Supersonic and transonic airfoil optimization design based on superimposing thickness on suction surface

-

摘要:

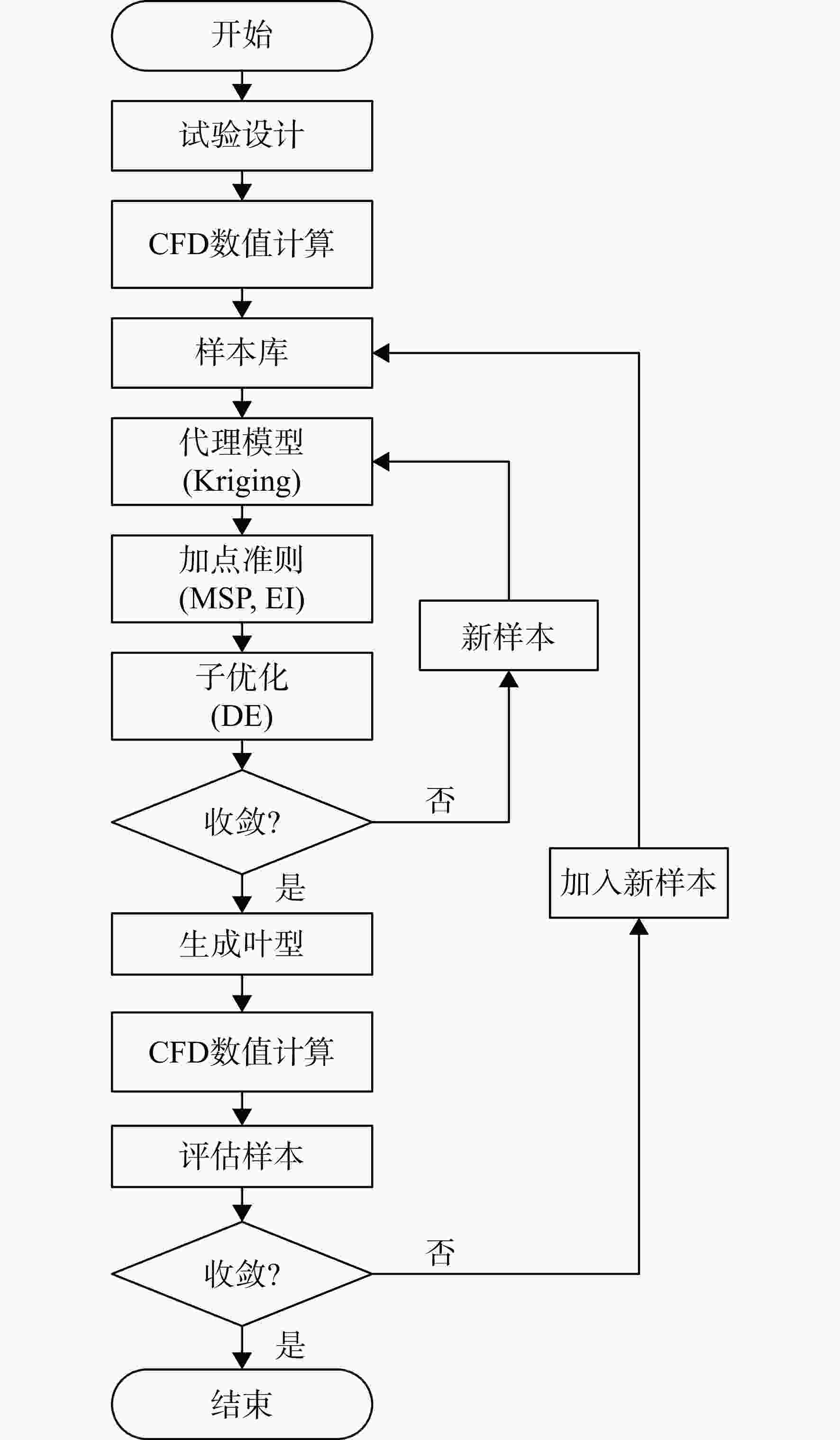

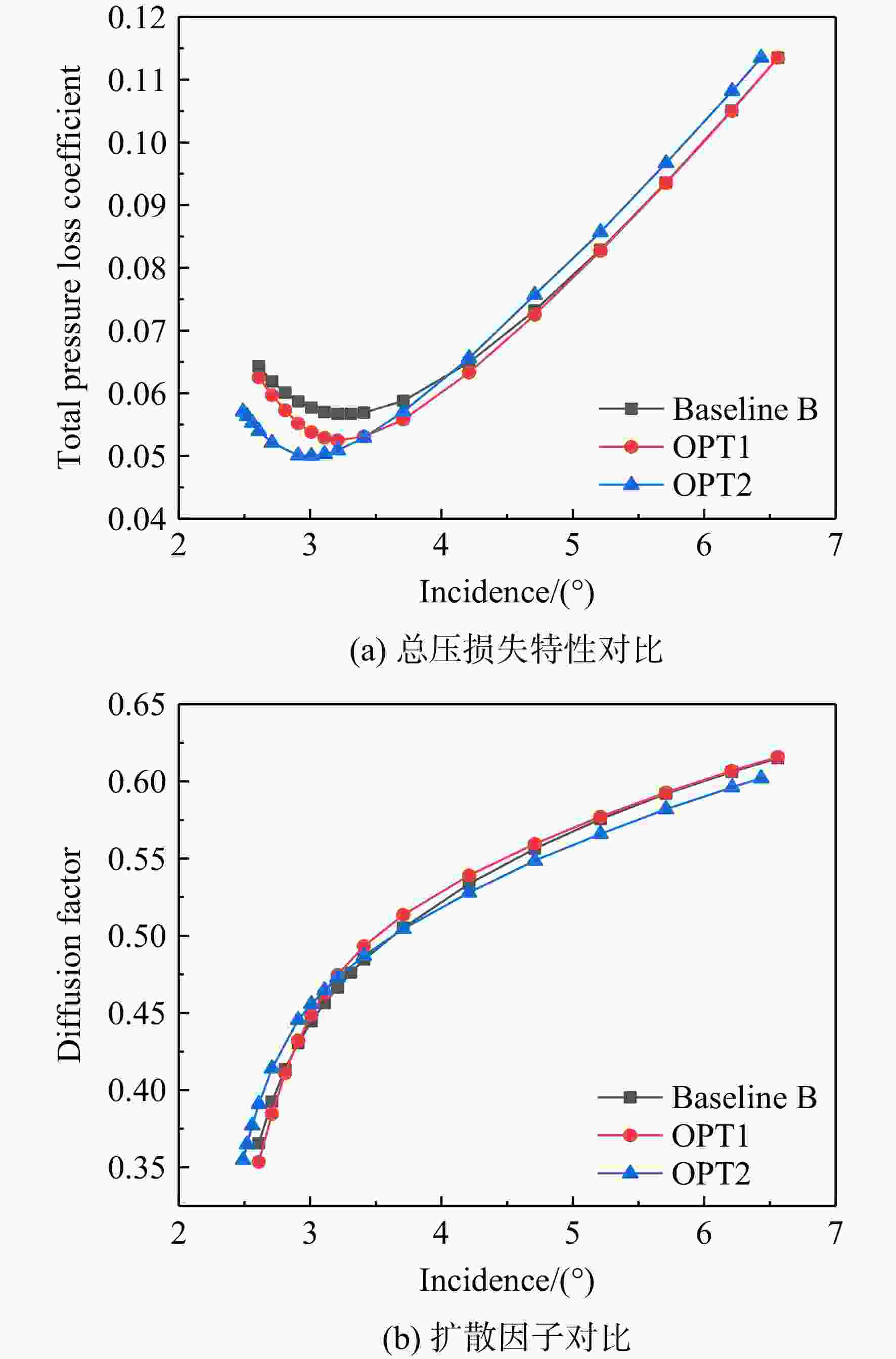

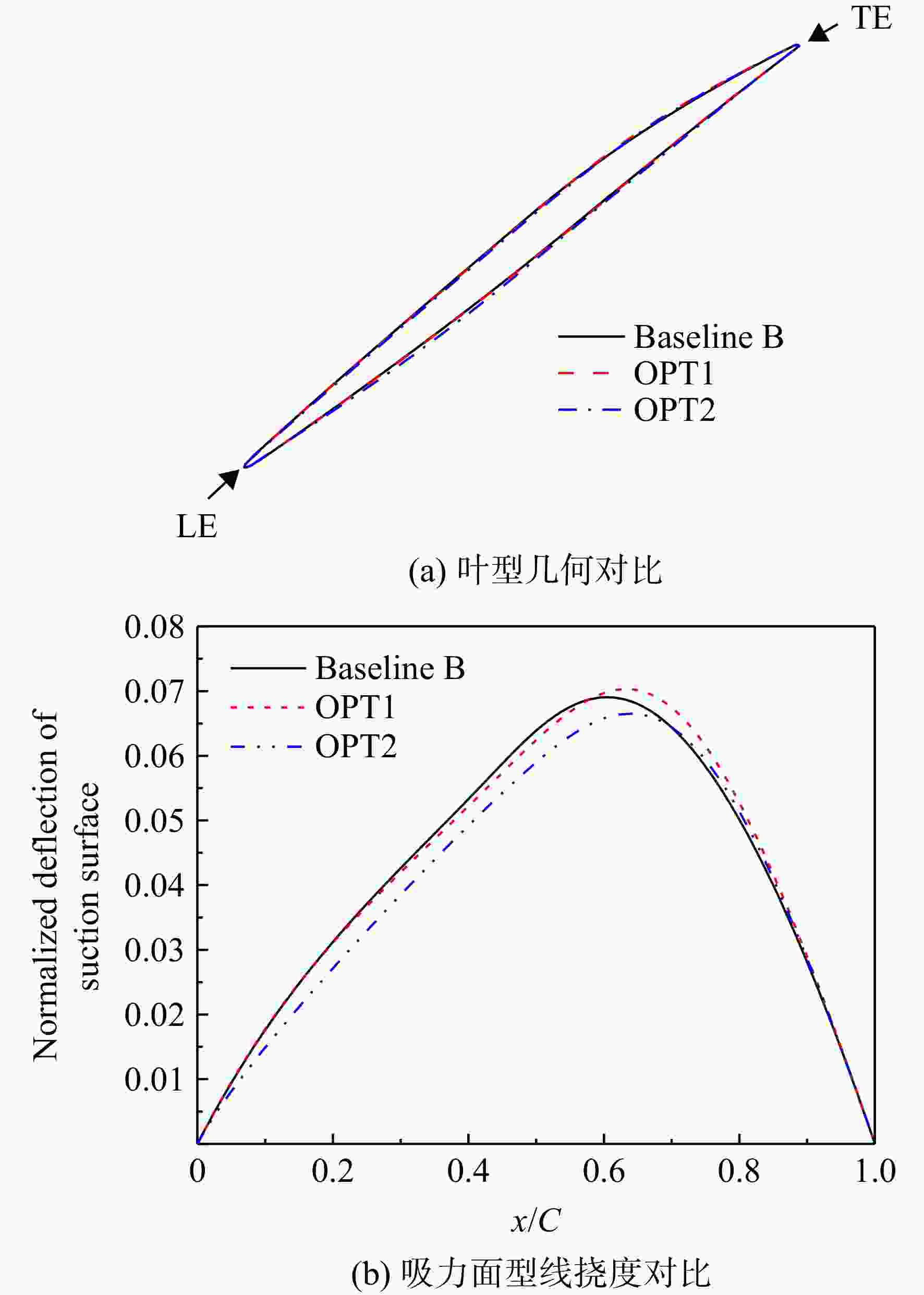

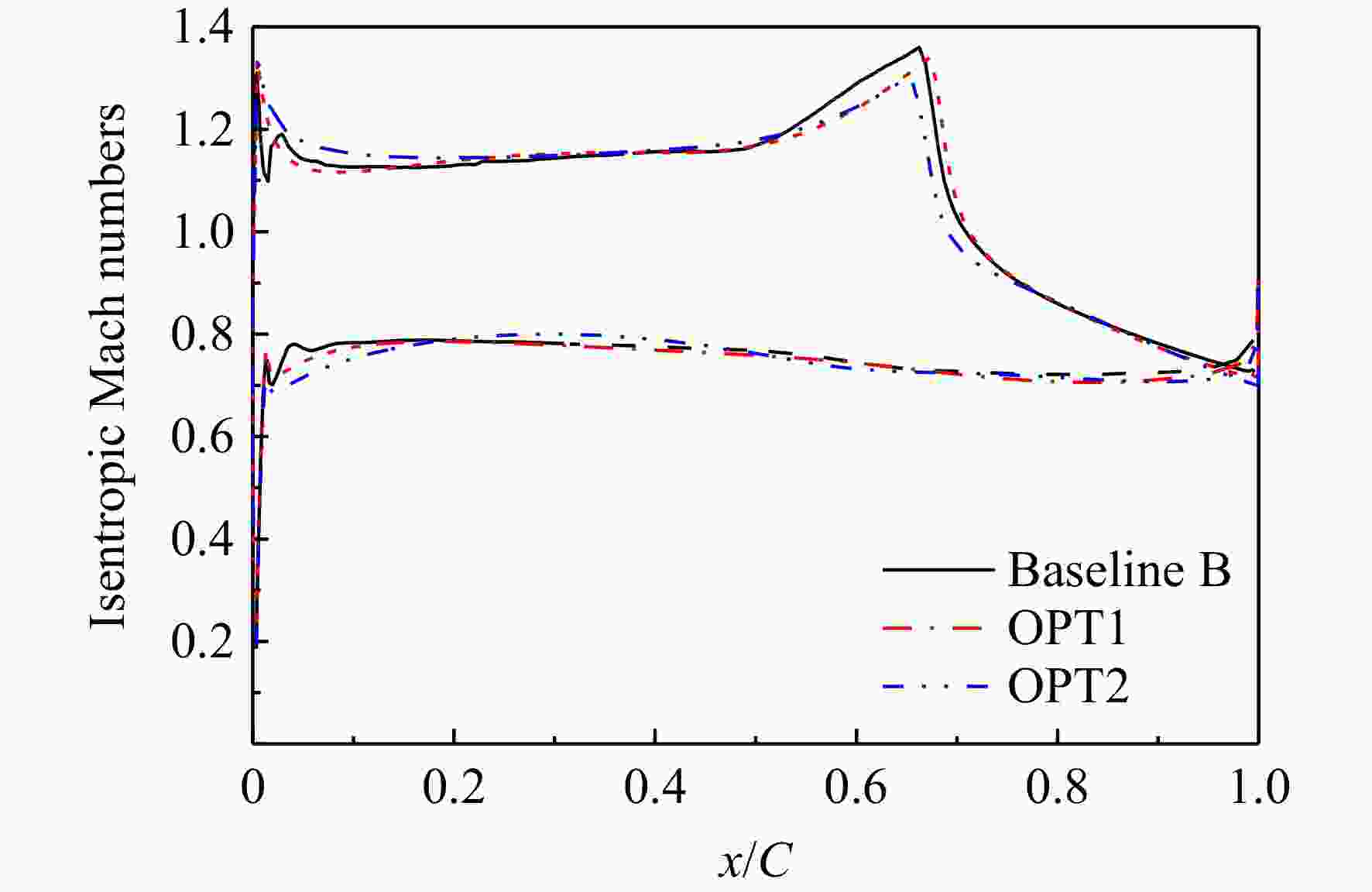

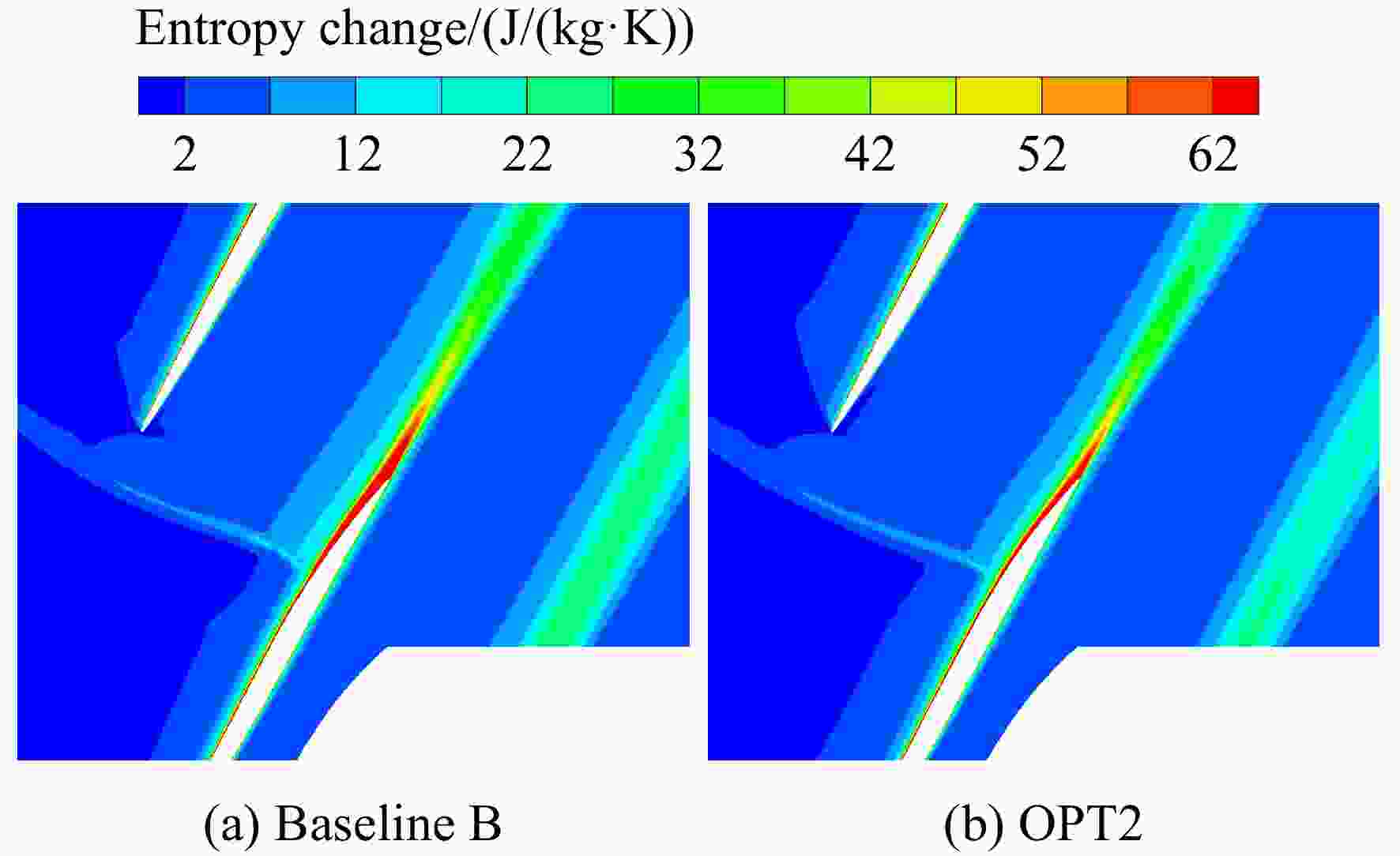

为提高轴流压气机叶型优化设计水平,提出了一种基于吸力面叠加厚度分布的参数化造型方法,结合基于Kriging代理模型与差分进化的代理优化方法开发了一套优化设计平台,并将吸力面控制参数作为优化变量,对某跨声与超声叶型进行性能优化。结果表明:基于吸力面叠加厚度分布的叶片造型方法能对叶型进行较好的表达,并成功应用在优化设计平台中。跨声、超声优化叶型在设计点损失分别降低了10.66%与7.4%。分析表明:跨声优化叶型的主要特征是吸力面型线前缘附近型线弯度降低,使得激波强度降低,激波损失与边界层损失降低,同时中后部位置处的负荷增大,扩张通道扩压能力增强;超声叶型优化由于边界层影响更显著,因此还需要更多考虑吸力面扩张通道区域型线;叶型喉部位置与喉部宽度会影响堵塞冲角的变化。

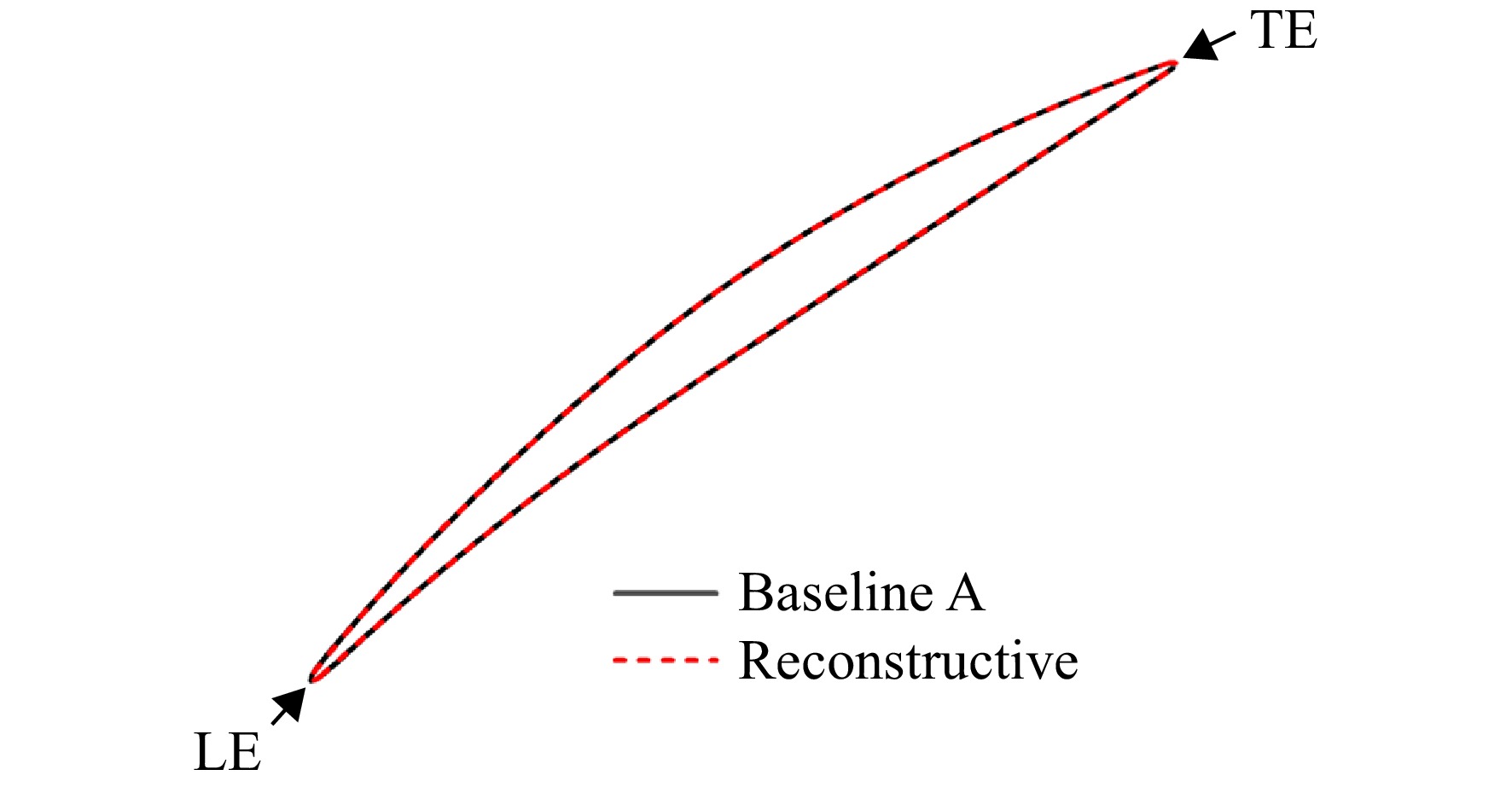

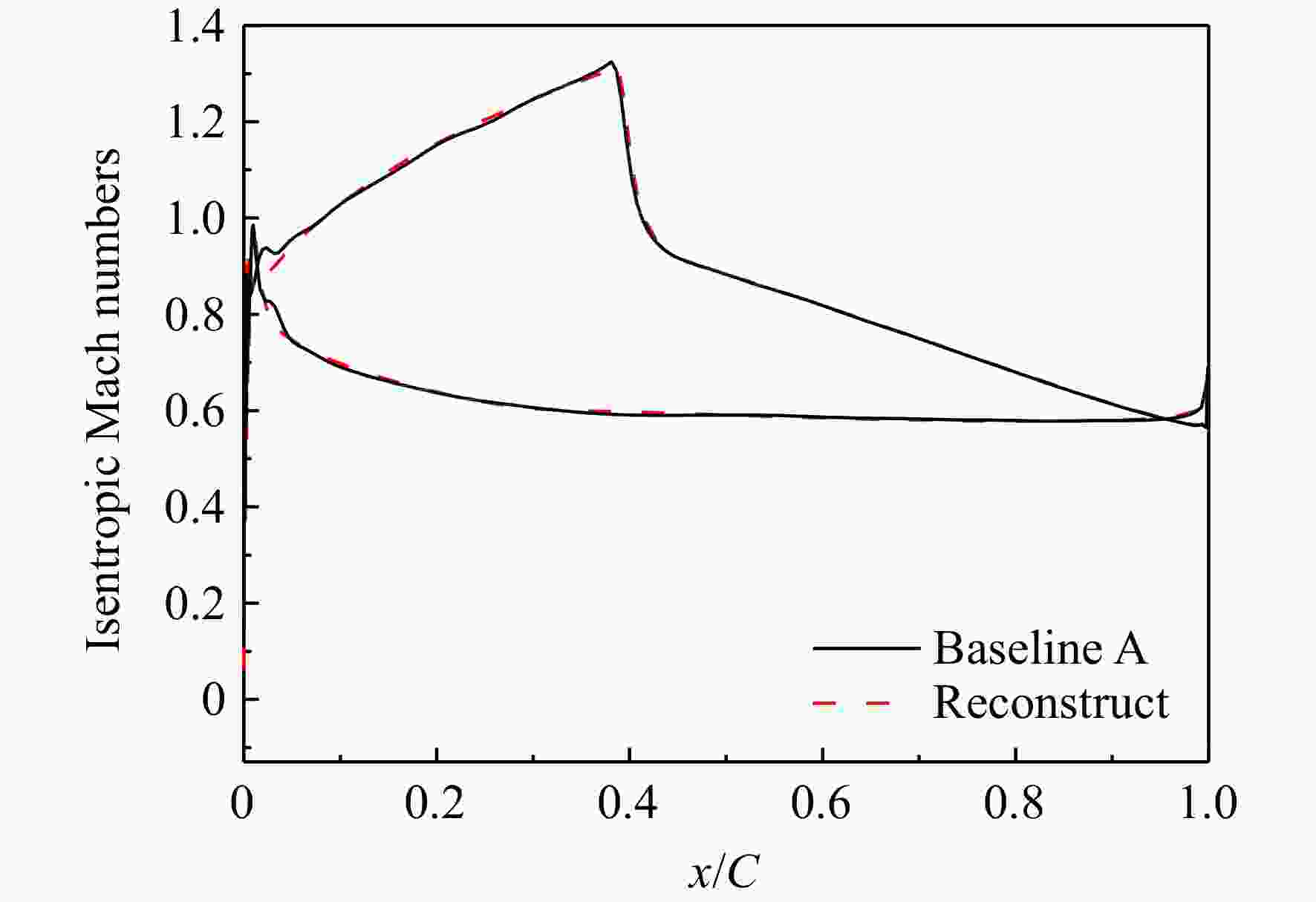

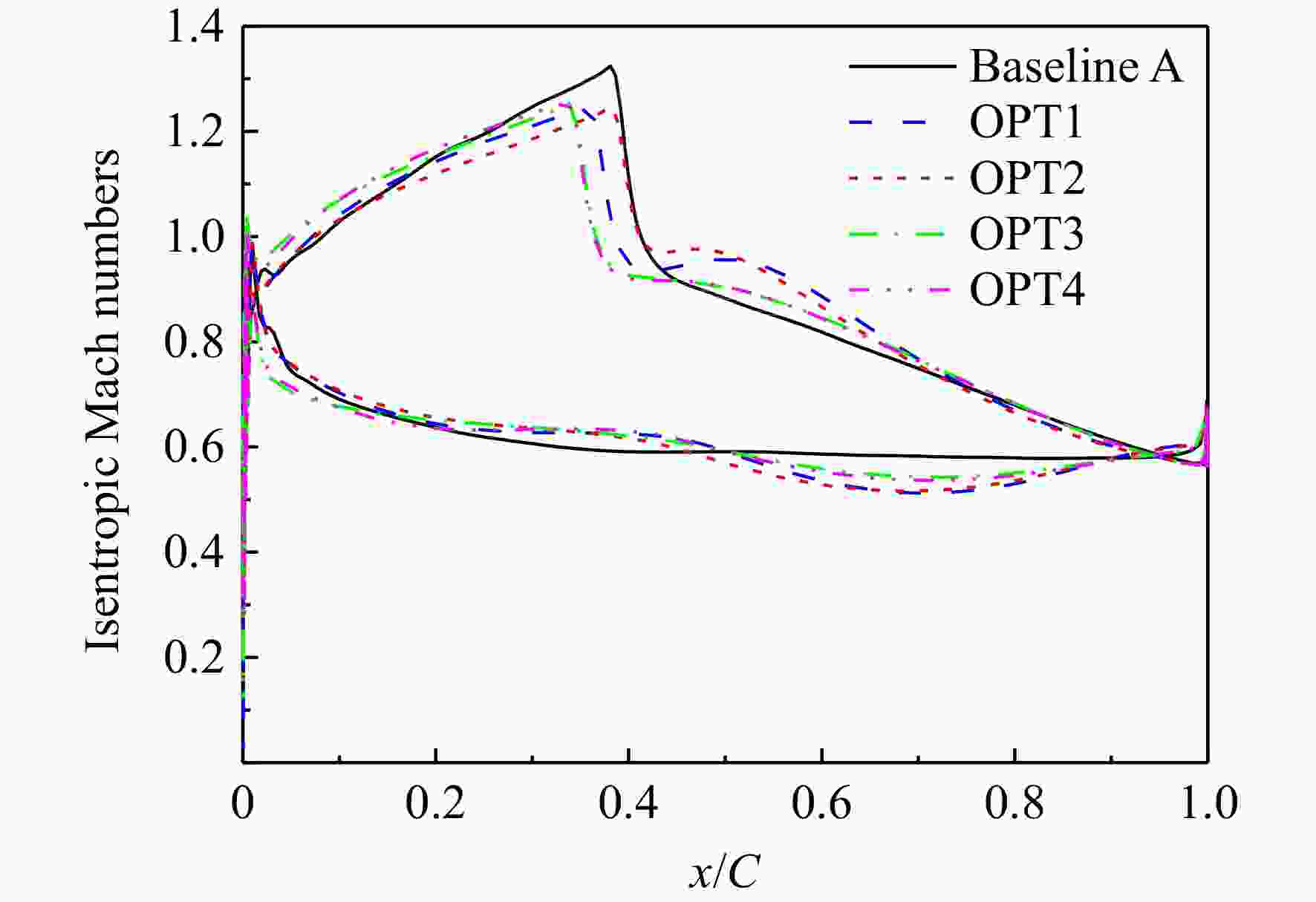

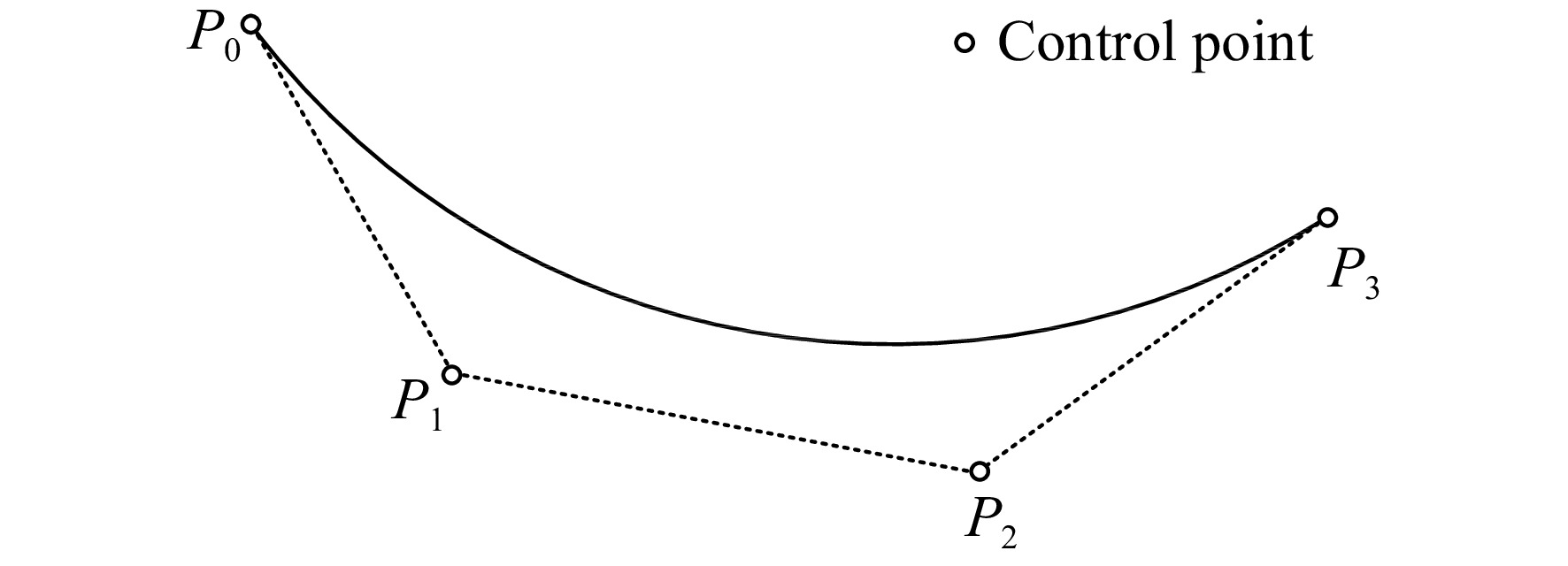

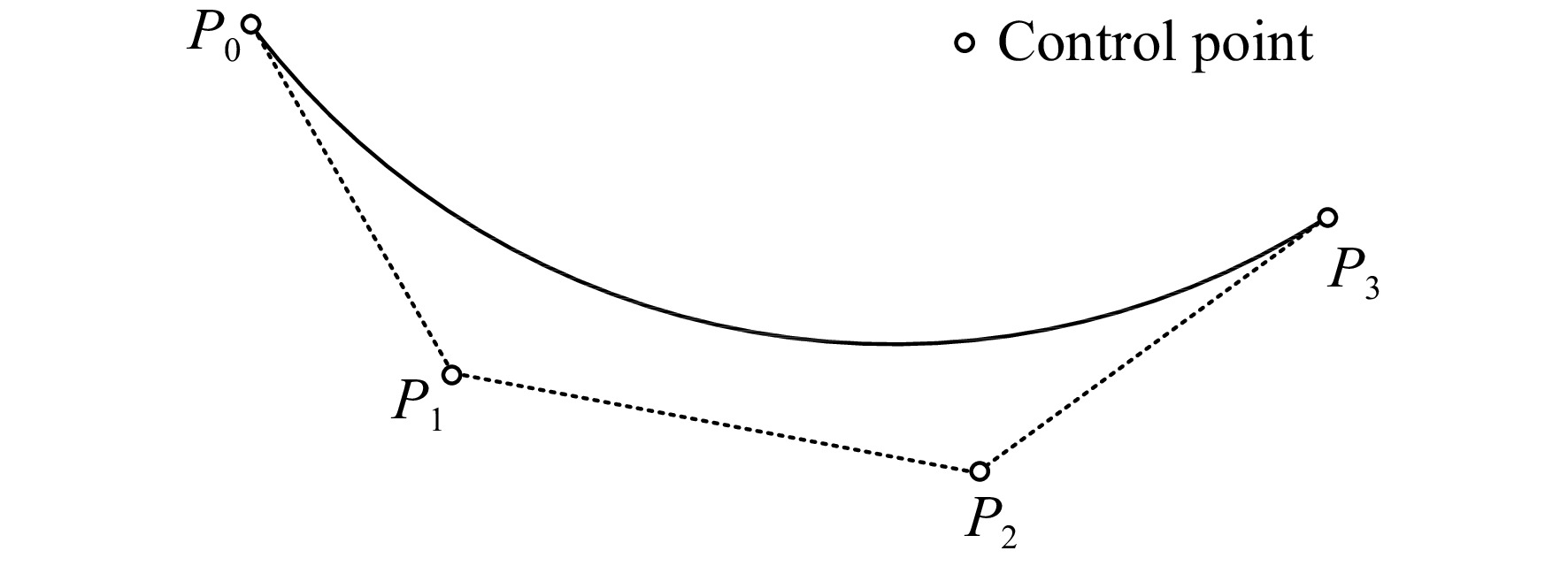

Abstract:To improve the optimization design quality of axial compressor airfoil, the parametric modeling method based on superimposing thickness on suction surface was proposed. The compressor airfoil optimization platform based on Kriging surrogate model and Differential Evolution algorithms was developed, and the control parameters of the suction surface were used as optimization variables to optimize the performance of transonic and supersonic airfoils. The results showed that the parametric modeling method based on superposing thickness distribution on suction surface can express the airfoil well and was successfully applied to the optimization design platform. The loss of optimized transonic and supersonic airfoils at design condition decreased by 10.66 % and 7.4%, respectively. The analysis showed that as for the main characteristics of optimized transonic airfoil, the curvature of the profile near the leading edge of suction surface decreased, and the shock wave intensity decreased. Therefore, the shock wave loss and boundary layer loss decreased, the load at the middle and rear positions increased and the expansion capacity of the expansion channel increased. The optimization of supersonic airfoil should consider the profile of suction surface within the aft expansion passage additionally, because of more significant boundary layer influence. The position and width of throat can affect the chocking incidence angle.

-

表 1 DFVLR叶型设计参数

Table 1. Design parameters of the DFVLR cascade

设计参数 数值 安装角/(°) 48.51 弦长/mm 90 叶型弯角/(°) 14.9 稠度 1.610 设计进口马赫数 1.09 设计进气角/(°) 58.5 表 2 原始叶型设计参数

Table 2. Design parameters of the baseline

参数 叶型A 叶型B 设计进口马赫数 0.95 1.08 设计冲角/(°) −0.81 3.21 安装角/(°) 44.3 59.7 叶型弯角/(°) 21.3 6.7 弦长/mm 291 291 稠度 1.31 1.04 Re/106 5.3 6.02 表 3 叶型A和重构叶型气动参数对比

Table 3. Comparisons of aerodynamic parameters between baseline A and reconstructive airfoil

参数 叶型A 重构叶型 相对误差/% 设计进口马赫数 0.95 0.95 0 设计冲角/(°) −0.81 −0.81 0 总压损失系数 0.0366 0.0373 1.9 气流折转角/(°) 12.97 13.00 0.2 静压比 1.442 1.442 0 表 4 叶型优化参数值及其变化范围

Table 4. Optimized parameter values and variation ranges

参数 叶型A 叶型B 原型参数值 变化下限 变化上限 原型参数值 变化下限 变化上限 $ {c_{{\text{b1}}}} $ 0.361 0.3 0.5 0.166 0.08 0.33 ${c_{{\text{b2}}}} $/(°) 4.24 2.29 5.73 2.91 1.15 5.16 $ {c_{{\text{p}}3}} $ 0.456 0.35 0.55 0.529 0.4 0.65 $ {c_{{\text{p}}1}} $ 0.720 0.6 0.78 1.341 0.6 1.4 $ {c_{{\text{p}}2}} $ 0.617 0.5 0.65 0.443 0.35 0.65 $ {c_{{\text{q}}1}} $ 2.0 1 2.1 1 0.75 1.4 表 5 总压损失系数逐步线性回归结果

Table 5. Stepwise linear regression results of total pressure loss coefficient

叶型 参数 系数 显著性 ${R^2}$ $R_{{\text{adj}}}^2$ 叶型A (常数) 0.033 0 0.873 0.859 $ {c_{{\text{b1}}}} $ 0.033 0 $ {c_{{\text{p}}3}} $ −0.015 0 $ {c_{{\text{b2}}}} $ −0.006 0.007 叶型B (常数) 0.063 0 0.711 0.698 $ {c_{{\text{q}}1}} $ −0.009 0 $ {c_{{\text{p}}3}} $ −0.005 0 $ {c_{{\text{p}}2}} $ −0.003 0.001 表 6 扩散因子逐步线性回归结果

Table 6. Stepwise linear regression results of diffusion factor

叶型 参数 系数 显著性 ${R^2}$ $R_{{\text{adj}}}^2$ 叶型A (常数) 0.548 0 0.719 0.689 $ {c_{{\text{b1}}}} $ −0.057 0 $ {c_{{\text{p}}3}} $ 0.045 0 叶型B (常数) 0.407 0 0.708 0.685 $ {c_{{\text{b1}}}} $ 0.049 0 $ {c_{{\text{p}}3}} $ 0.019 0 $ {c_{{\text{p1}}}} $ 0.017 0 $ {c_{{\text{b2}}}} $ 0.058 0 $ {c_{{\text{q}}1}} $ 0.008 0.028 表 7 叶型A与优化叶型的喉部特性与堵塞工况特性对比

Table 7. Comparison of throat and choking condition characteristics between baseline A and optimized airfoils

叶型 喉部位置 喉部宽度 通道扩张比 堵塞工况 堵塞流量/(kg/s) 堵塞冲角/(°) ORI A 0.489 0.610 1.217 43.11 −1.772 OPT1 0.492 0.602 1.241 43.13 −1.791 OPT2 0.487 0.600 1.253 42.90 −1.560 OPT3 0.495 0.611 1.213 43.60 −2.251 OPT4 0.495 0.611 1.214 43.64 −2.292 表 8 叶型B与优化叶型的喉部特性与堵塞工况特性对比

Table 8. Comparison of throat and choking condition characteristics between baseline B and optimized airfoils

叶型 喉部位置 喉部宽度 通道扩张比 堵塞工况 堵塞流量/(kg/s) 堵塞冲角/(°) ORI B 0.751 0.470 1.051 46.67 2.61 OPT1 0.747 0.468 1.054 46.67 2.61 OPT2 0.751 0.469 1.044 46.87 2.49 -

[1] 宋寅. 先进高负荷压气机气动设计技术综述[J]. 分布式能源,2018,3(3): 1-9. SONG Yin. Review on aerodynamics design of advanced highly-loaded compressor[J]. Distributed Energy,2018,3(3): 1-9. (in ChineseSONG Yin. Review on aerodynamics design of advanced highly-loaded compressor[J]. Distributed Energy, 2018, 3(3): 1-9. (in Chinese) [2] KÖLLER U,MÖNIG R,KÜSTERS B,et al. 1999 turbomachinery committee best paper award: development of advanced compressor airfoils for heavy-duty gas turbines: Part Ⅰ design and optimization[J]. Journal of Turbomachinery, 2000, 122(3): 397-405. [3] 徐全勇,阙晓斌,吴锋. 可控扩散叶型的扩稳优化[J]. 航空动力学报,2017,32(7): 1762-1768. XU Quanyong,QUE Xiaobin,WU Feng. Aerodynamic stability optimization of controlled diffusion airfoil[J]. Journal of Aerospace Power,2017,32(7): 1762-1768. (in ChineseXU Quanyong, QUE Xiaobin, WU Feng. Aerodynamic stability optimization of controlled diffusion airfoil[J]. Journal of Aerospace Power, 2017, 32(7): 1762-1768. (in Chinese) [4] SANGER N L. The use of optimization techniques to design-controlled diffusion compressor blading[J]. Journal of Engineering for Power,1983,105(2): 256-264. doi: 10.1115/1.3227410 [5] 周铸,黄江涛,黄勇,等. CFD技术在航空工程领域的应用、挑战与发展[J]. 航空学报,2017,38(3): 020891. ZHOU Zhu,HUANG Jiangtao,HUANG Yong,et al. CFD technology in aeronautic engineering field: Applications,challenges and development[J]. Acta Aeronautica et Astronautica Sinica,2017,38(3): 020891. (in ChineseZHOU Zhu, HUANG Jiangtao, HUANG Yong, et al. CFD technology in aeronautic engineering field: Applications, challenges and development[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(3): 020891. (in Chinese) [6] 高正红,王超. 飞行器气动外形设计方法研究与进展[J]. 空气动力学学报,2017,35(4): 516-528,454. GAO Zhenghong,WANG Chao. Aerodynamic shape design methods for aircraft: Status and trends[J]. Acta Aerodynamica Sinica,2017,35(4): 516-528,454. (in Chinese doi: 10.7638/kqdlxxb-2017.0058GAO Zhenghong, WANG Chao. Aerodynamic shape design methods for aircraft: Status and trends[J]. Acta Aerodynamica Sinica, 2017, 35(4): 516-528, 454. (in Chinese) doi: 10.7638/kqdlxxb-2017.0058 [7] VIANA F A C,SIMPSON T W,BALABANOV V,et al. Special section on multidisciplinary design optimization: Metamodeling in multidisciplinary design optimization: How far have we really come?[J]. AIAA Journal,2014,52(4): 670-690. doi: 10.2514/1.J052375 [8] 韩忠华. Kriging模型及代理优化算法研究进展[J]. 航空学报,2016,37(11): 3197-3225. HAN Zhonghua. Kriging surrogate model and its application to design optimization: A review of recent progress[J]. Acta Aeronautica et Astronautica Sinica,2016,37(11): 3197-3225. (in ChineseHAN Zhonghua. Kriging surrogate model and its application to design optimization: A review of recent progress[J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(11): 3197-3225. (in Chinese) [9] 韩忠华,许晨舟,乔建领,等. 基于代理模型的高效全局气动优化设计方法研究进展[J]. 航空学报,2020,41(5): 623344. HAN Zhonghua,XU Chenzhou,QIAO Jianling,et al. Recent progress of efficient global aerodynamic shape optimization using surrogate-based approach[J]. Acta Aeronautica et Astronautica Sinica,2020,41(5): 623344. (in ChineseHAN Zhonghua, XU Chenzhou, QIAO Jianling, et al. Recent progress of efficient global aerodynamic shape optimization using surrogate-based approach[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(5): 623344. (in Chinese) [10] SIEVERDING F,RIBI B,CASEY M,et al. Design of industrial axial compressor blade sections for optimal range and performance[J]. Journal of Turbomachinery,2004,126(2): 323-331. doi: 10.1115/1.1737782 [11] 阙晓斌,蒋洪德. 重型燃气轮机压气机高雷诺数前转捩叶型设计[J]. 航空动力学报,2013,28(10): 2309-2315. QUE Xiaobin,JIANG Hongde. Design of high Reynolds number compressor airfoil with early transition for heavy-duty gas turbine[J]. Journal of Aerospace Power,2013,28(10): 2309-2315. (in ChineseQUE Xiaobin, JIANG Hongde. Design of high Reynolds number compressor airfoil with early transition for heavy-duty gas turbine[J]. Journal of Aerospace Power, 2013, 28(10): 2309-2315. (in Chinese) [12] CHEN Naixing,ZHANG Hongwu,HUANG Weiguang,et al. Study on aerodynamic design optimization of turbomachinery blades[J]. Journal of Thermal Science,2005,14(4): 298-304. doi: 10.1007/s11630-005-0048-5 [13] 孔庆国,杜旭博,羌晓青,等. 基于中弧线曲率控制的压气机叶型优化[J]. 推进技术,2020,41(8): 1740-1747. KONG Qingguo,DU Xubo,QIANG Xiaoqing,et al. Compressor airfoil optimization based on camber curvature control[J]. Journal of Propulsion Technology,2020,41(8): 1740-1747. (in ChineseKONG Qingguo, DU Xubo, QIANG Xiaoqing, et al. Compressor airfoil optimization based on camber curvature control[J]. Journal of Propulsion Technology, 2020, 41(8): 1740-1747. (in Chinese) [14] 成金鑫,向航,陈江. 基元叶栅攻角特性多目标优化[J]. 航空动力学报,2017,32(12): 3064-3072. CHENG Jinxin,XIANG Hang,CHEN Jiang. Multi-objective optimization of incidence features for cascade[J]. Journal of Aerospace Power,2017,32(12): 3064-3072. (in ChineseCHENG Jinxin, XIANG Hang, CHEN Jiang. Multi-objective optimization of incidence features for cascade[J]. Journal of Aerospace Power, 2017, 32(12): 3064-3072. (in Chinese) [15] SOMMER L,BESTLE D. Curvature driven two-dimensional multi-objective optimization of compressor blade sections[J]. Aerospace Science and Technology,2011,15(4): 334-342. doi: 10.1016/j.ast.2010.08.008 [16] SCHREIBER H A,STARKEN H. Experimental cascade analysis of a transonic compressor rotor blade section[J]. Journal of Engineering for Gas Turbines and Power,1984,106(2): 288-294. doi: 10.1115/1.3239561 [17] HAN Z H,ZHANG K S. Surrogate-based optimization[M]. London,United Kingdom: InTech Book,2012: 343-362. [18] JONES D R,SCHONLAU M,WELCH W J. Efficient global optimization of expensive black-box functions[J]. Journal of Global Optimization,1998,13(4): 455-492. doi: 10.1023/A:1008306431147 -

下载:

下载: