Fatigue life prediction of electron beam welding joint of superalloy

-

摘要:

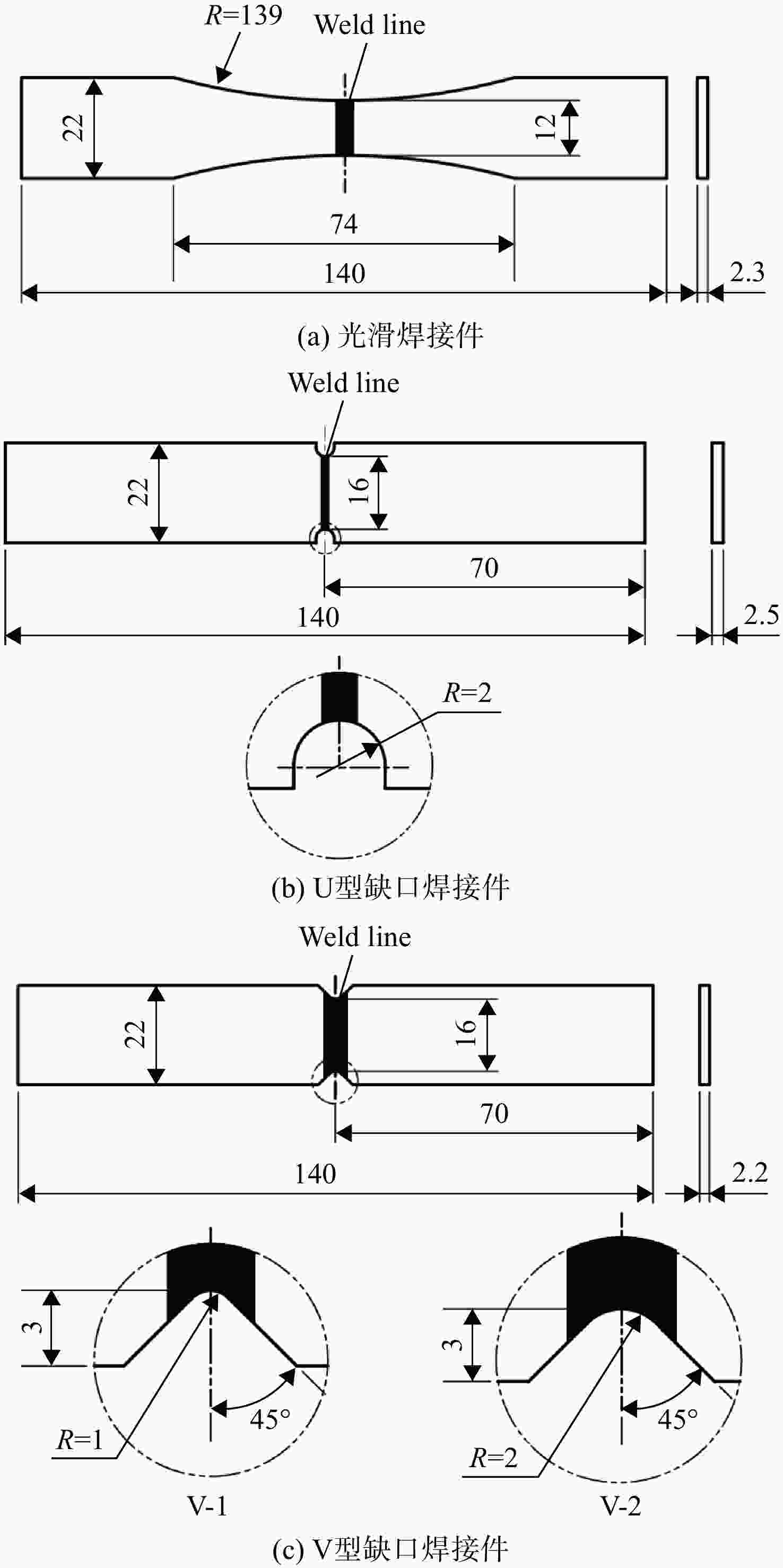

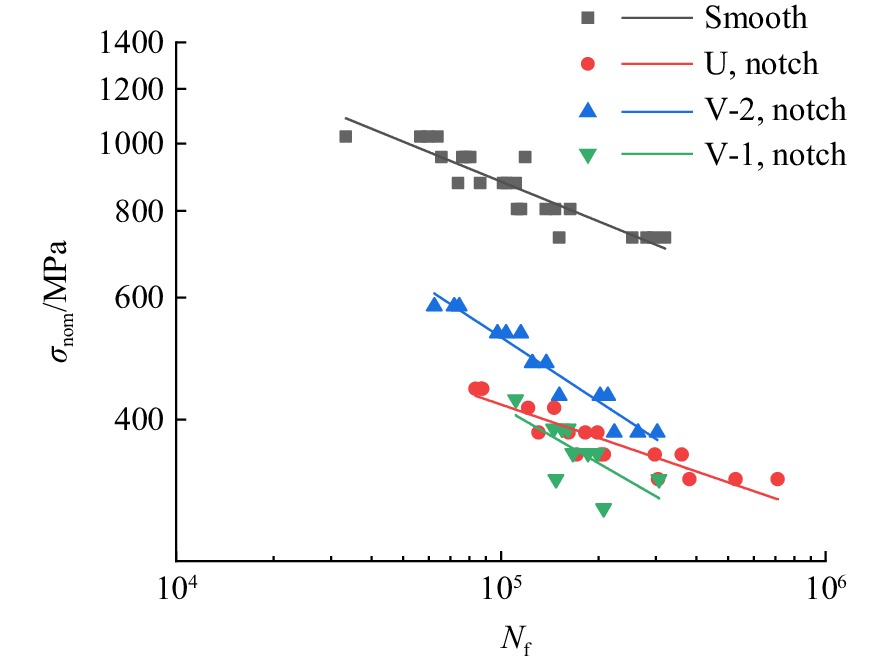

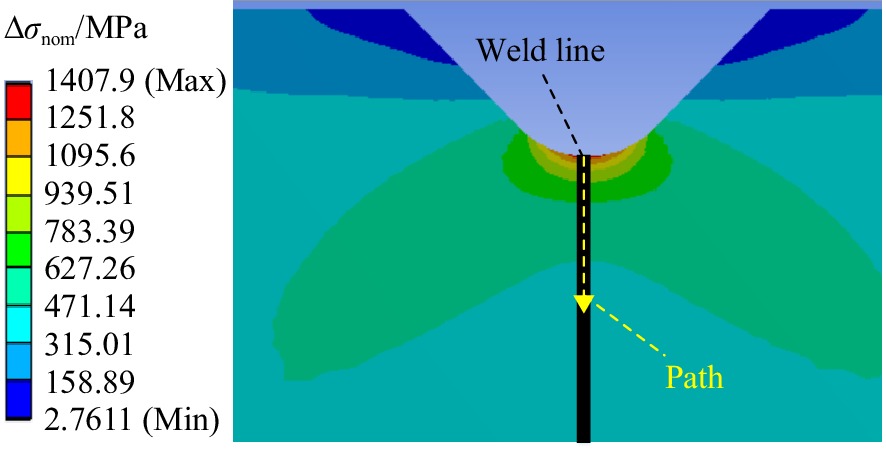

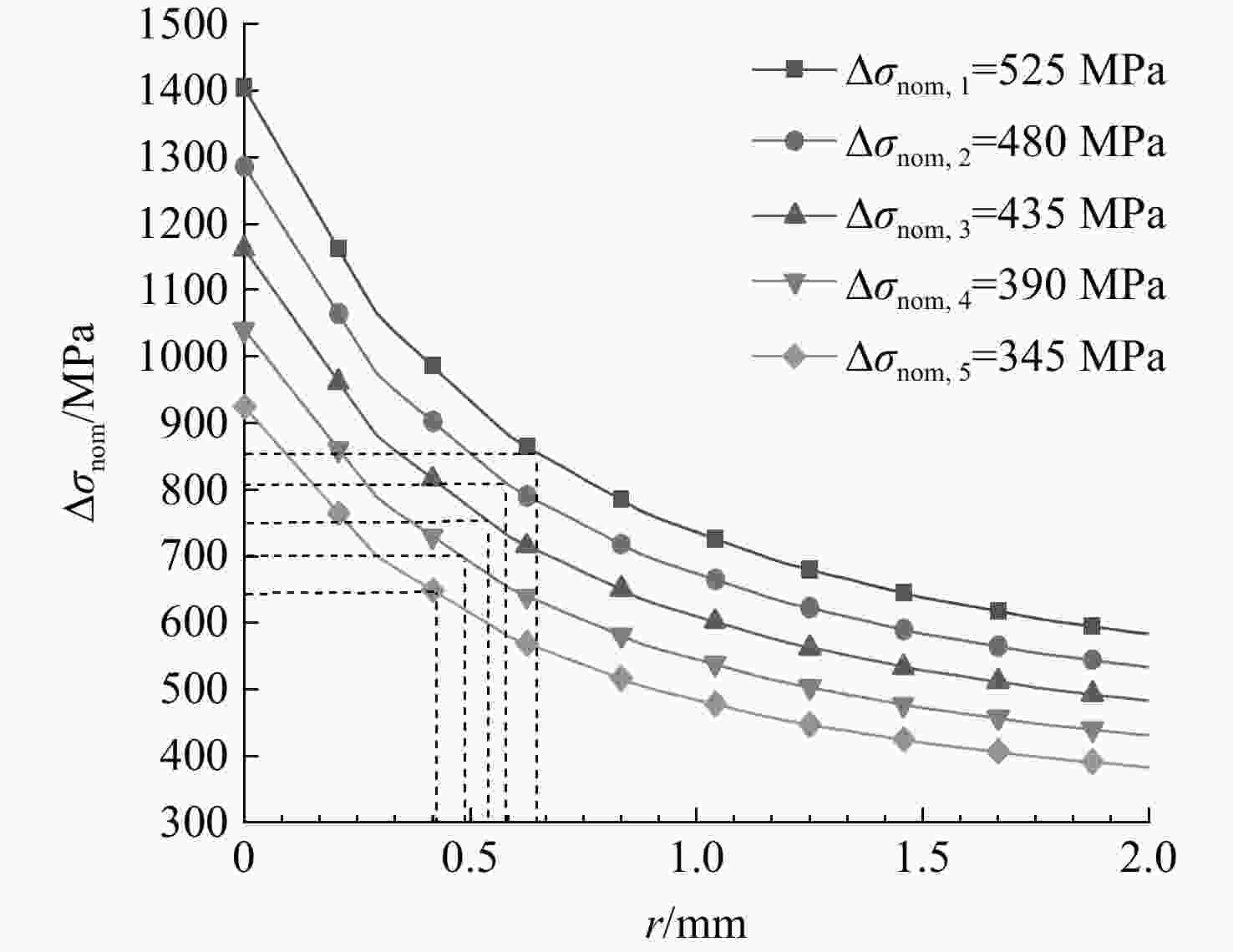

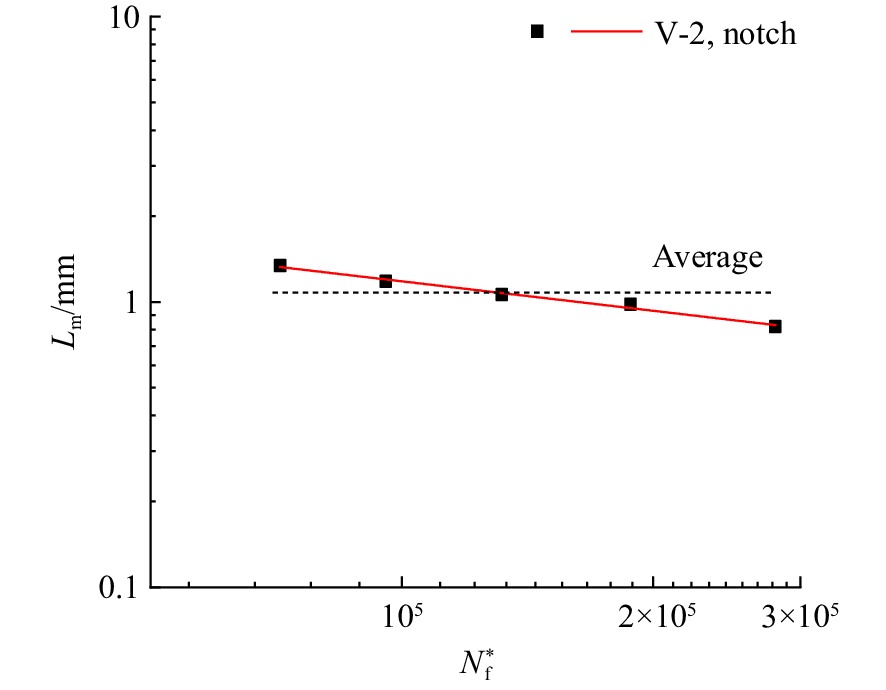

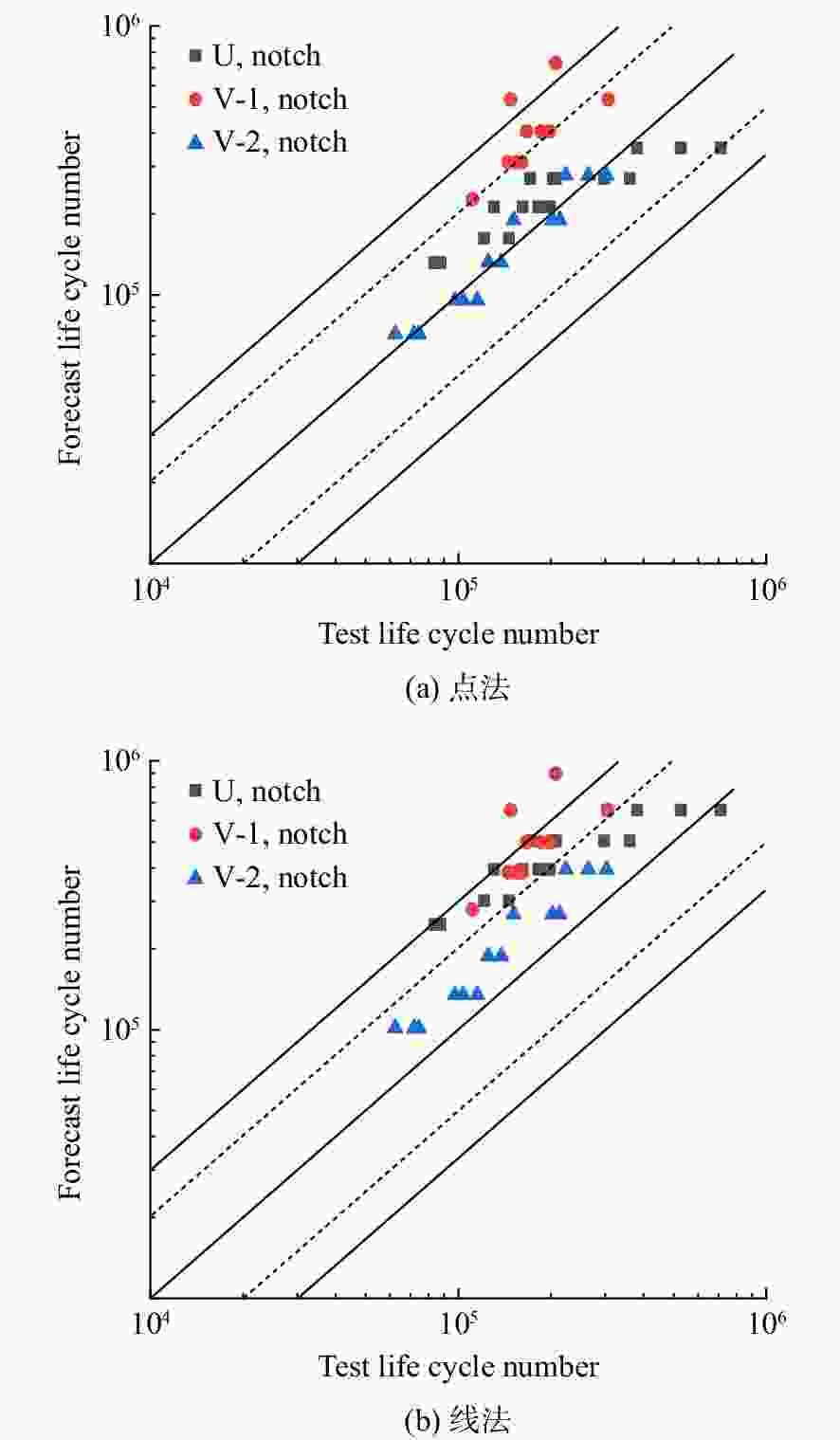

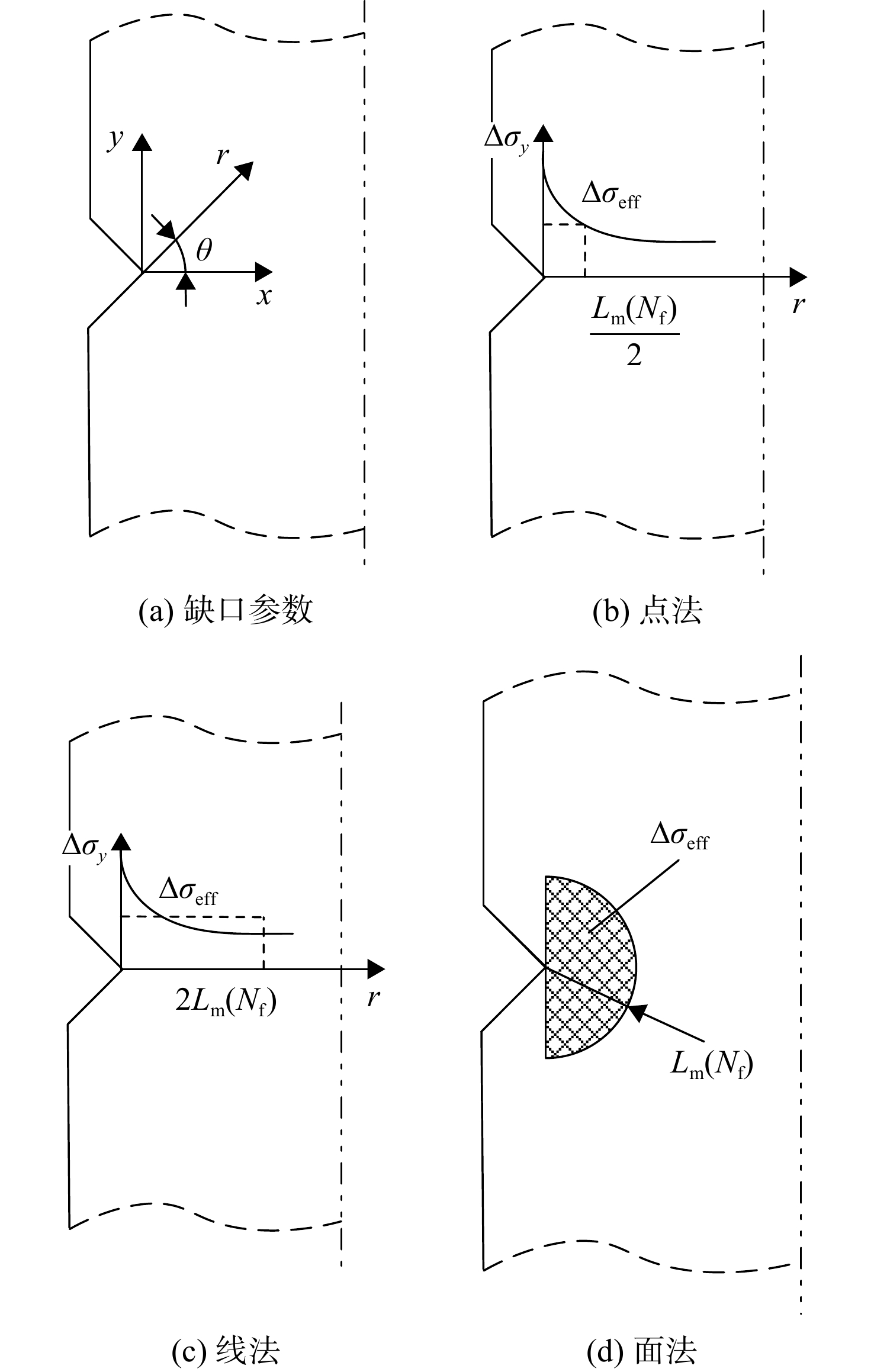

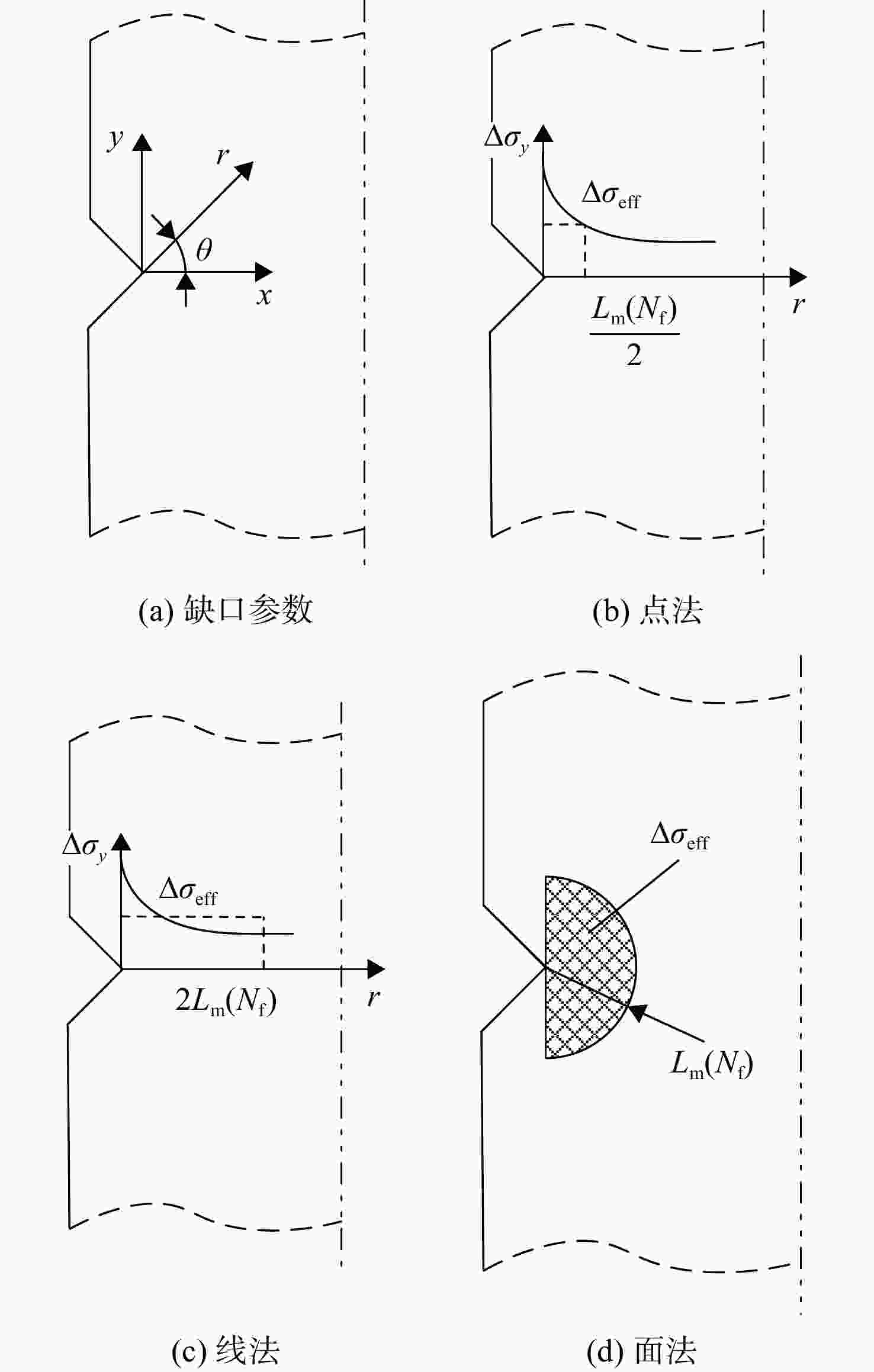

为了研究GH4169电子束焊接头缺口疲劳寿命预测方法,设计并开展了其缺口件的疲劳试验,基于临界距离理论,提出了适用于不同缺口形状的电子束焊接头疲劳寿命预测方法。通过试验,获得了GH4169电子束焊接头U型、V-1型及V-2型3种缺口件的名义应力-寿命曲线。基于V-2型缺口件试验结果,提出了一种临界距离的反推方法,确定了GH4169电子束焊接头缺口件的特征尺寸。据此,分别采用临界距离点法和线法对缺口件疲劳寿命预测。结果表明:临界距离点法对文中缺口件的适应性更好。进一步分析发现,对于不同缺口形状,当其理论应力集中系数相近时,采用相同的特征尺寸可以获得较好的寿命预测结果,均在2倍分散带以内。

-

关键词:

- GH4169合金 /

- 电子束焊接头 /

- 缺口疲劳 /

- 临界距离理论(TCD) /

- 疲劳寿命预测

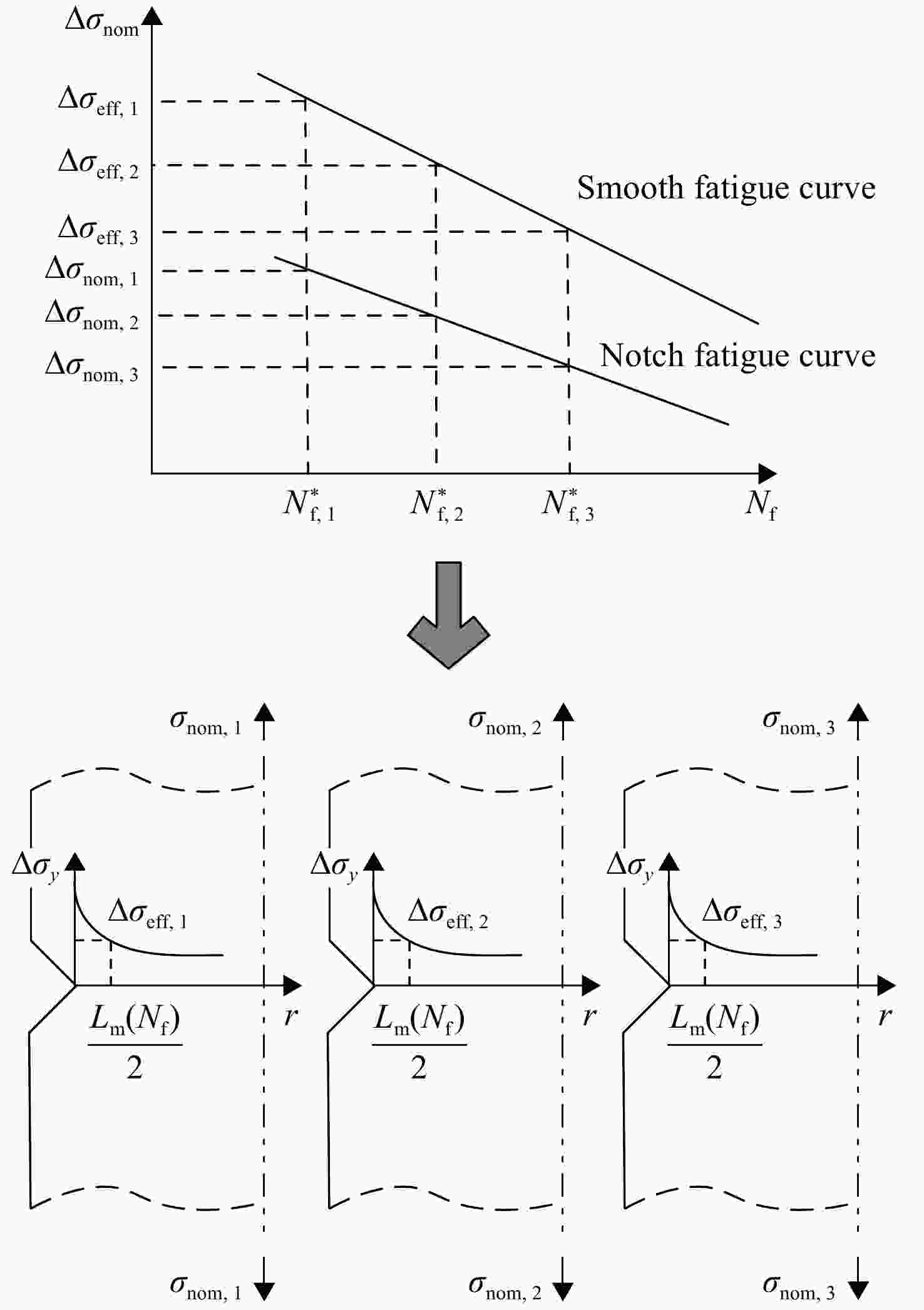

Abstract:In order to study the prediction method of notch fatigue life of GH4169 electron beam welded joints, the fatigue tests of notched specimens were designed and carried out. Based on the critical distance theory, the fatigue life prediction method for different notch shapes of electron beam welded joints was proposed. The nominal stress-life curves of three notched specimens of GH4169 electron beam welded joints (U type, V-1 type and V-2 type) were obtained through tests. Based on the test results of V-2 notched parts, an inverse method of critical distance was proposed to determine the characteristic dimensions of GH4169 electron beam welding notched joints. The fatigue life of notched joints was predicted by the critical distance point method and the line method, respectively. The results showed that the critical distance point method had better adaptability to the notched joints. Further analysis showed that for different notch shapes, when the theoretical stress concentration coefficients were similar, better life prediction results can be obtained by using the same characteristic size in the double dispersion zone.

-

表 1 各缺口的理论集中系数Kt

Table 1. Kt of each notched joint

缺口类型 Kt U型缺口 2.42 V-1型缺口 3.02 V-2型缺口 2.47 表 2 试验载荷级

Table 2. Test load class

载荷级 光滑件 U型缺口 V-1型缺口 V-2型缺口 $ {\sigma _{{\text{nom,1}}}} $/MPa 1024 443 428 583 $ {\sigma _{{\text{nom,2}}}} $/MPa 956 416 388 533 $ {\sigma _{{\text{nom,3}}}} $/MPa 878 383 358 483 $ {\sigma _{{\text{nom,4}}}} $/MPa 805 356 328 433 $ {\sigma _{{\text{nom,5}}}} $/MPa 732 328 298 383 表 3 V-2型缺口焊接接头试验件特征尺寸

Table 3. Characteristic dimensions of V-2 notch welded test pieces

$ {\sigma _{{\text{nom}}}} $/MPa $ N_{\text{f}}^* $ $ {L_{\text{m}}} $/mm 583 71479 1.3 533 95661 1.2 483 131755 1.1 433 187934 1.0 383 280022 0.9 -

[1] 刘强,柳万珠. GH4169G整体叶盘阶梯铣削稳定性研究[J]. 航空动力学报,2016,31(5): 1025-1031.LIU Qiang,LIU Wanzhu. Stability research on step milling of GH4169G blisk[J]. Journal of Aerospace Power,2016,31(5): 1025-1031. (in Chinese) [2] 陈曦,董金龙,陈昊,等. GH4169晶粒尺寸的双目标超声评价方法[J]. 航空动力学报,2021,36(4): 816-825. doi: 10.13224/j.cnki.jasp.2021.04.014CHEN Xi,DONG Jinlong,CHEN Hao,et al. Double objective ultrasonic evaluation method for grain size of GH4169[J]. Journal of Aerospace Power,2021,36(4): 816-825. (in Chinese) doi: 10.13224/j.cnki.jasp.2021.04.014 [3] DAMODARAN R,DAMAN S G S,RAO K P. Microstructure and mechanical properties of friction welded alloy 718[J]. Materials Science and Engineering: A,2013,560(10): 781-786. [4] 蒋绍堂. 电子束焊接在中小航空发动机上的应用[J]. 中国科技纵横,2014,13(7): 81-82. doi: 10.3969/j.issn.1671-2064.2014.07.055JIANG Shaotang. Application of electron beam welding in small and medium aero engine[J]. China Science and Technology,2014,13(7): 81-82. (in Chinese) doi: 10.3969/j.issn.1671-2064.2014.07.055 [5] 齐红宇,李少林,杨晓光,等. 锻造TC4钛合金电子束焊接接头的疲劳破坏机制[J]. 航空动力学报,2013,28(2): 264-269.QI Hongyu,LI Shaolin,YANG Xiaoguang,et al. Fatigue failure mechanism of forged TC4 alloy joints by electron beam welding[J]. Journal of Aerospace Power,2013,28(2): 264-269. (in Chinese) [6] 陈国庆,张秉刚,冯吉才,等. 电子束焊接在航空航天工业中的应用[J]. 航空制造技术,2011,54(11): 42-45. doi: 10.3969/j.issn.1671-833X.2011.11.005CHEN Guoqing,ZHANG Bingang,FENG Jicai,et al. Application of electron beam welding in aerospace industry[J]. Aeronautical Manufacturing Technology,2011,54(11): 42-45. (in Chinese) doi: 10.3969/j.issn.1671-833X.2011.11.005 [7] 魏祺,敖三三,王泰,等. 镍基合金 GH4169 电子束焊接头高温稳定性[J]. 中国有色金属学报,2020,30(11): 2578-2585. doi: 10.11817/j.ysxb.1004.0609.2020-35905WEI Qi,AO Sanan,WANG Tai,et al. High temperature stability of Ni-base GH4169 electron beam welded joints[J]. Chinese Journal of Nonferrous Metals,2020,30(11): 2578-2585. (in Chinese) doi: 10.11817/j.ysxb.1004.0609.2020-35905 [8] 高德平, 范引鹤, 龚良慈, 等. 航空涡喷、涡扇发动机结构设计准则(研究报告)第4册: 机匣[M]. 北京: 中国航空工业总公司发动机系统工程局, 1997. [9] 陈传尧. 疲劳与断裂[M]. 武汉: 华中科技大学出版社, 2002. [10] MANSON S. Behavior of materials under condition of the thermal stress[R]. National Advisory Committee for Aeronautics 1170, 1953. [11] COFFIN L F. A study of the effects of cyclic thermal stresses on a ductile metal[J]. Transaction of the American Society of Mechanical Engineers,1954,76(6): 931-950. [12] WEIBULL. A statistical distributions function of wide applicability[J]. Journal of Applied Mechanics,1951,18(3): 293-297. doi: 10.1115/1.4010337 [13] 辛朋朋. 基于最弱环理论的缺口疲劳寿命预测方法[D]. 南京: 南京航空航天大学, 2012.XIN Pengpeng. Notch fatigue life prediction method based on weakest loop theory[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012. (in Chinese) [14] 王昊元,吴昊. 基于改进临界距离理论的多轴缺口疲劳寿命预测[J]. 工程机械,2020,51(9): 31-40. doi: 10.3969/j.issn.1000-1212.2020.09.008WANG Haoyuan,WU Hao. Multiaxial notches fatigue life prediction base on improved critical distance[J]. Construction Machinery,2020,51(9): 31-40. (in Chinese) doi: 10.3969/j.issn.1000-1212.2020.09.008 [15] NEUBER H. Theory of notch stresses: principles for exact calculation of strength with reference to structural form and material[M]. 2nd ed. Berlin: Springer Verlag, 1958. [16] PETERSON R E, SINES G, WAISMAN J L. Notch sensitivity in metal fatigue[M]. New York: Mc-Graw Hill, 1959. [17] TAYLOR D. The theory of critical distances[J]. Engineering Fracture Mechanics,2007,75(7): 1696-1705. [18] TAYLOR D. Applications of the theory of critical distances in failure analysis[J]. Engineering Failure Analysis,2010,18(2): 543-549. [19] TAYLOR D. Geometrical effects in fatigue: a unifying theoretical model[J]. International Journal of Fatigue,1999,21(5): 413-420. doi: 10.1016/S0142-1123(99)00007-9 [20] DAVID B L,THEODORE N,GEORGE K H. On the use of critical distance theories for the prediction of the high cycle fatigue limit stress in notched Ti-6Al-4V[J]. International Journal of Fatigue,2004,27(1): 45-57. [21] SUSMEL L,TAYLOR D. A novel formulation of the theory of critical distances to estimate lifetime of notched components in the medium-cycle fatigue regime[J]. Fatigue and Fracture of Engineering Materials and Structures,2007,30(7): 567-581. [22] SUSMEL L,TAYLOR D. An elastoplastic reformulation of the theory of critical distances to estimate lifetime of notches components failing in the low/medium-cycle fatigue regime[J]. Journal of Engineering Materials and Technology,2010,132(2): 021002.1-021002.8. [23] YAMASHITA Y,UEDA Y,KUROKI H,et al. Fatigue life prediction of small notched Ti-6Al-4V specimens using critical distance[J]. Engineering Fracture Mechanics,2010,77(9): 1439-1453. doi: 10.1016/j.engfracmech.2010.04.001 [24] YANG X G,WANG J K,LIU J L. Systematic methodology for high temperature LCF life prediction of smooth and notched Ni-based superalloy with and without dwells[J]. Computational Materials Science,2014,89(15): 65-74. [25] TAYLOR D,HOEY D. High cycle fatigue of welded joints: the TCD experience[J]. International Journal of Fatigue,2009,31(6): 20-27. [26] WANG Y Y,SUSMEL L. The modified manson-coffin curve method to estimate fatigue lifetime under complex constant and variable amplitude multiaxial fatigue loading[J]. International Journal of Fatigue,2016,83(2): 135-149. doi: 10.1016/j.ijfatigue.2015.10.005 [27] ZAMZAMI I A,RAZAVI S M J,BERTO F,et al. The critical distance method to estimate the fatigue strength of notched additively manufactured titanium alloys[J]. Procedia Structural Integrity,2020,28: 994-1001. doi: 10.1016/j.prostr.2020.11.114 -

下载:

下载: