Influence of structure and working condition parameters on performance of motorized spindle’s hybrid bearings

-

摘要:

针对精密铣磨床的电主轴的使用需求,分析了动静压轴承的基本结构和使用工况,建立了动静压轴承静动特性参数的计算模型,静特性参数包括温升、流量、承载力和功耗,动特性参数为刚度。计算分析了结构参数半径间隙、节流孔径、宽径比和工况参数供油压力和工作转速对动静压轴承静动特性参数的影响,并将计算结果与层流模型结果和试验结果进行了对比。研究表明:半径间隙是一个较为敏感的变量,对温升的影响较大,使温升降低了约77.6%,和节流孔径、宽径比相比半径间隙对动静压轴承性能的影响程度最大;转速对动静压轴承的静动特性均有较为明显的影响,特别是对温升和功耗的影响幅度较大,分别增长了初值的17.8倍和18.1倍,电主轴在高速工况下需有较好的降温措施。

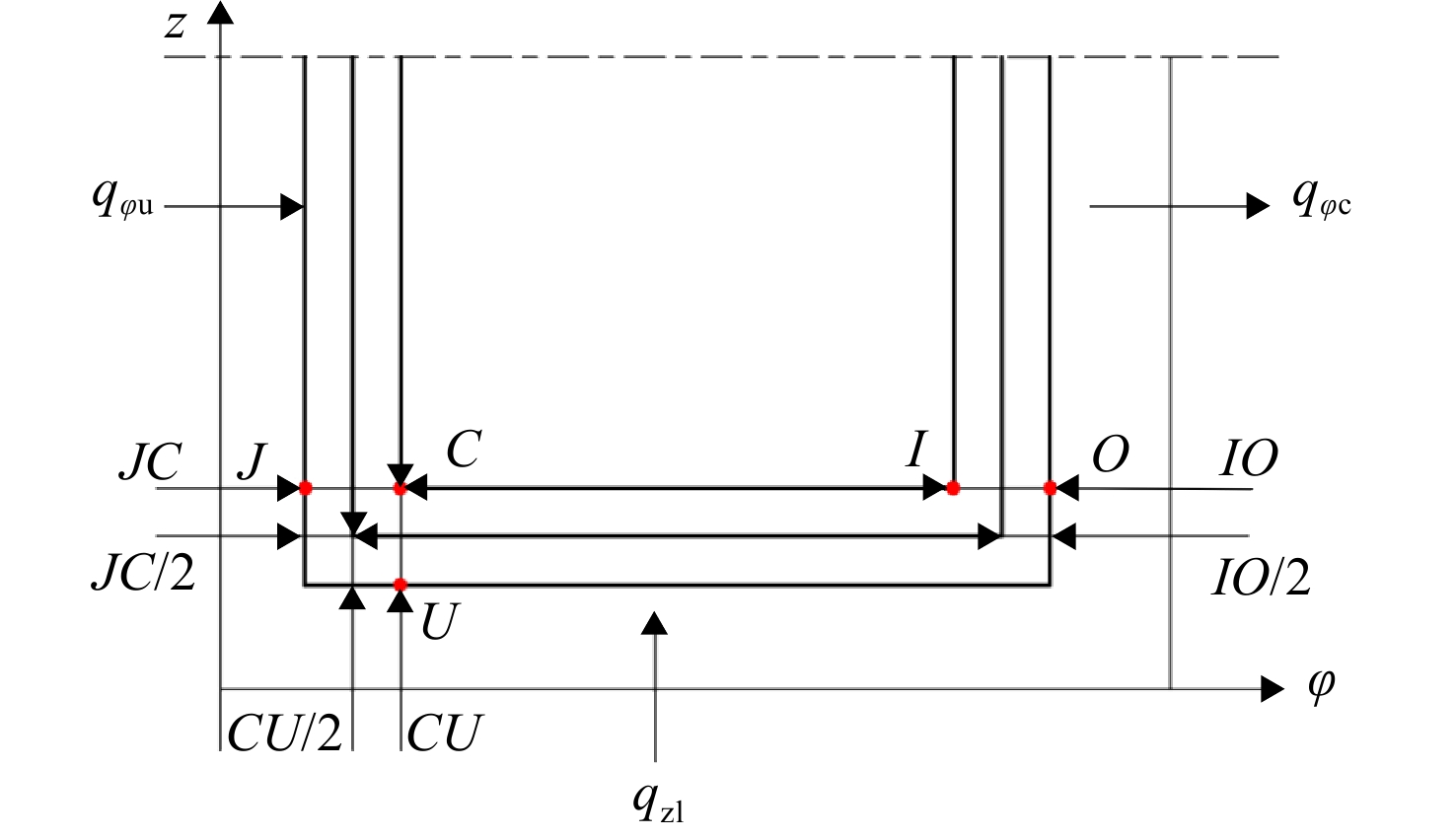

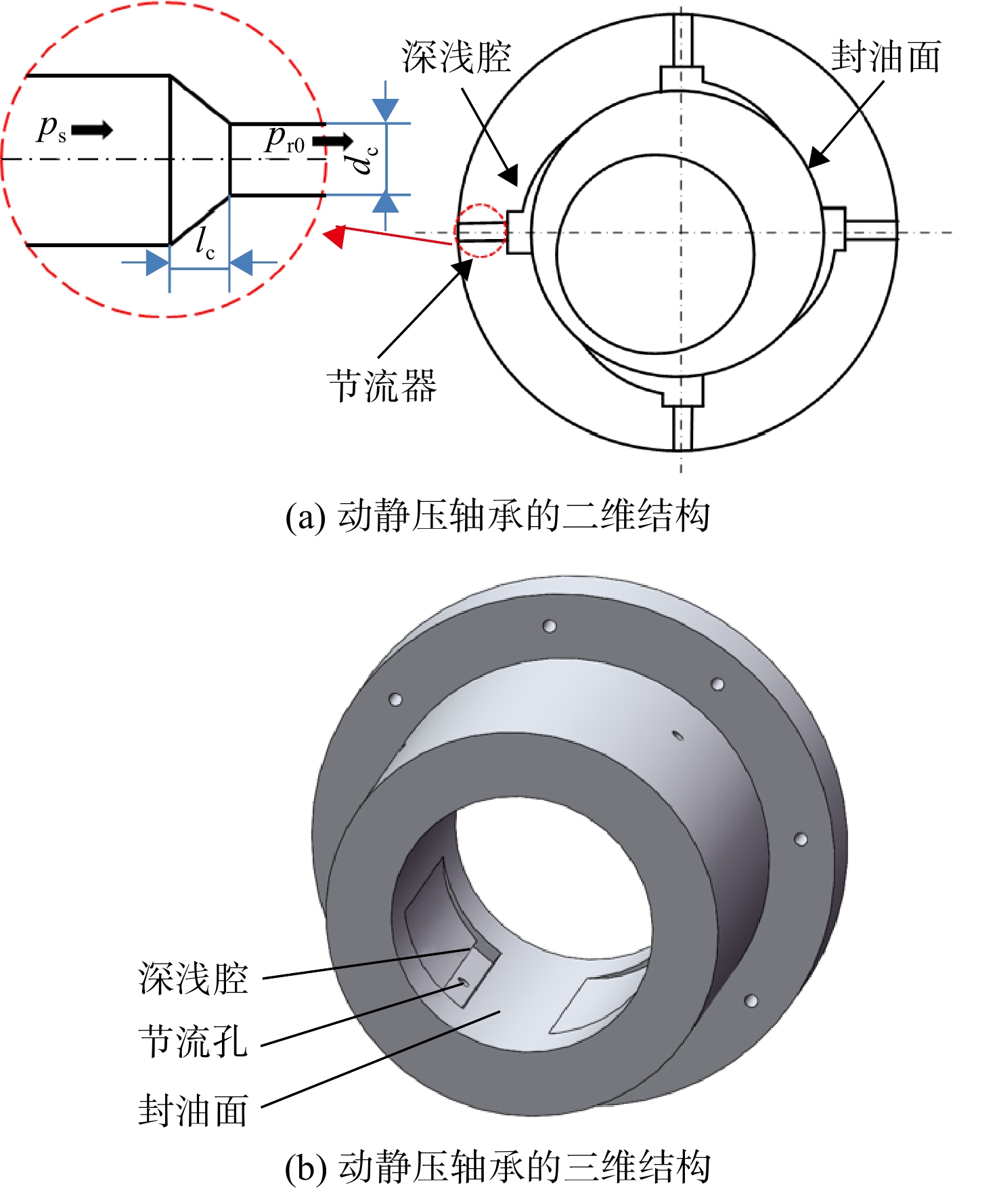

Abstract:In view of the demand for the use of the motorized spindle of the precision grinder, the basic structure and operating conditions of hydrodynamic bearing were analyzed, and the calculation model of the static and dynamic characteristics of the hybrid bearing was established. The static characteristics included temperature rise, flow rate, load bearing force and power consumption, the dynamic characteristic parameter included a stiffness

. The influences of structural parameters, radius clearance, throttle aperture, width-to-diameter ratio, working condition parameters oil supply pressure and rotate speed on the static and dynamic characteristics of hydrodynamic bearing were calculated and analyzed, then the calculated results were compared with the results of the laminar flow model and the test results. Research showed that: radius clearance was a more sensitive variable, which had a significant impact on temperature rise, reducing it by about 77.6%. Compared with throttle aperture and width-to-diameter ratio, radius clearance had the greatest impact on the performance of hydrodynamic bearing; rotating speed had a greater impact on the static and dynamic characteristics of hydrodynamic bearing. Obviously, the impact on temperature rise and power consumption was relatively large, increasing by 17.8 times and 18.1 times of the initial value respectively; the motorized spindle required for better cooling measures under high-speed working conditions. -

表 1 动静压轴承的结构参数

Table 1. Structural parameters of hydrodynamic bearing

参数 数值 参数 数值 外径/mm 180 半径间隙h0/μm 30 内径/mm 100 油腔宽度/mm 76 宽度/mm 100 深腔深度/mm 1.5 浅腔包角/(°) 70 浅腔深度/mm 0.05 深腔包角/(°) 11 节流孔径/mm 1.0 表 2 动静压轴承的工况参数

Table 2. Working condition parameters of hydrodynamic bearing

参数 数值 参数 数值 供油温度/℃ 25 主轴功率/kW 15 润滑油黏度/10−3(Pa∙s) 1.8 工作转速/(r/min) 0~12000 最大载荷/kN 5 供油压力/MPa 2 表 3 层紊流状态下结构和工况参数对温升影响的对比情况

Table 3. Comparison of the influence of structure and working condition parameters on temperature rise in the state of layered turbulent flow

参数 层流状态 紊流状态 半径间隙h0/μm 14.6953 14.715 节流孔径/mm 14.63 14.6386 宽径比 16.85 16.96 供油压力/MPa 13.1963 13.236 转速/(r/min) 3.825 3.839 表 4 不同转速下各参数仿真与试验数据的对比

Table 4. Comparison of simulation and test data of various parameters at different speeds

参数 转速/(r/min) 5000 7000 仿真 试验 仿真 试验 温升/℃ 3.839 2.689 7.4215 6.438 刚度/106 (kN/m) 0.75 0.55 0.95 0.80 承载力/kN 0.75 1.12 0.95 1.20 -

[1] 延育东. 机床电主轴静压轴承的设计及试验[D]. 西安: 西安理工大学, 2017.YAN Yudong. Design and test of hydrostatic bearing motorized spindle in machine tool[D]. Xi’an: Xi’an University of Technology, 2017. (in Chinese) [2] 史昊天,张东风,杨俊学,等. 航空铝合金薄壁件批量加工工艺探究[J]. 北华航天工业学院学报,2021,31(3): 11-13.SHI Haotian,ZHANG Dongfeng,YANG Junxue,et al. Batch processing technology for thin-walled parts of aviation aluminum alloy[J]. Journal of North China Institute of Aerospace Engineering,2021,31(3): 11-13. (in Chinese) [3] 陈润霖,欧阳武,王建磊,等. 动静压轴承支承电主轴服役精度保持用磁力减载研究[J]. 振动与冲击,2017,12(36): 30-35. doi: 10.13465/j.cnki.jvs.2017.12.005CHEN Runlin,OUYANG Wu,WANG Jianlei,et al. Magnetic lightening on service precision keeping of an electric spindle system supported by hybrid bearing[J]. Journal of Vibration and Shock,2017,12(36): 30-35. (in Chinese) doi: 10.13465/j.cnki.jvs.2017.12.005 [4] 王栋平. 加工中心精密主轴滑动轴承设计及摩擦学性能改进[D]. 西安: 西安理工大学, 2018.WANG Dongping. Design and tribological performance improvement of sliding bearing for precision spindle of machining center[D]. Xi’an: Xi’an University of Technology, 2018. (in Chinese) [5] 贾谦. 巴氏合金与石墨轴承的制造工艺、质检与性能试验研究[D]. 西安: 西安交通大学, 2017.JIA Qian. Study on the manufacturing process, quality and performance tests of Babbitt and graphite bearing[D]. Xi’an: Xi’an Jiaotong University, 2017. (in Chinese) [6] 丁海兵,刘扬扬,郑志强,等. 高速精密磨床主轴动静压轴承动静态特性分析[J]. 计量与测试技术,2019,46(8): 82-85, 93.DING Haibing,LIU Yangyang,ZHENG Zhiqiang,et al. Dynamic and static characteristics analysis of dynamic and static bearings for high speed precision grinding machine[J]. Metrology and Measurement Technique,2019,46(8): 82-85, 93. (in Chinese) [7] 郭力,李波,章泽. 液体动静压轴承的温度场与热变形仿真分析[J]. 机械科学与技术,2014,33(4): 511-515.GUO Li,LI Bo,ZHANG Ze. Simulating temperature field and thermal deformation of liquid dynamic and static pressure bearing[J]. Mechanical Science and Technology for Aerospace Engineering,2014,33(4): 511-515. (in Chinese) [8] ANDRES L S,CHILDS D,YANG Z. Turbulent-flow hydrostatic bearings analysis and experimental results[J]. International Journal of Mechanical Sciences,1995,37(8): 815-829. doi: 10.1016/0020-7403(94)00104-R [9] 王建磊,王云龙,门川皓,等. 精密磨床转台静压轴承的强健化设计[J]. 中国机械工程,2020,31(10): 1155-1161,1168.WANG Jianlei,WANG Yunlong,MEN Chuanhao,et al. Robust design of hydrostatic bearings on precision grinding machine rotary tables[J]. China Mechanical Engineering,2020,31(10): 1155-1161,1168. (in Chinese) [10] 刘豪杰,郭红,张绍林. 基于FLUENT的深浅腔动静压轴承油膜压力研究[J]. 润滑与密封,2013,38(10): 35-38. doi: 10.3969/j.issn.0254-0150.2013.10.008LIU Haojie,GUO Hong,ZHANG Shaolin. Research on static characteristics of deep/shallow pockets hybrid bearing based on FLUENT[J]. Lubrication Engineering,2013,38(10): 35-38. (in Chinese) doi: 10.3969/j.issn.0254-0150.2013.10.008 [11] 张绍林,杨帅,李瑞珍,等. 低含气率影响下圆柱动静压轴承特性分析[J]. 航空动力学报,2021,36(4): 741-750.ZHANG Shaolin,YANG Shuai,LI Ruizhen,et al. Characteristic analysis of cylindrical hydrodynamic/hydrostatic bearing under low gas fraction[J]. Journal of Aerospace Power,2021,36(4): 741-750. (in Chinese) [12] SCHARRER J K,HECHT R,HIBBS R I. The effects of wear on the rotor dynamic coefficients of a hydrostatic bearing[J]. ASME Journal of Tribology,1991,113: 210-21. doi: 10.1115/1.2920591 [13] 杜雄. 不对称三油腔动静压轴承设计及仿真验证[J]. 精密制造与自动化,2013(4): 22-26.DU Xiong. Design and simulation verification of asymmetrical three-oil cavity hydrostatic and hydrostatic bearings[J]. Precise Manufacturing and Automation,2013(4): 22-26. (in Chinese) [14] 戴攀, 徐华. 高速水润滑动静压轴承环面节流器节流系数研究[J]. 润滑与密封, 2010, 35(2): 40-43.DAI Pan, XU Hua. Discharge coefficient of orifice restrictor in high-speed hybrid bearings[J]. Lubrication Engineering, 2010, 35(2): 40-43. (in Chinese) [15] 杨建玺,周浩兵,崔凤奎. 液体动静压轴承油腔结构对承载特性的影响[J]. 河南科技大学学报,2012,33(5): 37-40.YANG Jianxi,ZHOU Haobing,CUI Fengkui. The influence of the structure of the oil cavity of the hydrodynamic and hydrostatic bearing on the load-carrying characteristics[J]. Journal of Henan University of Science and Technology,2012,33(5): 37-40. (in Chinese) [16] 岑少起,郭红,张少林,等. 多种节流形式的动静压轴承有限元优化分析[J]. 机械科学与技术,2002,21(2): 237-239.CEN Shaoqi,GUO Hong,ZHANG Shaolin,et al. The finite-optimal analysis of hybrid bearing with different kinds of throttle form[J]. Mechanical Science and Technology for Aerospace Engineering,2002,21(2): 237-239. (in Chinese) [17] KUMAR V,SHARMA S C,JAIN S C. On the restrictor design parameter of hybrid journal bearing for optimum rotor dynamic coefficients[J]. Tribology International,1995,28(8): 531-539. doi: 10.1016/0301-679X(96)85541-1 [18] CHEN C H,KANG Y,HUANG Y N. The restrictive effects of capillary compensation on the stability of the Jeffcott rotor-hybrid bearing system[J]. Tribology International,2002,35(12): 849-855. doi: 10.1016/S0301-679X(02)00070-1 [19] SINGH N,SHARMA S C,JAIN S C,et al. Performance of membrane compensated multirecess hydrostatic/hybrid flexible journal bearing system considering various recess shapes[J]. Journal of Tribology,2004,37(1): 11-24. doi: 10.1016/S0301-679X(03)00110-5 -

下载:

下载: