Rolling bearing fault diagnosis method based on GWO-NLM and CEEMDAN

-

摘要:

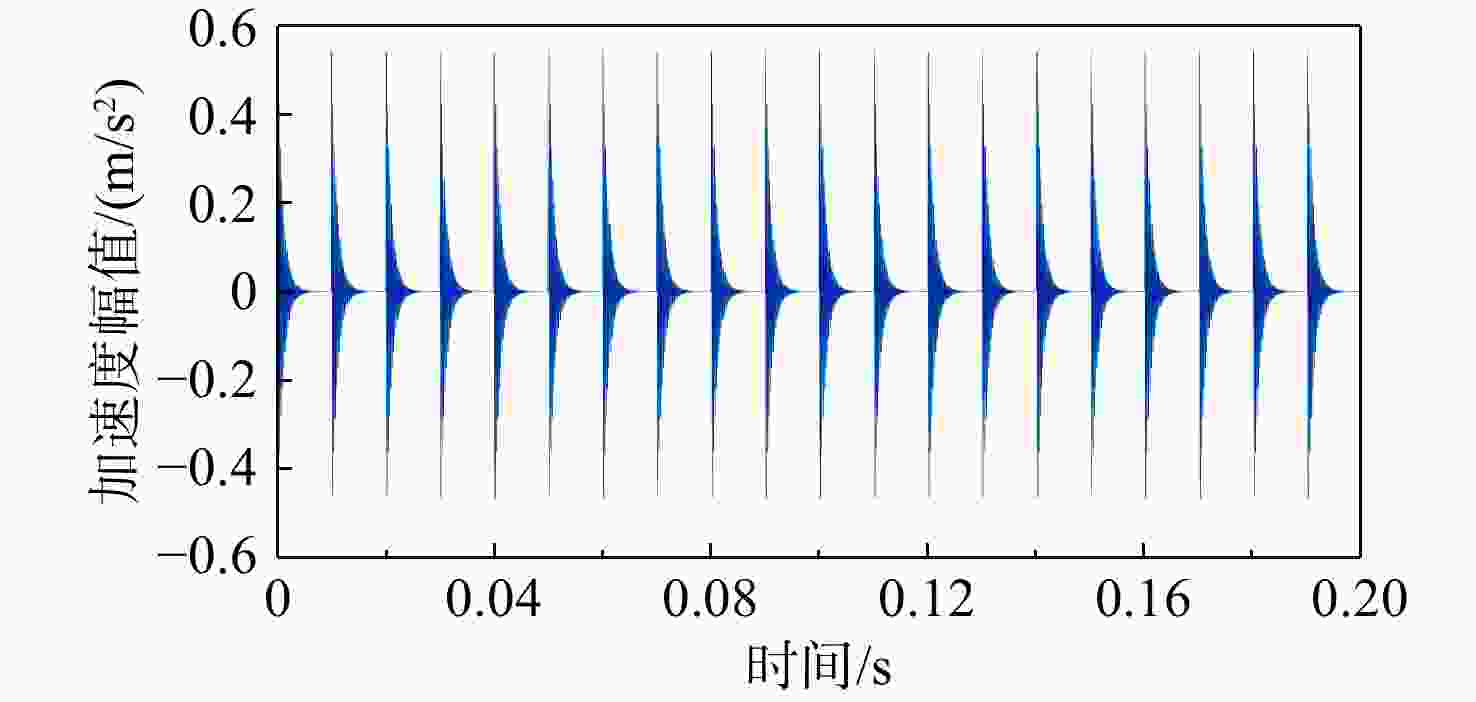

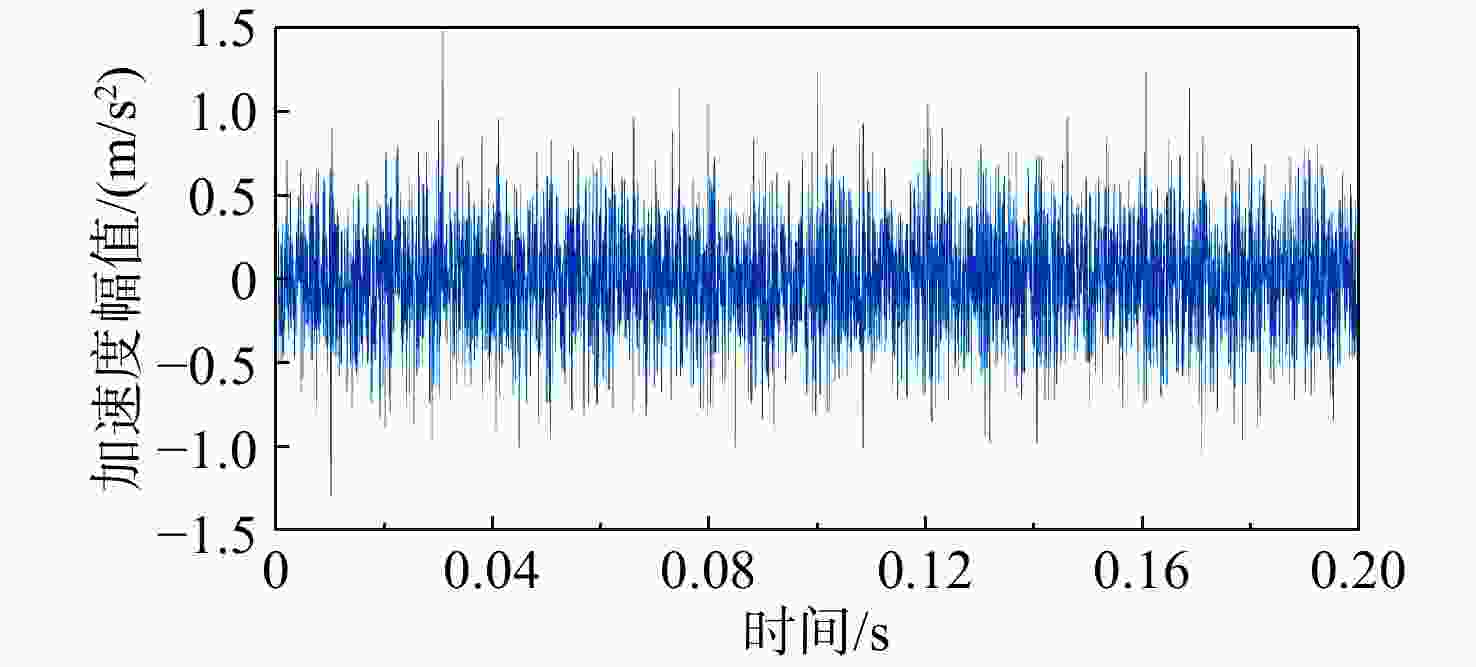

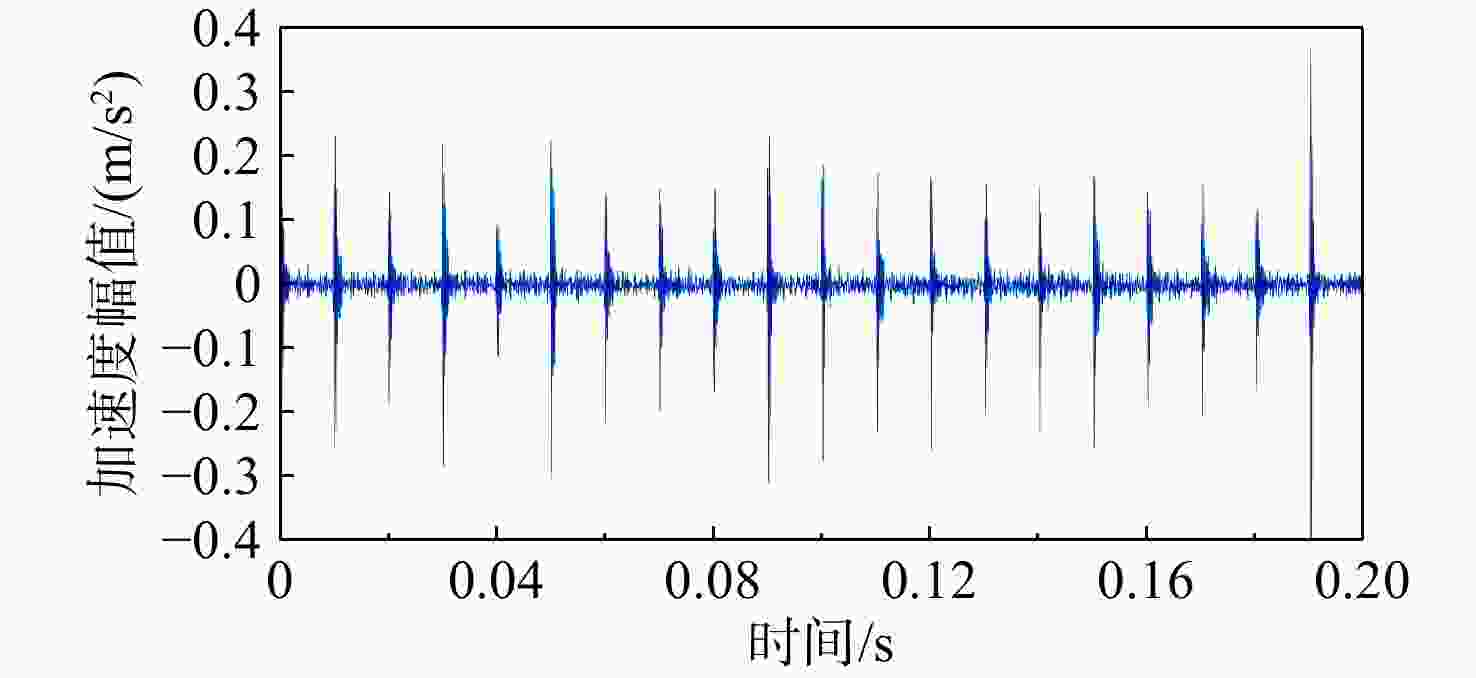

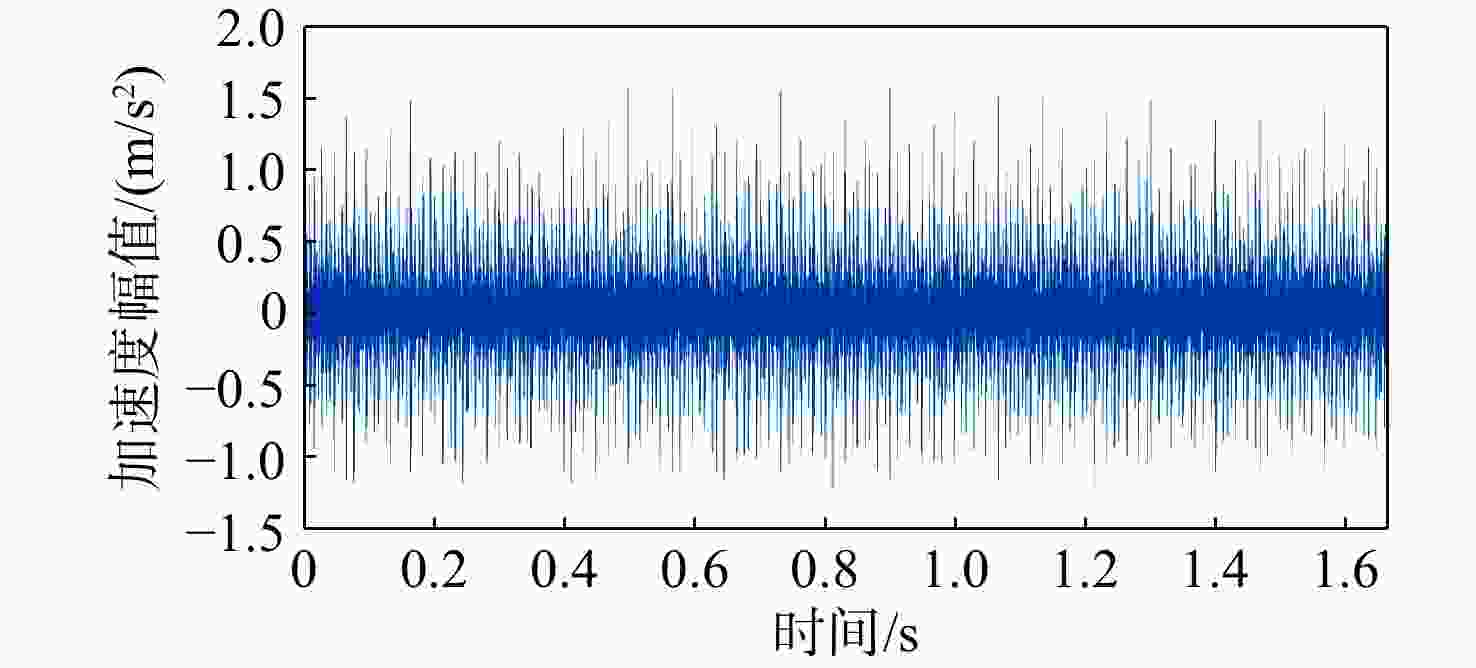

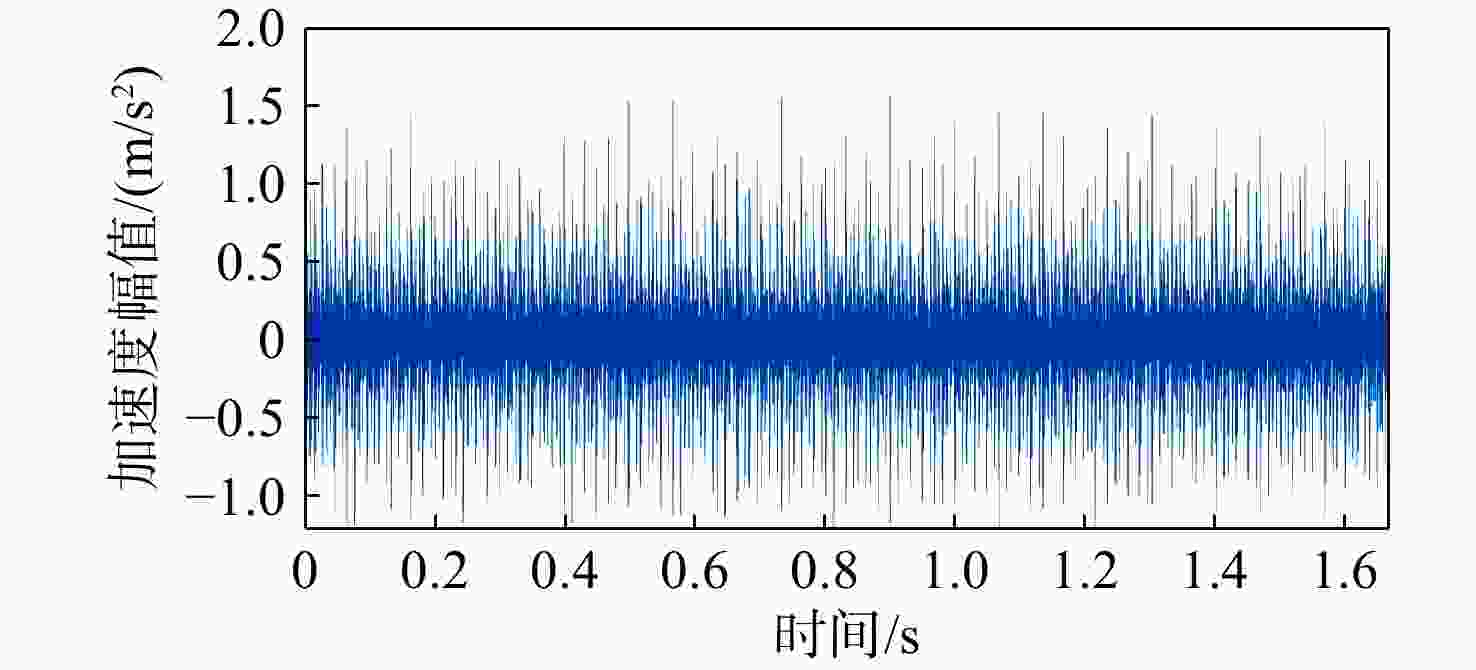

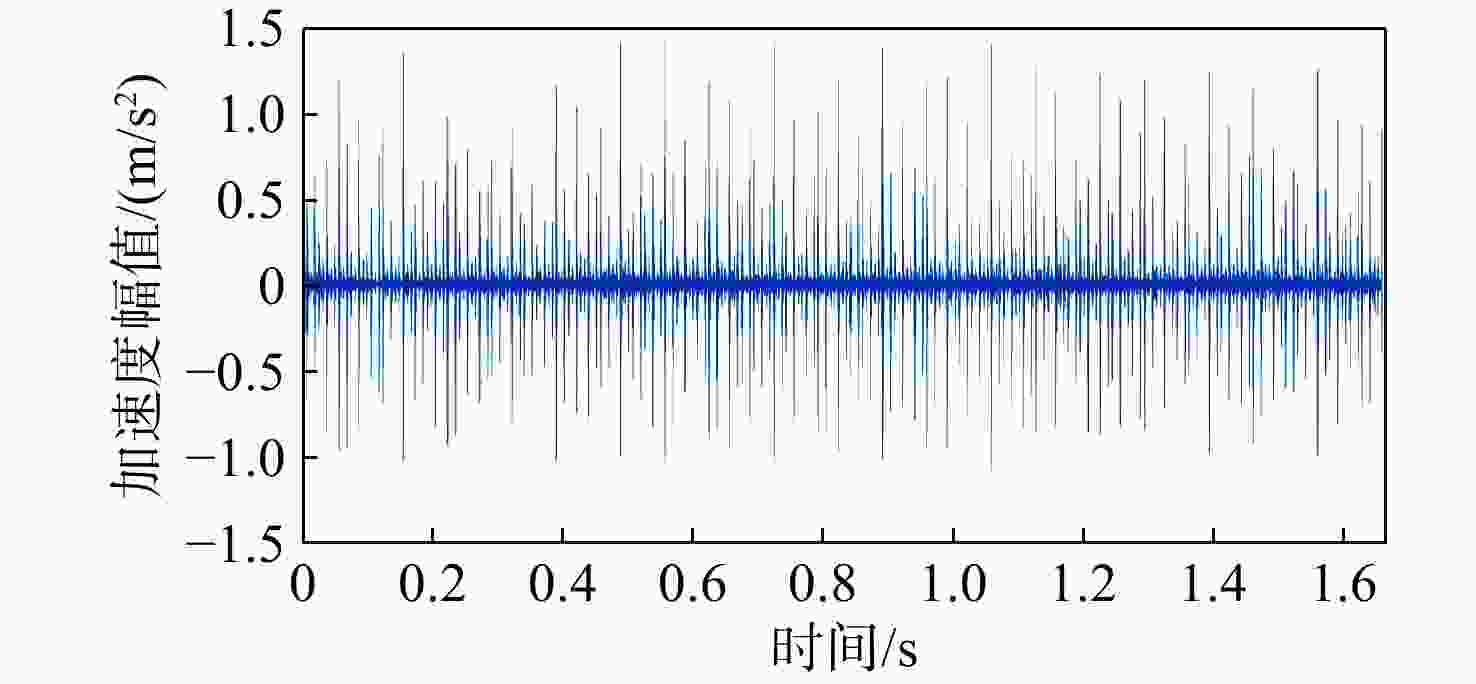

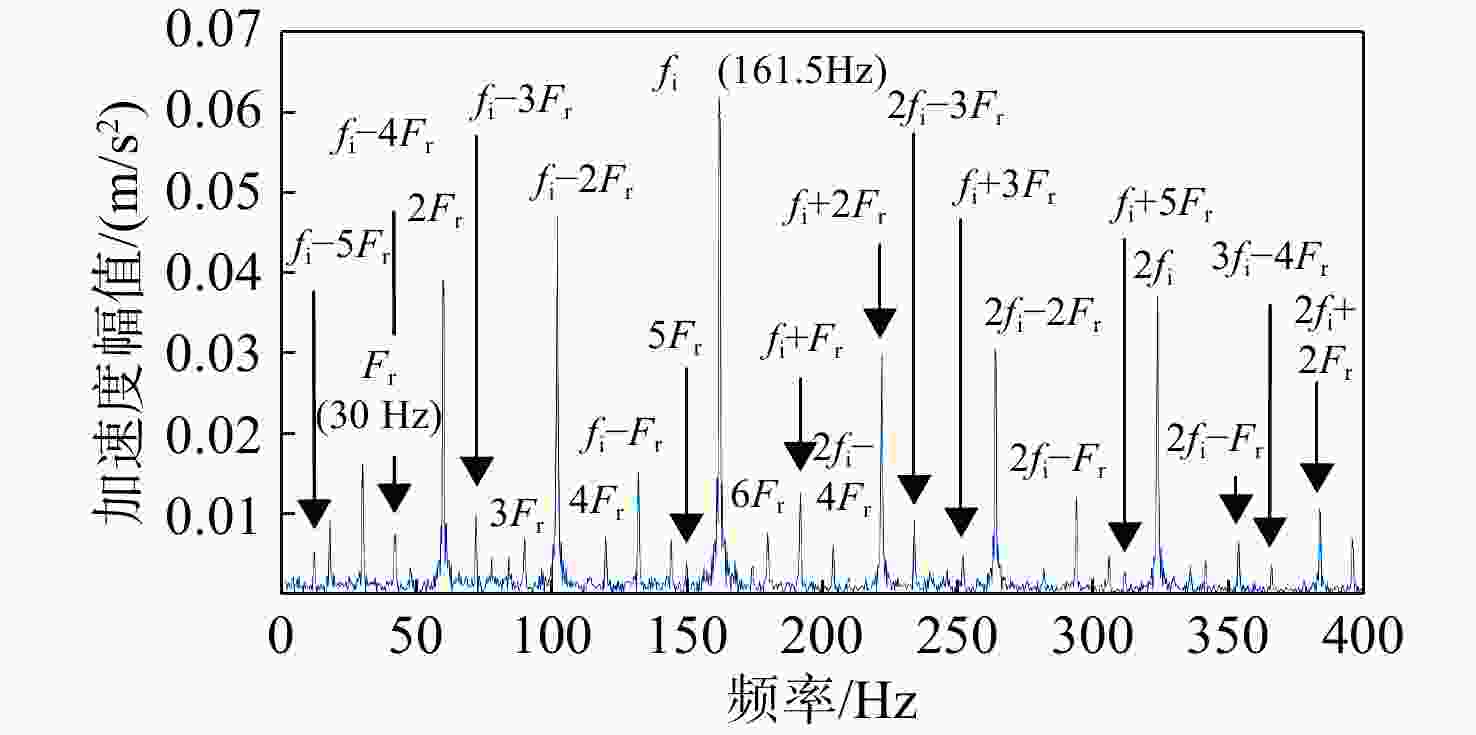

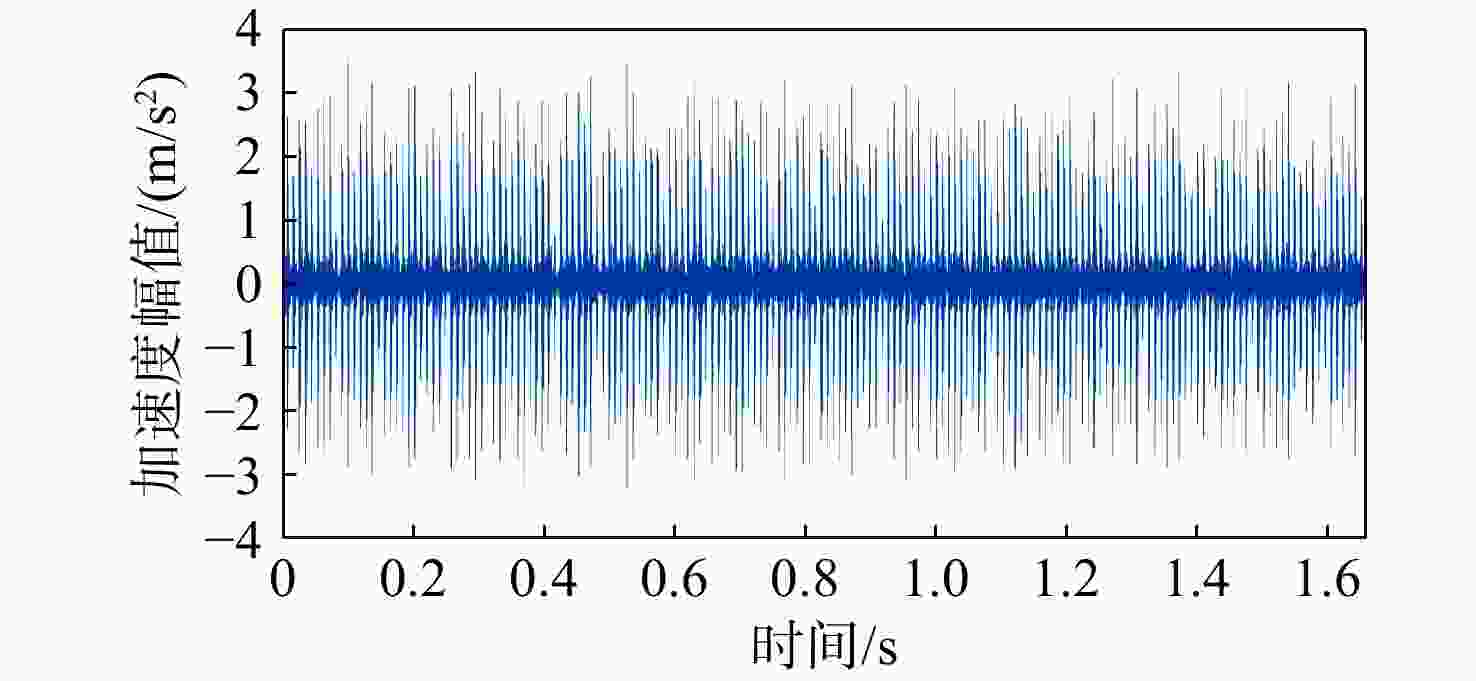

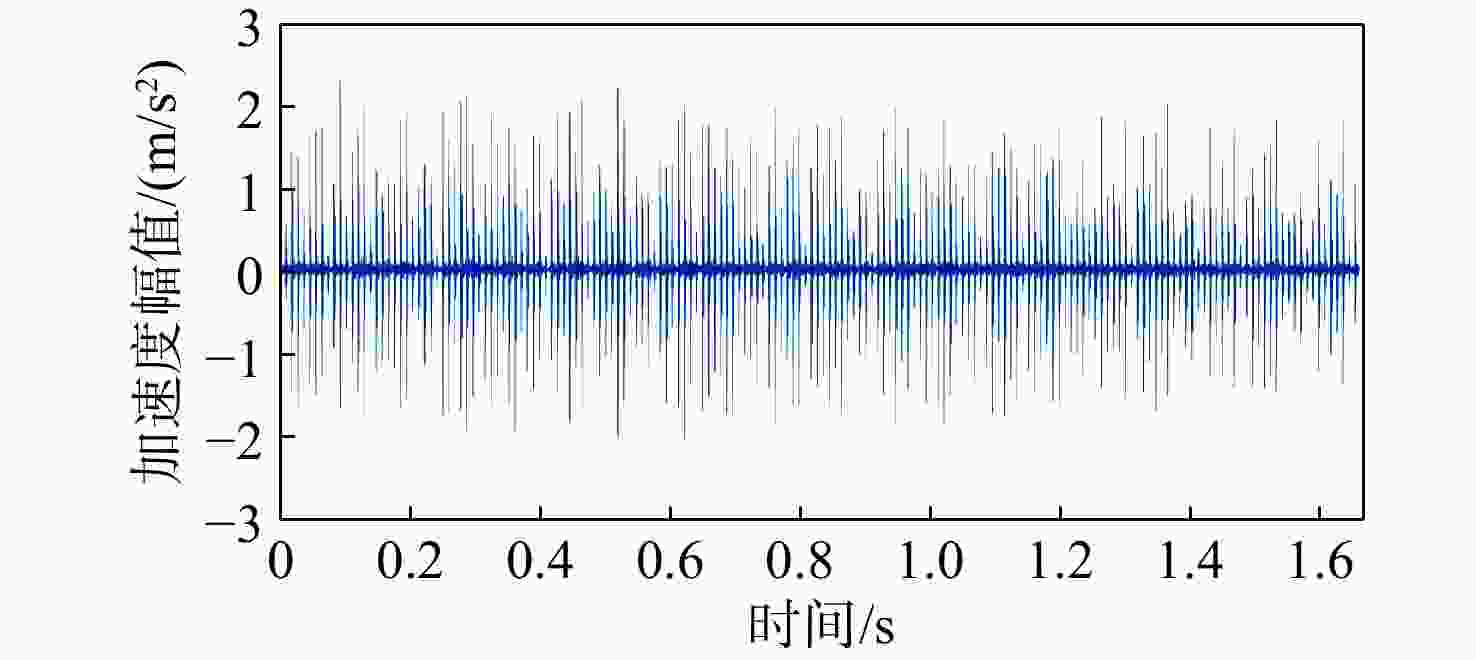

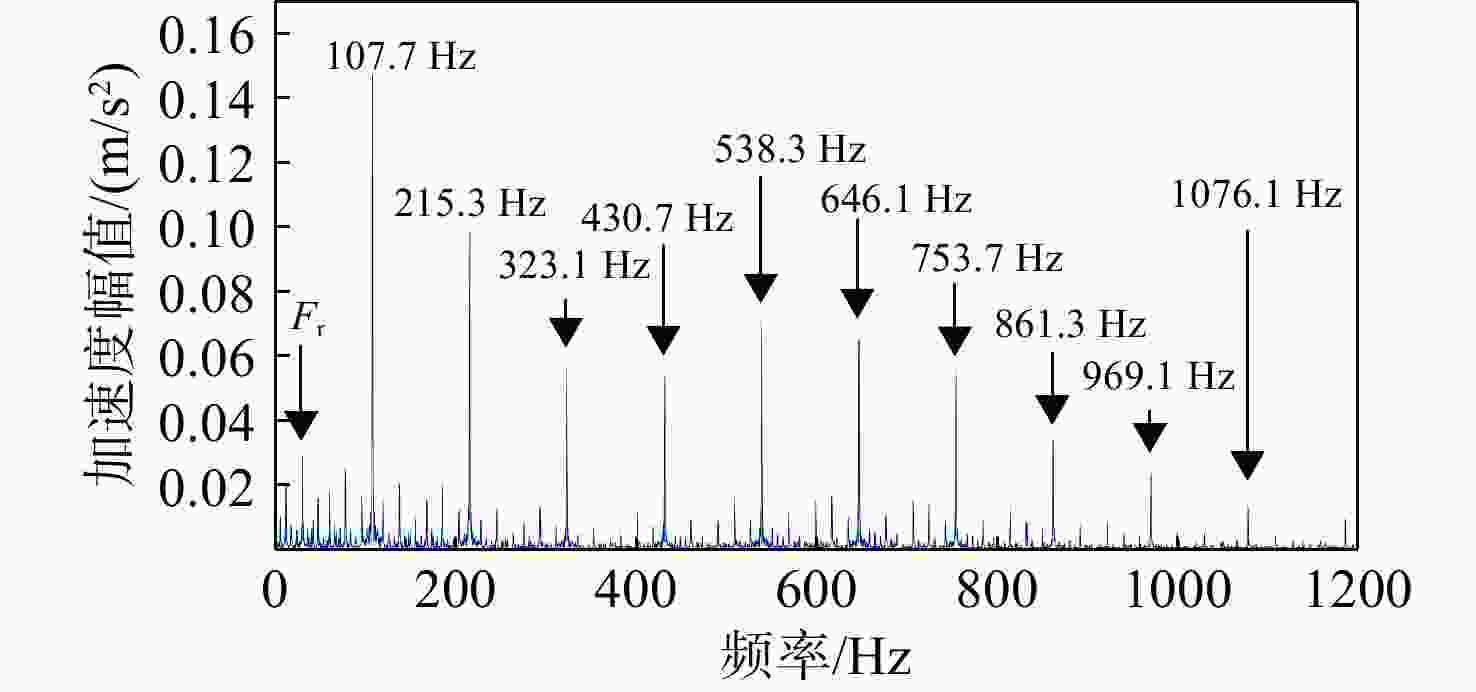

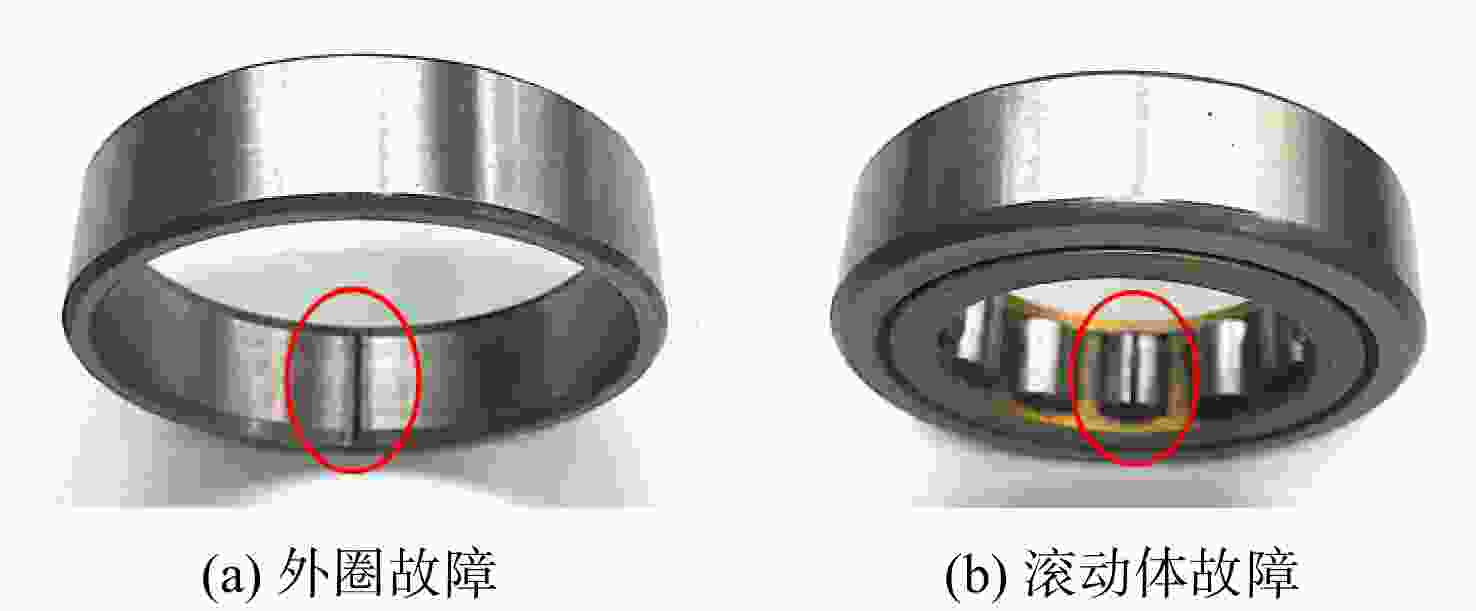

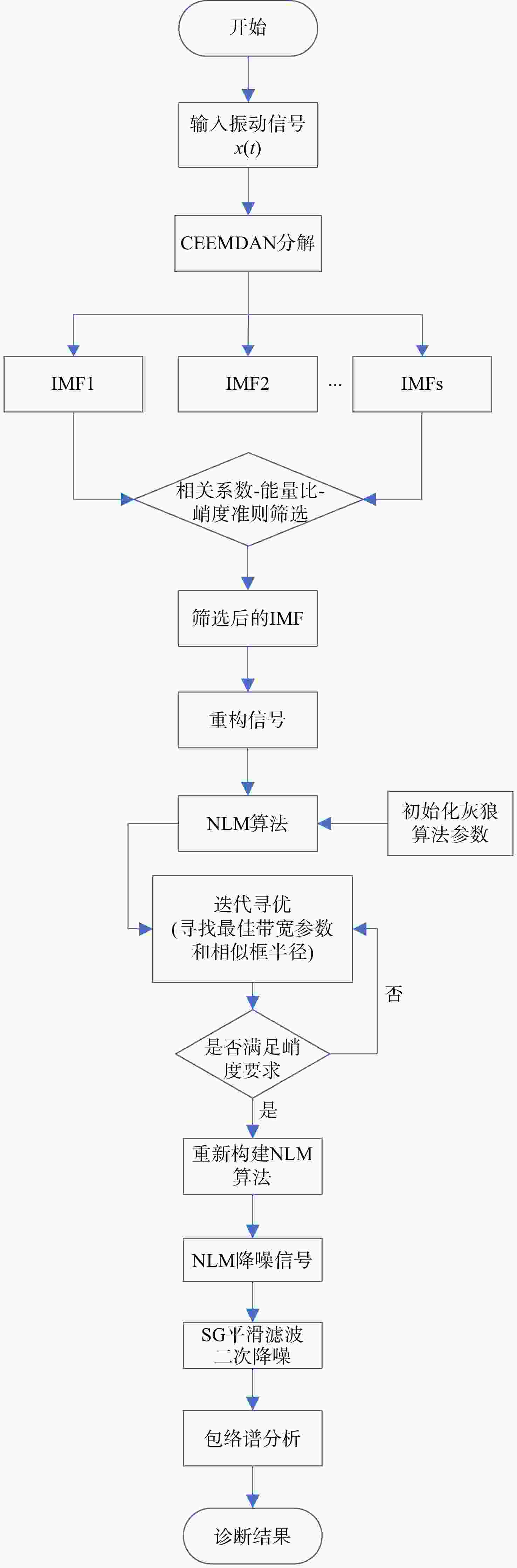

针对滚动轴承故障振动信号受背景噪声干扰大、故障特征不易提取的问题,提出了基于灰狼算法(GWO)优化的非局部均值去噪(NLM)和完全自适应噪声集合经验模态分解(CEEMDAN)相结合的轴承故障诊断方法。先将CEEMDAN和相关系数-能量比-峭度准则作为预处理手段,并进行信号重构;然后使用灰狼算法对NLM的参数进行优化,利用最优参数对重构信号进行降噪,将降噪后的信号通过SG(Savitzky-Golay)滤波进行二次降噪,得到最终去噪信号,对最终信号进行包络分析得到诊断结果。GWO-NLM去噪、CEEMDAN和包络分析的混合特征提取技术,由仿真信号可知去噪后的信噪比提高了9.31 dB,由实验信号可知能清晰地提取轴承的故障特征频率及倍频、转频以及故障特征频率与转频的系列调制频率。

-

关键词:

- 完全自适应噪声集合经验模态分解(CEEMDAN) /

- 非局部均值去噪(NLM) /

- 包络谱分析 /

- 灰狼算法 /

- 特征提取 /

- 故障诊断

Abstract:For the problem that the vibration signal of rolling bearing faults is disturbed by background noise and the fault features are not easily extracted, a combination of non-local mean denoising (NLM) based on the optimization of the gray wolf algorithm (GWO) and fully adaptive noise-enabled ensemble empirical modal decomposition (CEEMDAN) was proposed for bearing fault diagnosis. First, CEEMDAN and the Correlation coefficient-energy ratio-kurtosis criterion were used as preprocessing way, and signal reconstruction was performed; then the grey wolf algorithm was used to optimize the parameters of NLM, and the optimal parameters were used to denoise the reconstructed signal, and secondary denoising of the denoised signal was achieved through SG (Savitzky-Golay) filtering to obtain the final denoised signal, and envelope analysis of the final signal was performed to obtain diagnostic results. For the hybrid feature extraction technique of GWO-NLM denoising, CEEMDAN and envelope analysis, the signal-to-noise ratio was improved by 9.31 dB after denoising as shown by the simulated signal, and the fault characteristic frequency and multiplication frequency of the bearing and the series modulation frequency of the fault characteristic frequency and rotation frequency can be clearly extracted by the experimental signal.

-

表 1 不同信号信噪比

Table 1. Signal-to-noise ratio of different signals

信号 信噪比/dB 原始信号 −5.47 NLM 0.638 GWO-NLM 3.51 GWO-NLM-SG 3.84 表 2 6205-2RS JEM SKF深沟球轴承几何参数

Table 2. 6205-2RS JEM SKF deep groove ball bearing geometric parameters

参数 数值 节径 D/mm 39.039 滚珠直径 d/mm 7.940 接触角 $ \alpha $/(°) 0 滚珠数 Z 9 表 3 内圈故障数据实验参数

Table 3. Experimental parameters for inner ring fault data

参数 数值 转速/(r/min) 1797 故障直径/mm 0.18 故障深度/mm 0.28 负载/W 0 表 4 外圈故障数据实验参数

Table 4. Experimental parameters for outer ring fault data

参数 数值 转速/(r/min) 1797 故障直径/mm 0.18 故障深度/mm 0.28 表 5 前6个IMFs的能量比、相关系数、峭度

Table 5. Energy ratio, correlation coefficient, kurtosis of the first six IMFs

IMF 能量比 相关系数 峭度 $K_ { {\rm{r} }\text{ε} }$值 1 1.00 0.86 0.15 0.67 2 0.02 0.44 1.00 0.48 3 0.07 0.45 0.25 0.25 4 0.05 0.35 0.03 0.14 5 0.06 0.23 0.02 0.106 6 0.05 0.10 0.01 0.04 表 6 转频及其倍频、故障频率及其倍频、调制频率(部分包络谱、外圈故障)

Table 6. Rotation frequency and its multiplier, fault frequency and its multiplier, modulation frequency (partial envelope spectrum, outer ring fault)

特征频率 n 1 2 3 4 5 6 7 $n{F_{\text{r}}}$ √ √ √ √ √ $n{f_{\rm{o}}}$ √ √ √ ${f_{\rm{o}}} - n{F_{\rm{r}}}$ √ √ √ ${f_{\rm{o}}} + n{F_{\rm{r}}}$ √ √ √ √ √ $2{f_{\rm{o}}} - n{F_{\rm{r}}}$ √ √ √ √ √ $2{f_{\rm{o}}} + n{F_{\rm{r}}}$ √ √ √ √ $3{f_{\rm{o}}} - n{F_{\rm{r}}}$ √ √ √ √ √ √ √ $3{f_{\rm{o}}} + n{F_{\rm{r}}}$ √ √ 注:n为频率倍数;√代表可以提取出该特征频率。 表 7 NJ204EM滚棒轴承参数

Table 7. Parameters of NJ204EM roller bearing

参数 数值 节径D/mm 33.5 滚棒直径d/mm 7 接触 α/(°) 0 滚棒数Z 11 -

[1] 武英杰,辛红伟,王建国,等. 基于VMD滤波和极值点包络阶次的滚动轴承故障诊断[J]. 振动与冲击,2018,37(14): 102-107.WU Yingjie,XIN Hongwei,WANG Jianguo,et al. Rolling bearing fault diagnosis based on the variational mode decomposition filtering and extreme point envelope order[J]. Journal of Vibration and Shock,2018,37(14): 102-107. (in Chinese) [2] 邓飞跃,强亚文,杨绍普,等. 一种自适应频率窗经验小波变换的滚动轴承故障诊断方法[J]. 西安交通大学学报,2018,52(8): 22-29.DENG Feiyue,QIANG Yawen,YANG Shaopu,et al. A fault diagnosis method of rolling element bearings with adaptive frequency window empirical wavelet transform[J]. Journal of Xi’an Jiaotong University,2018,52(8): 22-29. (in Chinese) [3] 陶洁, 刘义伦, 付卓, 等. 基于Teager能量算子和深度置信网络的滚动轴承故障诊断[J]. 中南大学学报(自然科学版), 2017, 48(1): 61-68.TAO Jie, LIU Yilun, FU Zhuo, et al. Fault damage degrees diagnosis for rolling bearing based on Teager energy operator and deep belief network[J]. Journal of Central South University (Science and Technology), 2017, 48(1): 61-68. (in Chinese) [4] YAN Xiaoan,JIA Minping. Application of CSA-VMD and optimal scale morphological slice bispectrum in enhancing outer race fault detection of rolling element bearings[J]. Mechanical Systems and Signal Processing,2019,122: 56-86. doi: 10.1016/j.ymssp.2018.12.022 [5] AI Yanting,GUAN Jiaoyue,FEI Chengwei,et al. Fusion information entropy method of rolling bearing fault diagnosis based on n-dimensional characteristic parameter distance[J]. Mechanical Systems and Signal Processing,2017,88: 123-136. doi: 10.1016/j.ymssp.2016.11.019 [6] 陈鹏, 赵小强. 基于优化VMD与改进阈值降噪的滚动轴承早期故障特征提取[J]. 振动与冲击, 2021, 40(13): 146-153.CHEN Peng, ZHAO Xiaoqiang. Early fault feature extraction of rolling bearing based on optimized VMD and improved threshold denoising[J]. Journal of Vibration and Shock, 2021, 40(13): 146-153. (in Chinese) [7] 张景超, 张金敏, 张淑清, 等 . 基于小波及非线性预测的轴承故障诊断方法[J]. 仪器仪表学报, 2012, 33(1): 127-131.ZHANG Jingchao, ZHANG Jinmin, ZHANG Shuqing, et al. Bearing fault diagnosis method based on wavelet analysis and nonlinear prediction[J]. Chinese Journal of Scientific Instrument, 2012, 33(1): 127-131. (in Chinese) [8] NORDEN H E. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis[J]. Proceedings of the Royal Society: A Mathematical, Physical and Engineering Sciences,1998,454(1971): 903-995. doi: 10.1098/rspa.1998.0193 [9] WU Zhaohua,HUANG N E. Ensemble empirical mode decomposition: a noise-assisted data analysis method[J]. Advances in Adaptive Data Analysis,2009,1(1): 1-41. doi: 10.1142/S1793536909000047 [10] 李军,李青. 基于CEEMDAN-排列熵和泄漏积分ESN的中期电力负荷预测研究[J]. 电机与控制学报,2015,19(8): 70-80.LI Jun,LI Qing. Medium term electricity load forecasting based on CEEMDAN-permutation entropy and ESN with leaky integrator neurons[J]. Electric Machines and Control,2015,19(8): 70-80. (in Chinese) [11] 任学平, 王朝阁, 张玉皓, 等. 基于DT-CWT自适应Teager能量谱的轴承早期故障诊断[J]. 振动、测试与诊断, 2017, 37(4): 735-742, 842.REN Xueping, WANG Chaoge, ZHANG Yuhao, et al. Early fault diagnosis of rolling bearing based on dual-tree complex wavelet transform adaptive teager energy spectrum[J]. Journal of Vibration, Measurement and Diagnosis, 2017, 37(4): 735-742, 842. (in Chinese) [12] 赵洪山,李浪,王颖. 一种基于盲源分离和流形学习的风电机组轴承故障特征提取方法[J]. 太阳能学报,2016,37(2): 269-275.ZHAO Hongshan,LI Lang,WANG Ying. Fault feature extraction method of wind turbine bearing based on blind source separation and manifold learning[J]. Acta Energiae Solaris Sinica,2016,37(2): 269-275. (in Chinese) [13] BUADES A,COLL B,MOREL J M. A review of image denoising algorithms, with a new one[J]. Multiscale Modeling and Simulation,2005,4(2): 490-530. doi: 10.1137/040616024 [14] 胡新海, 欧阳永林, 曾庆才, 等. 叠前非局部平均滤波压制随机噪音[J]. 煤田地质与勘探, 2014, 42(5): 87-91.HU Xinhai, OUYANG Yonglin, ZHNG Qingcai, et al. De-noising seismic data with pre-stack nonlocal means method[J]. Coal Geology and Exploration, 2014, 42(5): 87-91. (in Chinese) [15] TRACEY B H,MILLER E L. Nonlocal means denoising of ECG signals.[J]. IEEE Transactions on Bio-Medical Engineering,2012,59(9): 2383-2386. doi: 10.1109/TBME.2012.2208964 [16] LÜ Yong,ZHU Qinglin,YUAN Rui. Fault diagnosis of rolling bearing based on fast nonlocal means and envelop spectrum[J]. Sensors,2015,15(1): 1182-1198. doi: 10.3390/s150101182 [17] 熊国良,胡俊锋,陈慧,等. 基于SK-NLM包络的滚动轴承故障冲击特征增强[J]. 仪器仪表学报,2016,37(10): 2176-2184.XIONG Guoliang,HU Junfeng,CHEN Hui,et al. Rolling bearing fault impact feature enhancement based on spectral kurtosis and non-local means (SK-NLM)[J]. Chinese Journal of Scientific Instrument,2016,37(10): 2176-2184. (in Chinese) [18] KUAI Moshen,CHENG Guang,PANG Yusong,et al. Research of planetary gear fault diagnosis based on permutation entropy of CEEMDAN and ANFIS[J]. Sensors,2018,18(3): 782.1-782.17. doi: 10.3390/s18030782 [19] 谷然, 陈捷, 洪荣晶, 等. 基于改进自适应变分模态分解的滚动轴承微弱故障诊断[J]. 振动与冲击, 2020, 39(8): 1-7, 22GU Ran, CHEN Jie, HONG Rongjing, et al. Early fault diagnosis of rolling bearings based on adaptive variational mode decomposition and the Teager energy operator[J]. Journal of Vibration and Shock, 2020, 39(8): 1-7, 22. (in Chinese) [20] 唐晓红, 胡俊锋, 熊国良, 等. 自适应非局部均值及在轴承故障检测中的应用[J]. 振动. 测试与诊断, 2019, 39(1): 61-67, 221.TANG Xiaohong, HU Junfeng, XIONG Guoliang, et al. Adaptive non-local means with applications in fault detection of rolling[J]. Journal of Vibration, Measurement and Diagnosis, 2019, 39(1): 61-67, 221. (in Chinese) [21] 陆子鸣. 基于NLM-VMD和度量学习的滚动轴承故障诊断研究[D]. 武汉: 华中科技大学, 2019.LU Ziming. Research on fault diagnosis of rolling bearing based on NLM-VMD and metric learning[D]. Wuhan: Huazhong University of Science and Technology, 2019. (in Chinese) [22] MIRJALILI S,MIRJALILI S M,LEWIS A. Grey wolf optimizer[J]. Advances in Engineering Software,2014,69: 46-61. doi: 10.1016/j.advengsoft.2013.12.007 [23] MIAO Yonghao,ZHAO Ming,LIN Jing,et al. Application of an improved maximum correlated kurtosis deconvolution method for fault diagnosis of rolling element bearings[J]. Mechanical Systems and Signal Processing,2017,92: 173-195. doi: 10.1016/j.ymssp.2017.01.033 [24] 万书亭, 张雄, 豆龙江. 强噪源干扰下的滚动轴承复合故障分离方法研究[J]. 中南大学学报(自然科学版), 2018, 49(8): 1950-1959.WAN Shuting, ZHANG Xiong, DOU Longjiang. Separation of composite rolling bearings fault features with strong noise interference[J]. Journal of Central South University (Science and Technology), 2018, 49(8): 1950-1959. (in Chinese) [25] 田晶,王英杰,王志,等. 基于EEMD与空域相关降噪的滚动轴承故障诊断方法[J]. 仪器仪表学报,2018,39(7): 144-151.TIAN Jing,WANG Yingjie,WANG Zhi,et al. Fault diagnosis for rolling bearing based on EEMD and spatial correlation denoising[J]. Chinese Journal of Scientific Instrument,2018,39(7): 144-151. (in Chinese) -

下载:

下载: