Study on flow and heat transfer performance and entropy generation in concave-convex channel with frustum of a cone

-

摘要:

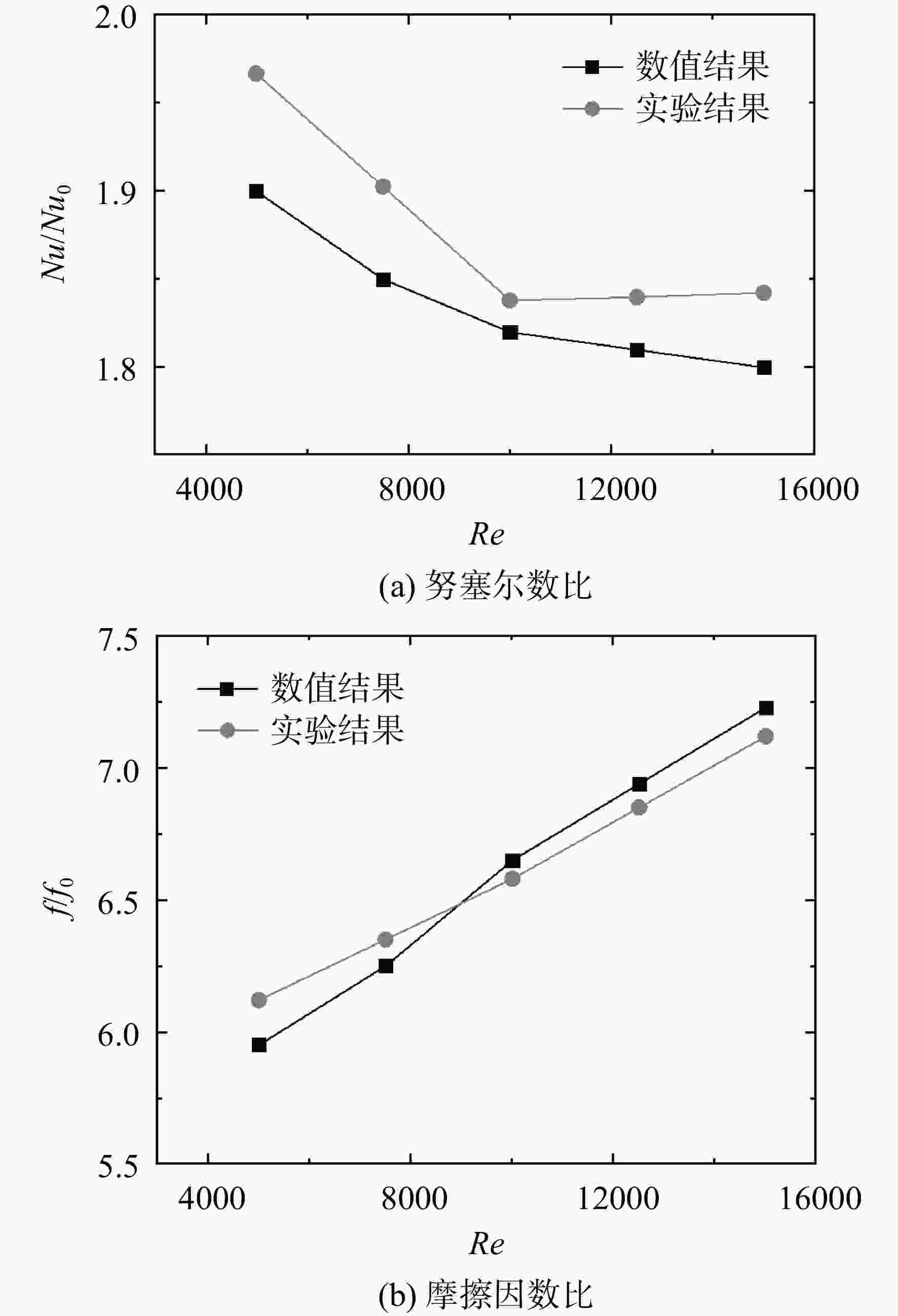

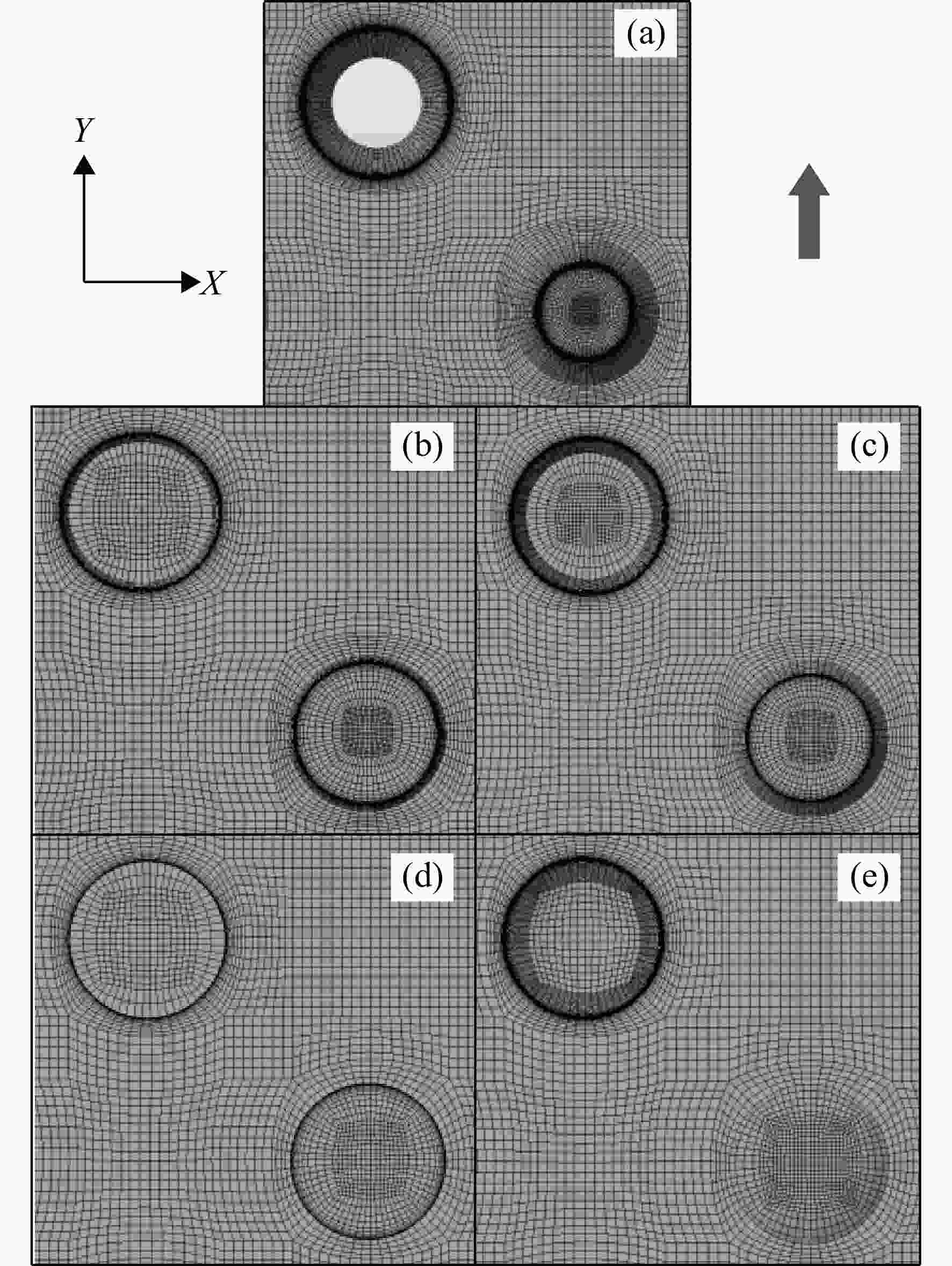

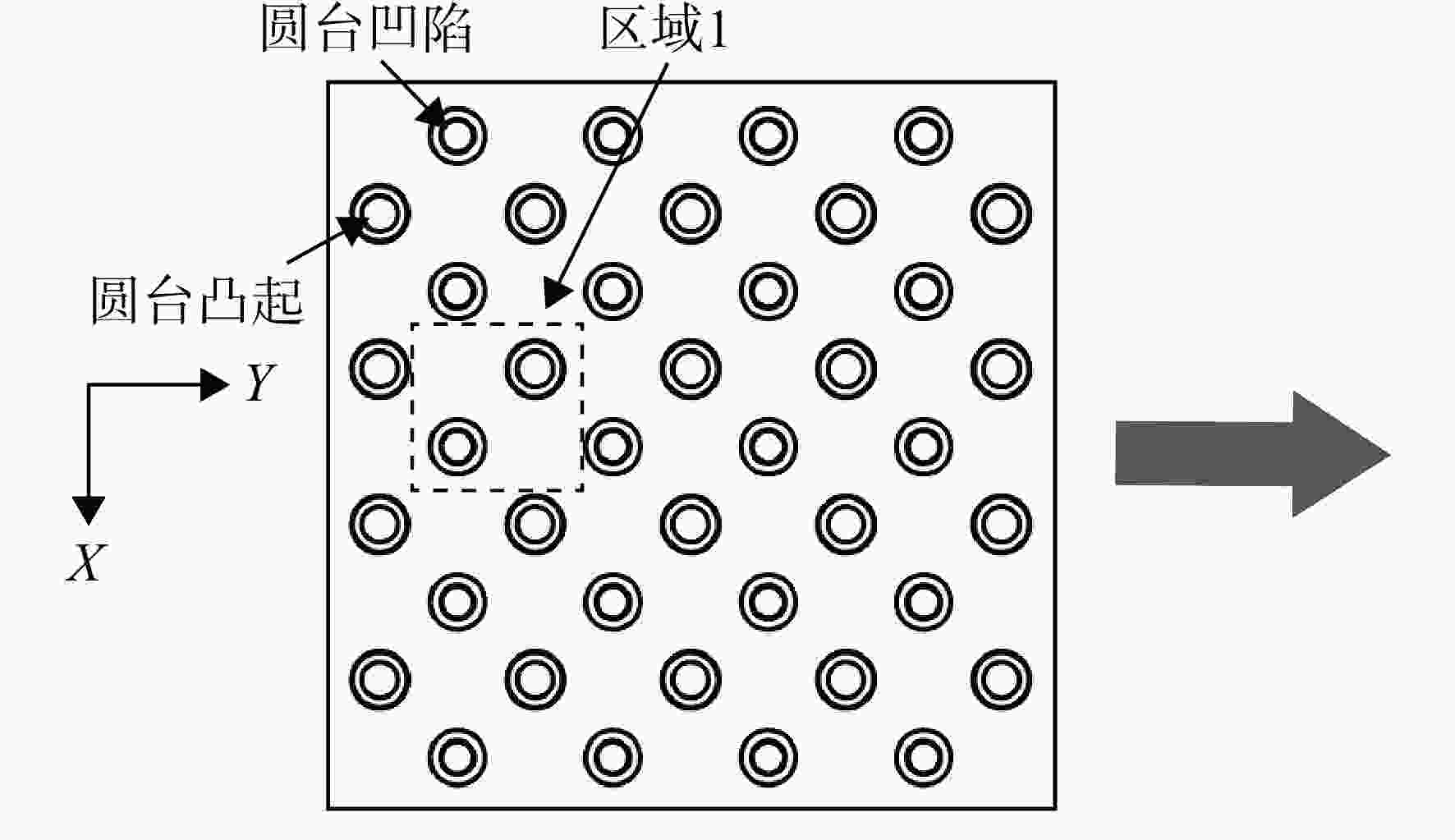

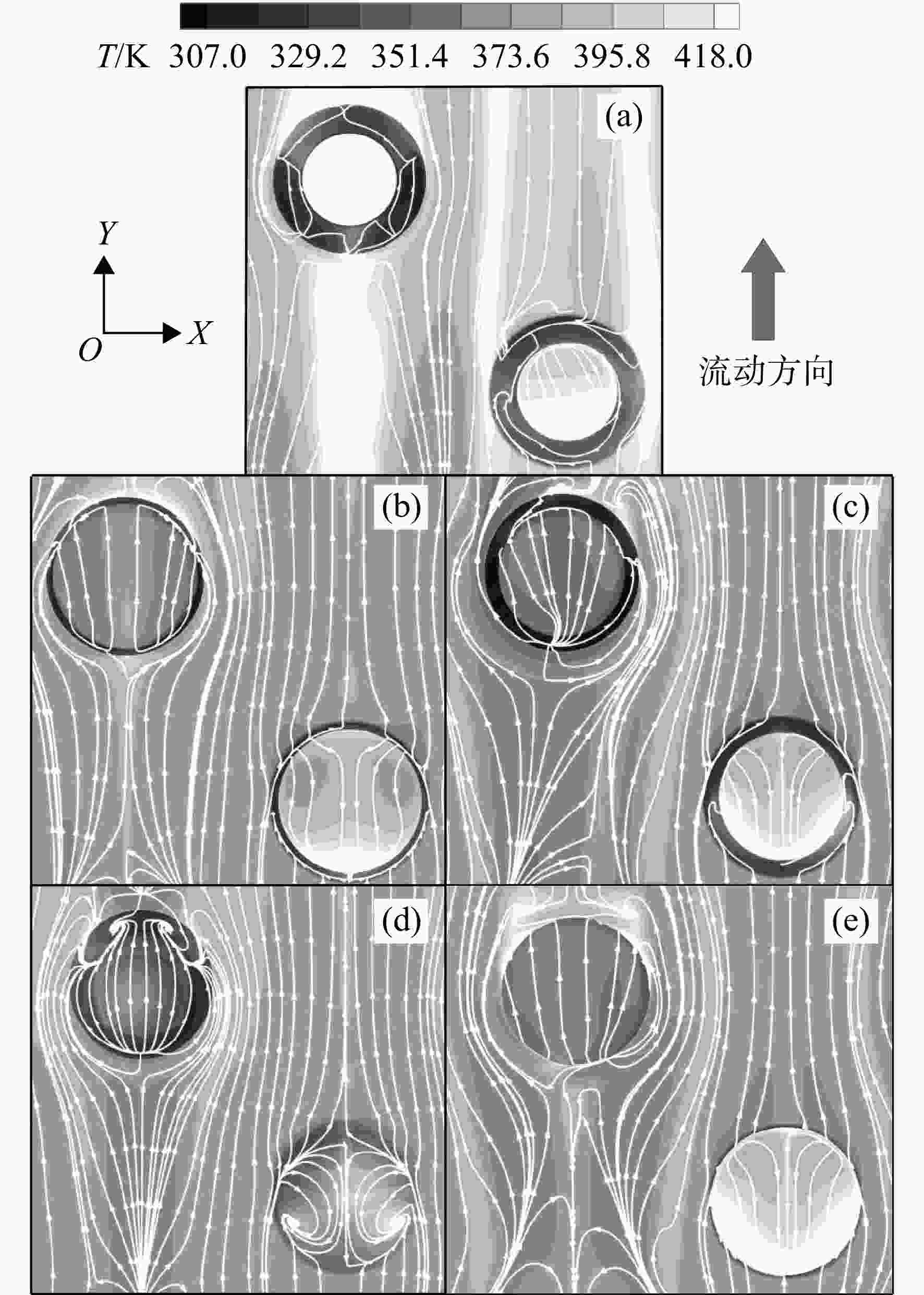

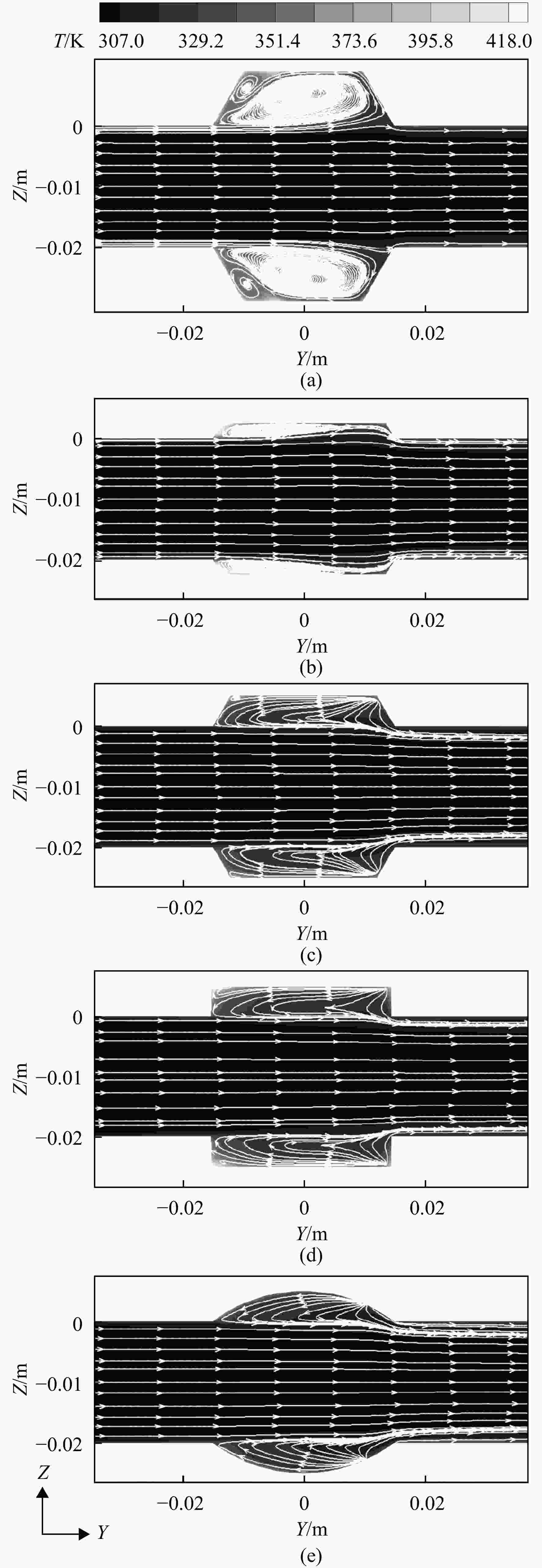

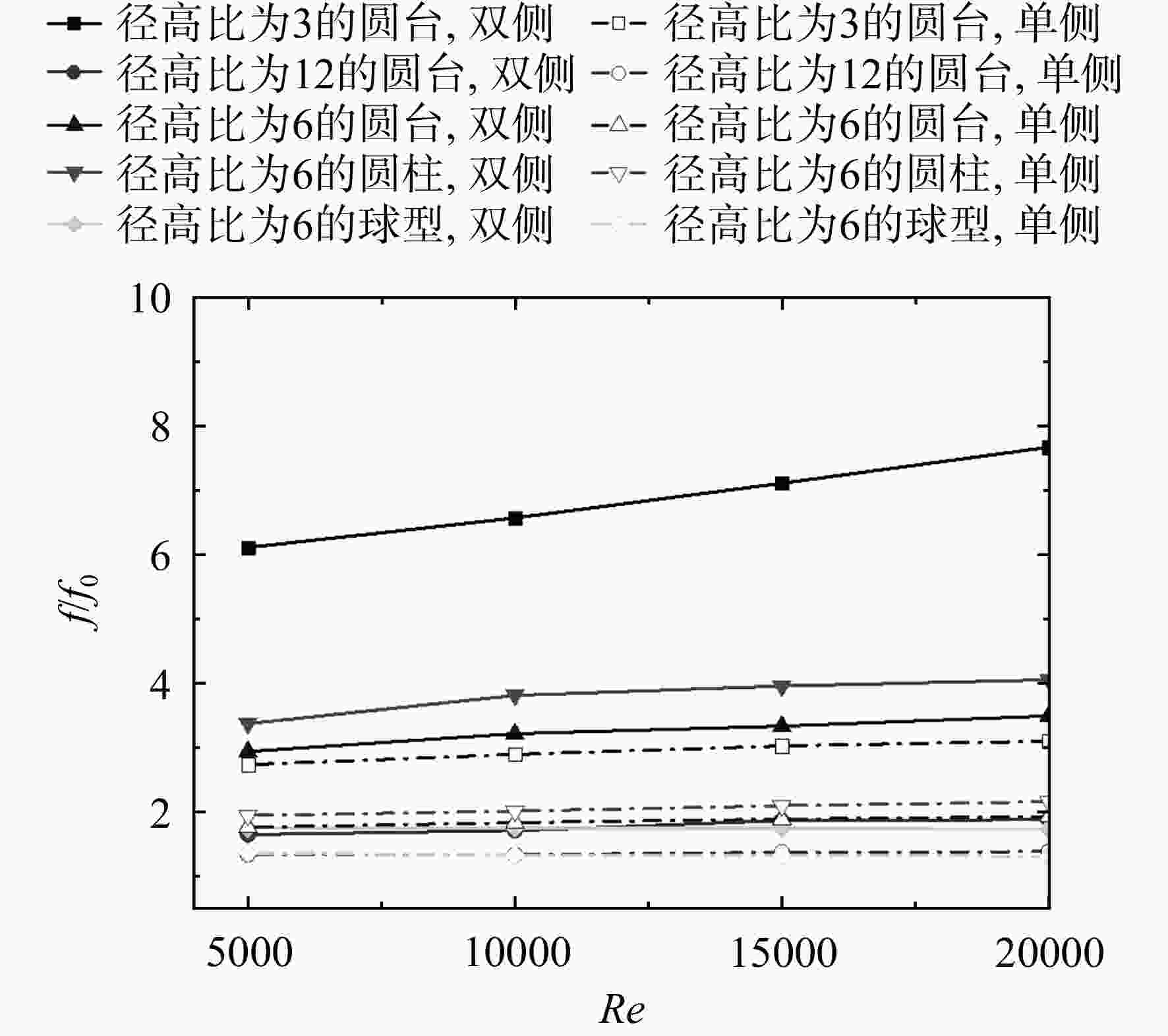

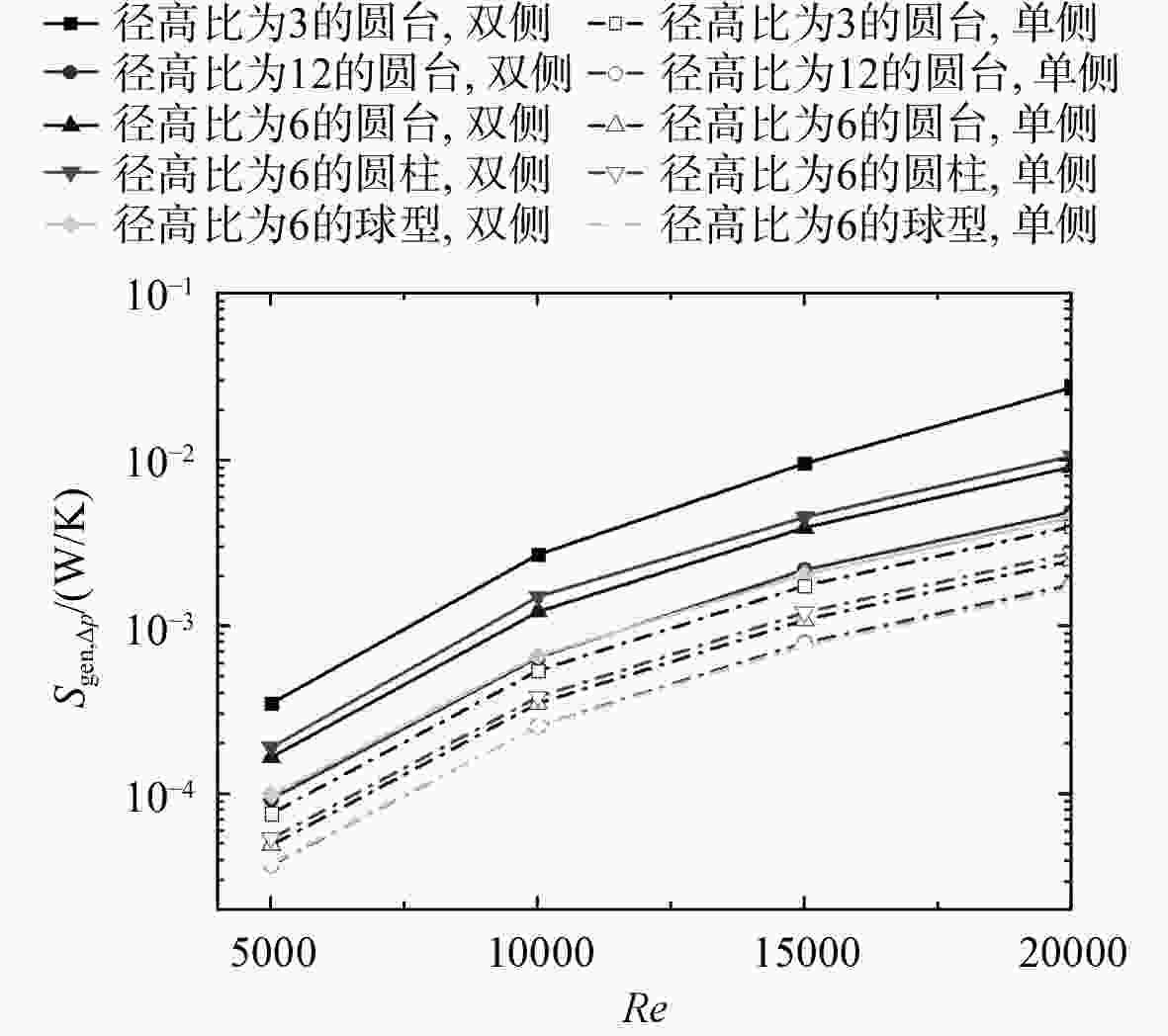

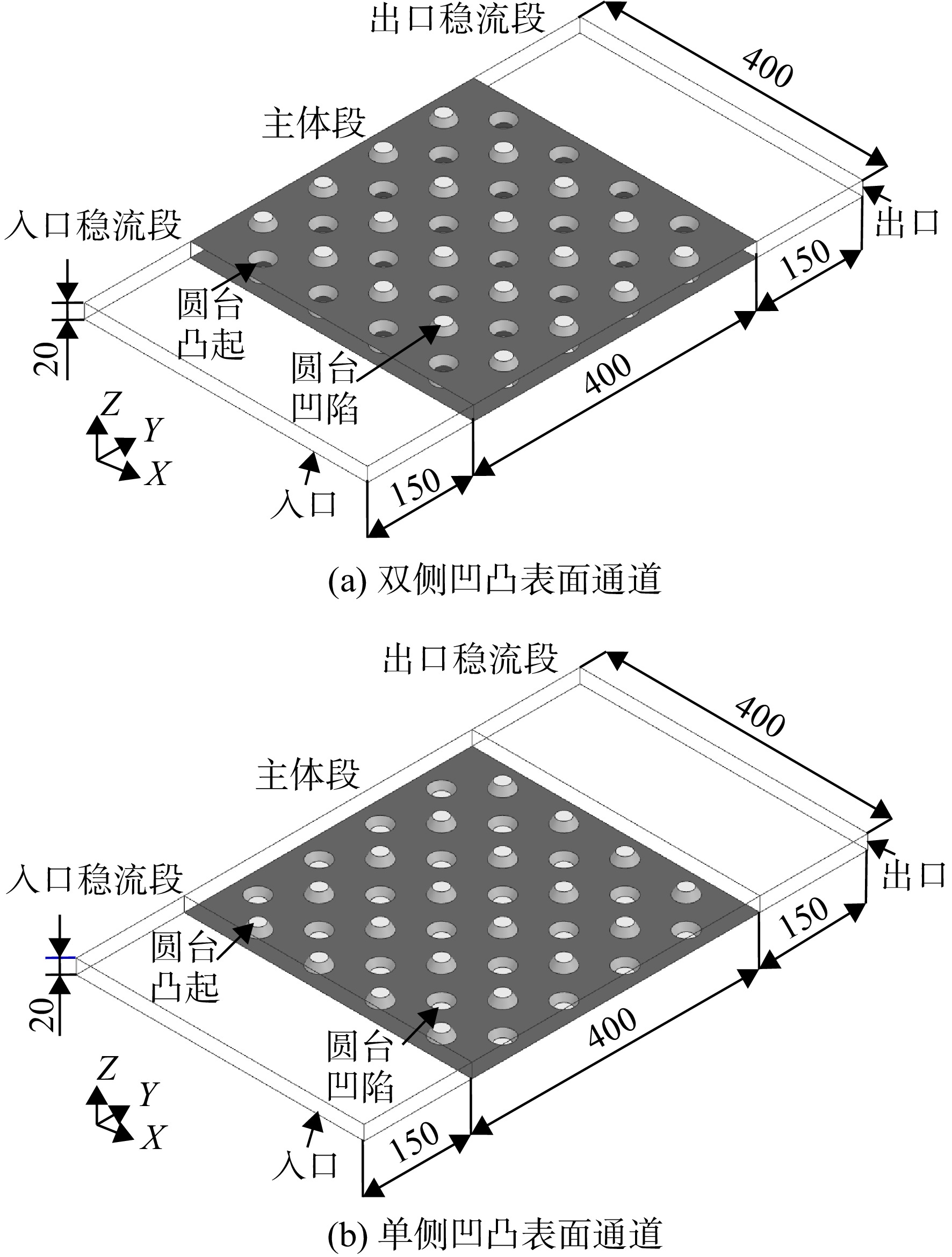

为提高换热器的结构强度和降低接触热阻,提出一种新型采用热冲压成形工艺的圆台凹凸板片。对径高比为3、6、12的圆台凹凸结构通道和径高比为6的圆柱和球型凹凸结构通道进行了数值研究,并探究了不同雷诺数下单侧和双侧凹凸表面通道的流动传热性能和熵产的分布规律。研究表明:单侧和双侧凹凸表面通道传热壁面的传热分布相似,但前者的流动传热性能要优于后者;当雷诺数从5 000增大到20 000时,圆台凹凸结构通道的摩擦因数比和综合传热因子均随着圆台径高比的增大而增大;当径高比一定时,通道的综合传热因子从大到小依次为球型、圆台和圆柱凹凸结构;此外,随着雷诺数的增大5种结构下通道的传热和摩擦熵产的比值会减小。

Abstract:In order to improve the structural strength of heat exchanger and reduce the contact thermal resistance, a new concave-convex plate of frustum of a cone with hot stamping process was proposed. Numerical studies were carried out on the concave-convex structure channels of frustum of a cone with diameter height ratio of 3, 6 and 12 and on those of cylinder and spherical shape structure with diameter height ratio of 6. The flow and heat transfer performance and entropy generation distribution of channels with one and two concave-convex surfaces under different Reynolds numbers were studied. The results showed that the heat transfer distribution on the heat transfer wall of channels with one and two concave-convex surfaces was similar, but the flow and heat transfer performance of the former was better than that of the latter. When the Reynolds number increased from 5 000 to 20 000, the friction coefficient ratio and comprehensive heat transfer factor increased with the increasing diameter height ratio of frustum of a cone. When the diameter height ratio was constant, the comprehensive heat transfer factor of the channel was a spherical shape, frustum of a cone and cylinder concave-convex structure from large to small. In addition, the ratio of heat transfer and friction entropy generation decreased with the increase of Reynolds number.

-

表 1 网格无关性验证

Table 1. Grid independence verification

网格数量/万 压差/Pa 平均努塞尔数 230 31.7 47.9 360 32.6 48.7 540 35.2 49.6 860 35.8 52.8 970 36.2 54.1 1 250 36.3 54.6 -

[1] 王深,吕连宏,张保留,等. 基于多目标模型的中国低成本碳达峰、碳中和路径[J]. 环境科学研究,2021,34(9): 2044-2055. WANG Shen,LYU Lianhong,ZHANG Baoliu,et al. Multi objective programming model of low-cost path for China’s peaking carbon dioxide emissions and carbon neutrality[J]. Research of Environmental Sciences,2021,34(9): 2044-2055. (in ChineseWANG Shen, LYU Lianhong, ZHANG Baoliu, et al. Multi objective programming model of low-cost path for China’s peaking carbon dioxide emissions and carbon neutrality[J]. Research of Environmental Sciences, 2021, 34(9): 2044-2055. (in Chinese) [2] 席雷,徐亮,高建民,等. X型桁架阵列通道流动及传热性能的数值研究[J]. 西安交通大学学报,2021,55(8): 101-110. XI Lei,XU Liang,GAO Jianmin,et al. Numerical research on flow and heat transfer performance of X-type truss array channels[J]. Journal of Xi’an Jiaotong University,2021,55(8): 101-110. (in ChineseXI Lei, XU Liang, GAO Jianmin, et al. Numerical research on flow and heat transfer performance of X-type truss array channels[J]. Journal of Xi’an Jiaotong University, 2021, 55(8): 101-110. (in Chinese) [3] 鲍锋,侯昶,江裕荣. 带三棱锥体群通道流动和传热特性的数值模拟[J]. 航空动力学报,2020,35(12): 2543-2552. BAO Feng,HOU Chang,JIANG Yurong. Numerical simulation of flow and heat transfer characteristics in passage with triangular Pyramids[J]. Journal of Aerospace Power,2020,35(12): 2543-2552. (in ChineseBAO Feng, HOU Chang, JIANG Yurong. Numerical simulation of flow and heat transfer characteristics in passage with triangular Pyramids[J]. Journal of Aerospace Power, 2020, 35(12): 2543-2552. (in Chinese) [4] 杨云,饶宇. 不同深度凹陷内湍流流动与传热性能的数值研究[J]. 上海交通大学学报,2017,51(1): 18-25. YANG Yun,RAO Yu. A numerical study of turbulent flow and heat transfer of dimples at different depths[J]. Journal of Shanghai Jiao Tong University,2017,51(1): 18-25. (in ChineseYANG Yun, RAO Yu. A numerical study of turbulent flow and heat transfer of dimples at different depths[J]. Journal of Shanghai Jiao Tong University, 2017, 51(1): 18-25. (in Chinese) [5] 文键,王春龙,刘华清,等. 板翅式换热器波纹翅片性能数值模拟及其优化[J]. 高校化学工程学报,2020,34(2): 335-341. WEN Jian,WANG Chunlong,LIU Huaqing,et al. Numerical simulation and optimization on performance of wavy fins in plate-fin heat exchangers[J]. Journal of Chemical Engineering of Chinese Universities,2020,34(2): 335-341. (in ChineseWEN Jian, WANG Chunlong, LIU Huaqing, et al. Numerical simulation and optimization on performance of wavy fins in plate-fin heat exchangers[J]. Journal of Chemical Engineering of Chinese Universities, 2020, 34(2): 335-341. (in Chinese) [6] XIE Gongnan,LIU Jian,LIGRANI P M,et al. Numerical predictions of heat transfer and flow structure in a square cross-section channel with various non-spherical indentation dimples[J]. Numerical Heat Transfer,Part A: Applications,2013,64(3): 187-215. [7] CHEN Yu,CHEW Y T,KHOO B C. Enhancement of heat transfer in turbulent channel flow over dimpled surface[J]. International Journal of Heat and Mass Transfer,2012,55(25/26): 8100-8121. [8] JING Qi,XIE Yonghui,ZHANG Di. Thermal-hydraulic performance and entropy generation of supercritical carbon dioxide in heat exchanger channels with teardrop dimple/protrusion[J]. International Journal of Heat and Mass Transfer,2019,135: 1082-1096. doi: 10.1016/j.ijheatmasstransfer.2019.02.058 [9] 陈炎嗣,郭景仪. 冲压模具设计与制造技术[M]. 北京: 北京出版社,1991. [10] 王定标,夏春杰,董永申. 凹凸板换热器强化传热的数值模拟[J]. 化工进展,2014,33(增刊1): 106-112. WANG Dingbiao,XIA Chunjie,DONG Yongshen. Performance study of honeycomb plate heat exchanger[J]. Chemical Industry and Engineering Progress,2014,33(Suppl.1): 106-112. (in ChineseWANG Dingbiao, XIA Chunjie, DONG Yongshen. Performance study of honeycomb plate heat exchanger[J]. Chemical Industry and Engineering Progress, 2014, 33(Suppl.1): 106-112. (in Chinese) [11] LIU Jian,SONG Yidan,XIE Gongnan,et al. Numerical modeling flow and heat transfer in dimpled cooling channels with secondary hemispherical protrusions[J]. Energy,2015,79: 1-19. doi: 10.1016/j.energy.2014.05.075 [12] HWANG S D,KWON H G,CHO H H. Local heat transfer and thermal performance on periodically dimple-protrusion patterned walls for compact heat exchangers[J]. Energy,2010,35(12): 5357-5364. doi: 10.1016/j.energy.2010.07.022 [13] LI Ming,CHEN Xin,RUAN Xinjian. Investigation of flow structure and heat transfer enhancement in rectangular channels with dimples and protrusions using large eddy simulation[J]. International Journal of Thermal Sciences,2020,149: 106207. doi: 10.1016/j.ijthermalsci.2019.106207 [14] 王光辉,王定标,彭旭,等. 凹凸板的传热流阻特性及其多目标优化[J]. 工程热物理学报,2019,40(1): 143-149. WANG Guanghui,WANG Dingbiao,PENG Xu,et al. Heat transfer and resistance performance of plate heat exchanger with dimples and protrusions and optimization[J]. Journal of Engineering Thermophysics,2019,40(1): 143-149. (in ChineseWANG Guanghui, WANG Dingbiao, PENG Xu, et al. Heat transfer and resistance performance of plate heat exchanger with dimples and protrusions and optimization[J]. Journal of Engineering Thermophysics, 2019, 40(1): 143-149. (in Chinese) [15] 李光耀,王琥,杨旭静,等. 板料冲压成形工艺与模具设计制造中的若干前沿技术[J]. 机械工程学报,2010,46(10): 31-39. LI Guangyao,WANG Hu,YANG Xujing,et al. Some new topics on process design and mould manufacture for sheet metal forming[J]. Journal of Mechanical Engineering,2010,46(10): 31-39. (in Chinese doi: 10.3901/JME.2010.10.031LI Guangyao, WANG Hu, YANG Xujing, et al. Some new topics on process design and mould manufacture for sheet metal forming[J]. Journal of Mechanical Engineering, 2010, 46(10): 31-39. (in Chinese) doi: 10.3901/JME.2010.10.031 [16] 马鸣图,蒋松蔚,李光瀛,等. 热冲压成形钢的研究进展[J]. 机械工程材料,2020,44(7): 1-7,27. MA Mingtu,JIANG Songwei,LI Guangying,et al. Research progress on hot stamping steel[J]. Materials for Mechanical Engineering,2020,44(7): 1-7,27. (in ChineseMA Mingtu, JIANG Songwei, LI Guangying, et al. Research progress on hot stamping steel[J]. Materials for Mechanical Engineering, 2020, 44(7): 1-7, 27. (in Chinese) [17] 华林,魏鹏飞,胡志力. 高强轻质材料绿色智能成形技术与应用[J]. 中国机械工程,2020,31(22): 2753-2762,2771. HUA Lin,WEI Pengfei,HU Zhili. Green and intelligent forming technology and its applications for high strength lightweight materials[J]. China Mechanical Engineering,2020,31(22): 2753-2762,2771. (in ChineseHUA Lin, WEI Pengfei, HU Zhili. Green and intelligent forming technology and its applications for high strength lightweight materials[J]. China Mechanical Engineering, 2020, 31(22): 2753-2762, 2771. (in Chinese) [18] 赵振,徐亮,高建民,等. 圆台扰流换热器的流动与传热特性研究[J]. 西安交通大学学报,2021,55(10): 131-143. ZHAO Zhen,XU Liang,GAO Jianmin,et al. A study on the flow and heat transfer characteristics of heat exchanger with cone-type vortex generators[J]. Journal of Xi’an Jiaotong University,2021,55(10): 131-143. (in ChineseZHAO Zhen, XU Liang, GAO Jianmin, et al. A study on the flow and heat transfer characteristics of heat exchanger with cone-type vortex generators[J]. Journal of Xi’an Jiaotong University, 2021, 55(10): 131-143. (in Chinese) [19] 赵振,高建民,徐亮,等. 圆台扰流换热器结构参数优化的数值模拟研究[J]. 西安交通大学学报,2021,55(12): 35-46. ZHAO Zhen,GAO Jianmin,XU Liang,et al. Numerical simulation on structural parameter optimization of heat exchanger with frustum of a cone[J]. Journal of Xi’an Jiaotong University,2021,55(12): 35-46. (in ChineseZHAO Zhen, GAO Jianmin, XU Liang, et al. Numerical simulation on structural parameter optimization of heat exchanger with frustum of a cone[J]. Journal of Xi’an Jiaotong University, 2021, 55(12): 35-46. (in Chinese) [20] BEJAN A,TSATSARONIS G,MORAN M J. Thermal design and optimization[M]. New York: John Wiley,1996. [21] ZHAI Y L,XIA G D,LIU X F,et al. Heat transfer in the microchannels with fan-shaped reentrant cavities and different ribs based on field synergy principle and entropy generation analysis[J]. International Journal of Heat and Mass Transfer,2014,68: 224-233. doi: 10.1016/j.ijheatmasstransfer.2013.08.086 -

下载:

下载: