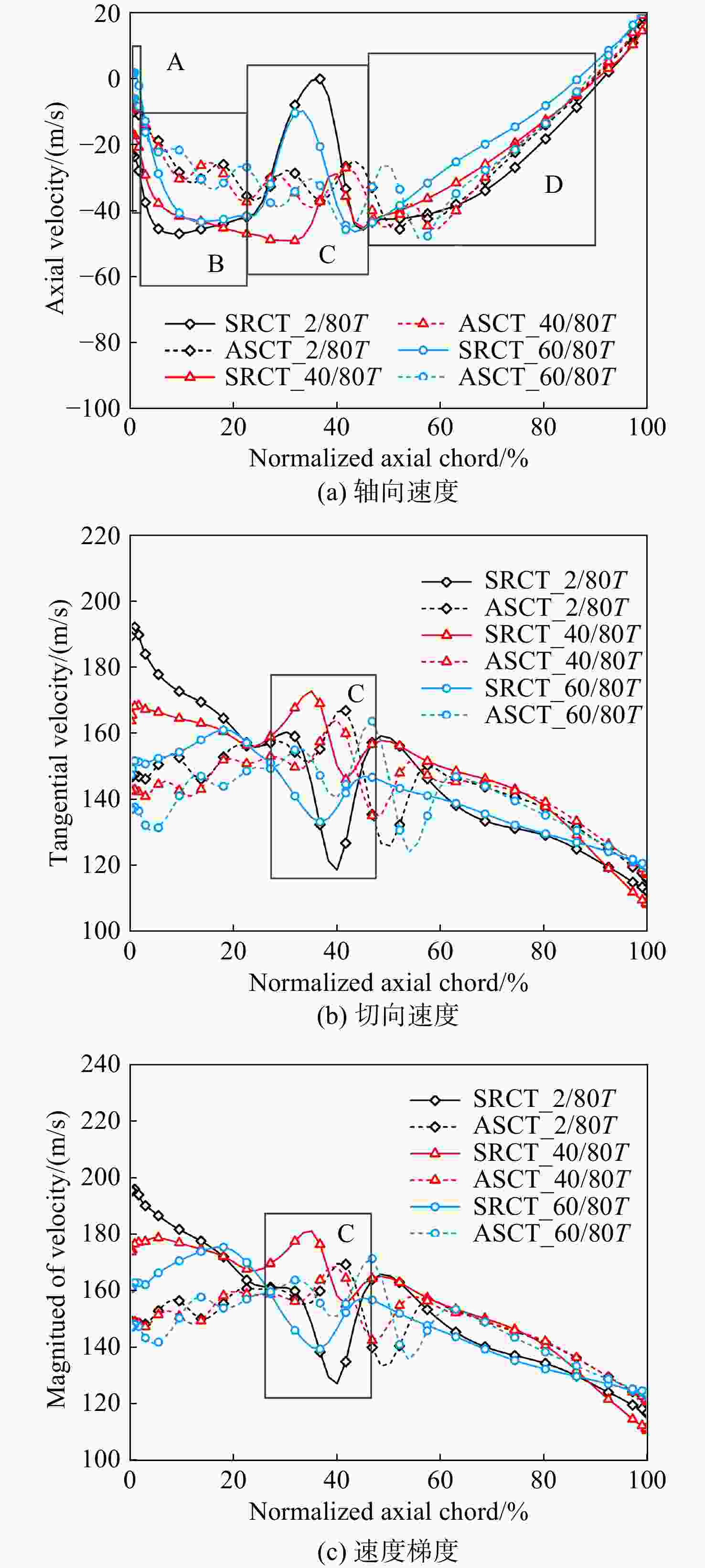

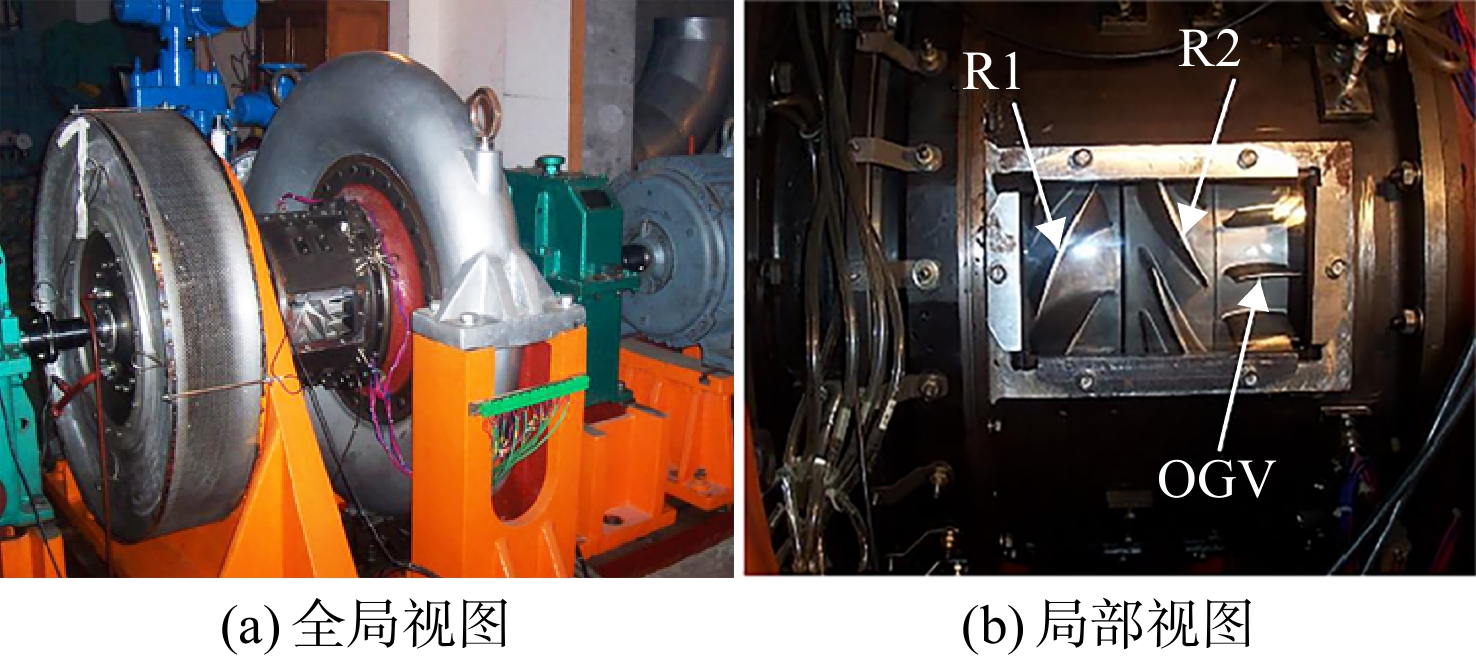

Abstract:In order to reveal the difference between the stability enhancement mechanism and the loss of different forms of casing treatment, a two-stage counter-rotating axial flow compressor (CRAC) was taken as the research object, the stability enhancement mechanism of self-recirculating casing treatment (SRCT) and axial slot casing treatment (ASCT) was studied by unsteady numerical simulations. The results showed that both SRCT and ASCT significantly improved the stall margin and total pressure ratio at the near-stall point, and increased the efficiency loss at the peak efficiency point. The casing treatment reduced the dynamic-dynamic interference effect between the two rotors by acting on the tip leakage flow and suppressing the pressure potential flow. The flow in axial slots was related to the relative position of the rotor. The periodic sweeping of the rotor to the casing treatment slots increased the unsteadiness of flow in casing treatment slots, and the mixing of the flow in casing treatment slots was the main reason for the decrease of efficiency.

-

表 1 对转压气机主要设计参数

Table 1. Main design parameters of the counter-rotating axial flow compressor

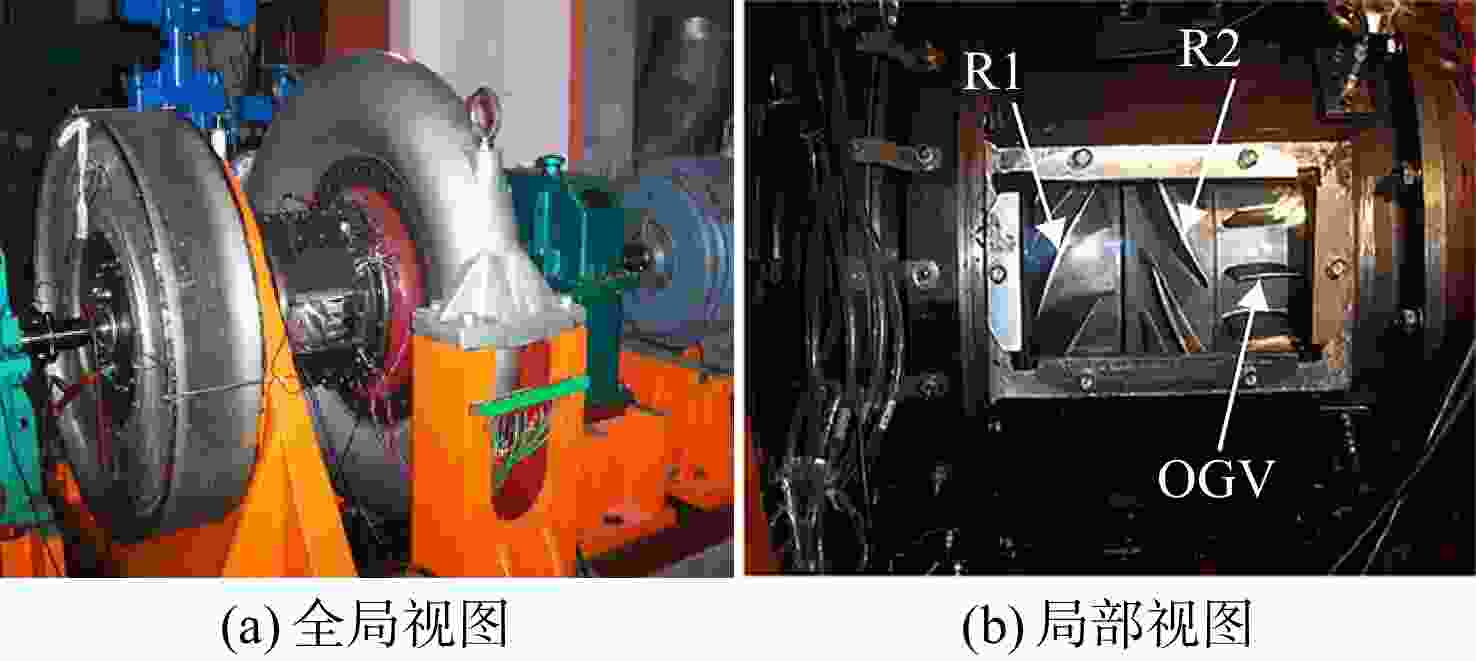

设计参数 IGV R1 R2 OGV 转速/103 (r/min) 8 −8 叶顶间隙/mm 0.5 0.5 叶尖速度/(m/s) 167.6 167.6 叶片数 22 19 20 32 轮毂比 0.485 0.641 -

[1] VIJAYRAJ K, GOVARDHAN M. Aerodynamics of contra-rotating fans with swept blades[R]. ASME Paper GT2015-1383, 2015. [2] 韩少冰,张雯棋,钟兢军. 跨声速风扇转子叶尖小翼设计与扩稳机理研究[J]. 推进技术,2020,41(7): 1484-1492. doi: 10.13675/j.cnki.tjjs.190551HAN Shaobing,ZHANG Wenqi,ZHONG Jingjun. Research on design of blade tip winglet for transonicfan rotor and mechanism of stability enhancement[J]. Journal of Propulsion Technology,2020,41(7): 1484-1492. (in Chinese) doi: 10.13675/j.cnki.tjjs.190551 [3] CHEN Y,YANG L,ZHONG J. Numerical study on endwall fence with varying geometrical parameters in a highly-loaded compressor cascade[J]. Aerospace Science and Technology,2019,94: 105390.1-105390.10. [4] MA S, CHU W, ZHANG H, et al. Impact of a combination of micro-vortex generator and boundary layer suction on performance in a high-load compressor cascade[R]. ASME Paper GT2018-75520, 2018. [5] SHI L,LIU B,NA Z,et al. Experimental investigation of a counter-rotating compressor with boundary layer suction[J]. Chinese Journal of Aeronautics,2015,28(4): 1044-1054. doi: 10.1016/j.cja.2015.05.003 [6] KHALEGHI H. Parametric study of injector radial penetration on stalling characteristics of a transonic fan[J]. Aerospace Science and Technology,2017,66: 112-118. doi: 10.1016/j.ast.2017.02.020 [7] LI J. Self-adaptive stability-enhancing technology with tip air injection in an axial flow compressor[J]. Journal of Turbomachinery,2017,139(1): 81-89. [8] 楚武利,卢新根,吴艳辉. 带周向槽机匣处理的压气机内部流动数值模拟与试验[J]. 航空动力学报,2006,21(1): 100-105. doi: 10.3969/j.issn.1000-8055.2006.01.019CHU Wuli,LU Xingen,WU Yanhui. Numerical and experimental investigations of the flow in a compressor with circumferential grooves[J]. Journal of Aerospace Power,2006,21(1): 100-105. (in Chinese) doi: 10.3969/j.issn.1000-8055.2006.01.019 [9] DAY I J. Stall, surge, and 75 years of research[J]. Journal of Turbomachinery,2016,138(1): 1-16. [10] CHEN H, KOLEY S S, LI Y, et al. Systematic experimental evaluations aimed at optimizing the geometry of axial casing groove in a compressor[R]. ASME Paper GT2019-91050, 2019. [11] BRANDSTETTER C,WARTZEK F,WERNER J,et al. Unsteady measurements of periodic effects in a transonic compressor with casing treatments[J]. Journal of Turbomachinery,2016,138(5): 1-9. [12] HATHAWAY M D. Self-recirculating casing treatment concept for enhanced compressor performance[R]. ASME Paper GT2002-30368, 2002. [13] STRAZISAR A J, BRIGHT M M, THORP S, et al. Compressor stall control through endwall recirculation[R]. ASME Paper GT2004-54295, 2004. [14] KHALEGHI H. Effect of discrete endwall recirculation on the stability of a high-speed compressor rotor[J]. Aerospace Science and Technology,2014,37: 130-137. doi: 10.1016/j.ast.2014.05.009 [15] KHALEGHI H. A new approach of endwall recirculation in axial compressors[J]. Aerospace Science and Technology,2020,98: 105704.1-105704.7. [16] KUMAR S S, CHOTALIA R J, JANA S, et al. Single stage axial compressor stability management with self-recirculating casing treatment[R]. AIAA 2019-0942, 2019. [17] 张皓光,安康,谭锋,等. 自循环机匣处理轴向位置影响扩稳能力的机理[J]. 航空动力学报,2017,32(4): 983-989. doi: 10.13224/j.cnki.jasp.2017.04.026ZHANG Haoguang,AN Kang,TAN Feng,et al. Mechanism of affecting ability of stability enhancement with varying axial position of self-recirculating casing treatment[J]. Journal of Aerospace Power,2017,32(4): 983-989. (in Chinese) doi: 10.13224/j.cnki.jasp.2017.04.026 [18] LI Jichao,DU Juan,NAN Xi,et al. Coupling stability-enhancing mechanism with compact self-recirculating injection in an axial flow compressor[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy,2016,230(7): 696-708. doi: 10.1177/0957650916659778 [19] LI Jichao,DU Juan,LI Zhiyuan,et al. Stability enhancement with self-recirculating injection in axial flow compressor[J]. Journal of Turbomachinery,2018,140(7): 1001-1013. [20] GUINET C,INZENHOFER A,GÜMMER V. Influencing parameters of tip blowing interacting with rotor tip flow[J]. Journal of Turbomachinery,2017,139(2): 101-110. [21] 晏松,楚武利. 不同转速下自循环机匣处理对转子性能的影响[J]. 航空动力学报,2019,34(11): 2516-2528. doi: 10.13224/j.cnki.jasp.2019.11.024YAN Song,CHU Wuli. Effect of self-circulating treatment casing on rotor performance at different speeds[J]. Journal of Aerospace Power,2019,34(11): 2516-2528. (in Chinese) doi: 10.13224/j.cnki.jasp.2019.11.024 [22] PUNDHIR D S. A study of some factors affecting the effectiveness of casing treatment in contra-rotating axial compressor stage[J]. Indian Journal of Engineering and Materials Sciences,1994,1: 199-207. [23] MAO X,LIU B,ZHAO H. Numerical analysis of the circumferential grooves casing treatment in a counter-rotating axial flow compressor[J]. Applied Thermal Engineering,2018,130: 29-39. doi: 10.1016/j.applthermaleng.2017.11.044 [24] MAO X,LIU B,TANG T,et al. The impact of casing groove location on the flow instability in a counter-rotating axial flow compressor[J]. Aerospace Science and Technology,2018,76: 250-259. doi: 10.1016/j.ast.2018.01.037 [25] HEINRICH M, KHALEGHI H, FRIEBE C. Numerical investigation of circumferential groove casing treatment on a low speed contra-rotating fan[R]. ASME Paper GT2019-91705, 2019. [26] SUN X,DONG X,SUN D. Recent development of casing treatments for aero-engine compressors[J]. Chinese Journal of Aeronautics,2019,32(1): 1-36. doi: 10.1016/j.cja.2018.11.005 -

下载:

下载: