Effects of endwall movement on the aerodynamic performance of cantilevered stators

-

摘要:

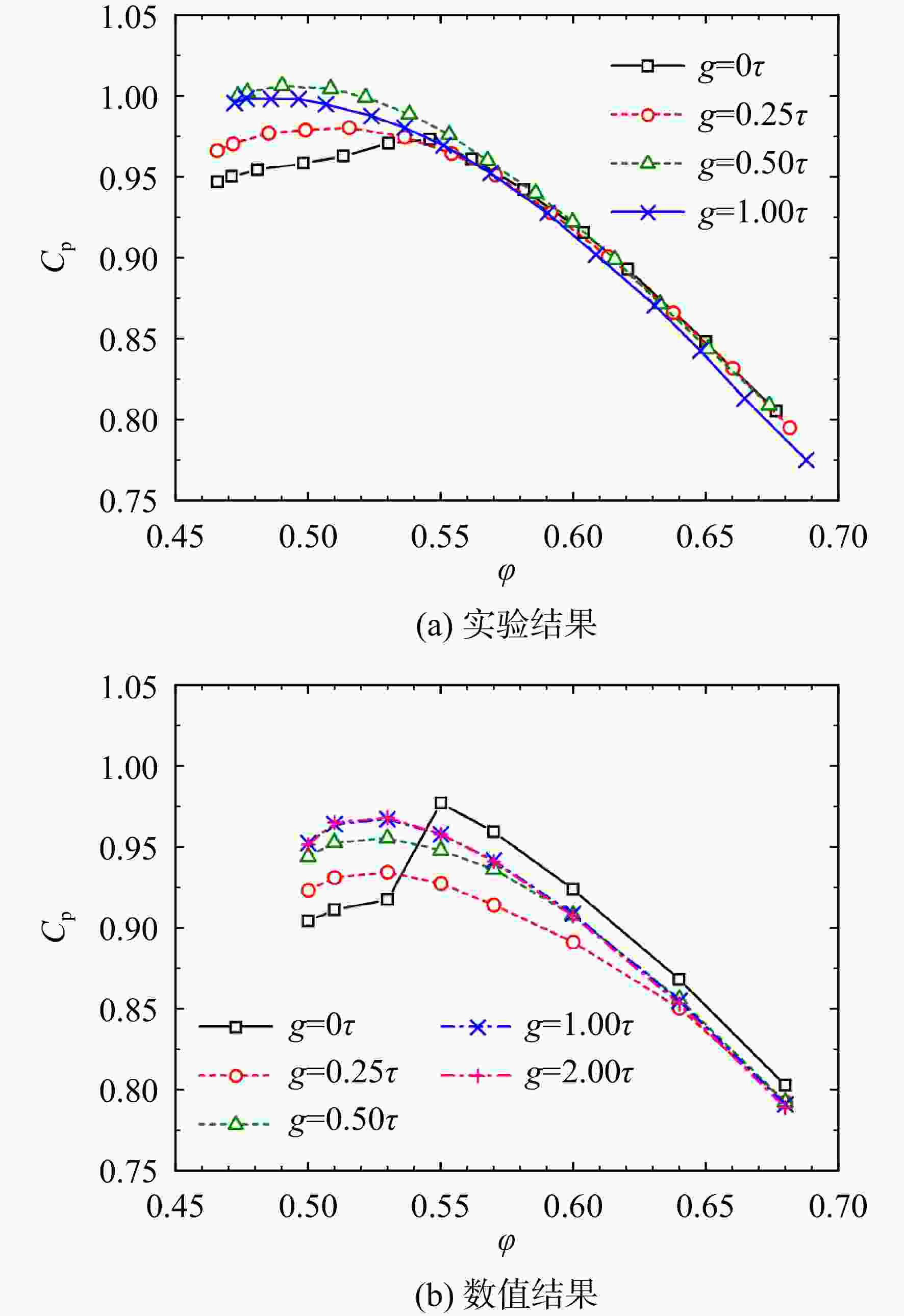

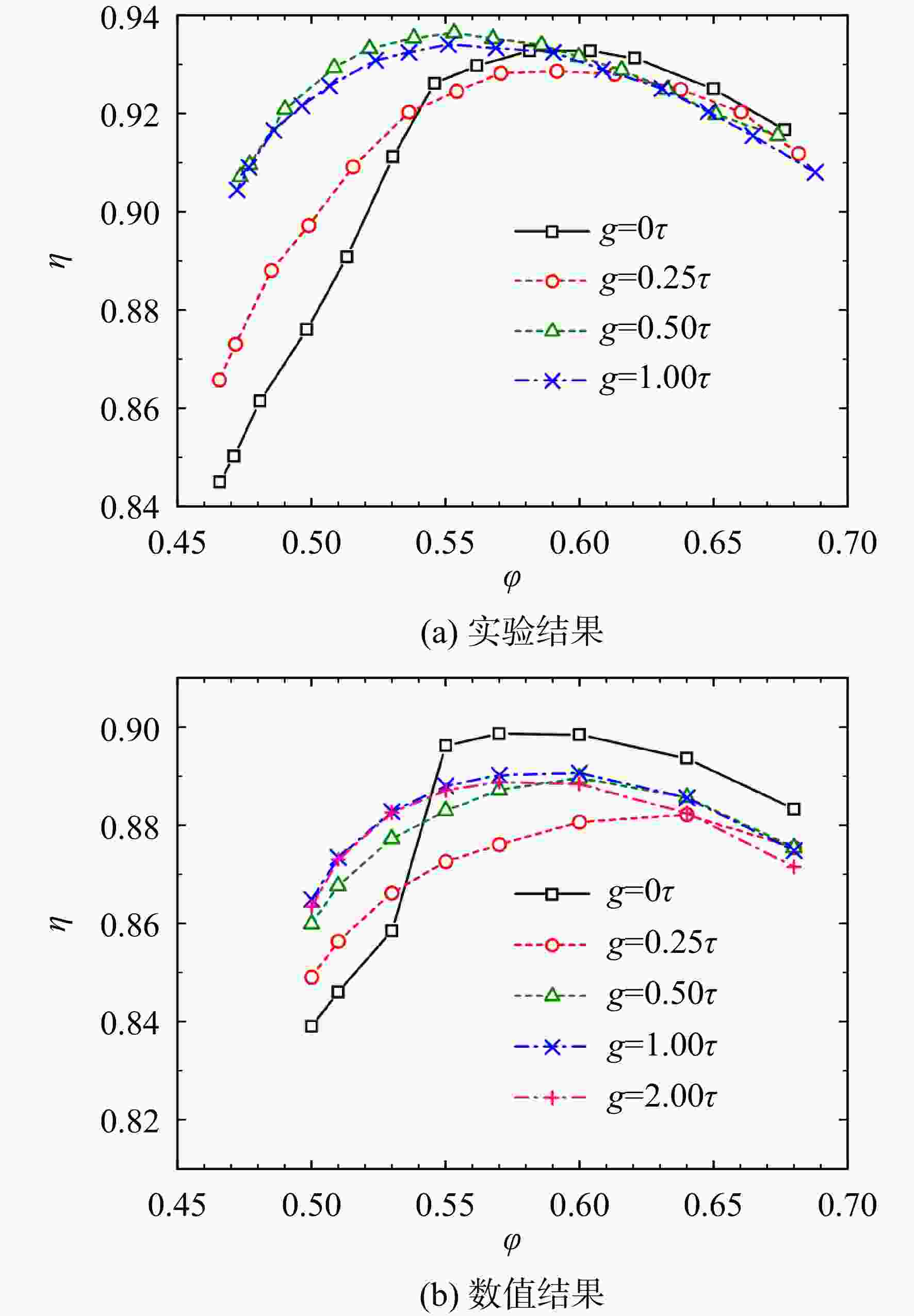

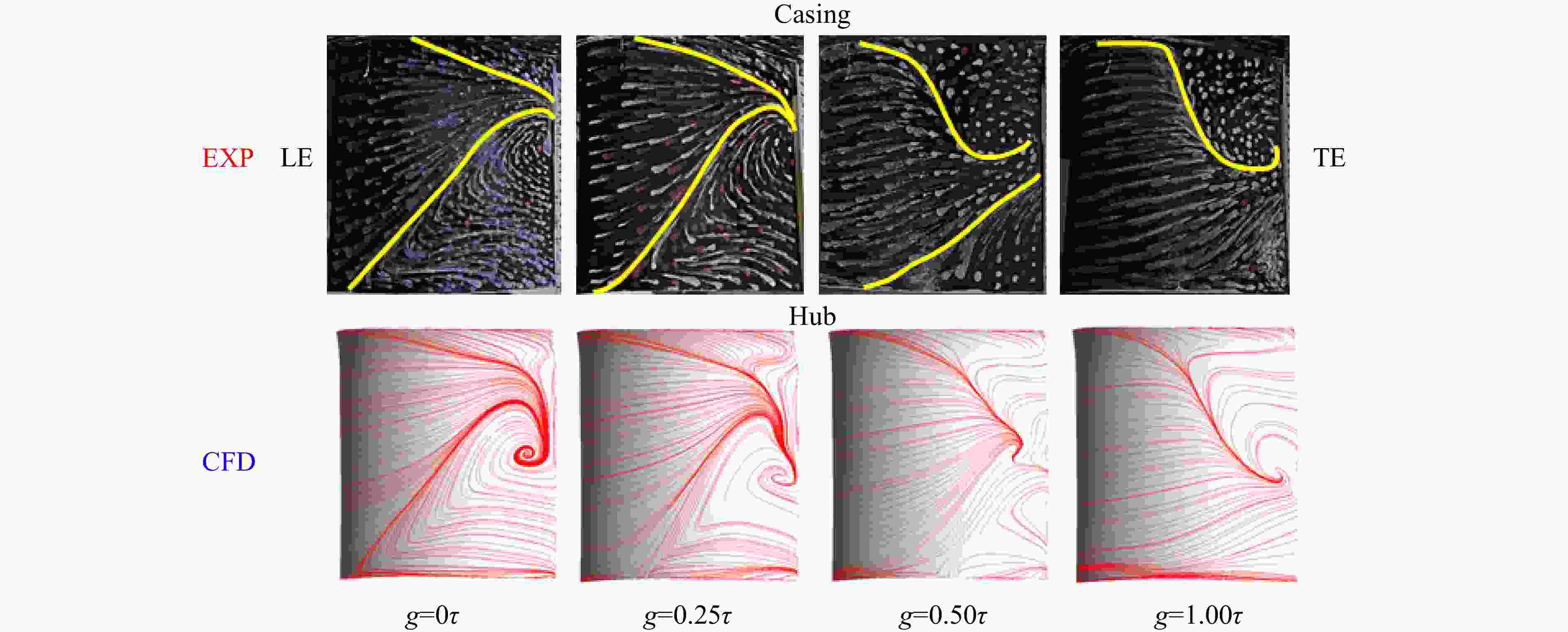

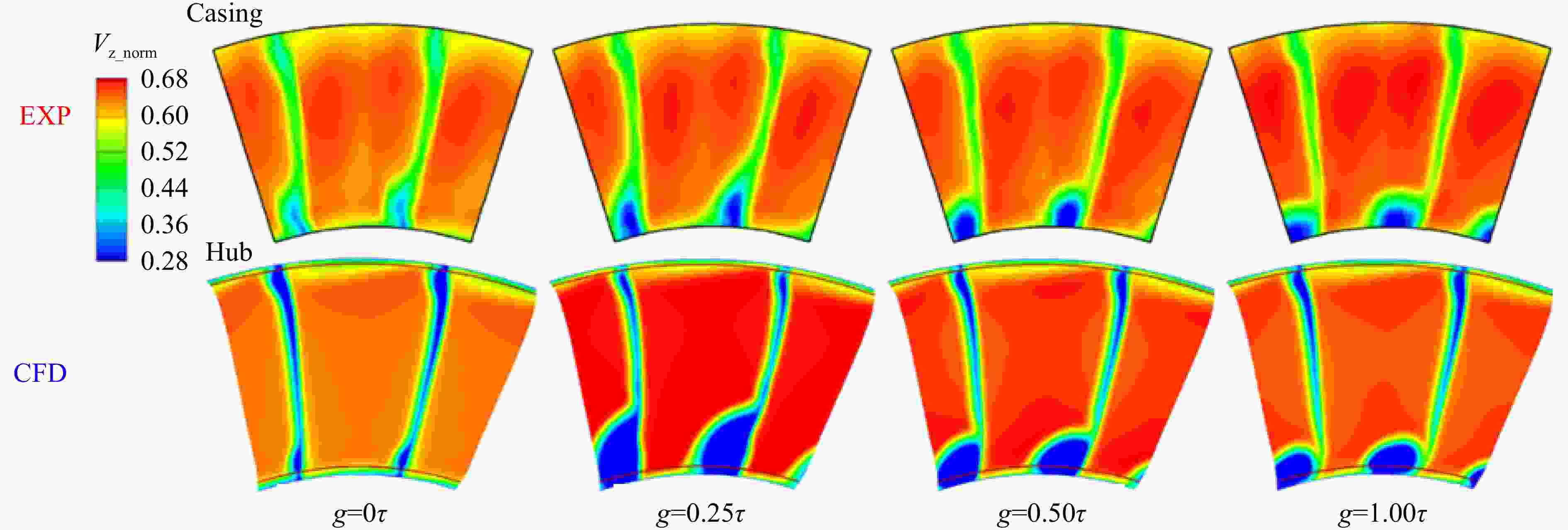

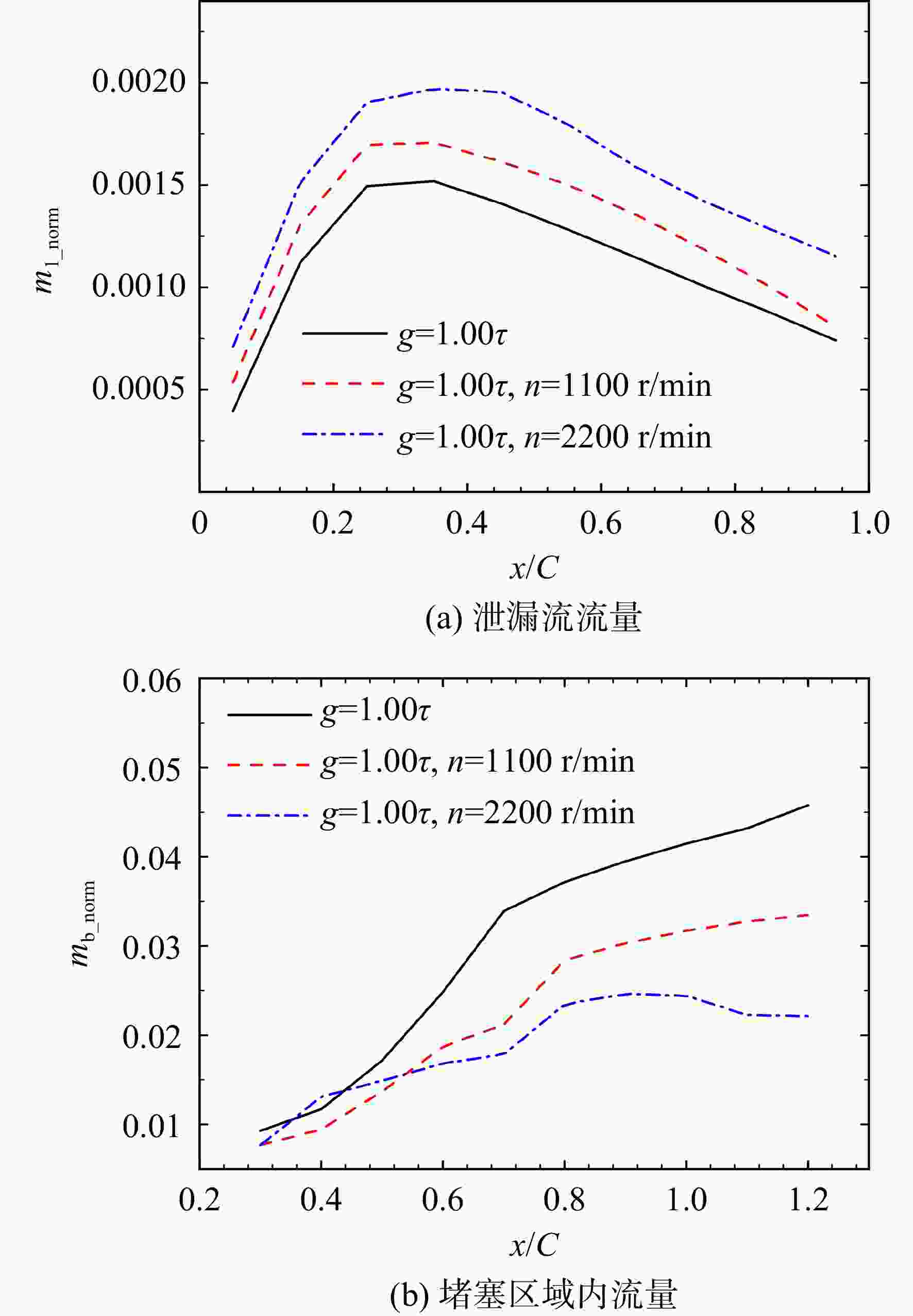

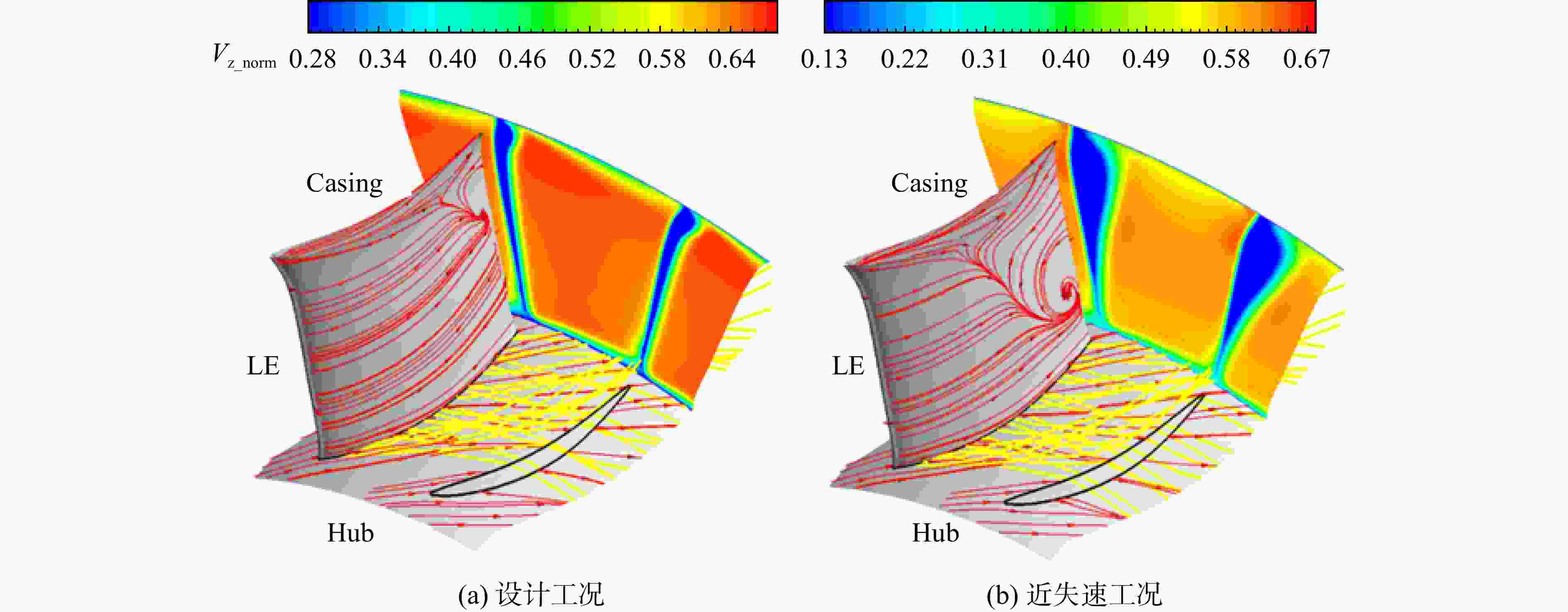

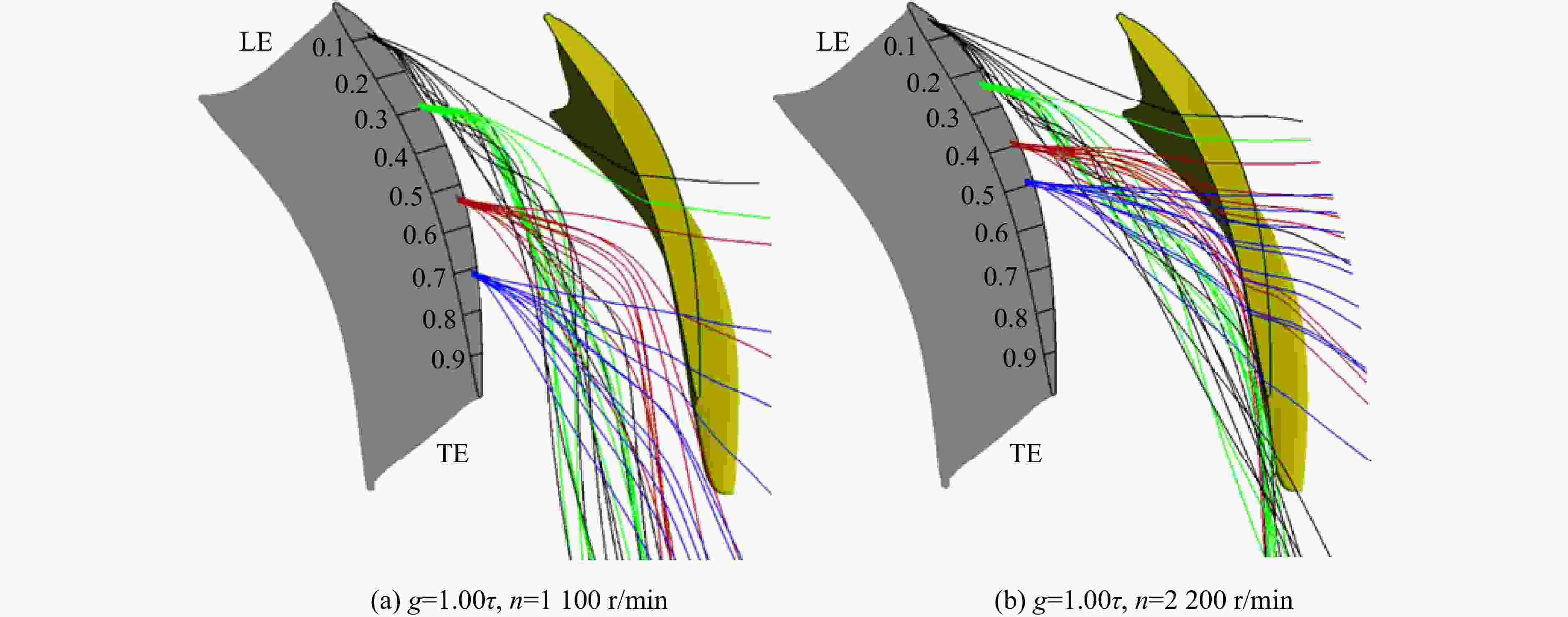

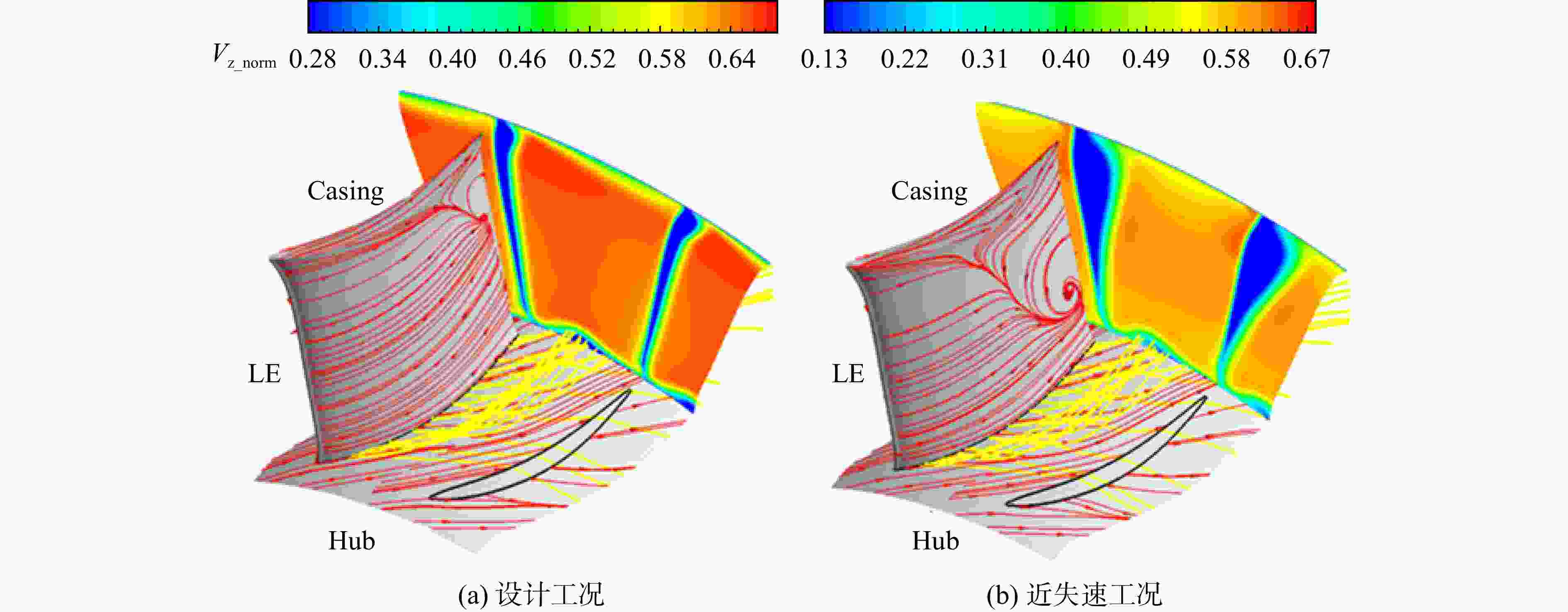

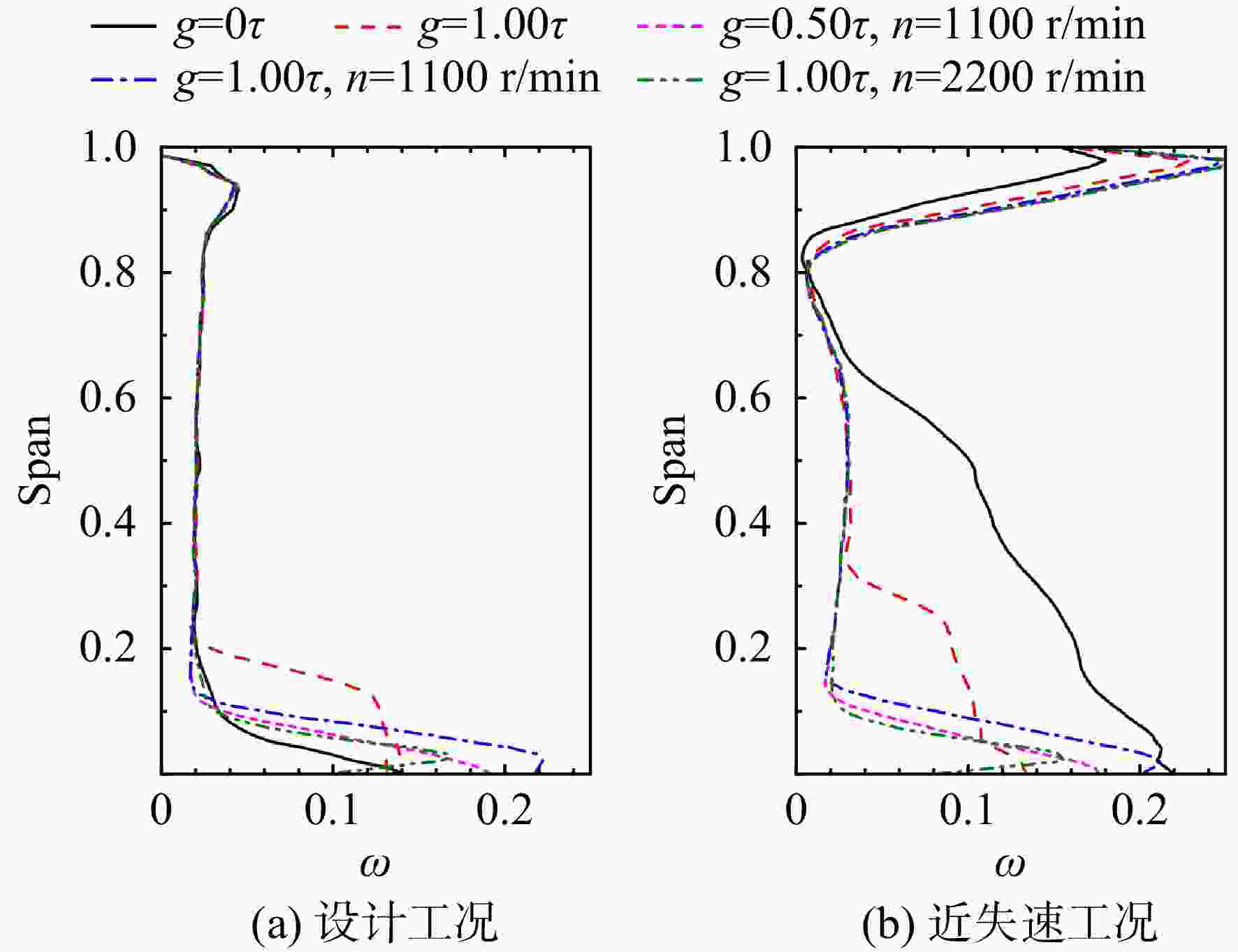

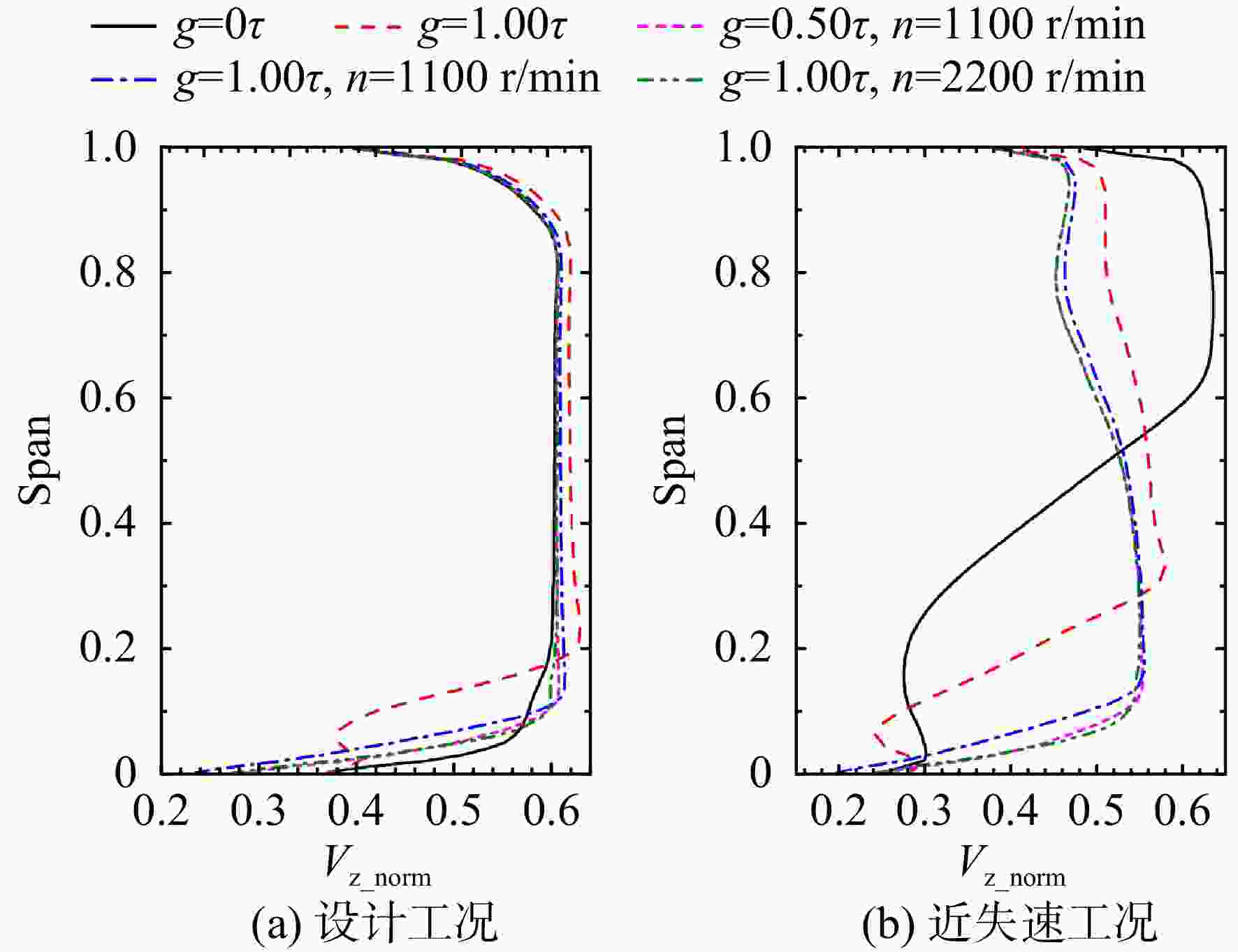

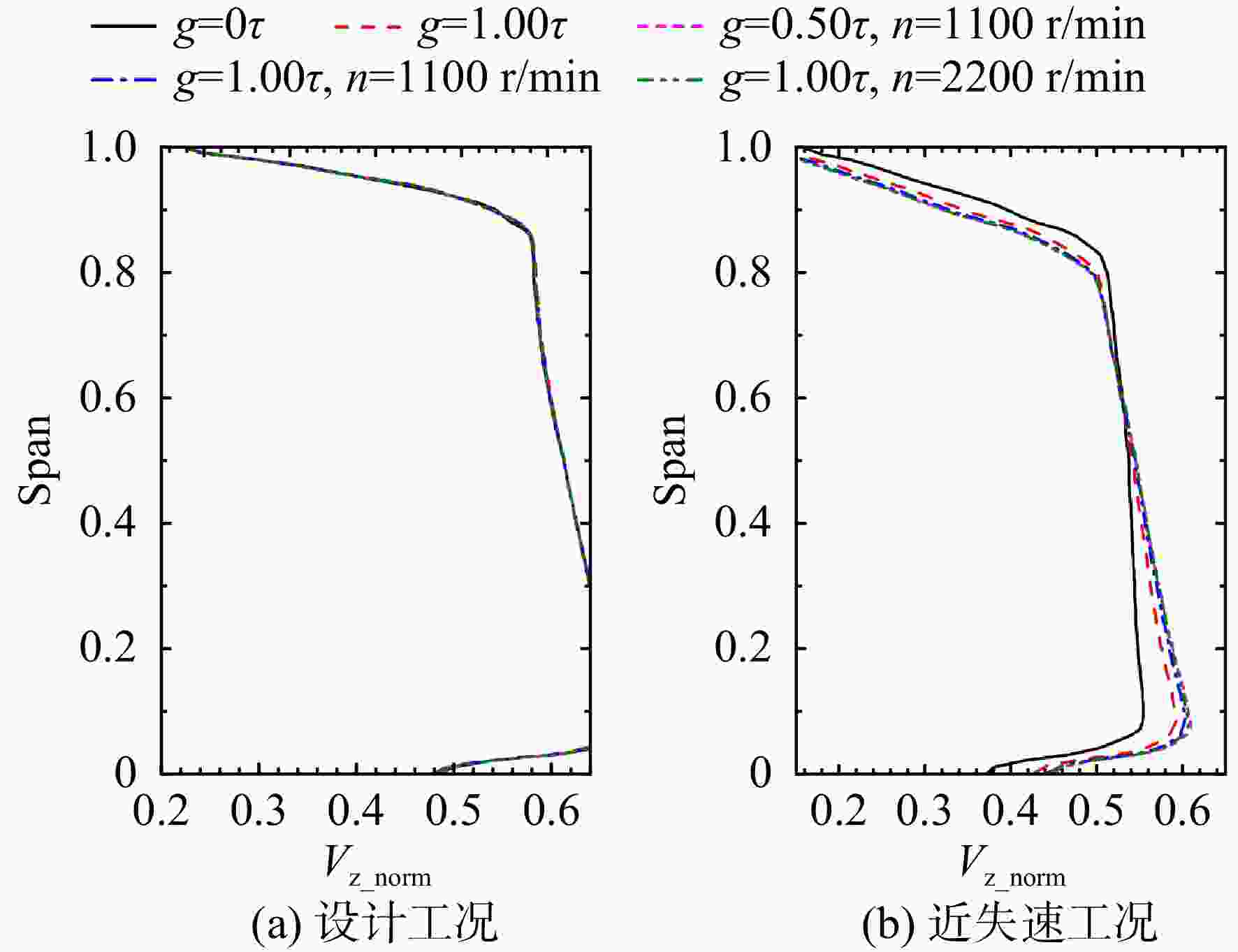

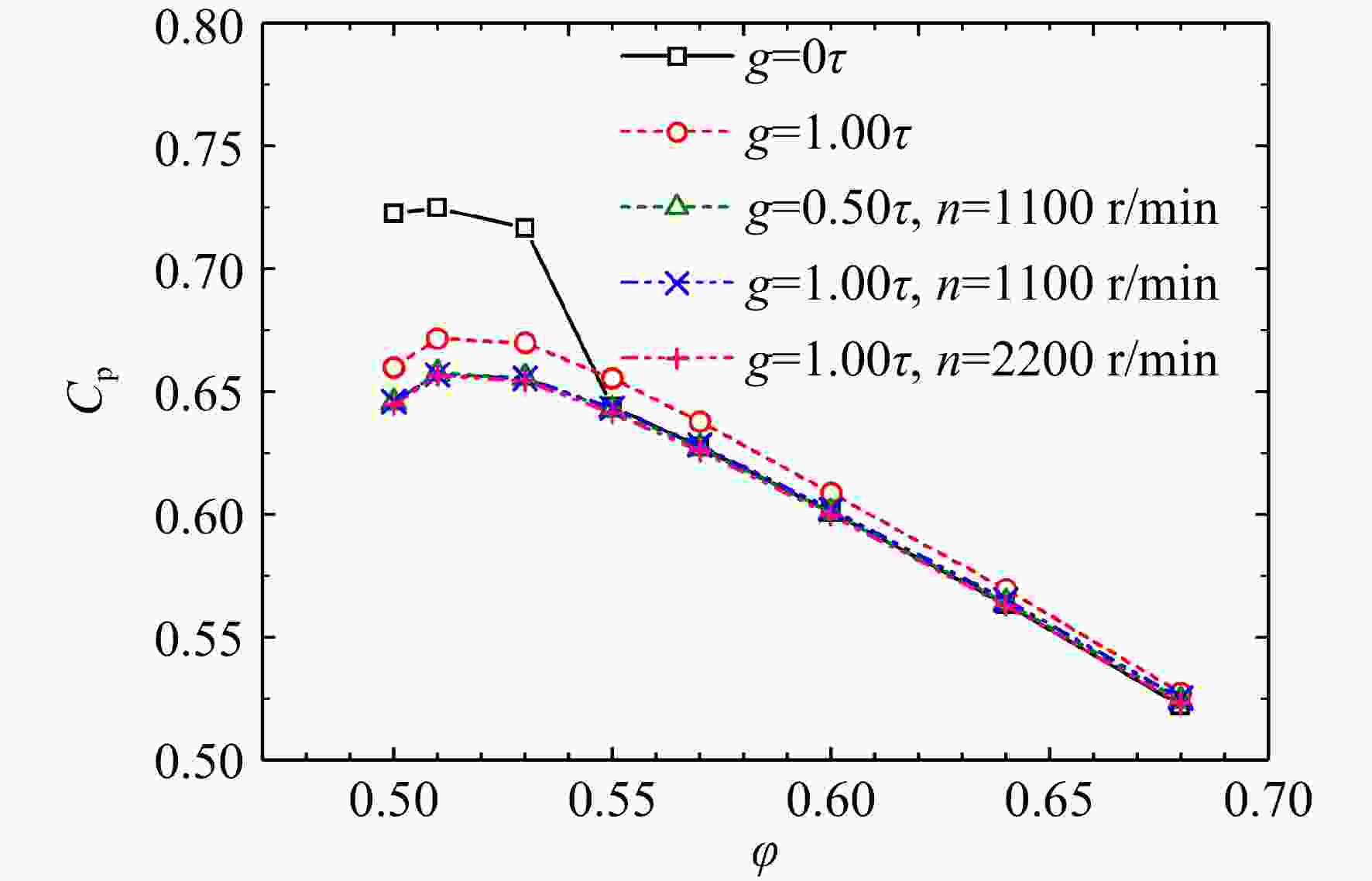

为了探究端壁移动对悬臂静子性能的影响,对轮毂移动与否、轮毂移动速度大小以及移动轮毂情况下间隙大小对某一低速轴流压气机悬臂静子内部流动及压气机性能的影响进行了详细的研究。结果表明,随着端壁移动速度的增加或者端壁移动情况下叶根间隙的减小,静子近轮毂区域的流动堵塞/流动损失减小、压气机性能得到提升,造成这一现象的主要原因是端壁移动情况下二次流的消失以及参与掺混的泄漏流流量的减小;端壁移动也会影响静子进口流场,进而影响转子的特性,但相对于对静子特性的影响,转子特性的变化幅值较小。

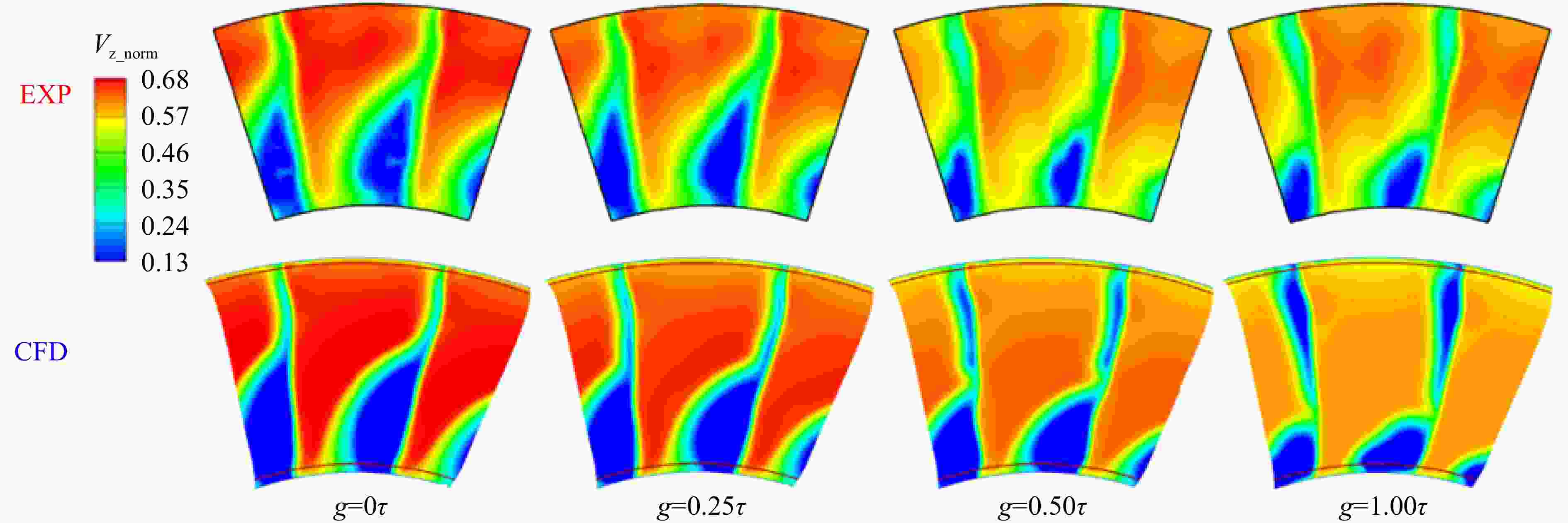

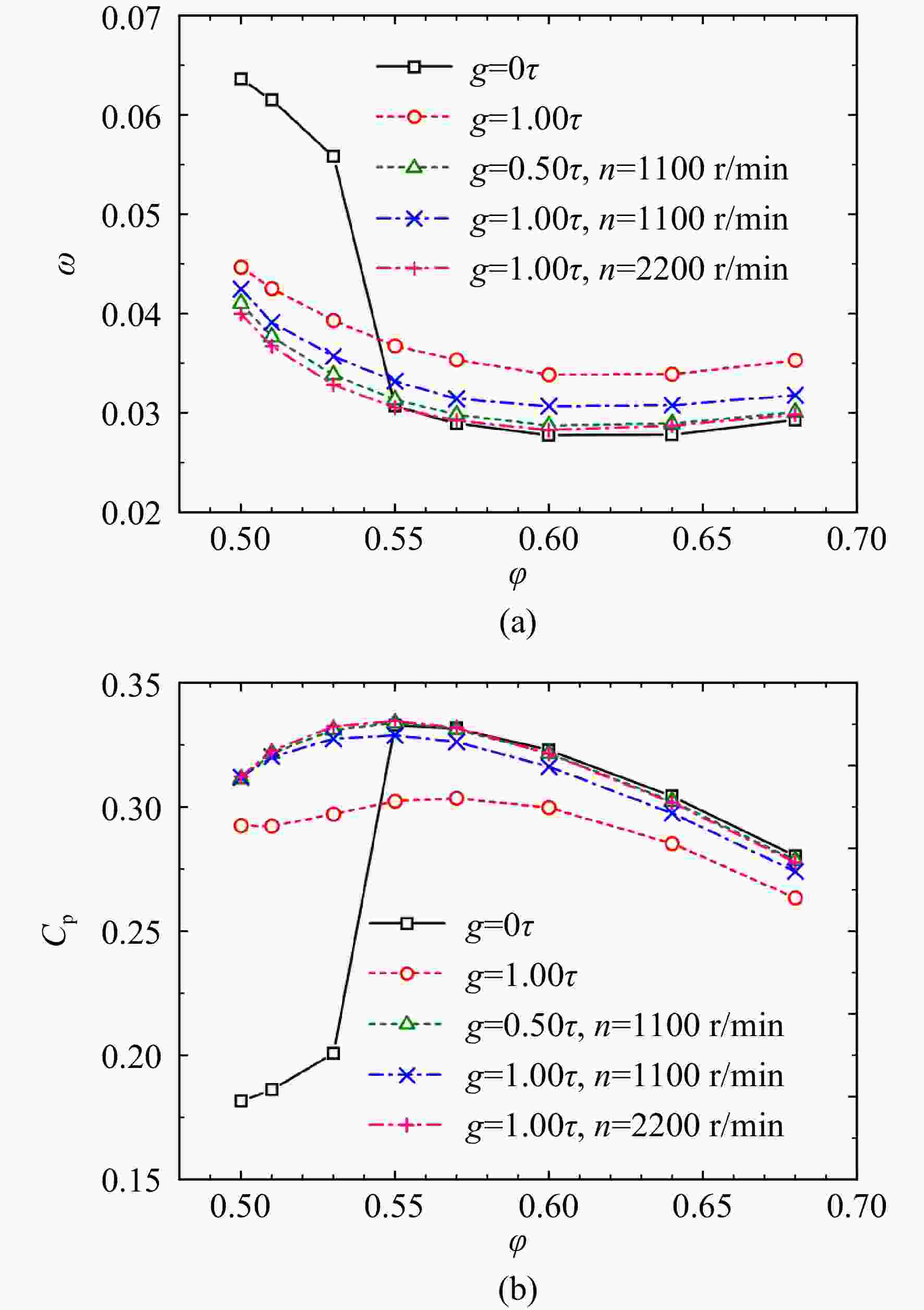

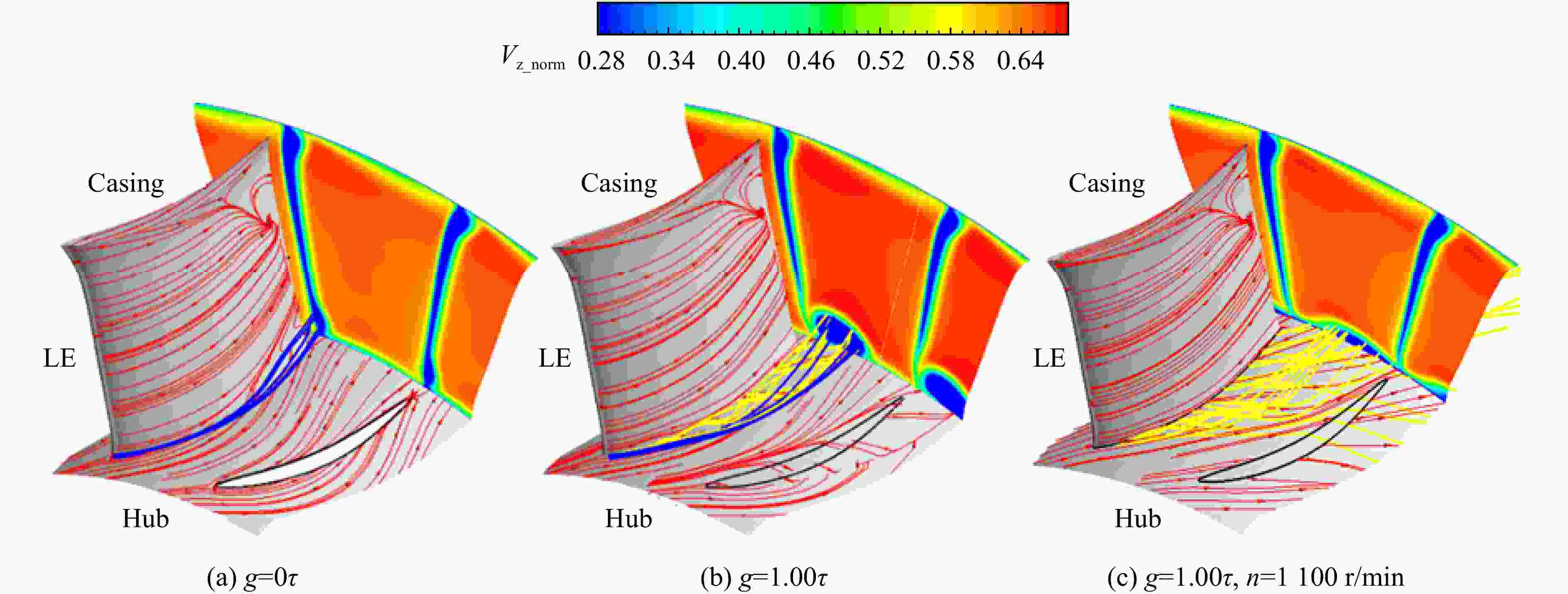

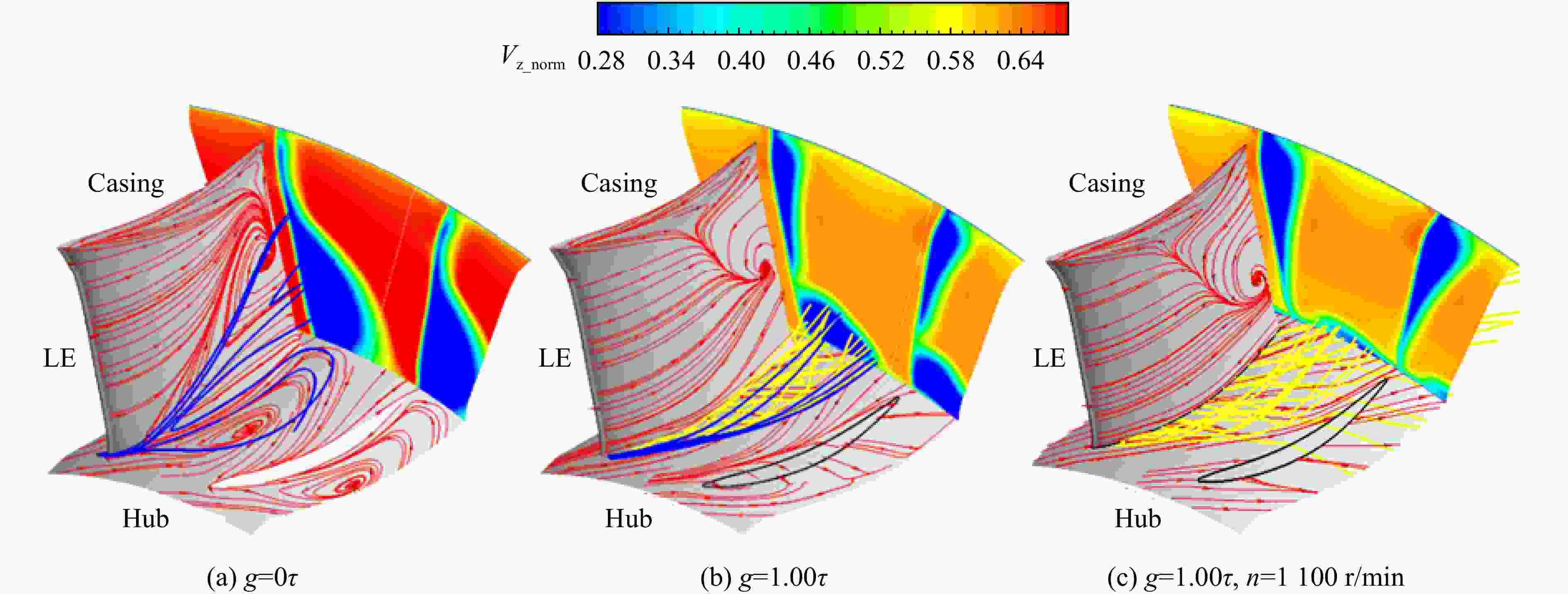

Abstract:To explore the impact of endwall movement on the performance of cantilevered stators, the effects of hub movement, hub movement speed and the gap size of cantilevered stators on the internal flow and performance of a low-speed axial compressor were researched in detail. The results showed the flow blockage/loss of hub area was reduced and the compressor performance was improved with the increase of the endwall movement speed or the decrease of the gap size in case of endwall movement. This phenomenon was mainly attributable to the disappearance of the secondary flow and the reduction of the leakage flow involved in the mixing. The endwall movement also affected the inlet flow field of the cantilevered stators, which in turn affected the characteristics of the rotor. However, compared with the effect on the characteristics of the stator, the change amplitude of the rotor characteristics was relatively small.

-

Key words:

- endwall movement /

- cantilevered stators /

- aerodynamic performance /

- leakage flow /

- axial flow compressor

-

表 1 算例设置

Table 1. Cases settings

悬臂静子端壁

转速n/ (r/min)静子间隙g 0 0τ, 0.25τ, 0.50τ, 1.00τ, 2.00τ 1100 0.50τ, 1.00τ 2200 1.00τ -

[1] DEAN R C. Secondary flow in axial compressors[D]. Cambridge,US: Massachusetts Institute of Technology,1954. [2] LAKSHMINARAYANA B,HORLOCK J H. Tip-clearance flow and losses for an isolated compressor blade[R]. London,UK: Aeronautical Research Council London,1963. [3] LAKSHMINARAYANA B,HORLOCK H. Leakage and secondary flows in compressor cascades[R]. Richmond,UK: HM Stationery Office,1967. [4] LAKSHMINARAYANA B. Methods of predicting the tip clearance effects in axial flow turbomachinery[J]. Journal of Basic Engineering,1970,92(3): 467-480. doi: 10.1115/1.3425036 [5] SINGH U K,GINDER R B. The effect of hub leakage flow in a transonic compressor stator[C]//Proceedings of ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition. Stockholm,Sweden: American Society of Mechanical Engineers,1998: 1-11. [6] LEE C Y,SONG J,LEE S,et al. Effect of a gap between inner casing and stator blade on axial compressor performance[C]//Proceedings of ASME Turbo Expo 2010: Power for Land,Sea,and Air. Glasgow,UK: American Society of Mechanical Engineers,2010: 203-210. [7] GEORGE K K,AGNIMITRA SUNKARA S N,GEORGE J T,et al. Investigations on stator hub end losses and its control in an axial flow compressor[C]//Proceedings of ASME Turbo Expo 2014: Turbine Technical Conference and Exposition. Düsseldorf,Germany: American Society of Mechanical Engineers,2014: 1-11. [8] GBADEBO S A,CUMPSTY N A,HYNES T P. Interaction of tip clearance flow and three-dimensional separations in axial compressors[J]. Journal of Turbomachinery,2007,129(4): 679-685. doi: 10.1115/1.2720876 [9] DONG Y,GALLIMORE S J,HODSON H P. Three-dimensional flows and loss reduction in axial compressors[J]. Journal of Turbomachinery,1987,109(3): 354-361. doi: 10.1115/1.3262113 [10] PEACOCK R E. A review of turbomachinery tip gap effects: Part 1 cascades[J]. International Journal of Heat and Fluid Flow,1982,3(4): 185-193. doi: 10.1016/0142-727X(82)90017-0 [11] SAKULKAEW S,TAN C S,DONAHOO E,et al. Compressor efficiency variation with rotor tip gap from vanishing to large clearance[J]. Journal of Turbomachinery,2013,135(3): 031030. doi: 10.1115/1.4007547 [12] 吴艳辉,楚武利,刘志伟. 移动壁对压气机叶栅间隙流动的影响[J]. 航空动力学报,2006,21(1): 112-118. WU Yanhui,CHU Wuli,LIU Zhiwei. Influence of moving end-wall on tip clearance flow in an axial-flow compressor cascade[J]. Journal of Aerospace Power,2006,21(1): 112-118. (in Chinese WU Yanhui, CHU Wuli, LIU Zhiwei . Influence of moving end-wall on tip clearance flow in an axial-flow compressor cascade[J]. Journal of Aerospace Power,2006 ,21 (1 ):112 -118 . (in Chinese)[13] 贾希诚,王正明,蔡睿贤. 叶轮机械中叶顶间隙形态对气动性能影响的数值研究[J]. 工程热物理学报,2001,22(4): 431-434. JIA Xicheng,WANG Zhengming,CAI Ruixian. Numerical investigation of the effects of tip gap shapes on aerodynamic performance in turbomachinery[J]. Journal of Engineering Thermophysics,2001,22(4): 431-434. (in Chinese JIA Xicheng, WANG Zhengming, CAI Ruixian . Numerical investigation of the effects of tip gap shapes on aerodynamic performance in turbomachinery[J]. Journal of Engineering Thermophysics,2001 ,22 (4 ):431 -434 . (in Chinese)[14] 余春华,陆亚钧,李秋实,等. 处理轮毂转速的实验研究[J]. 实验流体力学,2009,23(2): 20-25. YU Chunhua,LU Yajun,LI Qiushi,et al. Experimental investigation on hub treatment rotation speed[J]. Journal of Experiments in Fluid Mechanics,2009,23(2): 20-25. (in Chinese YU Chunhua, LU Yajun, LI Qiushi, et al . Experimental investigation on hub treatment rotation speed[J]. Journal of Experiments in Fluid Mechanics,2009 ,23 (2 ):20 -25 . (in Chinese)[15] YANG C W,LU X G,ZHANG Y F,et al. Numerical investigation of a cantilevered compressor stator at varying clearance sizes[C]//Proceedings of ASME Turbo Expo 2015: Turbine Technical Conference and Exposition. Montreal. Quebec,Canada: American Society of Mechanical Engineers,2015: 1-9. [16] JIANG C,HU J,WANG J Y,et al. The effect of tip clearance and hub rotation on the performance of an axial compressor stator[C]//Proceedings of ASME 2019 Gas Turbine India Conference. Chennai,Tamil Nadu,India: American Society of Mechanical Engineers,2019: 1-11. [17] LIU Baojie,QIU Ying,AN Guangfeng,et al. Experimental investigation of the flow mechanisms and the performance change of a highly loaded axial compressor stage with/without stator hub clearance[J]. Applied Sciences,2019,9(23): 5134-5153. doi: 10.3390/app9235134 [18] YU Xianjun,LIU Baojie. Research on three-dimensional blade designs in an ultra-highly loaded low-speed axial compressor stage: design and numerical investigations[J]. Advances in Mechanical Engineering,2016,8(10): 1-16. [19] LIU Baojie,AN Guangfeng,YU Xianjun. Assessment of curvature correction and reattachment modification into the shear stress transport model within the subsonic axial compressor simulations[J]. Proceedings of the Institution of Mechanical Engineers,Part A: Journal of Power and Energy,2015,229(8): 910-927. [20] CHEN G T. Vortical structures in turbomachinery tip clearance flows[D]. Cambridge,US: Massachusetts Institute of Technology,1991. -

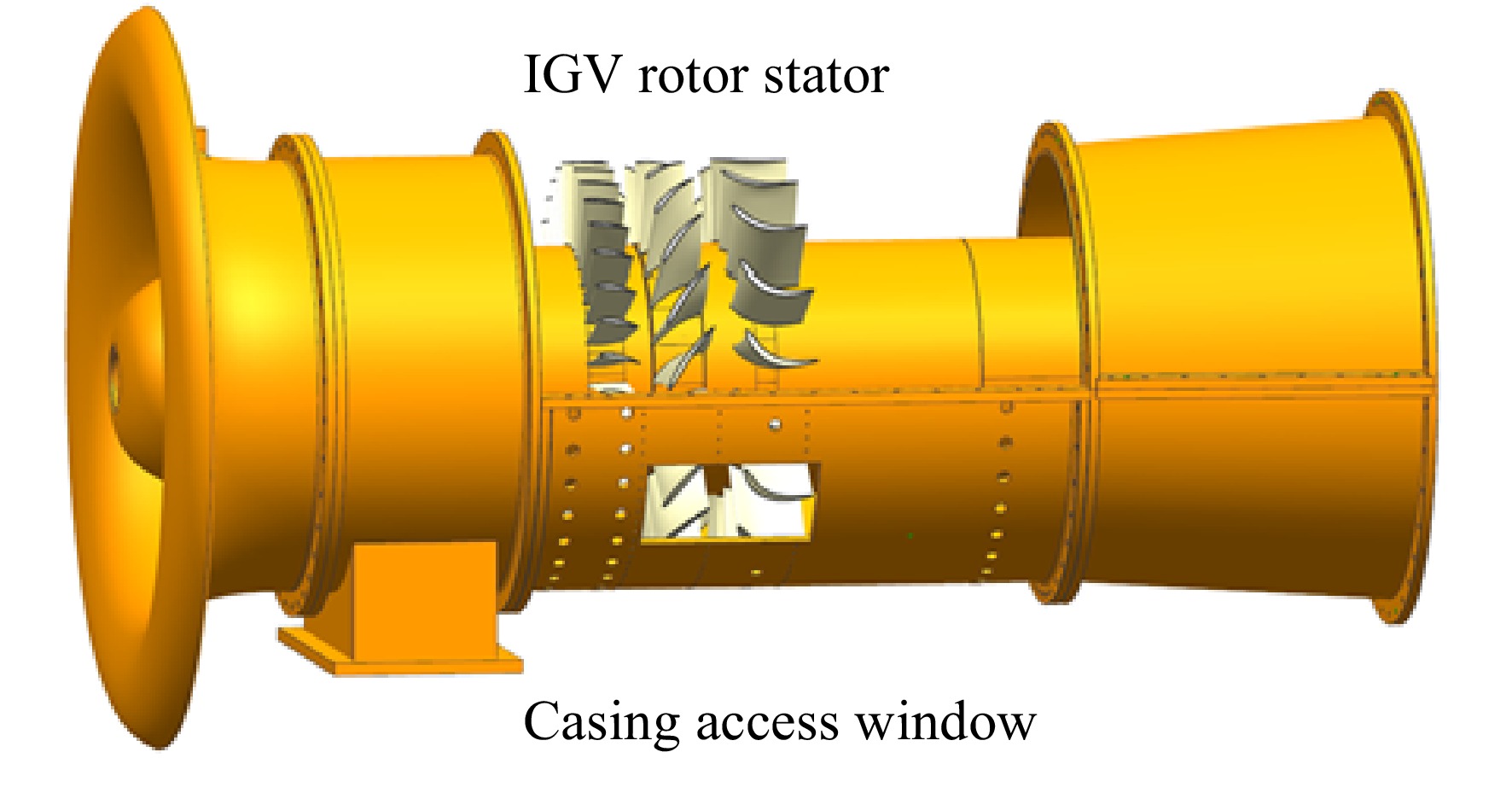

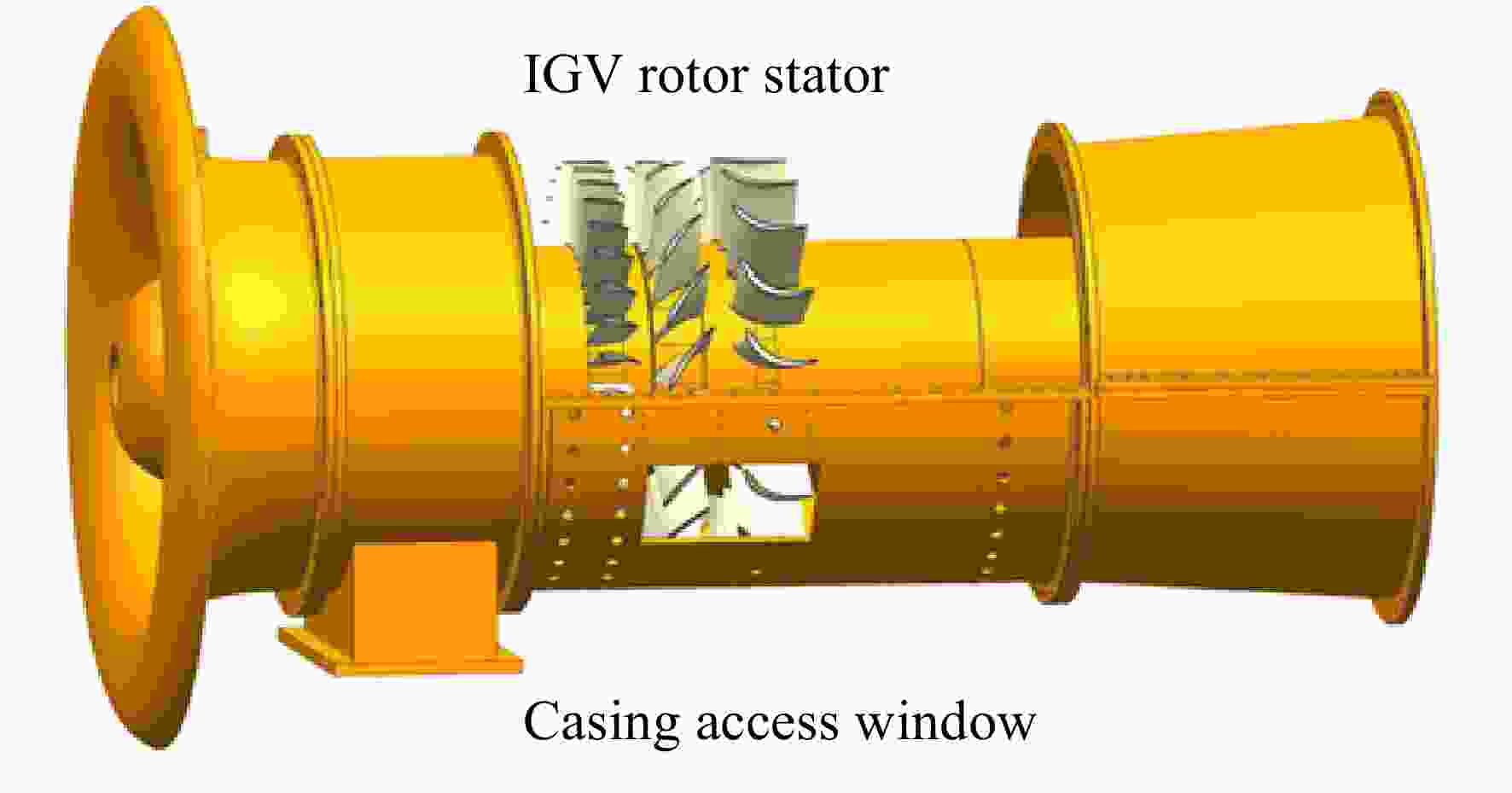

下载:

下载: