Simulation study on precooling process of liquid methane pipeline

-

摘要:

低温推进剂液体火箭发动机在推进剂加注时需要进行管道预冷以避免推进剂气化。为揭示管路预冷过程中低温流体的两相流动特性,针对小型液氧/甲烷发动机液态甲烷管道的预冷过程进行了研究。采用Lee蒸发模型,模拟并分析了不同入口流量下的湍流传热过程,得到了管道预冷过程中甲烷的体积分数、温度、压力和速度的变化规律。结果表明:在管道预冷过程中,液态甲烷会发生闪蒸现象,甲烷的温度和压力的变化是影响闪蒸的主要因素;在低流量时,预冷时间与质量流量呈负相关,当质量流量增大到一定程度后,预冷时间趋于稳定值。研究结果可预示容许时间内的最优预冷流量,对提高预冷效率和改进低温推进剂加注过程具有指导作用。

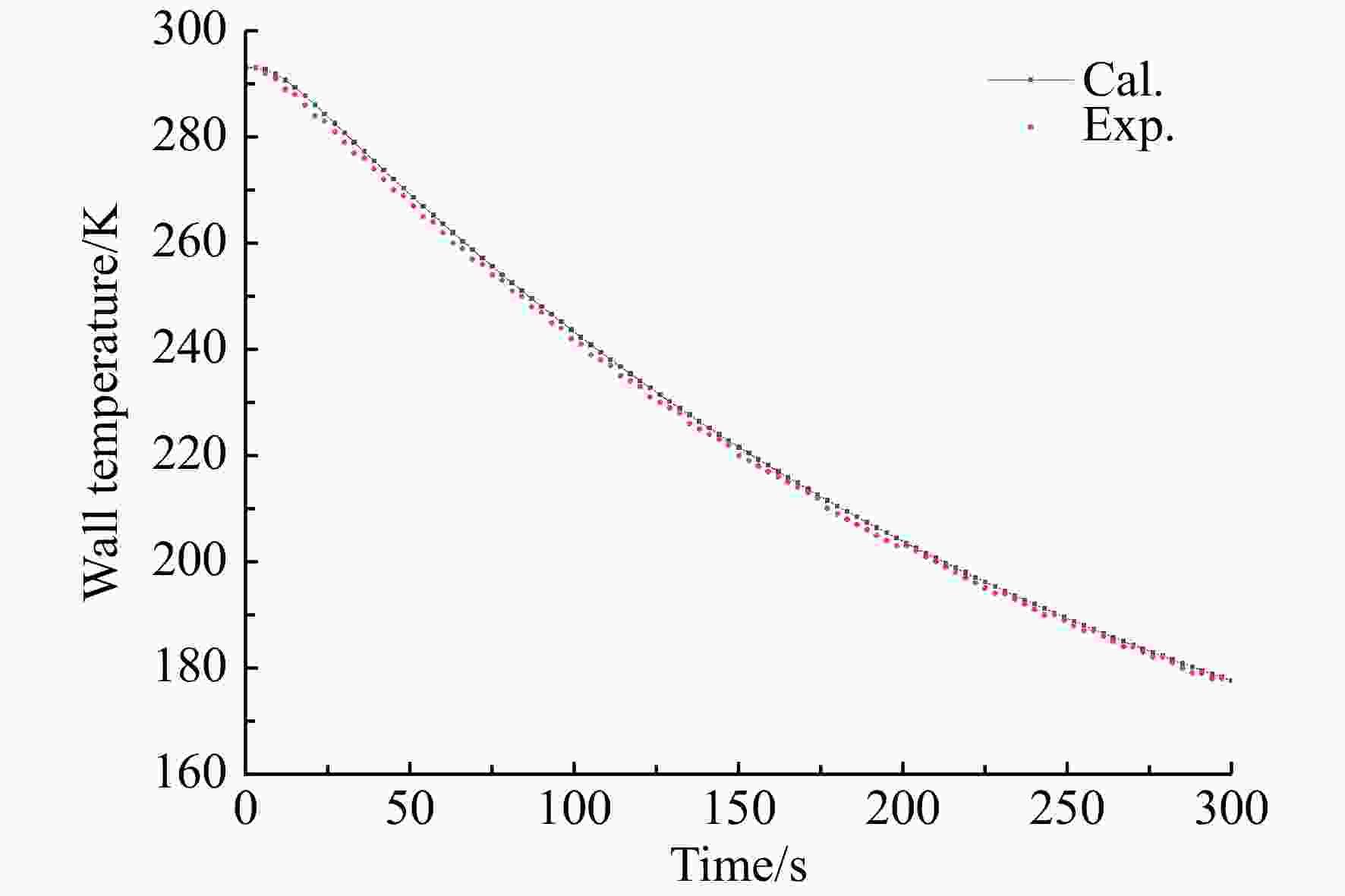

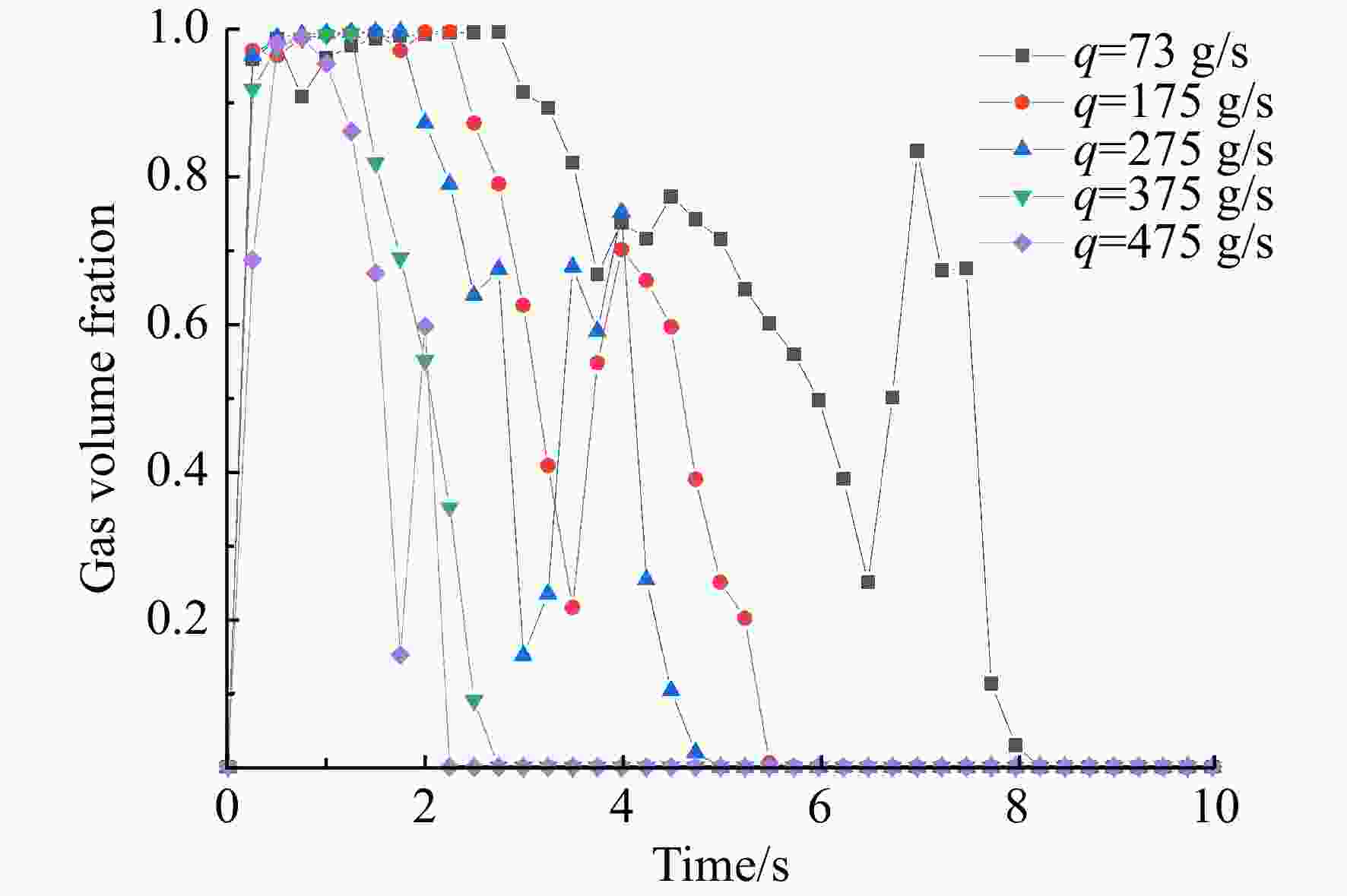

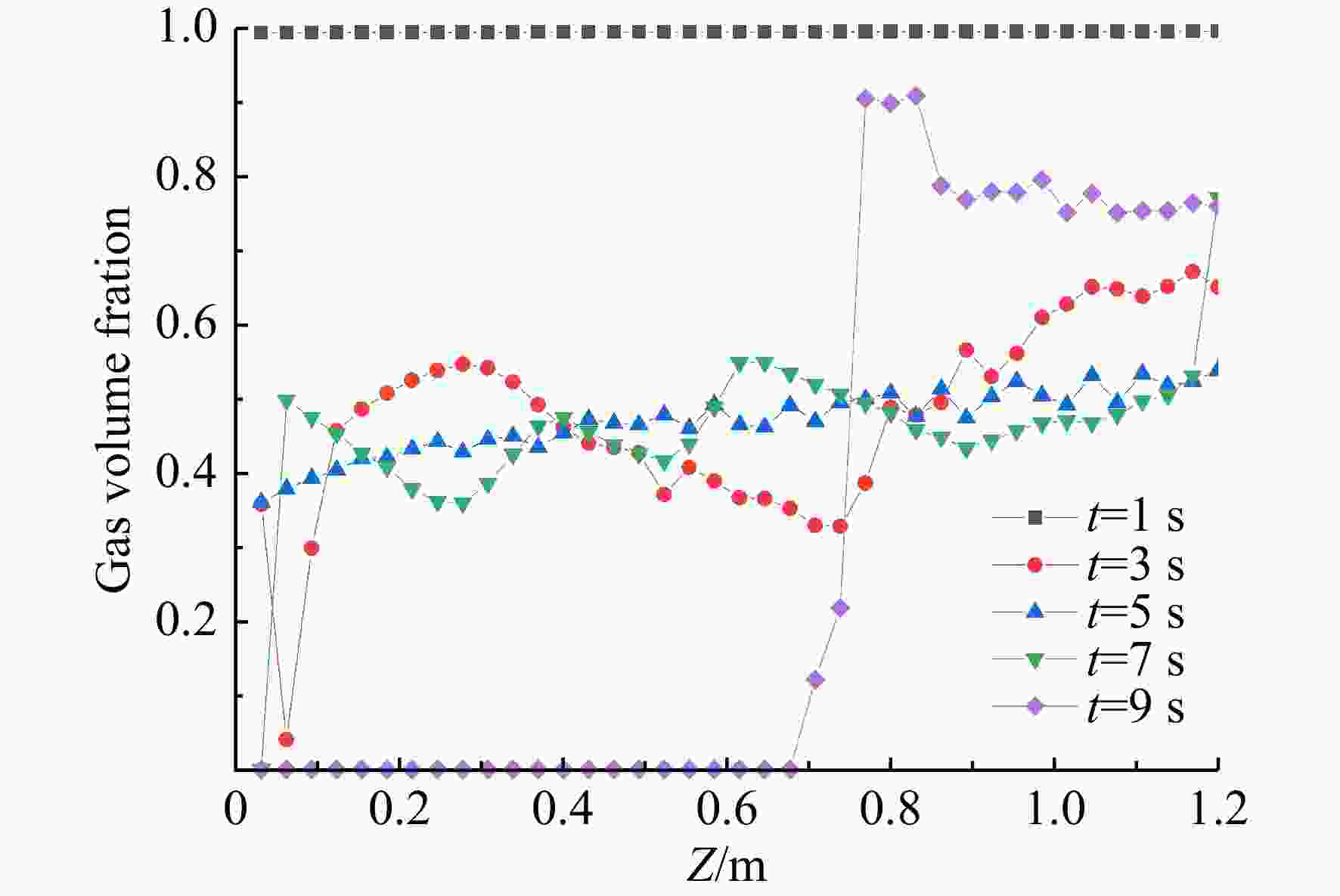

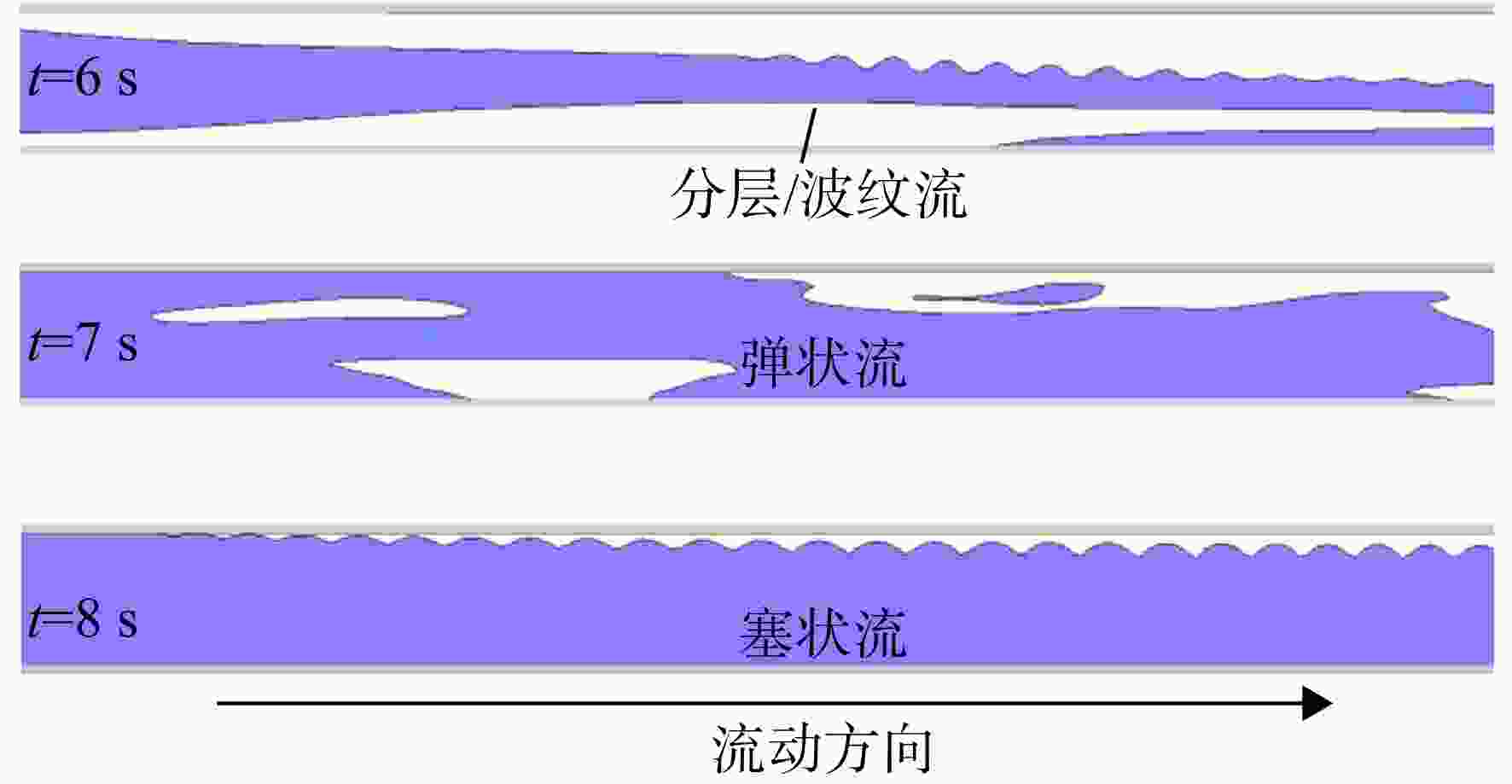

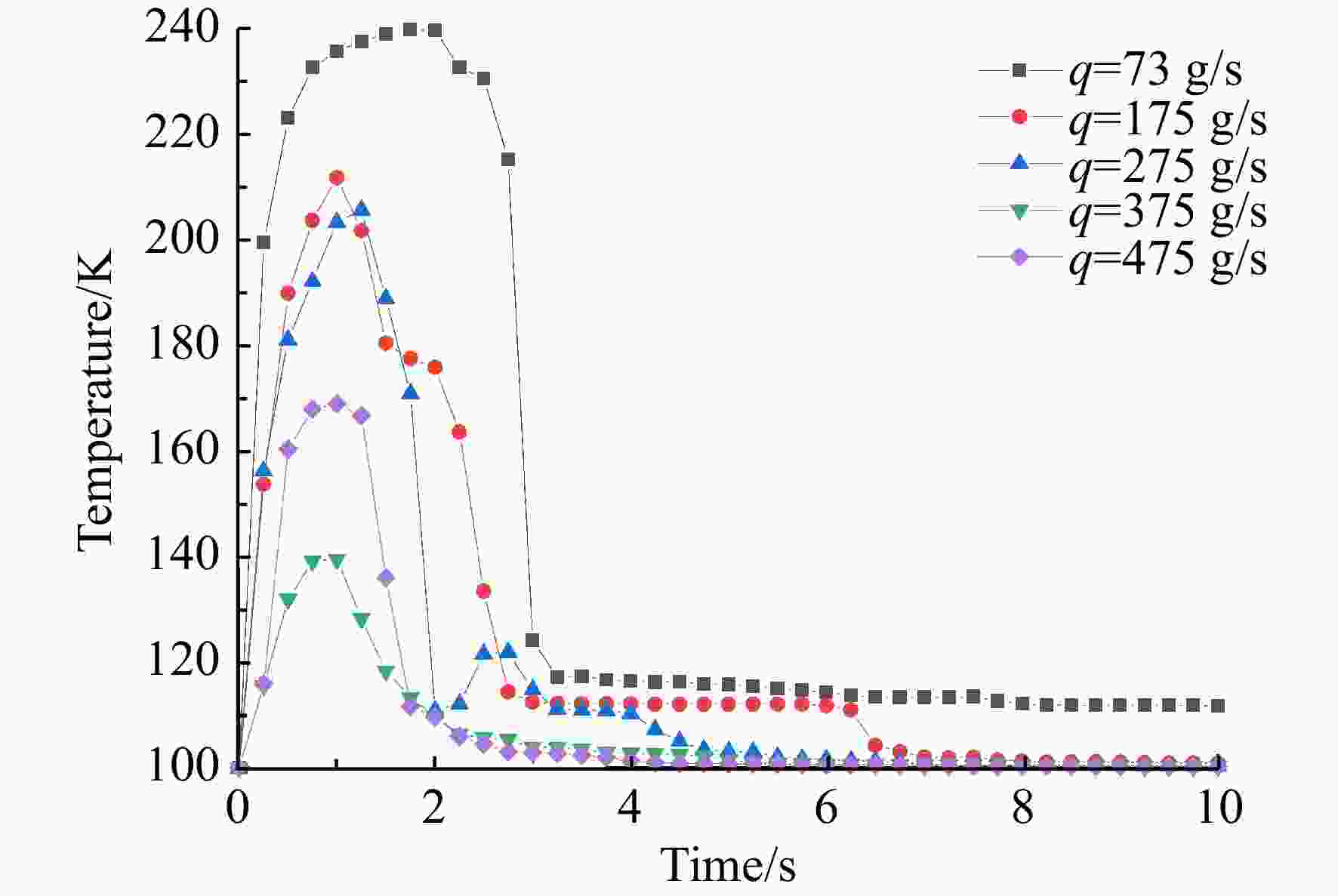

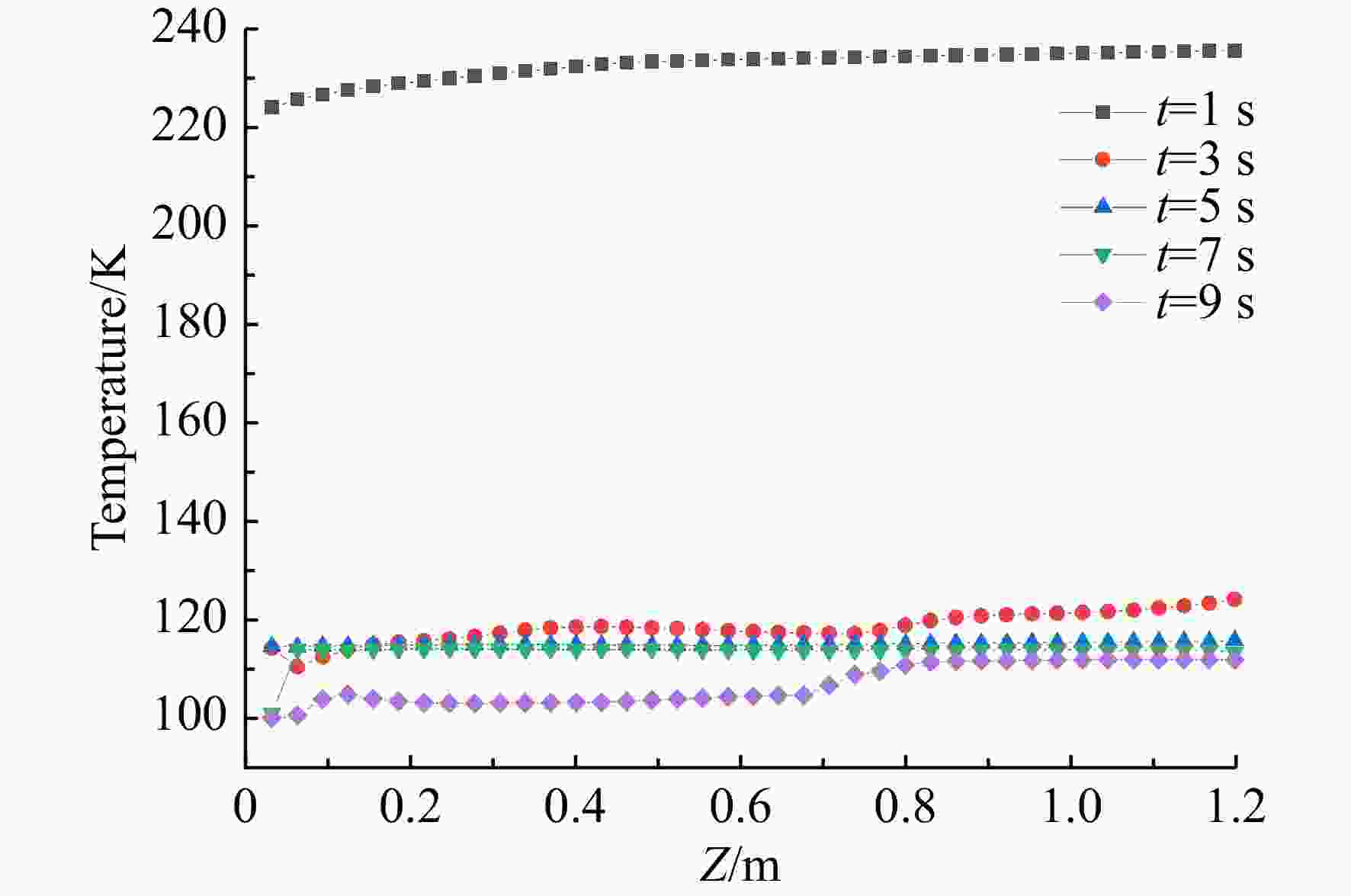

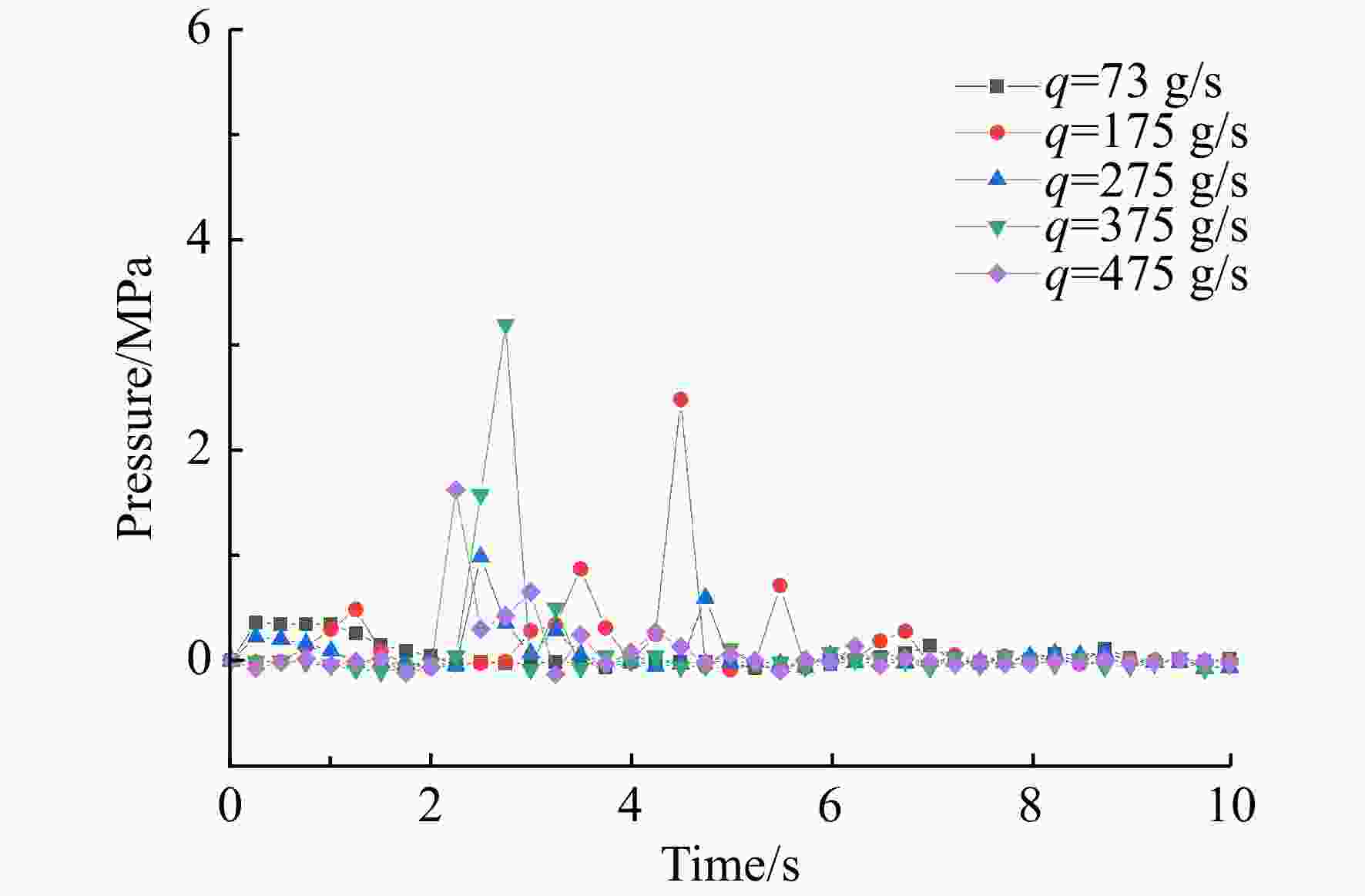

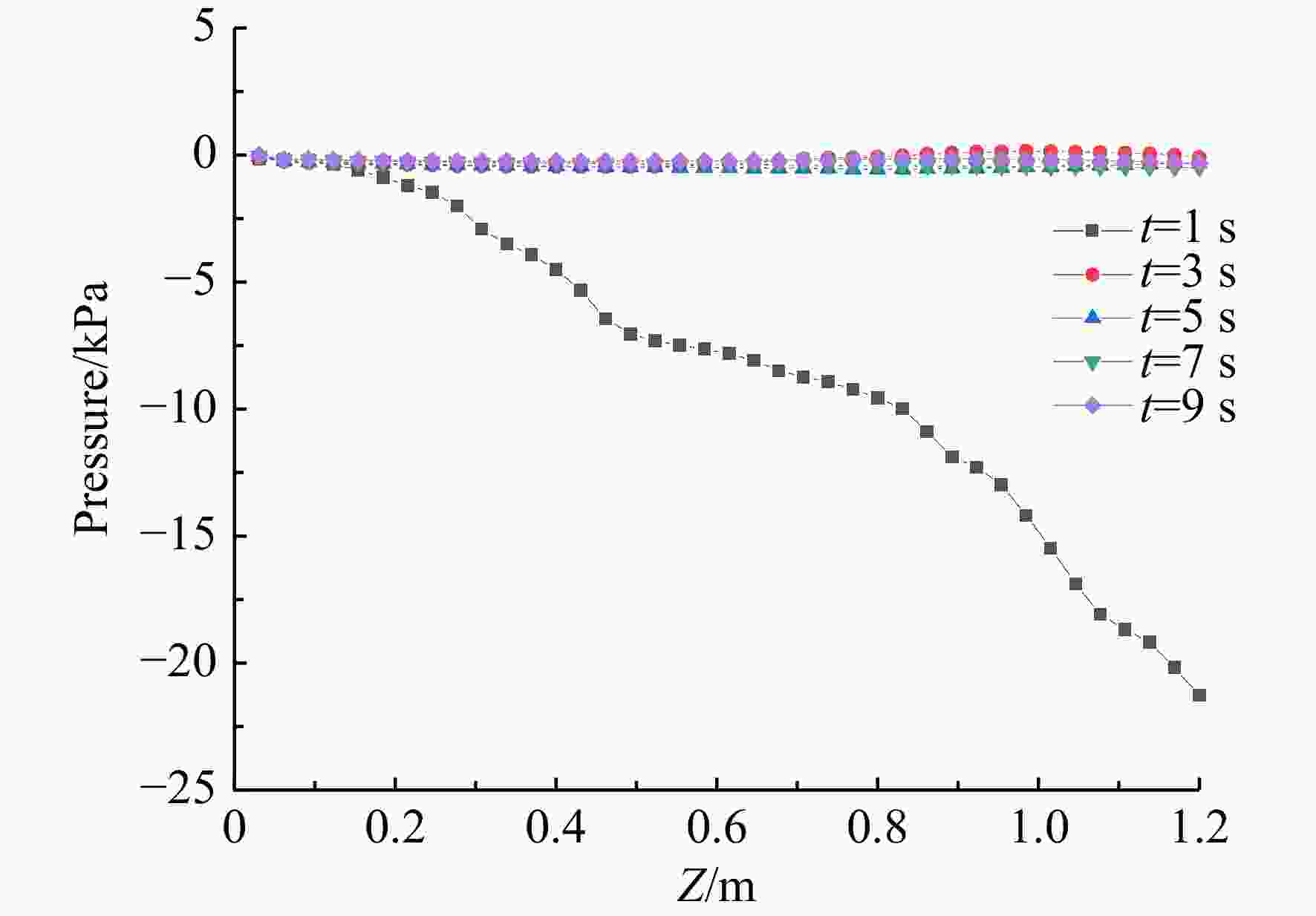

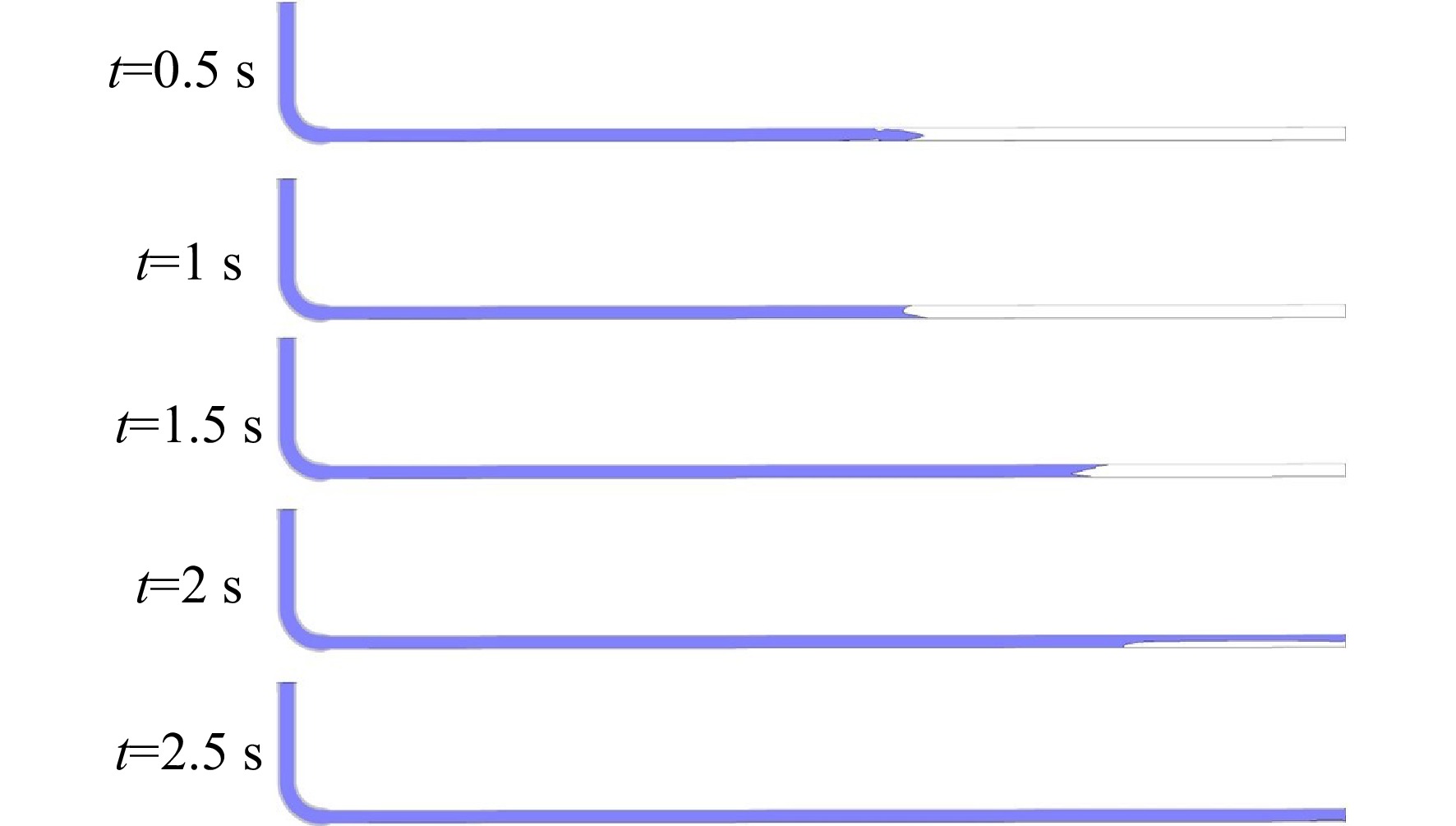

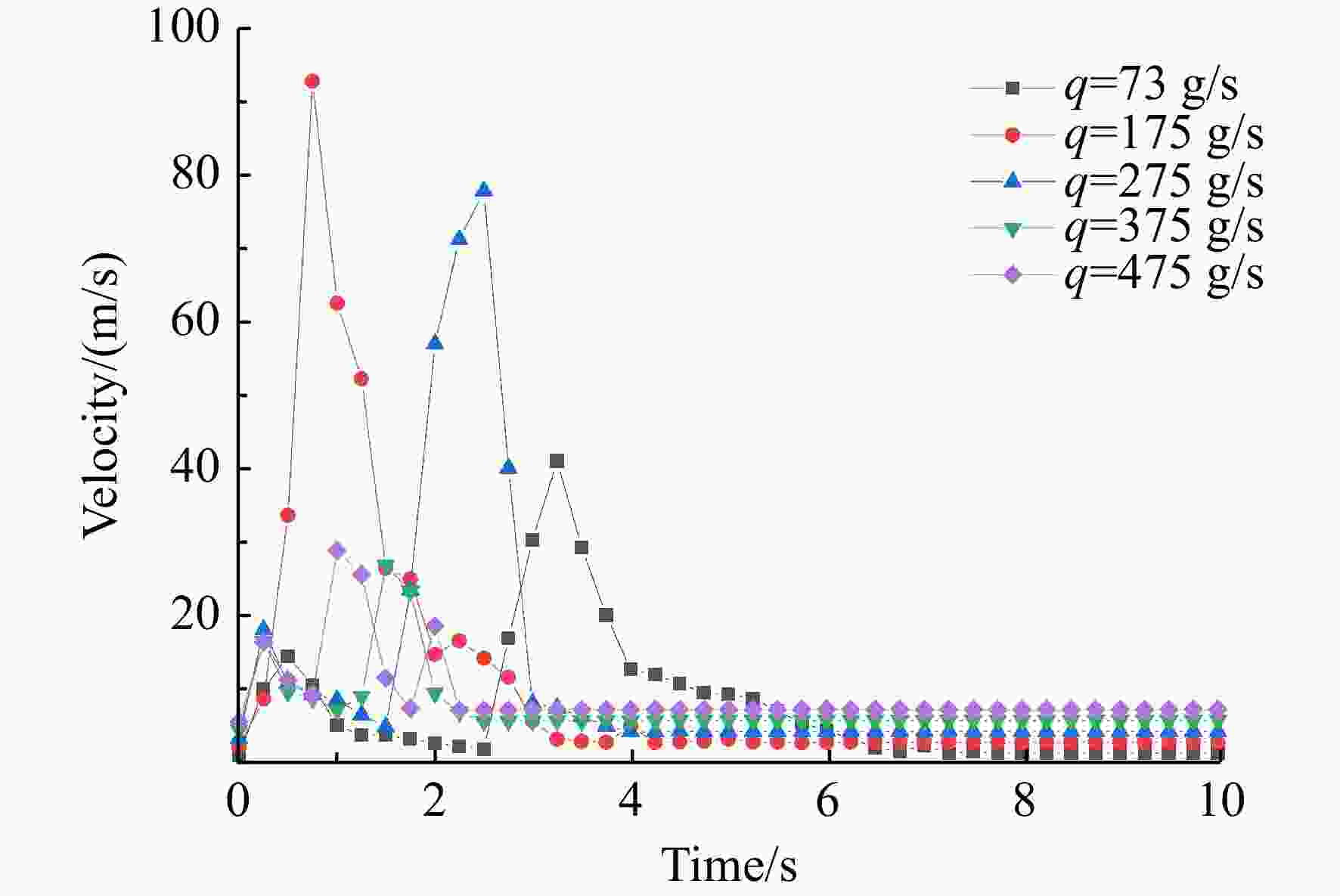

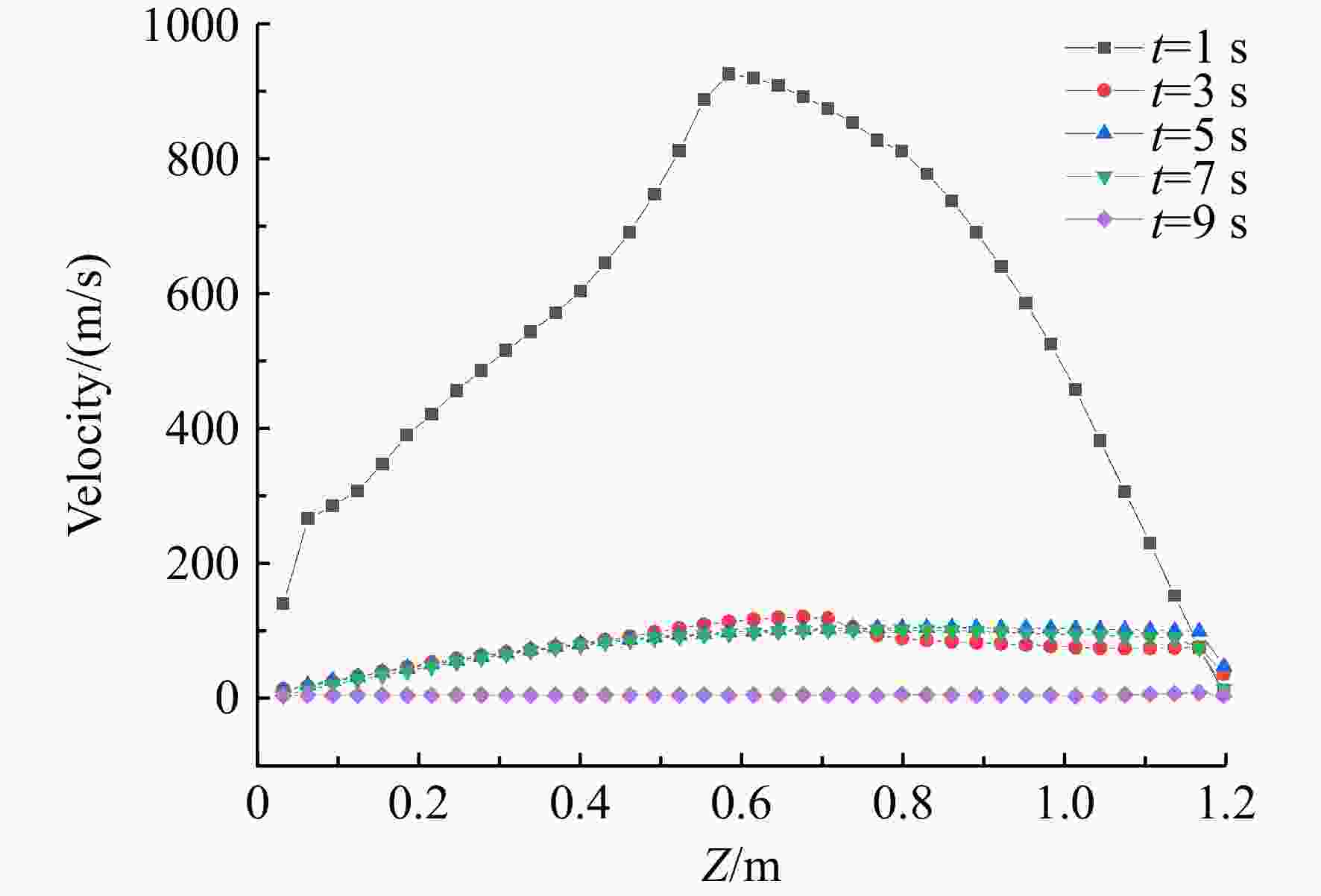

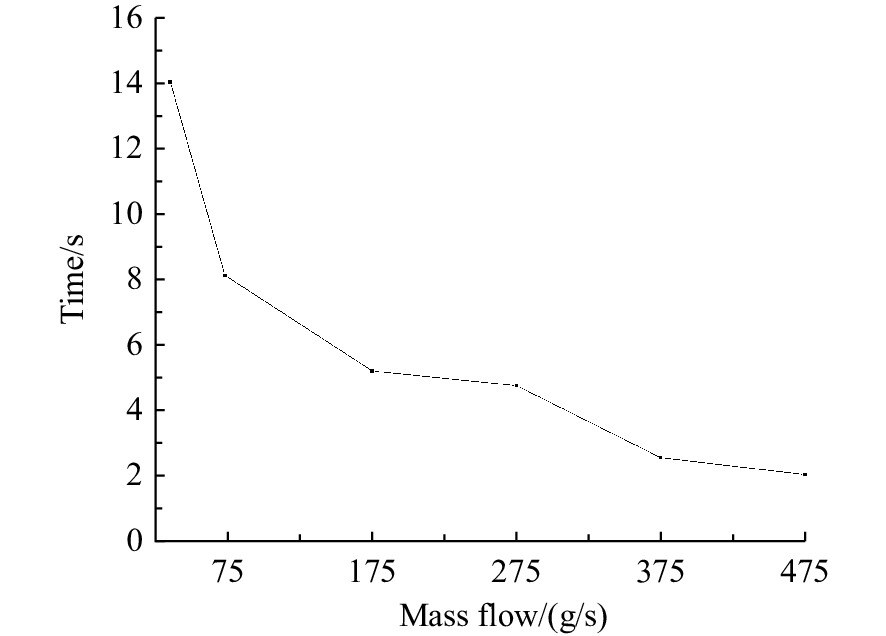

Abstract:In order to avoid propellant gasification, cryogenic liquid rocket engine needs pipeline precooling during propellant filling. To reveal the two-phase flow characteristics of cryogenic fluid during pipeline precooling, study was carried out for the precooling process of liquid methane pipeline in a small liquid oxygen/methane engine. The turbulent heat transfer process under different inlet flow rates was simulated and analyzed by Lee evaporation model, and the variation rules of methane volume fraction, temperature, pressure and velocity during the pipeline precooling process were obtained. The results showed that the flash of liquid methane occurred during the precooling process, and the change of methane temperature and pressure was the main factor affecting the flash. At low flow rate, the precooling time decreased with the increase of mass flow rate; when the mass flow rate increased to a certain extent, the precooling time was prone to be stable. The results can predict the optimal precooling flow rate in the allowable time, which has a guiding role in improving the precooling efficiency and the filling process of cryogenic propellant.

-

Key words:

- liquid methane /

- precooling process /

- phase change /

- Lee model /

- flash

-

-

[1] 王娇娇,厉彦忠,王鑫宝,等. 低温推进剂管路预冷沸腾换热特性研究综述[J]. 宇航学报,2017,38(8): 779-788. WANG Jiaojiao,LI Yanzhong,WANG Xinbao,et al. Review of cryogenic boiling heat transfer during pipe chilldown[J]. Journal of Astronautics,2017,38(8): 779-788. (in Chinese doi: 10.3873/j.issn.1000-1328.2017.08.001 WANG Jiaojiao, LI Yanzhong, WANG Xinbao, et al . Review of cryogenic boiling heat transfer during pipe chilldown[J]. Journal of Astronautics,2017 ,38 (8 ):779 -788 . (in Chinese) doi: 10.3873/j.issn.1000-1328.2017.08.001[2] JACKSON J K. Cryogenic two-phase flow during chilldown: flow transition and nucleate boiling heat transfer[D]. Gainesville,US: University of Florida ,2006. [3] JOHNSON J,SHINE S R. Transient cryogenic chill down process in horizontal and inclined pipes[J]. Cryogenics,2015,71: 7-17. doi: 10.1016/j.cryogenics.2015.05.003 [4] HU Hong,CHUNG J N,AMBER S H. An experimental study on flow patterns and heat transfer characteristics during cryogenic chilldown in a vertical pipe[J]. Cryogenics,2012,52(4/5/6): 268-277. [5] HU Hong,WIJERATNE T K,CHUNG J N. Two-phase flow and heat transfer during chilldown of a simulated flexible metal hose using liquid nitrogen[J]. Journal of Low Temperature Physics,2014,174(5/6): 247-268. [6] VELAT C J. Experiments in cryogenic two phase flow[D]. Gainesville,US: University of Florida,2004. [7] VELAT C,JACKSON J,KLAUSNER J F,et al. Cryogenic two-phase flow during chilldown[C]//Proceedings of ASME 2004 Heat Transfer/Fluids Engineering Summer Conference. Charlotte,US: ASME,2009: 717-722. [8] DARR S R,HU Hong,GLIKIN N G,et al. An experimental study on terrestrial cryogenic transfer line chilldown: Ⅰ effect of mass flux,equilibrium quality,and inlet subcooling[J]. International Journal of Heat and Mass Transfer,2016,103: 1225-1242. doi: 10.1016/j.ijheatmasstransfer.2016.05.019 [9] DARR S R,HU Hong,GLIKIN N,et al. An experimental study on terrestrial cryogenic tube chilldown: Ⅱ effect of flow direction with respect to gravity and new correlation set[J]. International Journal of Heat and Mass Transfer,2016,103: 1243-1260. doi: 10.1016/j.ijheatmasstransfer.2016.08.044 [10] HARTWIG J,HU Hong,STYBORSKI J,et al. Comparison of cryogenic flow boiling in liquid nitrogen and liquid hydrogen chilldown experiments[J]. International Journal of Heat and Mass Transfer,2015,88: 662-673. doi: 10.1016/j.ijheatmasstransfer.2015.04.102 [11] HARTWIG J,RAME E,MCQUILLEN J. Pulse chilldown tests of a tank-to-tank liquid hydrogen propellant transfer line[R]. AIAA 2016-2186,2016. [12] 陈二锋,厉彦忠,程向华. 液体火箭发动机自然循环预冷回路的数值研究[J]. 航空动力学报,2009,24(3): 698-704. CHEN Erfeng,LI Yanzhong,CHENG Xianghua. Numerical studies on natural circulation precooling loop of cryogenic liquid rocket engine[J]. Journal of Aerospace Power,2009,24(3): 698-704. (in Chinese doi: 10.13224/j.cnki.jasp.2009.03.033 CHEN Erfeng, LI Yanzhong, CHENG Xianghua . Numerical studies on natural circulation precooling loop of cryogenic liquid rocket engine[J]. Journal of Aerospace Power,2009 ,24 (3 ):698 -704 . (in Chinese) doi: 10.13224/j.cnki.jasp.2009.03.033[13] 程向华,薛会建,李宏刚,等. 低温预冷管路流动及传热非稳态特性研究[J]. 火箭推进,2018,44(6): 53-56. CHENG Xianghua,XUE Huijian,LI Honggang,et al. Investigation on unsteady characteristics of flow and heat transfer in cryogenic precooling pipe[J]. Journal of Rocket Propulsion,2018,44(6): 53-56. (in Chinese doi: 10.3969/j.issn.1672-9374.2018.06.008 CHENG Xianghua, XUE Huijian, LI Honggang, et al . Investigation on unsteady characteristics of flow and heat transfer in cryogenic precooling pipe[J]. Journal of Rocket Propulsion,2018 ,44 (6 ):53 -56 . (in Chinese) doi: 10.3969/j.issn.1672-9374.2018.06.008[14] 陈亮,梁国柱,邓新宇,等. 贮箱内低温推进剂汽化过程的CFD数值仿真[J]. 北京航空航天大学学报,2013,39(2): 264-268. CHEN Liang,LIANG Guozhu,DENG Xinyu,et al. CFD numerical simulation of cryogenic propellant vaporization in tank[J]. Journal of Beijing University of Aeronautics and Astronautics,2013,39(2): 264-268. (in Chinese doi: 10.13700/j.bh.1001-5965.2013.02.001 CHEN Liang, LIANG Guozhu, DENG Xinyu, et al . CFD numerical simulation of cryogenic propellant vaporization in tank[J]. Journal of Beijing University of Aeronautics and Astronautics,2013 ,39 (2 ):264 -268 . (in Chinese) doi: 10.13700/j.bh.1001-5965.2013.02.001[15] LEE W. A pressure iteration scheme for two-phase flow modeling[R]. Technical Report LA-UR,1979. [16] HERTZ H. On the evaporation of liquids,especially mercury,in vacuo[J]. Leipzig: Annalen der Physik,1882,17: 177-193. [17] KNUDSEN M. Maximum rate of vaporization of mercury[J]. Leipzig: Annalen der Physik,1915,47: 697-705. [18] TANASAWA I. Advances in condensation heat transfer[J]. Advances in Heat Transfer,1991,21: 55-139. [19] YUAN Kun,JI Yan,CHUNG J N. Cryogenic chilldown process under low flow rates[J]. International Journal of Heat and Mass Transfer,2007,50(19/20): 4011-4022. [20] 蔡凤英,谈宗山,孟赫,等. 化工安全工程[M]. 北京: 科学出版社,2001. -

下载:

下载: