Influence of injection position on combustion of multi-component fuel scramjet

-

摘要:

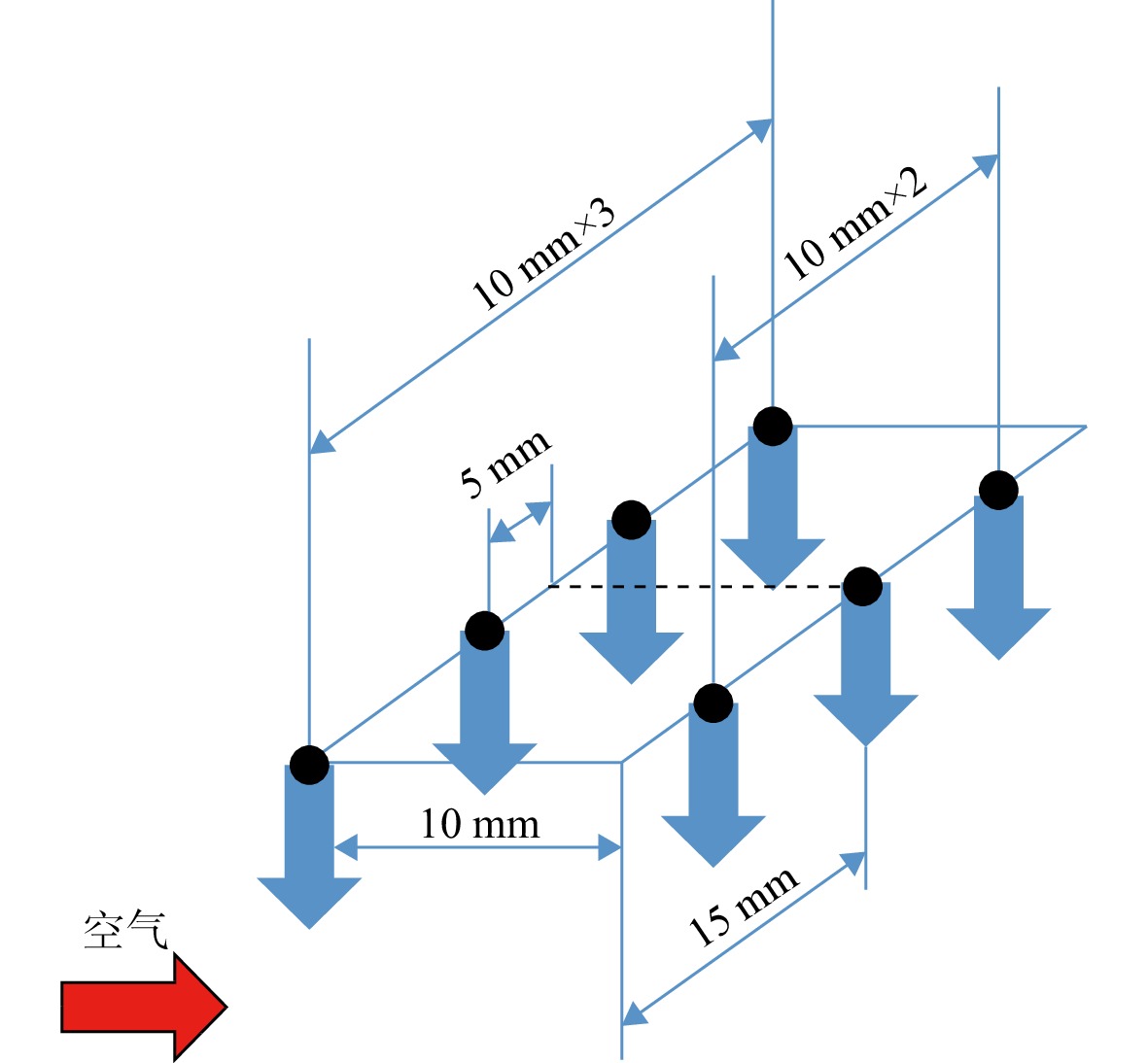

为研究含铝高能量密度碳氢燃料在超燃冲压发动机中的燃烧组织细节,使用离散相模型(DPM)和简化反应机理对不同燃料喷注位置下燃烧流动过程进行了数值模拟。结果表明:使用七喷注器从上壁面进行燃料喷注时,出口截面处温度场形成了以近上壁面轴线为中心低温-升至最高温-降至较低温度的分布特征,氧浓度在中心处的含量也较低,这都将影响燃烧反应的进程。在研究工况下随着喷注器与燃烧室入口距离增大,燃料比冲呈先增大后减小的变化趋势,在研究工况中实现燃料最大比冲11092 m/s,可以通过改变燃料从上壁面喷入燃烧室的喷注位置和优化喷注器布局等提升燃烧室性能,优化后最大比冲提升了12.68%。

Abstract:In order to investigate the details of the combustion organization of aluminum-containing high-energy-density hydrocarbon fuels in scramjet engine, a discrete phase model (DPM) and simplified reaction mechanism were used to numerically simulate the combustion flow process at different fuel injection positions. The results showed that when the seven injectors were used to inject fuel from the upper wall, the exit section formed a temperature distribution near the center of the upper wall from inside to outside, namely, relatively low temperature-warming-up to the highest temperature-cooling down. The lower oxygen concentration of the upper wall near the center area affected the progress of the reaction. Under the research conditions, as the distance between the injector and the inlet of the combustion chamber increased, the fuel specific impulse first increased and then decreased. In the research condition, the maximum specific impulse of fuel was 11092 m/s. The performance of the combustion chamber can be improved by changing the injection position of the fuel injected into the combustion chamber from the upper wall and optimizing the injector layout. After optimization, the maximum specific impulse increased by 12.68%.

-

表 1 C10H16的10组分11步反应机理

Table 1. The 10-component 11-step reaction mechanism of C10H16

编号 反应 1 C10H16+O2→10CH+6H+O2 2 CH+O2→CO+OH 3 CH+O→CO+H 4 2H$\longleftrightarrow $H2 5 H2+O2$\longleftrightarrow $H2O+O 6 H2+O$\longleftrightarrow $H+OH 7 H+O2$\longleftrightarrow $O+OH 8 H2O+O2$\longleftrightarrow $2O+H2O 9 CO+OH$\longleftrightarrow $CO2+H 10 CO+H2O$\longleftrightarrow $CO2+H2 11 CO+H2+O2$\longleftrightarrow $CO2+H2O 表 2 实验入口参数

Table 2. Experimental entrance parameters

马赫数 总温/K 总压/MPa 空气总质量

流率/(kg/s)燃料

当量比$ \varphi $2.0 1700 0.70 0.60 0.73 表 3 两排燃料喷注器与燃烧室入口截面的距离

Table 3. Distance between the two rows of fuel injectors and the entrance section of the combustion chamber

距离/mm 1 2 3 4 5 6 L1 90 110 130 150 170 190 L2 100 120 140 160 180 200 -

[1] GORDON L J,LEE J B. Metals as fuels in multicomponent propellants[J]. ARS Journal,1962,32(4): 600-606. doi: 10.2514/8.6078 [2] YOUNG G. Metallic nanoparticles as fuel additives in airbreathing combustion[D]. Washington: University of Maryland,2007. [3] PALASZEWSKI B,JURNS J,BREISACHER K,et al. Metallized gelled propellants combustion experiments in a pulse detonation engine[R]. AIAA 2004-4191,2004. [4] MORDOSKY J,ZHANG B,KUO K,et al. Spray combustion of gelled RP-1 propellants containing nano-sized aluminum particles in rocket engine conditions[R]. AIAA 2001-3274,2021. [5] LUO Yu,XU Xu,ZOU Jijun,et al. Combustion of JP-10-based slurry with nanosized aluminum additives[J]. Journal of Propulsion and Power,2016,32(5): 1167-1177. doi: 10.2514/1.B35969 [6] 邵昂,朱韶华,鄂秀天凤,等. 含铝金属化浆体推进剂火箭发动机燃烧性能试验研究[J]. 推进技术,2018,39(7): 1650-1659. SHAO Ang,ZHU Shaohua,E Xiutianfeng,et al. Experimental study on combustion characteristic of rocket engine based on slurry propellant containing aluminum particles[J]. Journal of Propulsion Technology,2018,39(7): 1650-1659. (in ChineseSHAO Ang, ZHU Shaohua, E Xiutianfeng, et al. Experimental study on combustion characteristic of rocket engine based on slurry propellant containing aluminum particles[J]. Journal of Propulsion Technology, 2018, 39(7): 1650-1659. (in Chinese) [7] 台经华,卓长飞,蒋显松,等. 粉末/液体燃料组合发动机燃烧性能数值研究[J]. 兵器装备工程学报,2020,41(11): 134-140. TAI Jinghua,ZHUO Changfei,JIANG Xiansong,et al. Numerical simulation investigation on combustion performance of powder/liquid fuel combined ramjet[J]. Journal of Ordnance Equipment Engineering,2020,41(11): 134-140. (in ChineseTAI Jinghua, ZHUO Changfei, JIANG Xiansong, et al. Numerical simulation investigation on combustion performance of powder/liquid fuel combined ramjet[J]. Journal of Ordnance Equipment Engineering, 2020, 41(11): 134-140. (in Chinese) [8] 鄂秀天凤. 基于亲油性纳米颗粒的高密度悬浮燃料研究[D]. 天津: 天津大学,2015. E Xiutianfeng. High-density suspension fuels containing oil-dispersable nanoparticles[D]. Tianjin: Tianjin University,2015. (in ChineseE Xiutianfeng. High-density suspension fuels containing oil-dispersable nanoparticles[D]. Tianjin: Tianjin University, 2015. (in Chinese) [9] 鄂秀天凤,彭浩,邹吉军,等. 含有纳米铝颗粒的高密度悬浮燃料研究[J]. 推进技术,2016,37(5): 974-978. E Xiutianfeng,PENG Hao,ZOU Jijun,et al. Study on Al NPs-containing suspension as high-density liquid fuel[J]. Journal of Propulsion Technology,2016,37(5): 974-978. (in ChineseE Xiutianfeng, PENG Hao, ZOU Jijun, et al. Study on Al NPs-containing suspension as high-density liquid fuel[J]. Journal of Propulsion Technology, 2016, 37(5): 974-978. (in Chinese) [10] 鄂秀天凤,张磊,谢君健,等. 添加纳米铝的高密度悬浮燃料点火性能[J]. 含能材料,2018,26(4): 290-296. E Xiutianfeng,ZHANG Lei,XIE Junjian,et al. Ignition performance of high-density suspension fuel of adding Al NPs[J]. Chinese Journal of Energetic Materials,2018,26(4): 290-296. (in ChineseE Xiutianfeng, ZHANG Lei, XIE Junjian, et al. Ignition performance of high-density suspension fuel of adding Al NPs[J]. Chinese Journal of Energetic Materials, 2018, 26(4): 290-296. (in Chinese) [11] E Xiutianfeng,PAN Lun,WANG Fang,et al. Al-nanoparticle-containing nanofluid fuel: synthesis,stability,properties,and propulsion performance[J]. Industrial & Engineering Chemistry Research,2016,55(10): 2738-2745. [12] E Xiutianfeng,ZHI Xiaomin,ZHANG Yamin,et al. Jet fuel containing ligand-protecting energetic nanoparticles: a case study of boron in JP-10[J]. Chemical Engineering Science,2015,129: 9-13. doi: 10.1016/j.ces.2015.02.018 [13] E Xiutianfeng,ZHI Xiaomin,ZHANG Xiangwen,et al. Ignition and combustion performances of high-energy-density jet fuels catalyzed by Pt and Pd nanoparticles[J]. Energy & Fuels,2018,32(2): 2163-2169. [14] 刘毅,鄂秀天凤,李智欣,等. 高能量密度液体燃料的火箭发动机燃烧性能研究[J]. 推进技术,2019,40(5): 1169-1176. LIU Yi,E Xiutianfeng,LI Zhixin,et al. Study on combustion performance of high-energy-density liquid fuels in rocket engine[J]. Journal of Propulsion Technology,2019,40(5): 1169-1176. (in ChineseLIU Yi, E Xiutianfeng, LI Zhixin, et al. Study on combustion performance of high-energy-density liquid fuels in rocket engine[J]. Journal of Propulsion Technology, 2019, 40(5): 1169-1176. (in Chinese) [15] JIN Yushu,DOU Suyi,YANG Qingchun,et al. Performance characteristics of a scramjet engine using JP-10 fuel containing aluminum nanoparticles[J]. Acta Astronautica,2021,185: 70-77. doi: 10.1016/j.actaastro.2021.04.044 [16] 吴先宇,李小山,丁猛,等. 超燃冲压发动机燃烧室构型对燃烧室性能影响[J]. 推进技术,2008,29(3): 300-305. WU Xianyu,LI Xiaoshan,DING Meng,et al. Effects of scramjet combustor configuration on combustor performance[J]. Journal of Propulsion Technology,2008,29(3): 300-305. (in ChineseWU Xianyu, LI Xiaoshan, DING Meng, et al. Effects of scramjet combustor configuration on combustor performance[J]. Journal of Propulsion Technology, 2008, 29(3): 300-305. (in Chinese) [17] 邓维鑫. 宽范围马赫数超燃冲压发动机燃烧组织技术研究[D]. 成都: 西南交通大学,2013. DENG Weixin. Research on combustion organizing technology of scramjet in wide range Mach number[D]. Chengdu: Southwest Jiaotong University,2013. (in ChineseDENG Weixin. Research on combustion organizing technology of scramjet in wide range Mach number[D]. Chengdu: Southwest Jiaotong University, 2013. (in Chinese) [18] 李凡,汪洪波,孙明波,等. 两种优化组合式燃料喷注方案的凹腔稳焰特性实验研究[J]. 固体火箭技术,2021,44(2): 152-159. LI Fan,WANG Hongbo,SUN Mingbo,et al. Experiments on flame stabilization of two combined fuel injection schemes in a cavity-based combustor[J]. Journal of Solid Rocket Technology,2021,44(2): 152-159. (in ChineseLI Fan, WANG Hongbo, SUN Mingbo, et al. Experiments on flame stabilization of two combined fuel injection schemes in a cavity-based combustor[J]. Journal of Solid Rocket Technology, 2021, 44(2): 152-159. (in Chinese) [19] ECKER T,KARL S,HANNEMANN K. Modeling of aluminum particle combustion in solid rocket combustion chambers[R]. AIAA 2017-4781,2017. [20] CATOIRE L,LEGENDRE J F,GIRAUD M. Kinetic model for aluminum-sensitized ram accelerator combustion[J]. Journal of Propulsion and Power,2003,19(2): 196-202. doi: 10.2514/2.6118 [21] LIU Bing,HE G,QIN F,et al. Simulation of kerosene fueled RBCC Engine based on skeletal mechanism[R]. AIAA 2017-2288,2017. [22] WANG T S. Thermophysics characterization of kerosene combustion[J]. Journal of Thermophysics and Heat Transfer,2001,15(2): 140-147. doi: 10.2514/2.6602 [23] JIA Boqi,FU Qingfei,XU Xu,et al. Spray characteristics of Al-nanoparticle-containing nanofluid fuel in a self-excited oscillation injector[J]. Fuel,2021,290: 120057. doi: 10.1016/j.fuel.2020.120057 [24] 王绍卿. 组合发动机多种燃料和多种氧化剂的当量比计算法[J]. 推进技术,1992,13(3): 41-46,40. WANG Shaoqing. Calculation methods on equivelence ratio of multi-propellant for propulsion system[J]. Journal of Propulsion Technology,1992,13(3): 41-46,40. (in ChineseWANG Shaoqing. Calculation methods on equivelence ratio of multi-propellant for propulsion system[J]. Journal of Propulsion Technology, 1992, 13(3): 41-46, 40. (in Chinese) -

下载:

下载: