Study on thermal field characteristics of high speed cylindrical roller bearing under ring lubrication

-

摘要:

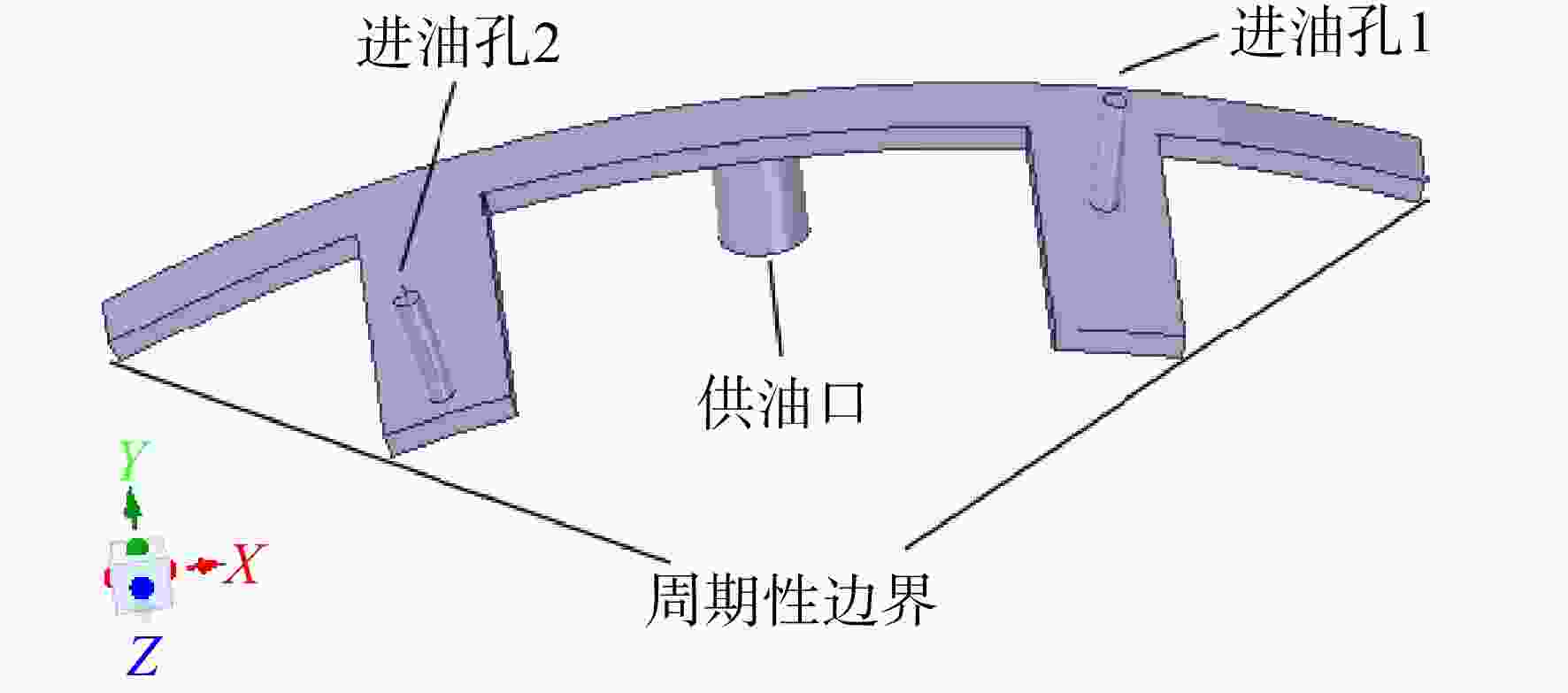

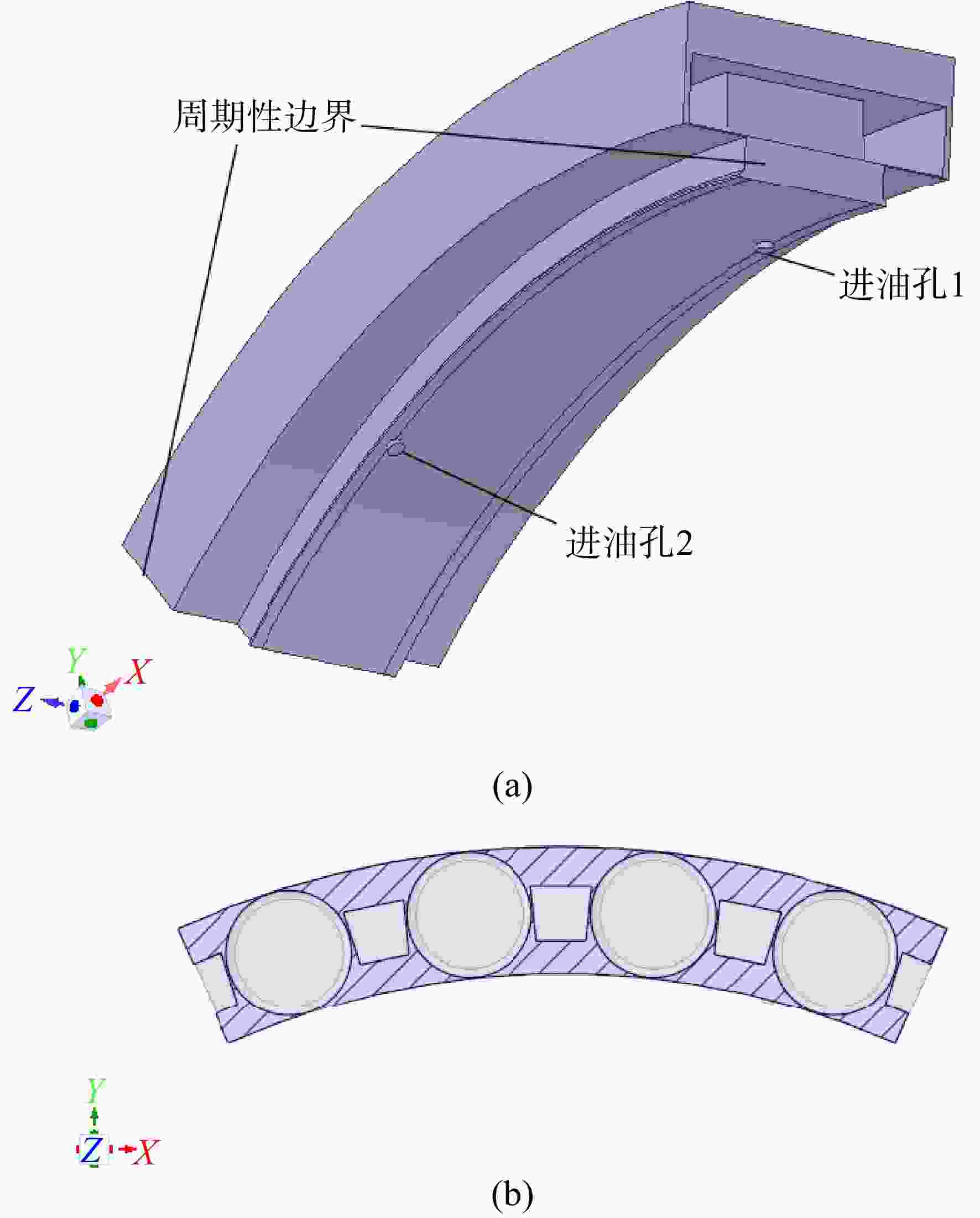

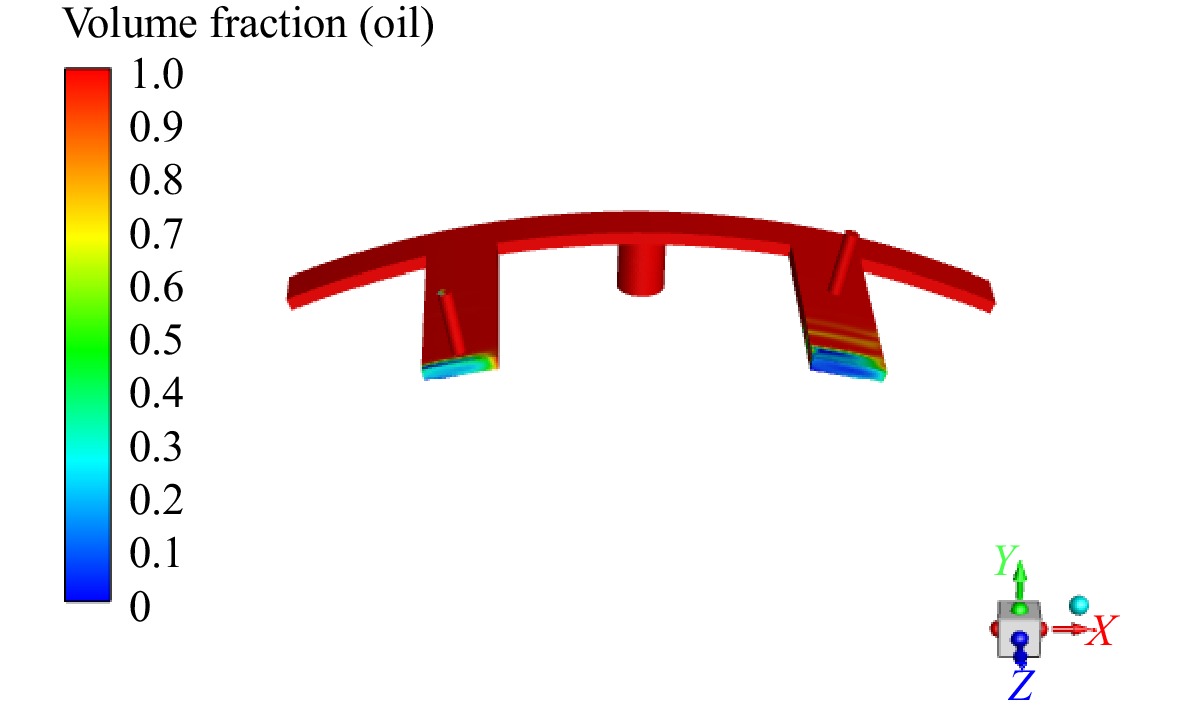

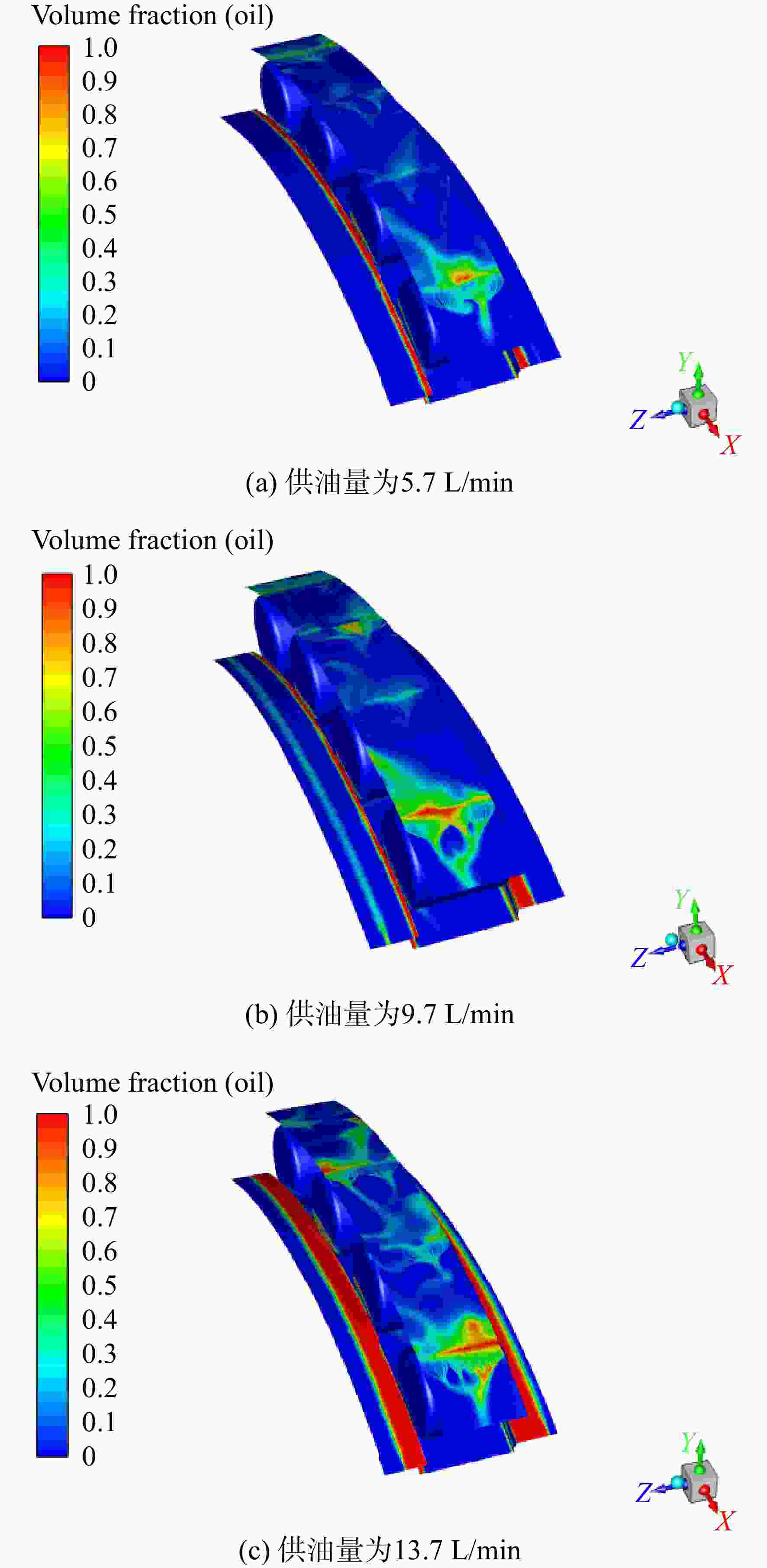

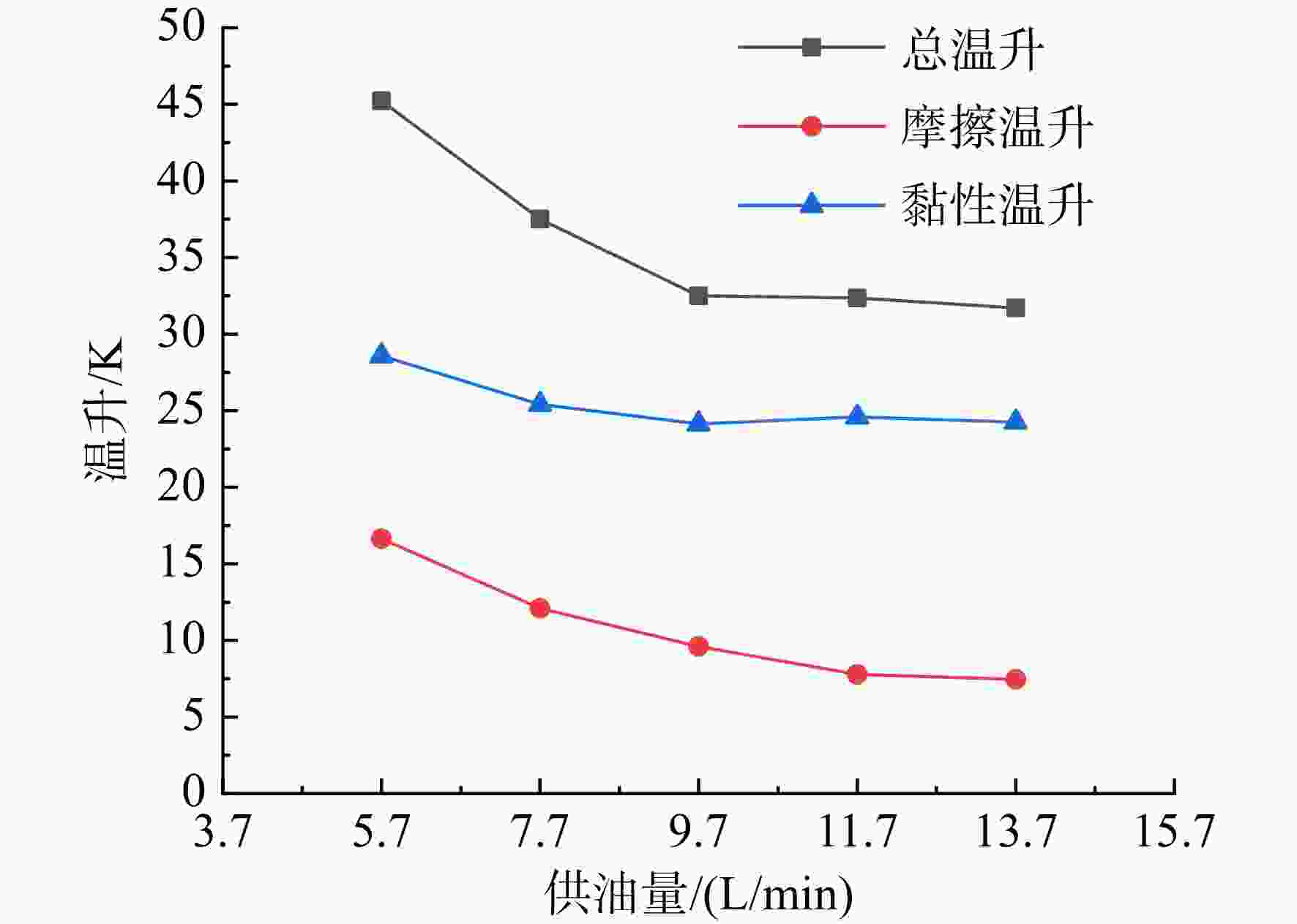

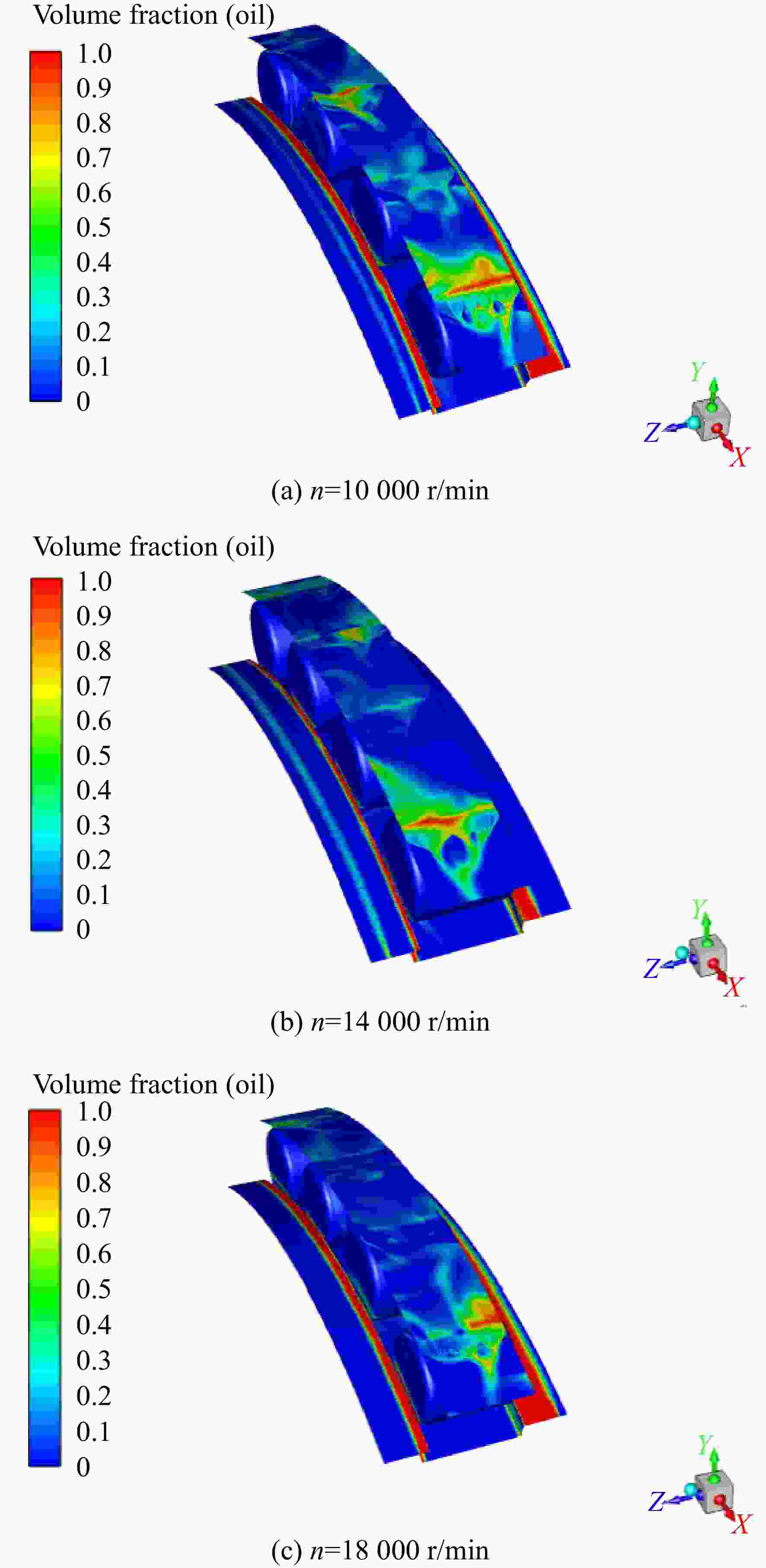

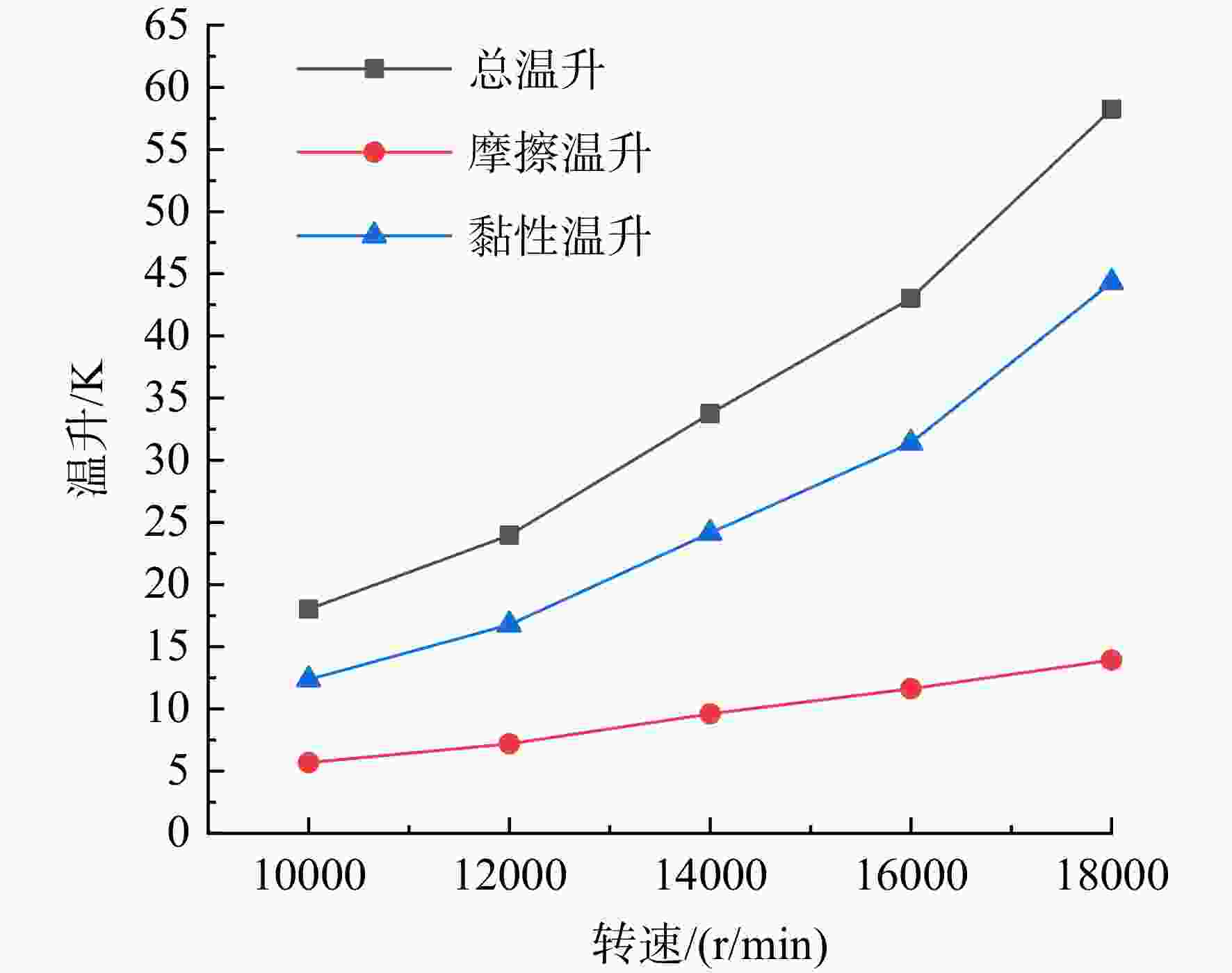

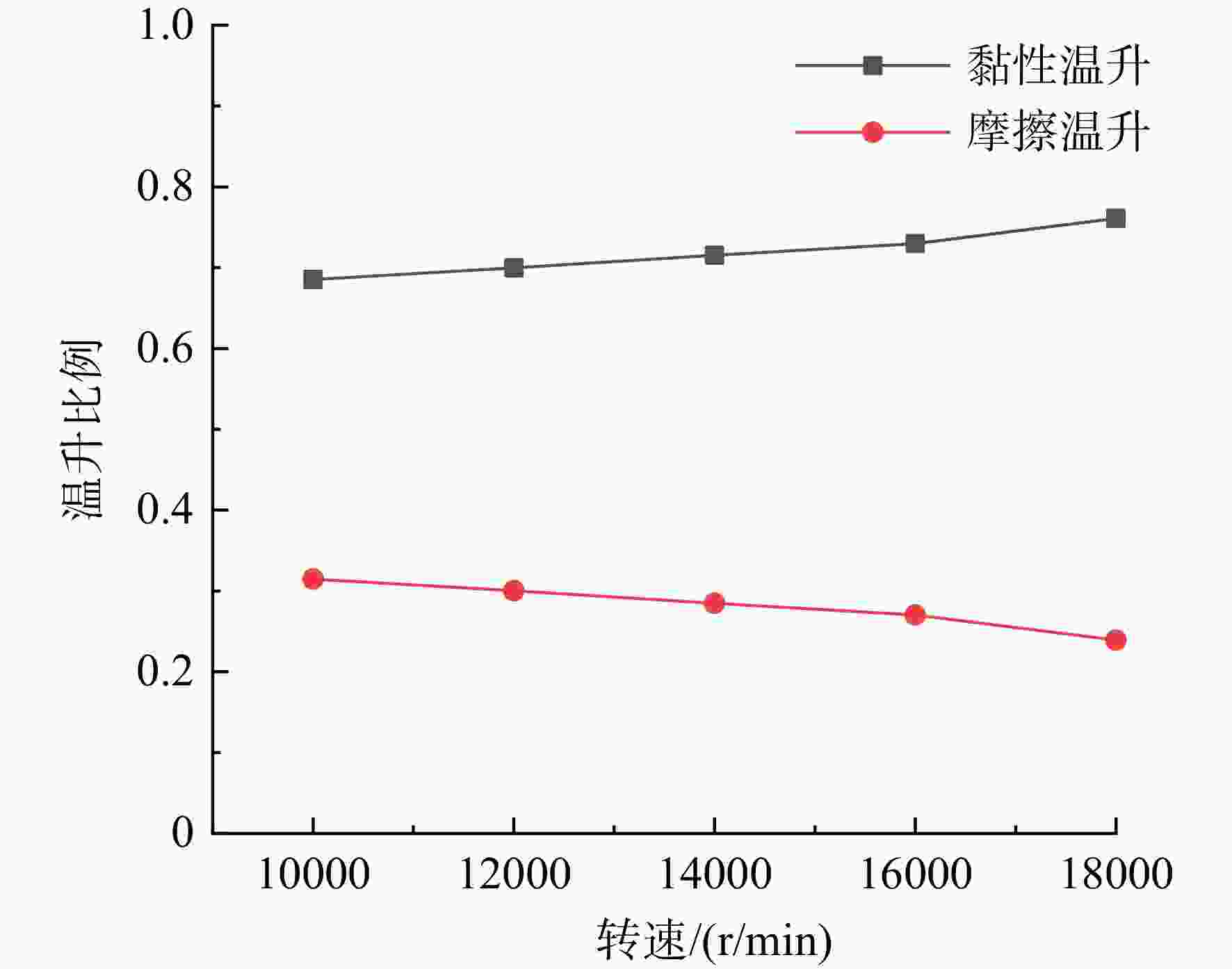

针对高速圆柱滚子轴承高温失效问题,采用流体体积(VOF)方法和多重参考系(MRF)模型对圆柱滚子轴承内圈供油槽和轴承腔进行建模,计算供油槽油液供给情况并将结果施加到轴承腔内模型中,计算环下进油孔相对于滚子多个位置处的温升,并通过加权平均得到轴承腔内最终温升。分析轴承转速、供油量对轴承腔内摩擦温升和润滑油黏性剪切温升的影响规律。结果表明:轴承供油量一定时,转速越高,轴承内部组件摩擦加剧,腔内润滑油受到的黏性剪切力增大,摩擦、黏性温升均升高;轴承转速一定时,由于油量增加造成的润滑油黏性剪切温升的增加和冷却效果的提高在油量较低时前者高于后者,随后两者逐渐持平,黏性温升先下降然后维持在一定水平,摩擦温升降低。该研究对高速圆柱滚子轴承环下润滑设计提供了参考依据。

-

关键词:

- 高速圆柱滚子轴承 /

- 环下润滑 /

- 轴承腔 /

- 计算流体动力学(CFD) /

- 热场

Abstract:To solve the problem of high temperature failure of cylindrical roller bearing under high-speed operation, volume of fluid (VOF) method and multiple reference frame (MRF) model were used to model the oil supply groove and bearing cavity of cylindrical roller bearing inner ring, respectively, the oil supply situation of the oil supply groove was calculated and the result was applied to the bearing cavity model. The temperature rise of the oil inlet hole under the ring relative to the roller was calculated, and the final temperature rise in the bearing cavity was obtained by weighted average. The effects of bearing speed and oil supply rate on the temperature rise of friction in bearing chamber and the temperature rise of lubricating oil viscous shear were analyzed. The results showed that when the oil supply rate of the bearing was constant, the higher rotational speed indicated all the increase in the friction of the internal components of the bearing, the viscous shear force of the lubricating oil in the cavity and the friction and viscous temperature rise. When the bearing speed was constant, the increase of lubricating oil viscosity shear temperature rise and the improvement of cooling effect caused by the increase of oil content were higher than the latter when the oil content was low, and then these two were gradually flat. The viscosity temperature rise first decreased and then stayed at a certain level, while the friction temperature rise decreased. This study can provide a reference for lubrication design of high-speed cylindrical roller bearing ring.

-

表 1 圆柱滚子轴承基本参数

Table 1. Basic parameters of cylindrical roller bearings

参数 数值 外圈直径/mm 194 内圈直径/mm 144 滚子个数 30 滚子长度/mm 12 滚子直径/mm 12 表 2 不同转速时轴承的生热状态

Table 2. Heat generation state of bearings with different speed

转速n/

(r/min)总生热量

Q/W外圈热流密度

qo/(W/m2)内圈热流密度

qi/(W/m2)滚子热流密度

qr/(W/m2)10000 883.01 35292.19 40880.12 37542.97 12000 1155.28 46174.22 53485.13 49119.00 14000 1453.37 58088.42 67285.76 61793.04 16000 1775.99 70982.84 82221.79 75509.81 18000 2122.06 84814.63 98243.62 90223.73 表 3 计算参数

Table 3. Calculation parameters

参数 主相(空气) 次相

(4050航空润滑油)密度/(kg/m3) 1.225 960 黏度/(Pa·s) 1.79×10−5 1.733×10−3 表 4 供油量为9.7 L/min时进油孔流速、油相体积分数

Table 4. Oil inlet flow rate and oil phase volume fraction when the oil supply is 9.7 L/min

转速/(r/min) 进油孔1流速/(m/s) 进油孔1油相体积分数 进油孔2流速/(m/s) 进油孔2油相体积分数 10000 12.2 1 6.5 1 12000 13.4 1 5.5 1 14000 14.2 1 5.2 0.92 16000 14.5 1 5.4 0.82 18000 15.9 1 5.4 0.56 表 5 转速为14000 r/min时进油孔流速、油相体积分数

Table 5. Oil inlet flow rate and oil phase volume fraction when speed is 14000 r/min

供油量/(L/min) 进油孔1流速/(m/s) 进油孔1油相体积分数 进油孔2流速/(m/s) 进油孔2油相体积分数 5.7 9.6 1 4.8 0.27 7.7 12.5 1 4.7 0.53 9.7 14.2 1 5.2 0.92 11.7 15.6 1 7.3 1 13.7 17.8 1 8.9 1 -

[1] 王振岭,葛泉江,林国昌. 航空发动机主轴轴承润滑与冷却技术研究[J]. 航空发动机,2012,38(3): 15-17,23. WANG Zhenling,GE Quanjiang,LIN Guochang. Investigation on lubricating and cooling technologies for aeroengine mainshaft bearings[J]. Aeroengine,2012,38(3): 15-17,23. (in ChineseWANG Zhenling, GE Quanjiang, LIN Guochang. Investigation on lubricating and cooling technologies for aeroengine mainshaft bearings[J]. Aeroengine, 2012, 38(3): 15-17, 23. (in Chinese) [2] 林基恕,张振波. 21世纪航空发动机动力传输系统的展望[J]. 航空动力学报,2001,16(2): 108-114,118. LIN Jishu,ZHANG Zhenbo. Prospects of aeroengine power transmission system in the 21st century[J]. Journal of Aerospace Power,2001,16(2): 108-114,118. (in Chinese doi: 10.3969/j.issn.1000-8055.2001.02.003LIN Jishu, ZHANG Zhenbo. Prospects of aeroengine power transmission system in the 21st century[J]. Journal of Aerospace Power, 2001, 16(2): 108-114, 118. (in Chinese) doi: 10.3969/j.issn.1000-8055.2001.02.003 [3] LEE C W,JOHNSON G R,PALMA P C,et al. Factors affecting the behaviour and efficiency of a targeted jet delivering oil to a bearing lubrication system: GT2004-53606[R]. Vienna: ASME,2008. [4] 王赵蕊佳. 高速球轴承环下润滑两相流及耦合传热分析[D]. 哈尔滨: 哈尔滨工程大学,2020. WANG Zhaoruijia. Analysis of lubrication two-phase flow and coupled heat transfer in high-speed ball bearing ring[D]. Harbin: Harbin Engineering University,2020. (in ChineseWANG Zhaoruijia. Analysis of lubrication two-phase flow and coupled heat transfer in high-speed ball bearing ring[D]. Harbin: Harbin Engineering University, 2020. (in Chinese) [5] 李潇潇,闫柯,葛临风,等. 高速球轴承喷油润滑流场特性研究[J]. 西安交通大学学报,2019,53(12): 17-24. LI Xiaoxiao,YAN Ke,GE Linfeng,et al. Research on flow field characteristics of oil injection lubrication for high-speed ball bearings[J]. Journal of Xi’an Jiaotong University,2019,53(12): 17-24. (in ChineseLI Xiaoxiao, YAN Ke, GE Linfeng, et al. Research on flow field characteristics of oil injection lubrication for high-speed ball bearings[J]. Journal of Xi’an Jiaotong University, 2019, 53(12): 17-24. (in Chinese) [6] 覃经文,曾广乐,郭晖,等. 某涡轴发动机轴承环下润滑结构试验研究[J]. 润滑与密封,2019,44(7): 138-142. QIN Jingwen,ZENG Guangle,GUO Hui,et al. Experimental research on under-race lubrication of bearing for a turboshaft aeroengine[J]. Lubrication Engineering,2019,44(7): 138-142. (in ChineseQIN Jingwen, ZENG Guangle, GUO Hui, et al. Experimental research on under-race lubrication of bearing for a turboshaft aeroengine[J]. Lubrication Engineering, 2019, 44(7): 138-142. (in Chinese) [7] 陈军. 涡扇发动机主轴承环下供油方法分析研究[D]. 西安: 西北工业大学,2007. CHEN Jun. Analysis and research on oil supply method under main bearing ring of turbofan engine[D]. Xi’an: Northwestern Polytechnical University,2007. (in ChineseCHEN Jun. Analysis and research on oil supply method under main bearing ring of turbofan engine[D]. Xi’an: Northwestern Polytechnical University, 2007. (in Chinese) [8] 朱冬磊,陈国定,李炎军,等. 中介轴承环下流道滑油流动及润滑效率分析[J]. 航空学报,2019,40(11): 423022. ZHU Donglei,CHEN Guoding,LI Yanjun,et al. Inner ring oil flow and lubrication efficiency analysis of intershaft bearing[J]. Acta Aeronautica et Astronautica Sinica,2019,40(11): 423022. (in ChineseZHU Donglei, CHEN Guoding, LI Yanjun, et al. Inner ring oil flow and lubrication efficiency analysis of intershaft bearing[J]. Acta Aeronautica et Astronautica Sinica, 2019, 40(11): 423022. (in Chinese) [9] 刘鲁. 航空发动机叶轮式径向收油装置收油效率研究[D]. 哈尔滨: 哈尔滨工业大学,2011. LIU Lu. Study on oil collection efficiency of impeller radial oil collection device of aero-engine[D]. Harbin: Harbin Institute of Technology,2011. (in ChineseLIU Lu. Study on oil collection efficiency of impeller radial oil collection device of aero-engine[D]. Harbin: Harbin Institute of Technology, 2011. (in Chinese) [10] WU Wei,HU Chenhui,HU Jibin,et al. Jet cooling for rolling bearings: flow visualization and temperature distribution[J]. Applied Thermal Engineering,2016,105: 217-224. doi: 10.1016/j.applthermaleng.2016.05.147 [11] WU Wei,HU Chenhui,HU Jibin,et al. Jet cooling characteristics for ball bearings using the VOF multiphase model[J]. International Journal of Thermal Sciences,2017,116: 150-158. doi: 10.1016/j.ijthermalsci.2017.02.014 [12] WU Wei,HU Jibin,YUAN Shihua,et al. Numerical and experimental investigation of the stratified air-oil flow inside ball bearings[J]. International Journal of Heat and Mass Transfer,2016,103: 619-626. doi: 10.1016/j.ijheatmasstransfer.2016.07.090 [13] JENG Y,GAO C. Investigation of the ball-bearing temperature rise under an oil-air lubrication system[J]. Proceedings of the Institution of Mechanical Engineers,Part J: Journal of Engineering Tribology,2001,215: 139-148. [14] WANG Yunlong,WANG Wenzhong,LI Yulong,et al. Lubrication and thermal failure mechanism analysis in high-speed angular contact ball bearing[J]. Journal of Tribology,2018,140(3): 031503. doi: 10.1115/1.4038356 [15] FLOUROS M. Correlations for heat generation and outer ring temperature of high speed and highly loaded ball bearings in an aero-engine[J]. Aerospace Science and Technology,2006,10(7): 611-617. doi: 10.1016/j.ast.2006.08.002 [16] YUAN Xi,GUO Hui,WANG Liang. Experiment study of heat transfer in aeroengine bearing chambers[J]. Applied Mechanics and Materials,2011,86: 448-453. doi: 10.4028/www.scientific.net/AMM.86.448 [17] HARRIS T A. Rolling bearing analysis[M]. 2nd ed. New York: Wiley,1984. [18] YAN Ke,DONG Lei,ZHENG Junhao,et al. Flow performance analysis of different air supply methods for high speed and low friction ball bearing[J]. Tribology International,2018,121: 94-107. doi: 10.1016/j.triboint.2018.01.035 -

下载:

下载: