Analysis of thermo-aerodynamic heat and flow characteristics in clearance of dynamic pressure gas thrust bearing

-

摘要:

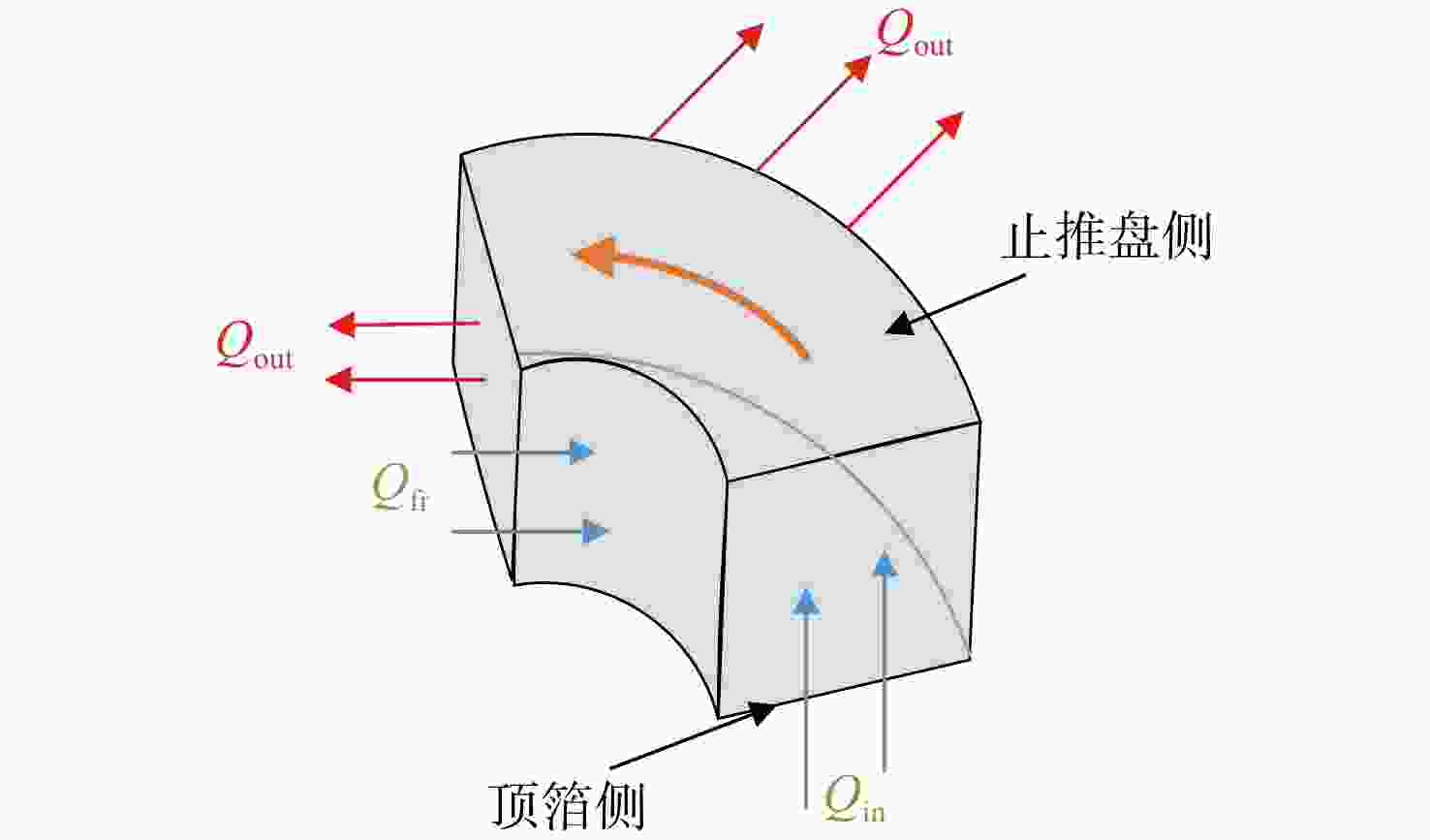

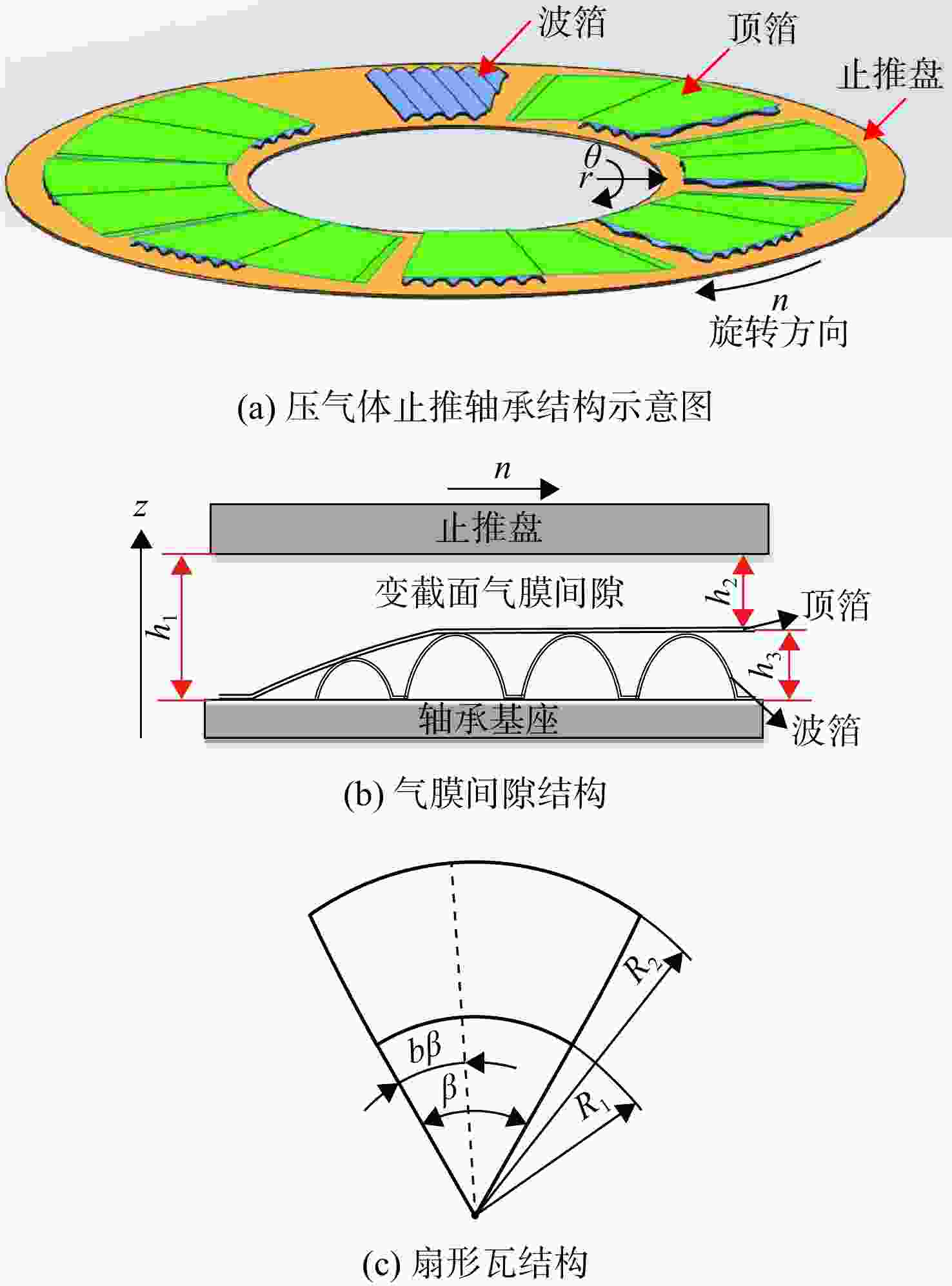

以波箔型动压气体止推轴承为研究对象,建立变截面气膜间隙润滑模型,研究了有无黏性耗散时动压气体止推轴承间隙压力场及温度场分布,获得几何参数以及转速对轴承间隙气膜压力和温度的影响规律。结果表明:考虑黏性耗散时,在收敛段末端和平直段外缘形成高温区;无黏性耗散时,轴承气膜高温区位于收敛间隙末端;轴承气膜温升随转速线性增加;考虑黏性耗散时,气膜温升随楔形因子的增加而减小,无黏性耗散热时则与之相反;气膜厚度越大,温升越小,厚度对轴承气膜温度分布无影响。本文参数范围内,黏性耗散产生的温升占比达90%。该研究证实了黏性耗散对动压气体止推轴承热流动物理机制有重要的影响,可为动压气体轴承设计和高效运行提供理论基础。

Abstract:In order to reveal the thermo-aerodynamic characteristics of foil-type dynamic pressure gas thrust bearings in the presence or absence of viscosity dissipation, the lubrication models in the cross-section air film gap were built, and the term of viscosity dissipation and pressure variation term in the energy equations were decoupled and discussed respectively. The effects of wedge factor, air film thickness and rotation speed on flow field of the air film were obtained. The temperature distributions in air film between the presence and absence of viscosity dissipation were presented and compared. Results showed that the peak temperature in the air film was located near the circumferential air outlet and the side of outer diameter in the presence of viscosity dissipation, while the peak value took place near the end of the convergence channel in the absence of viscosity dissipation. Contrary to the case without viscosity dissipation, the magnitude of temperature rise in the air film increased with the increase of wedge factor in the presence of viscosity dissipation. The magnitude of temperature rise increased with the increase of the rotational speed, and had no effect on the variation of air film thickness. This study confirmed that viscosity dissipation played a significant role in the temperature rise and flow field of the foil-type dynamic pressure gas thrust bearings. In high-speed working conditions, the temperature rise in the presence of viscosity dissipation accounted for more than 90%. The results are of significant importance by providing basic design guidelines for temperature rise of the air film.

-

Key words:

- gas thrust bearing /

- viscous dissipation /

- temperature field /

- rotational speed /

- wedge factor

-

表 1 计算工况

Table 1. Parameters of the calculation operating condition

参数 数值 初始最小气膜厚度h2/μm 8~36 楔形因子hf=h3/h2 2~8 转速n/104 (r/min) 2~10 轴承外半径R2/mm 21.5 轴承内半径R1/mm 12 扇形瓦张角β/(°) 60 节距比b 0.5 箔片数N 6 -

[1] XU F, KIM D, YAZDI B Z. Theoretical study of top foil sagging effect on the performance of air thrust foil bearing[R]. Seoul, South Korea: ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, 2016. [2] HESHMAT H,WALOWIT J A,PINKUS O. Analysis of gas lubricated compliant thrust bearings[J]. Journal of Lubrication Technology,1983,105(4): 638-646. doi: 10.1115/1.3254696 [3] KIM T H,LEE Y B,KIM T Y,et al. Rotor dynamic performance of an oil-free turbo blower focusing on load capacity of gas foil thrust bearings[J]. Journal of Engineering for Gas Turbines and Power,2012,134(2): 1-7. [4] 闫佳佳. 弹性箔片动压气体止推轴承-转子系统动力学特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2012.YAN Jiajia. Research on dynamic characteristics of compliant foil gas bearing-rotor system[D]. Harbin: Harbin Institute of Technology, 2012. (in Chinese) [5] 李映宏,胡小强,张凯,等. 叠片式气体箔片推力轴承热特性分析[J]. 摩擦学学报,2019,39(3): 295-303. doi: 10.16078/j.tribology.2018193LI Yinghong,HU Xiaoqiang,ZHANG Kai,et al. A thermohydrodynamic analysis of laminated gas foil thrust bearing[J]. Journal of Tribology,2019,39(3): 295-303. (in Chinese) doi: 10.16078/j.tribology.2018193 [6] LEE D,KIM D. Designand performance prediction of hybrid airfoil thrust bearings[J]. Journal of Engineering for Gas Turbines and Power,2015,133(4): 425-426. [7] 罗轶欣,张镜洋. 动压气体止推轴承间隙气动热特性分析[J]. 机械制造与自动化,2019,48(5): 39-42, 63. doi: 10.19344/j.cnki.issn1671-5276.2019.05.010LUO Yixin,ZHANG Jingyang. Analysis of gas film thermal characteristics of gas thrust bearing[J]. Machine Building and Automation,2019,48(5): 39-42, 63. (in Chinese) doi: 10.19344/j.cnki.issn1671-5276.2019.05.010 [8] 徐方程,张广辉,孙毅,等. 平箔片楔形高度对气体止推箔片轴承特性影响[J]. 航空动力学报,2016,31(12): 3064-3072. doi: 10.13224/j.cnki.jasp.2016.12.031XU Fangcheng,ZHANG Guanghui,SUN Yi,et al. Performance analysis of air foil thrust bearings with different top foil taper heights[J]. Journal of Aerospace Power,2016,31(12): 3064-3072. (in Chinese) doi: 10.13224/j.cnki.jasp.2016.12.031 [9] SIM K,KIM D. Thermo hydrodynamic analysis of compliant flexure pivot tilting pad gas bearings[J]. Journal of Engineering for Gas Turbines and Power,2008,130(3): 502-513. [10] UNTAROIU A. Effect of foil geometry on the static performance of thrust foil bearings[J]. Journal of Engineering for Gas Turbines and Power,2018,140(8): 1-9. [11] 冯欣凯,杨利花. 重载下可倾瓦推力轴承的热弹流润滑特性分析[J]. 航空动力学报,2021,36(9): 1861-1870. doi: 10.13224/j.cnki.jasp.20200514FENG Xinkai,YANG Lihua. Analysis on thermoelasto -hydrodynamic lubrication characteristics of tilting pad thrust bearings under heavy load[J]. Journal of Aerospace Power,2021,36(9): 1861-1870. (in Chinese) doi: 10.13224/j.cnki.jasp.20200514 [12] PENG Z C,KHONSARI M M. A thermo hydrodynamic analysis of foil journal bearings[J]. Journal of Tribology,2006,128(3): 534-541. doi: 10.1115/1.2197526 [13] FENG K, KANEKO S. A Study of thermo hydrodynamic features of multi wound foil bearing using Lobatto point quadrature[R]. ASME Paper GT2008-50110, 2008. [14] SALEHI M,HESHMAT H. On the fluid flow and thermal analysis of a compliant surface foil bearing and seal[J]. ASLE(Association for the Study of Literature and Environment) Transactions,2000,43(2): 318-324. [15] SALEHI M,SWANSON E,HESHMAT H. Thermal features of compliant foil bearings: theory and experiments[J]. Journal of Tribology,2001,123(3): 18-34. [16] NONINO C,GIUDICE S D,SAVINO S. Temperature-dependent viscosity and viscous dissipation effects in microchannel flows with uniform wall heat flux[J]. Heat Transfer Engineering,2010,31(8): 682-691. doi: 10.1080/01457630903466670 [17] AYDIN O. Effects of viscous dissipation on the heat transfer in forced pipe flow: Part 1 both hydrodynamically and thermally fully developed flow[J]. Energy Conversion and Management,2005,46(5): 757-769. doi: 10.1016/j.enconman.2004.05.004 [18] AYDIN O. Effects of viscous dissipation on the heat transfer in a forced pipe flow: Part 2 thermally developing flow[J]. Energy Conversion and Management,2005,46(18): 3091-3102. [19] RAMADAN KM. Pressure work and viscous dissipation effects on heat transfer in a parallel-plate microchannel gas flow[J]. Journal of Mechanics,2019,35(2): 243-254. doi: 10.1017/jmech.2017.105 [20] GAD A M, KANEKO S. Fluid flow and thermal features of gas foil thrust bearings at moderate operating temperatures[R]. Milan, Italy: the 9th IFToMM International Conference on Rotor Dynamics. Mechanisms and Machine Science, 2015. [21] 侯安平,林蓬成,王锐,等. 气体动压止推轴承性能及实验[J]. 航空动力学报,2018,33(6): 1510-1518. doi: 10.13224/j.cnki.jasp.2018.06.025HOU Anping,LIN Pengcheng,WANG Rui,et al. Performance of air-dynamic lubrication thrust bearing and experiment[J]. Journal of Aerospace Power,2018,33(6): 1510-1518. (in Chinese) doi: 10.13224/j.cnki.jasp.2018.06.025 [22] LIU X,LI C,DU J,et al. Thermal characteristics study of the bump foil thrust bearing[J]. Applied Sciences,2021,11(9): 11-23. -

下载:

下载: