Bayes feature fusion reliability evaluation model based on data migration

-

摘要:

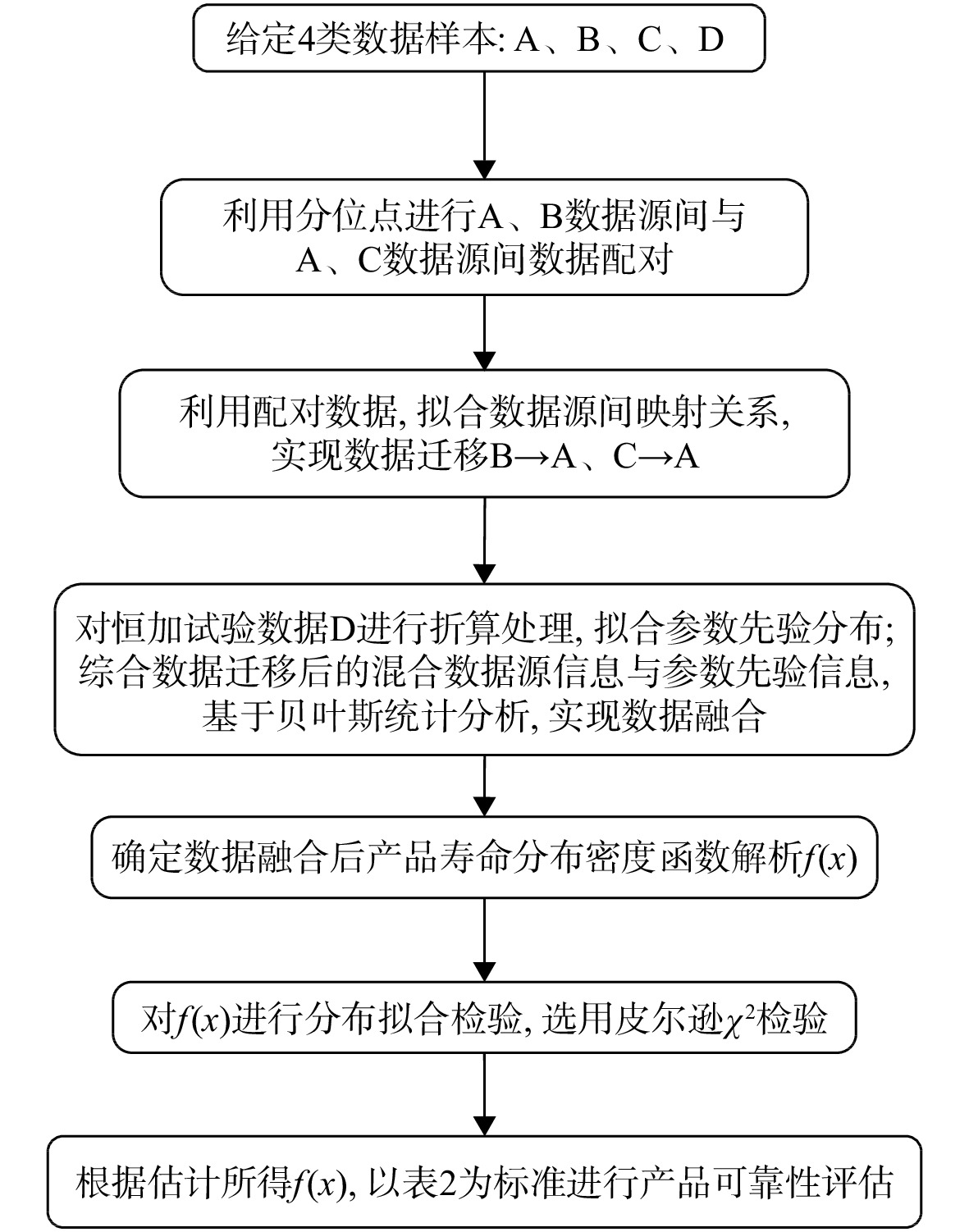

基于同种产品的多类试验源寿命数据信息,利用不同数据源间的映射关系,将多源数据迁移至现场数据源中形成混合数据源,以此作为产品可靠性贝叶斯统计分析基础。对于不同应力下加速寿命数据,将其折算至常应力水平下确定参数分布密度函数解析,以此作为产品可靠性贝叶斯统计分析的先验条件。将贝叶斯统计模型与数据迁移模型进行结合,融合多源数据的同时确定其参数估计值,得到产品密度函数解析并完成产品可靠性分析。算例表明:该类模型利用数据源间映射关系可有效实现数据迁移,且能实现加速寿命数据与其他各类数据源的同步融合,融合样本数据后的产品可靠性综合评估比单一寿命数据源的产品可靠性评估更全面、客观。

Abstract:Based on the life data information from multiple test sources, using the mapping relationship between different data sources, the multi-source data were migrated to the field data source to form a mixed data source, which was used as the basis for the Bayesian statistical analysis of product reliability. For the accelerated life data under different stresses, it was converted to the constant stress level to determine the parameter distribution density function, which was used as the priori condition for the product reliability Bayesian statistical analysis. By combining the Bayesian statistical model with the data migration model, and fusing multi-source data while determining the parameter estimates at the same time, the product density function and the product reliability analysis were obtained. The example showed that this model can effectively achieve data migration by utilizing the mapping relationship between data sources, and can accelerate the synchronous fusion of life data with other types of data sources. The comprehensive evaluation of product reliability after fusing sample data was more comprehensive and objective than that of a single life data source.

-

Key words:

- data migration /

- Bayesian /

- data fusion /

- exponential distribution /

- reliability

-

表 1 多源数据结构表

Table 1. Multi-source data structure table

数据源类别 数据结构 A类 $ {y_1},{y_2},\cdots,{y_{{n_1}}},{y_{_i}} > 0,i = 1,2,\cdots,{n_1} $ B类 $ {x_{11}},{x_{12}},\cdots,{x_{1{n_2}}},{x_{1j}} > 0,j = 1,2,\cdots,{n_2} $ C类 $ {x_{21}},{x_{22}},\cdots,{x_{2{n_3}}},{x_{2k}} > 0,k = 1,2,\cdots,{n_3} $ D类 应力条件为$ {S_a},a = 1,2,\cdots,n $

寿命数据为$ {t_{a1}},{t_{a2}},\cdots,{t_{a{r_a}}} $产品可靠度 产品失效率 产品平均寿命 $ R ( t ) = 1 - \displaystyle\int_0^t {f ( {{x_i};{\boldsymbol{\varPsi }}} ) } {\text{d}}x $ $ \lambda ( t ) = \dfrac{{{F'} ( t ) }}{{1 - F ( t ) }} = \dfrac{{f ( {t;{\boldsymbol{\varPsi }}} ) }}{{R ( t ) }} $ $ E ( X ) = \displaystyle\int_0^\infty {tf ( t ) } {\text{d}}t $ 表 3 某产品电子元件试验寿命数据初始数值

Table 3. Initial value of product electronic component test life data

h 试验种类 寿命数据值 A类 742.79, 2878.35, 2723.95, 3752.92, 4391.46, 1102.8, 1222.4, 3400.68, 830.10, 870.62 B类 1225.18, 737.35, 526.60, 649.87, 3399.11, ···, 980.47, 22.99, 772.24, 4029.56 C类 8260.48, 1782.21, 611.91, 2491.37, 2765.02, ···, 2980.49, 5465.17, 592.64, 888.10 表 4 恒定电压加速寿命试验数据

Table 4. Constant voltage accelerated life test data

试验条件 $ {S_1} = 12 $

$ {r_1} = 10 $$ {S_2} = 15 $

$ {r_2} = 15 $$ {S_3} = 19 $

$ {r_3} = 20 $$ {S_4} = 25 $

$ {r_4} = 25 $$ {S_5} = 35 $

${r_5} = 30$失效时间

$ {t_{al}} $/h4915.23

1060.47

$ \vdots $

563.14

2380.15438.03

4124.38

$ \vdots $

728.86

58.44353.50

726.93

$ \vdots $

684.05

705.74180.36

370.88

$ \vdots $

161.04

279.4036.42

146.84

$ \vdots $

101.93

27.98表 5 三源样本顺序统计量

Table 5. Three-source sample order statistics

h 数据源分类 样本顺序统计量 A源 742.79, 830.10, 870.62, 1102.80, 1222.40, 2723.95, 2878.35, 3400.68, 3752.92, 4391.46 B源 6.18, 22.2, 22.99, 29.53, 37.41, ···, 5320.39, 7694.58, 7793.3, 8970.31, 9031.32, 9265.99 C源 10.31, 11.77, 15.9, 55.2, 68.98, 71.79, ···, 10783.7, 11256.8, 11454.9, 13073.3, 20468.0 表 6 基于分位点的三源样本配对表

Table 6. Three-source sample pairing table based on quantile

h 样本对 样本配对值 A源与B源 (225.24, 742.79),(455.74, 830.10), ···, (3508.84, 3752.92), (4955.55, 4391.46) A源与C源 (315.16, 742.79), (574.70, 830.10), ··· , (4693.42, 3752.92), (7501.01, 4391.46) 表 7 B、C两源迁移数据表

Table 7. B and C two source migration data table

h 数据源分类 折算数据 B类 1721.74, 1299.1, 1116.61, 1223.31, ···, 1509.74, 680.21, 1329.33, 4151.37 C类 5508.77, 1735.96, 1054.40,2148.96, ···, 2433.81, 3880.84, 1043.18, 1215.25 表 8 不同应力下折算数据表

Table 8. Conversion data table under different stress

h 应力水平 折算至常应力下样本数据 $ {S_1} = 12 $ 7633.9, 1466.77, 352.67, ···, 3491.81, 671.10, 3578.11 $ {S_2} = 15 $ 1544.12,5310.3,3050,36, ···, 2563.29, 1842.24, 1156.30 $ {S_3} = 19 $ 1792.73, 3327.34, 4454.96, ···, 5769.81, 1284.01, 3151.12,3240.25 $ {S_4} = 25 $ 1831.09, 3451.93, 4642.90, ···, 1055.61, 1666.79, 2673.67 $ {S_5} = 35 $ 1887.88, 5547.53, 3083.96, ···, 1385.83, 4059.09, 1608.34 表 9 加速寿命试验折算样本参数估计表

Table 9. Parameter estimation table of the converted sample of accelerated life test

应力水平 折算样本参数估计值 $ {S_1} = 12 $ $ {\tilde \lambda _1} = \dfrac{1}{{2\;417.109}} $ $ {S_2} = 15 $ $ {\tilde \lambda _2} = \dfrac{1}{{2\;451.604}} $ $ {S_3} = 19 $ $ {\tilde \lambda _3} = \dfrac{1}{{2\;365.011}} $ $ {S_4} = 25 $ $ {\tilde \lambda _4} = \dfrac{1}{{2\;371.819}} $ $ {S_5} = 35 $ $ {\tilde \lambda _5} = \dfrac{1}{{2\;363.386}} $ 表 10 产品可靠性评估指标结果表

Table 10. Product reliability evaluation index results table

可靠度 失效率 平均寿命 $ R ( t ) = {{\text{e}}^{ - 0.000\;422x}} $ $ \lambda ( t ) = 0.000\;422 $ $ E ( x ) = \theta = 2\;369.67 $ -

[1] SCHREIBER-EHLE S,KOCH W. The JDL model of data fusion applied to cyber-defence—a review paper[C]//2012 Workshop on Sensor Data Fusion: Trends,Solutions,Applications. Piscataway,US: IEEE,2012: 116-119. [2] 罗俊海,杨阳. 基于数据融合的目标检测方法综述[J]. 控制与决策,2020,35(1): 1-15. LUO Junhai,YANG Yang. An overview of target detection methods based on data fusion[J]. Control and Decision,2020,35(1): 1-15. (in Chinese doi: 10.13195/j.kzyjc.2019.0649 LUO Junhai, YANG Yang . An overview of target detection methods based on data fusion[J]. Control and Decision,2020 ,35 (1 ):1 -15 . (in Chinese) doi: 10.13195/j.kzyjc.2019.0649[3] 许凌天,沈雪瑾,蒋爽,等. 退化量有缺失的无失效小样本轴承可靠性评估[J]. 航空动力学报,2020,35(9): 1977-1987. XU Lingtian,SHEN Xuejin,JIANG Shuang,et al. Reliability assessment of bearings with incomplete performance degradation data under small and non-failure samples[J]. Journal of Aerospace Power,2020,35(9): 1977-1987. (in Chinese doi: 10.13224/j.cnki.jasp.2020.09.020 XU Lingtian, SHEN Xuejin, JIANG Shuang, et al . Reliability assessment of bearings with incomplete performance degradation data under small and non-failure samples[J]. Journal of Aerospace Power,2020 ,35 (9 ):1977 -1987 . (in Chinese) doi: 10.13224/j.cnki.jasp.2020.09.020[4] 何宇廷,高潮. 基于试验数据与使用数据融合的产品寿命可靠性分析方法[J]. 航空工程进展,2015,6(2): 205-210,216. HE Yuting,GAO Chao. Method of reliability life analysis for product based on the fusion of test data and usage data[J]. Advances in Aeronautical Science and Engineering,2015,6(2): 205-210,216. (in Chinese doi: 10.3969/j.issn.1674-8190.2015.02.012 HE Yuting, GAO Chao . Method of reliability life analysis for product based on the fusion of test data and usage data[J]. Advances in Aeronautical Science and Engineering,2015 ,6 (2 ):205 -210, 216 . (in Chinese) doi: 10.3969/j.issn.1674-8190.2015.02.012[5] WEI Yupeng,WU Dazhong,TERPENNY J. Robust incipient fault detection of complex systems using data fusion[J]. IEEE Transactions on Instrumentation and Measurement,2020,69(12): 9526-9534. doi: 10.1109/TIM.2020.3003359 [6] ZHANG Weibin,QI Yong,ZHOU Zhuping,et al. Method of speed data fusion based on Bayesian combination algorithm and high-order multi-variable Markov model[J]. IET Intelligent Transport Systems,2018,12(10): 1312-1321. doi: 10.1049/iet-its.2018.5020 [7] 韦金芬,宋保维,毛昭勇. 多阶段实验数据融合的Bayes可靠性评定模型[J]. 计算机工程,2012,38(9): 265-267. WEI Jinfen,SONG Baowei,MAO Zhaoyong. Bayes reliability evaluation model of multistage experimental data fusion[J]. Computer Engineering,2012,38(9): 265-267. (in Chinese doi: 10.3969/j.issn.1000-3428.2012.09.081 WEI Jinfen, SONG Baowei, MAO Zhaoyong . Bayes reliability evaluation model of multistage experimental data fusion[J]. Computer Engineering,2012 ,38 (9 ):265 -267 . (in Chinese) doi: 10.3969/j.issn.1000-3428.2012.09.081[8] 吴艳. 多传感器数据融合算法研究[D]. 西安: 西安电子科技大学,2003. WU Yan. Study of multisensor data fusion algorithms[D]. Xi’an: Xidian University,2003. (in ChineseWU Yan. Study of multisensor data fusion algorithms[D]. Xi’an: Xidian University, 2003. (in Chinese) [9] 周荣喜,崔清德,郝惊雨. 一种基于证据融合的高可靠性产品可靠性评价方法[J]. 系统工程理论与实践,2018,38(11): 2979-2986. ZHOU Rongxi,CUI Qingde,HAO Jingyu. A reliability evaluation method of high reliability products based on evidence fusion[J]. Systems Engineering-Theory & Practice,2018,38(11): 2979-2986. (in Chinese doi: 10.12011/1000-6788(2018)11-2979-08 ZHOU Rongxi, CUI Qingde, HAO Jingyu . A reliability evaluation method of high reliability products based on evidence fusion[J]. Systems Engineering-Theory & Practice,2018 ,38 (11 ):2979 -2986 . (in Chinese) doi: 10.12011/1000-6788(2018)11-2979-08[10] OSMAN A,KAFTANDJIAN V,HASSLER U. Improvement of X-ray castings inspection reliability by using Dempster-Shafer data fusion theory[J]. Pattern Recognition Letters,2011,32(2): 168-180. doi: 10.1016/j.patrec.2010.10.004 [11] 贾祥,程志君,郭波. 基于信息熵和Bayes理论的高可靠性产品可靠性评估[J]. 系统工程理论与实践,2020,40(7): 1918-1926. JIA Xiang,CHENG Zhijun,GUO Bo. Reliability evaluation for products based on entropy and Bayes theory[J]. Systems Engineering-Theory & Practice,2020,40(7): 1918-1926. (in Chinese doi: 10.12011/1000-6788-2019-1306-09 JIA Xiang, CHENG Zhijun, GUO Bo . Reliability evaluation for products based on entropy and Bayes theory[J]. Systems Engineering-Theory & Practice,2020 ,40 (7 ):1918 -1926 . (in Chinese) doi: 10.12011/1000-6788-2019-1306-09[12] SUN Wei,CHEN Tao,WEI Jing. Dynamic reliability of gears in a wind turbine gearbox under the conditions of variable wind speed and small samples[J]. Proceedings of the Institution of Mechanical Engineers,Part C: Journal of Mechanical Engineering Science,2012,226(12): 3032-3042. [13] 孙祝岭,白吉潇. 可靠性数据的回归折算方法进一步研究[J]. 质量与可靠性,2010(5): 18-21. SUN Zhuling,BAI Jixiao. Further study on regression conversion method of reliability data[J]. Quality and Reliability,2010(5): 18-21. (in Chinese SUN Zhuling, BAI Jixiao . Further study on regression conversion method of reliability data[J]. Quality and Reliability,2010 (5 ):18 -21 . (in Chinese)[14] 赵亮,杨战平. 一种针对实验数据的裕量和不确定性量化方法[J]. 系统科学与数学,2016,36(8): 1138-1149. ZHAO Liang,YANG Zhanping. An approach of quantification of margins and uncertainties for test data[J]. Journal of Systems Science and Mathematical Sciences,2016,36(8): 1138-1149. (in Chinese doi: 10.12341/jssms12855 ZHAO Liang, YANG Zhanping . An approach of quantification of margins and uncertainties for test data[J]. Journal of Systems Science and Mathematical Sciences,2016 ,36 (8 ):1138 -1149 . (in Chinese) doi: 10.12341/jssms12855[15] 郭奎,于丹. 分位点随机配序抽样[J]. 数学物理学报,2006,26(1): 9-14. GUO Kui,YU Dan. Sampling method by allocating random order to percentiles[J]. Acta Mathematica Scientia,2006,26(1): 9-14. (in Chinese doi: 10.3321/j.issn:1003-3998.2006.01.002 GUO Kui, YU Dan . Sampling method by allocating random order to percentiles[J]. Acta Mathematica Scientia,2006 ,26 (1 ):9 -14 . (in Chinese) doi: 10.3321/j.issn:1003-3998.2006.01.002[16] 马溧梅,武小悦,刘琦. 分位点形式专家信息的一致性检验方法[J]. 航空动力学报,2008,23(9): 1637-1640. MA Limei,WU Xiaoyue,LIU Qi. Consistency test method for single expert’s information described by fractiles[J]. Journal of Aerospace Power,2008,23(9): 1637-1640. (in Chinese doi: 10.13224/j.cnki.jasp.2008.09.003 MA Limei, WU Xiaoyue, LIU Qi . Consistency test method for single expert’s information described by fractiles[J]. Journal of Aerospace Power,2008 ,23 (9 ):1637 -1640 . (in Chinese) doi: 10.13224/j.cnki.jasp.2008.09.003[17] 冯海林,王雨薇. 基于支持向量回归与Bayesian理论的性能退化产品可靠性分析[J]. 南京大学学报(自然科学),2019,55(2): 161-169. FENG Hailin,WANG Yuwei. Reliability analysis of performance degradation product based on support vector regression and Bayesian theory[J]. Journal of Nanjing University (Natural Science),2019,55(2): 161-169. (in Chinese FENG Hailin, WANG Yuwei . Reliability analysis of performance degradation product based on support vector regression and Bayesian theory[J]. Journal of Nanjing University (Natural Science),2019 ,55 (2 ):161 -169 . (in Chinese)[18] 马涛,鞠成玉. 基于Bayes理论的测试性数据融合评估技术[J]. 火力与指挥控制,2017,42(8): 183-185. MA Tao,JU Chengyu. A data fusion method for testability evaluation based on Bayes theorem[J]. Fire Control & Command Control,2017,42(8): 183-185. (in Chinese doi: 10.3969/j.issn.1002-0640.2017.08.041 MA Tao, JU Chengyu . A data fusion method for testability evaluation based on Bayes theorem[J]. Fire Control & Command Control,2017 ,42 (8 ):183 -185 . (in Chinese) doi: 10.3969/j.issn.1002-0640.2017.08.041[19] 郝志鹏,曾声奎,郭健彬,等. 知识与数据融合的可靠性定量模型建模方法[J]. 北京航空航天大学学报,2016,42(1): 101-111. HAO Zhipeng,ZENG Shengkui,GUO Jianbin,et al. Integrated method of knowledge and data for quantitative reliability modeling[J]. Journal of Beijing University of Aeronautics and Astronautics,2016,42(1): 101-111. (in Chinese doi: 10.13700/j.bh.1001-5965.2015.0029 HAO Zhipeng, ZENG Shengkui, GUO Jianbin, et al . Integrated method of knowledge and data for quantitative reliability modeling[J]. Journal of Beijing University of Aeronautics and Astronautics,2016 ,42 (1 ):101 -111 . (in Chinese) doi: 10.13700/j.bh.1001-5965.2015.0029[20] 彭卫文,黄洪钟,李彦锋,等. 基于数据融合的加工中心功能铣头贝叶斯可靠性评估[J]. 机械工程学报,2014,50(6): 185-191. PENG Weiwen,HUANG Hongzhong,LI Yanfeng,et al. Bayesian information fusion method for reliability assessment of milling head[J]. Journal of Mechanical Engineering,2014,50(6): 185-191. (in Chinese doi: 10.3901/JME.2014.06.185 PENG Weiwen, HUANG Hongzhong, LI Yanfeng, et al . Bayesian information fusion method for reliability assessment of milling head[J]. Journal of Mechanical Engineering,2014 ,50 (6 ):185 -191 . (in Chinese) doi: 10.3901/JME.2014.06.185[21] 赵超,李东方,唐亚勇. 分位点门限自回归时间序列模型的贝叶斯分析[J]. 四川大学学报(自然科学版),2016,53(4): 748-752. ZHAO Chao,LI Dongfang,TANG Yayong. Bayesian analysis of quantile regression estimation of threshold autoregressive time series models[J]. Journal of Sichuan University (Natural Science Edition),2016,53(4): 748-752. (in Chinese ZHAO Chao, LI Dongfang, TANG Yayong . Bayesian analysis of quantile regression estimation of threshold autoregressive time series models[J]. Journal of Sichuan University (Natural Science Edition),2016 ,53 (4 ):748 -752 . (in Chinese)[22] 赵宇. 可靠性数据分析[M]. 北京: 国防工业出版社,2011. -

下载:

下载: