Experiment on spray distribution of an integrated strut flameholder with cross injection

-

摘要:

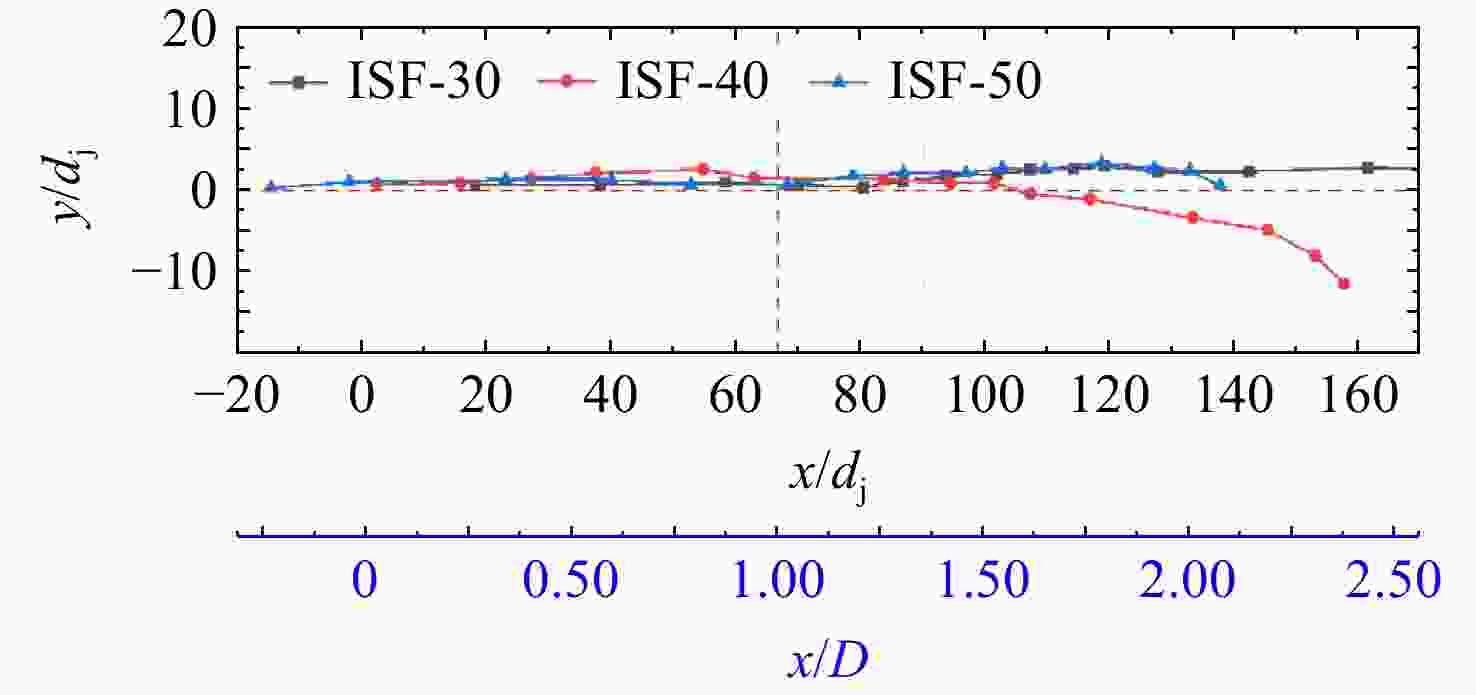

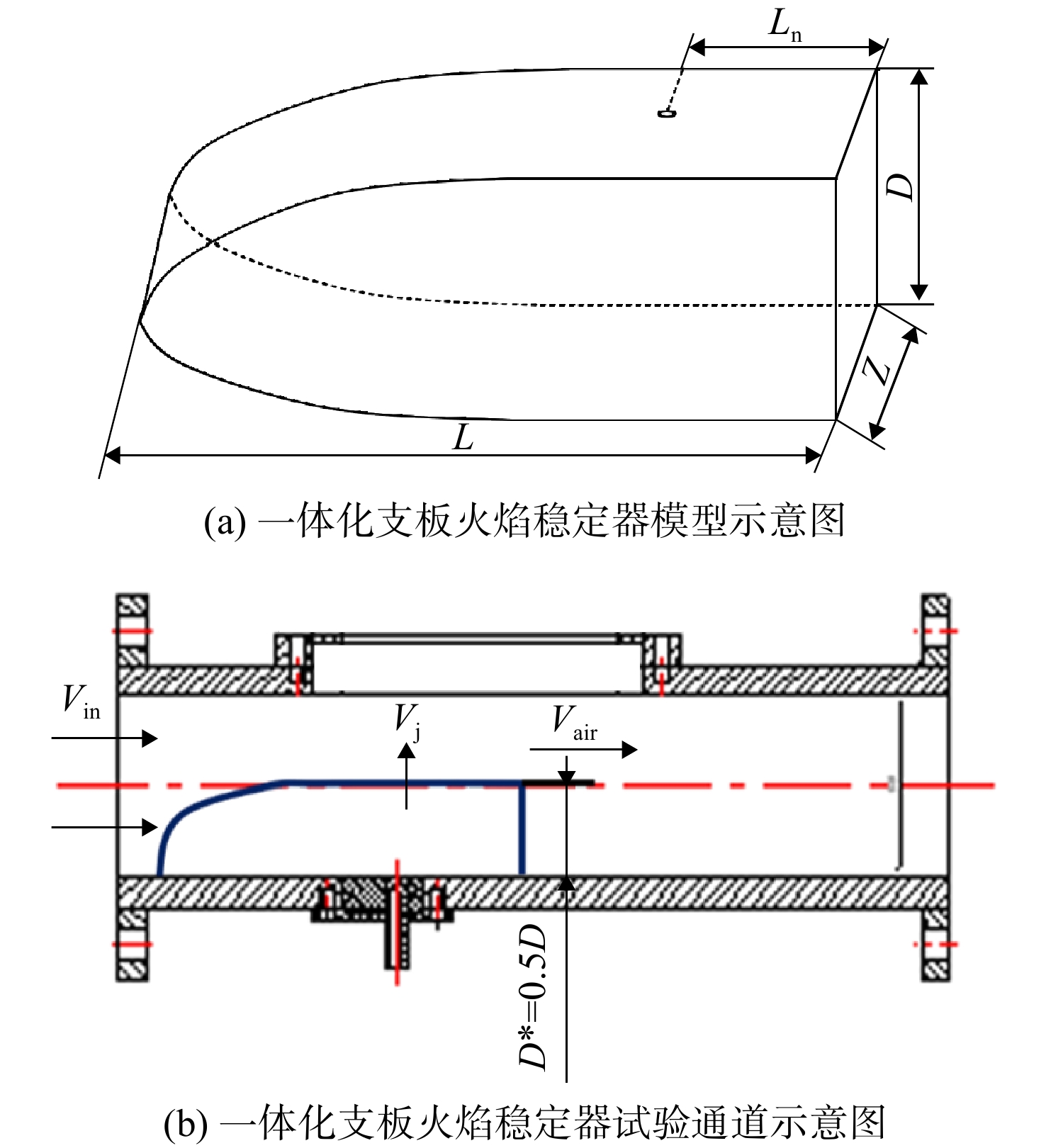

在常温常压、来流马赫数为0.182及液气动量比为10~70的条件下,以水为雾化介质,采用激光片光照相法开展了侧喷式一体化支板火焰稳定器的液雾分布特点研究,并探讨了液气动量比及喷射位置对液雾分布轨迹的影响规律。研究表明:侧喷式一体化支板火焰稳定器液雾分布的外轨迹与横向射流类似,内轨迹受稳定器回流区卷吸作用的影响而弯向回流区,且在低液气动量比条件下影响显著。液气动量比是影响一体化支板火焰稳定器喷雾内外轨迹的重要因素,液气动量比增加,液雾穿透深度增加。喷射位置对液雾外轨迹的影响较小,但对内轨迹影响显著;过近或过远的喷射距离均不利于回流区对液雾的卷吸,这与液雾喷射和稳定器的近距耦合有关。

-

关键词:

- 一体化支板火焰稳定器 /

- 液雾分布轨迹 /

- 液气动量比 /

- 喷射位置 /

- 一体化设计

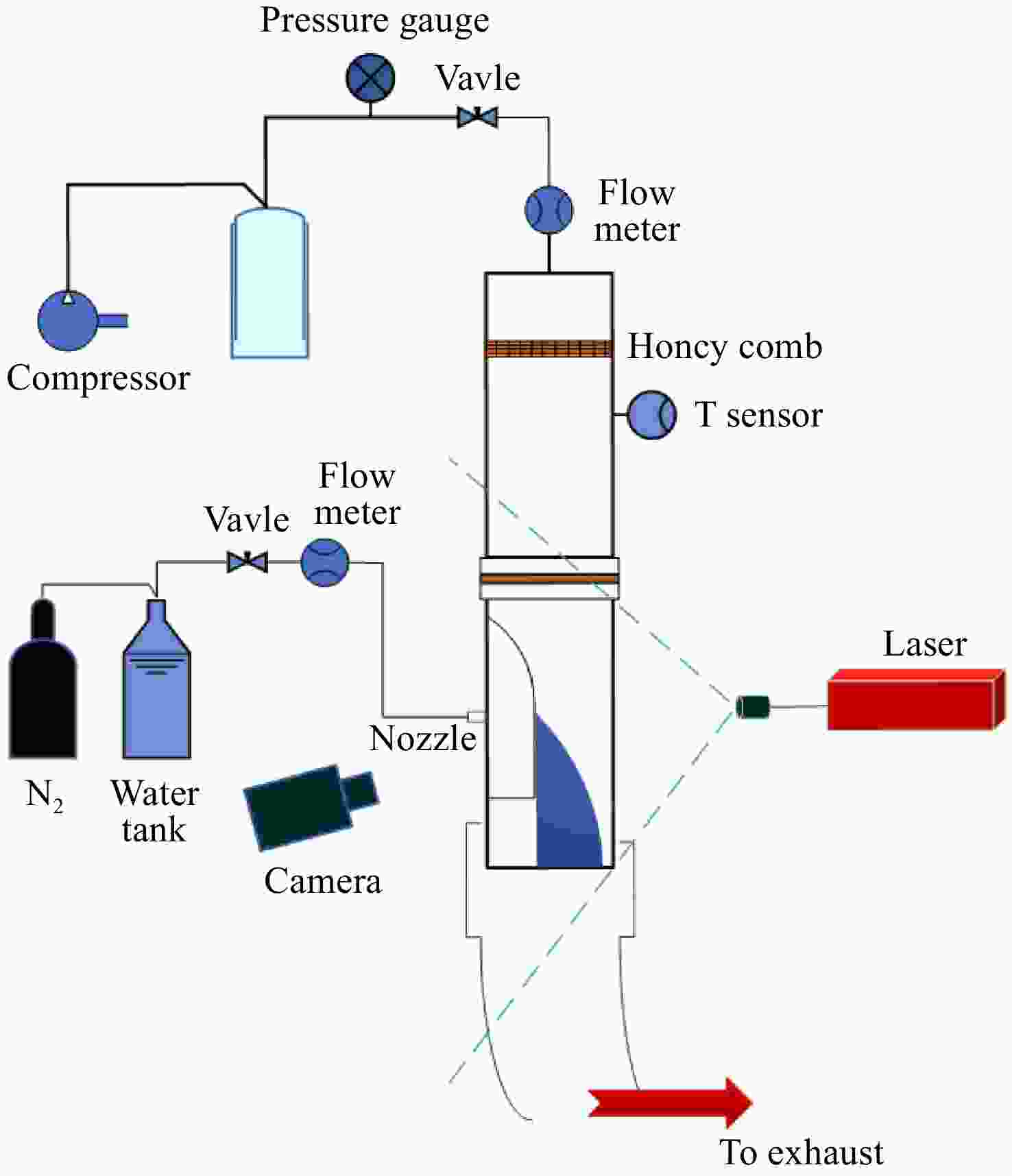

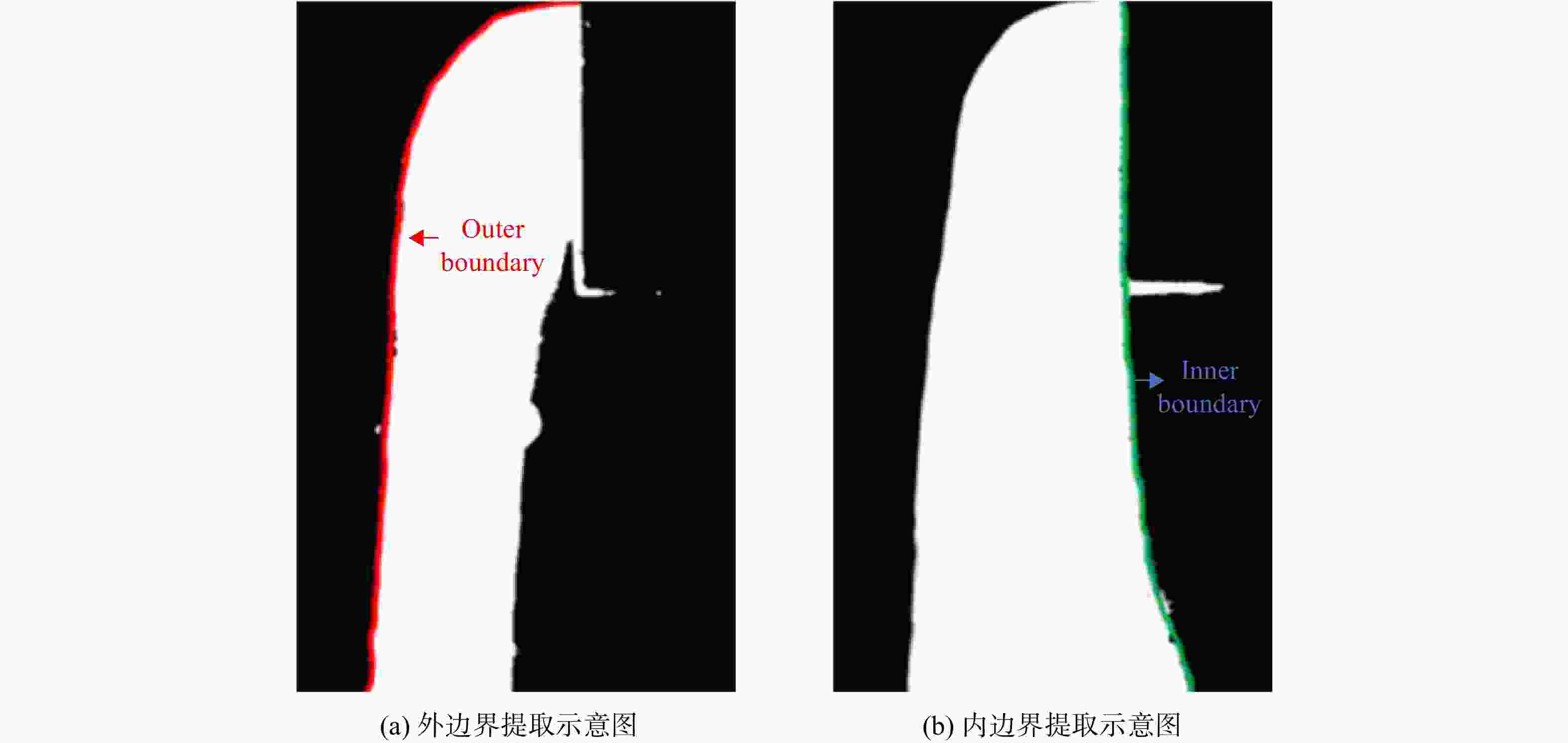

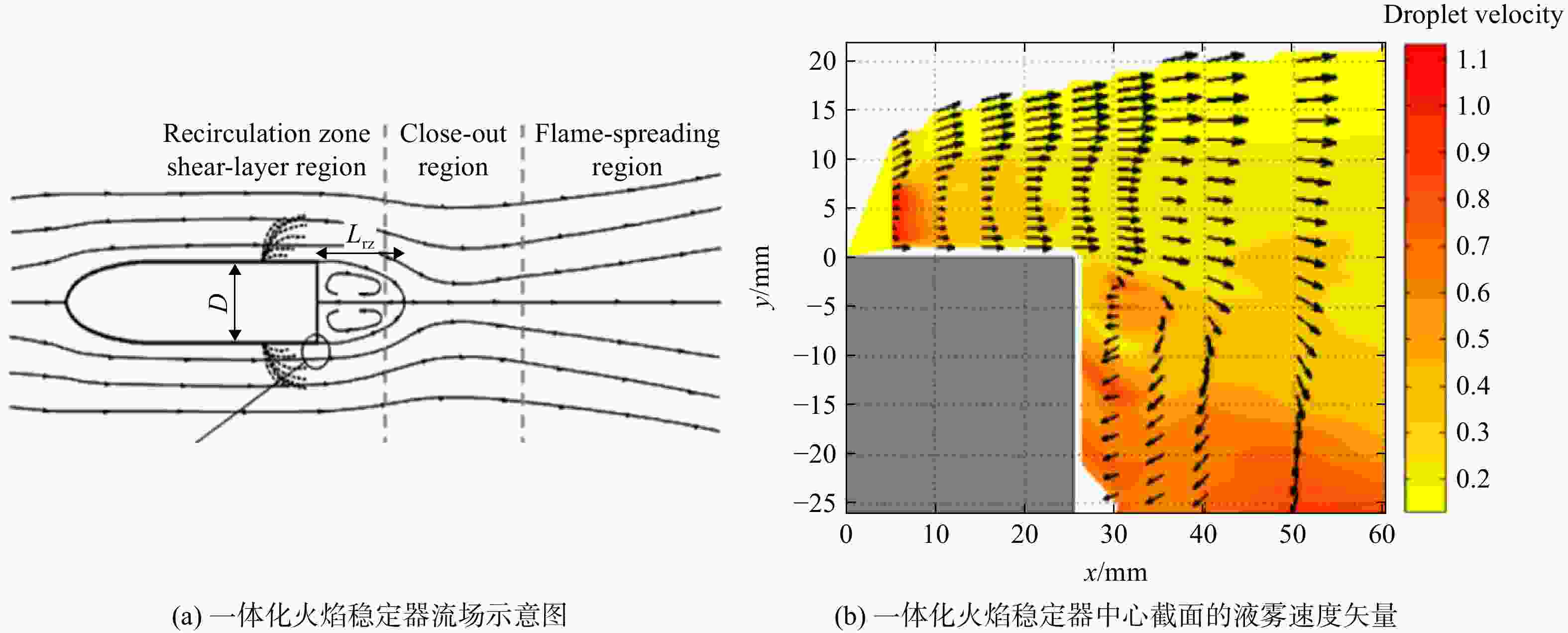

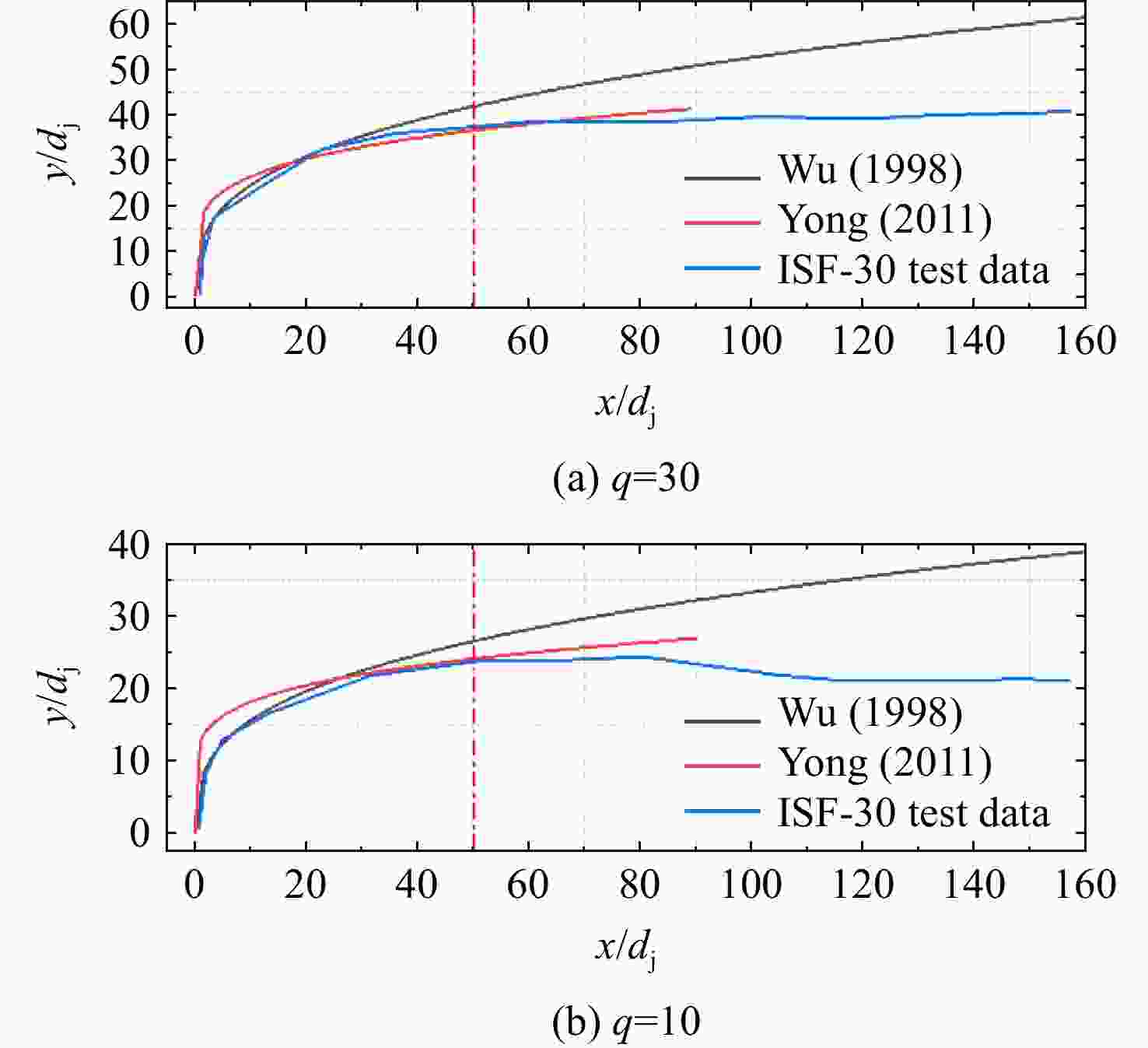

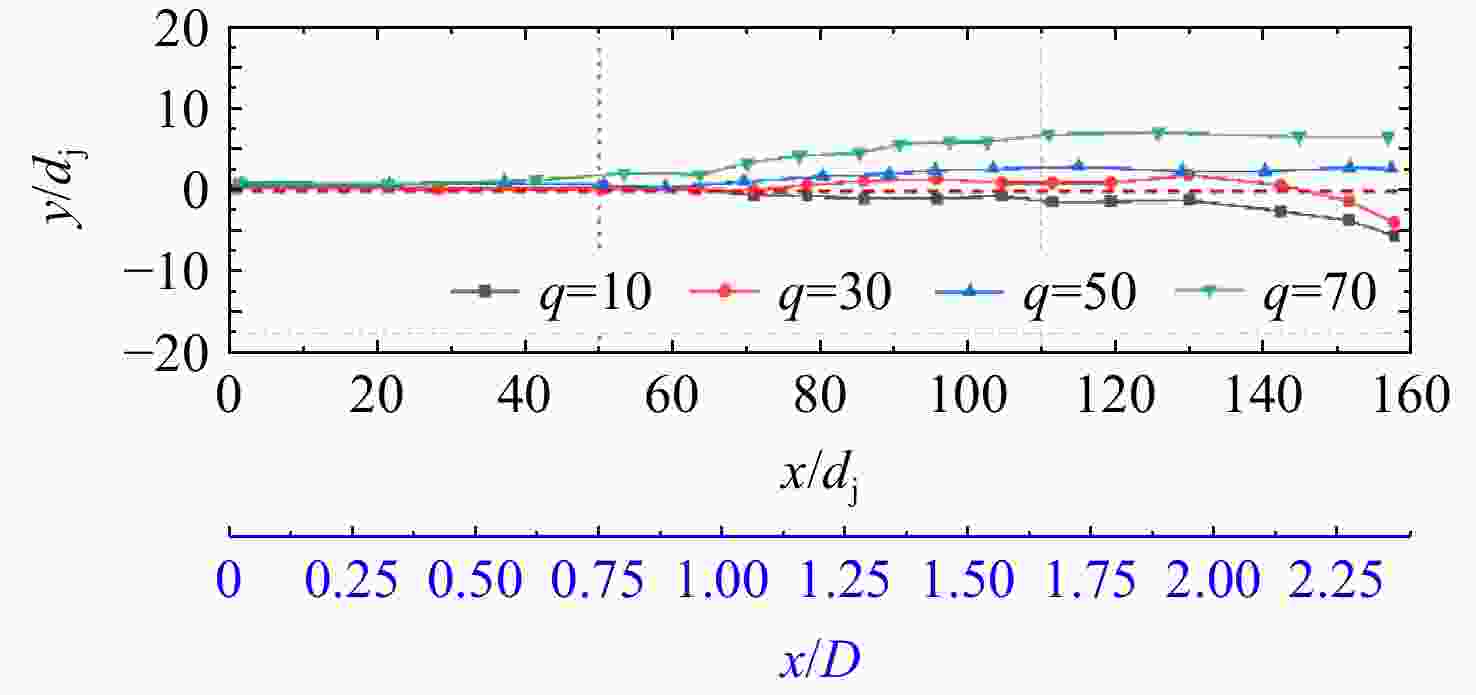

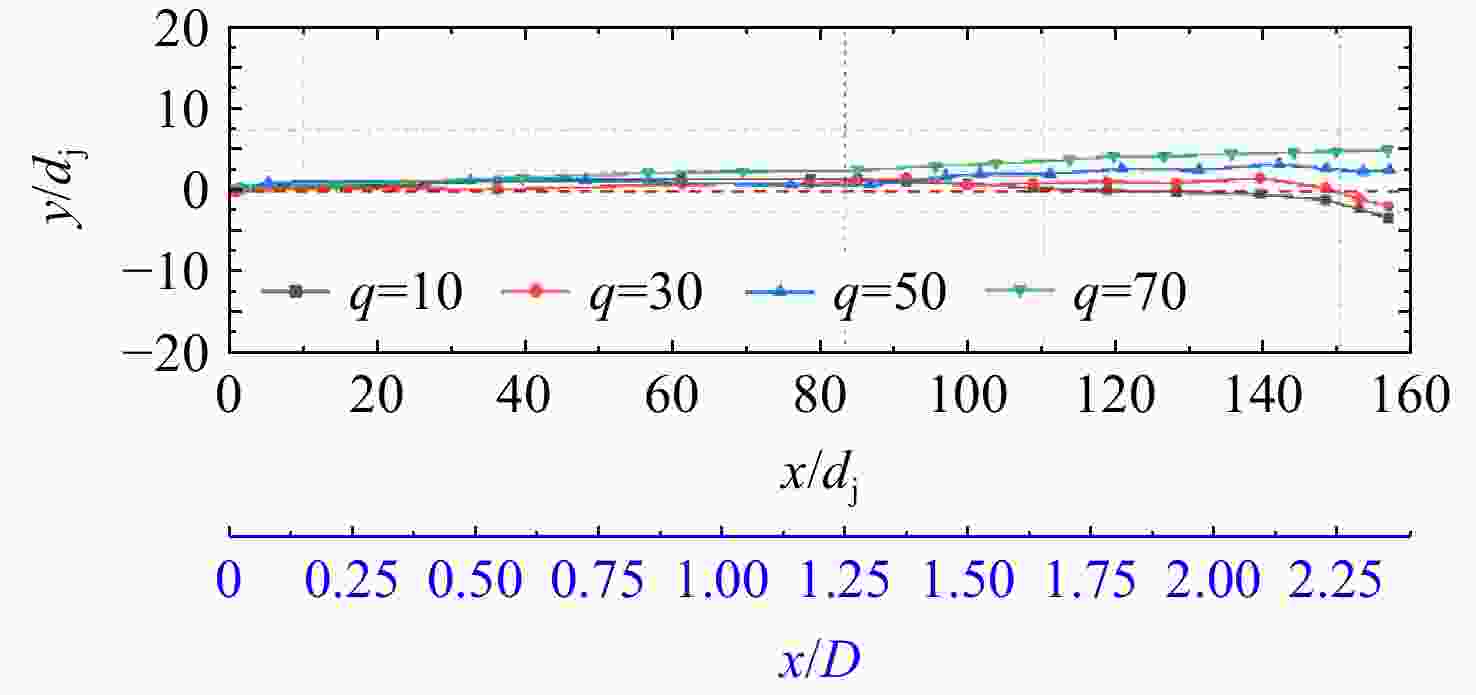

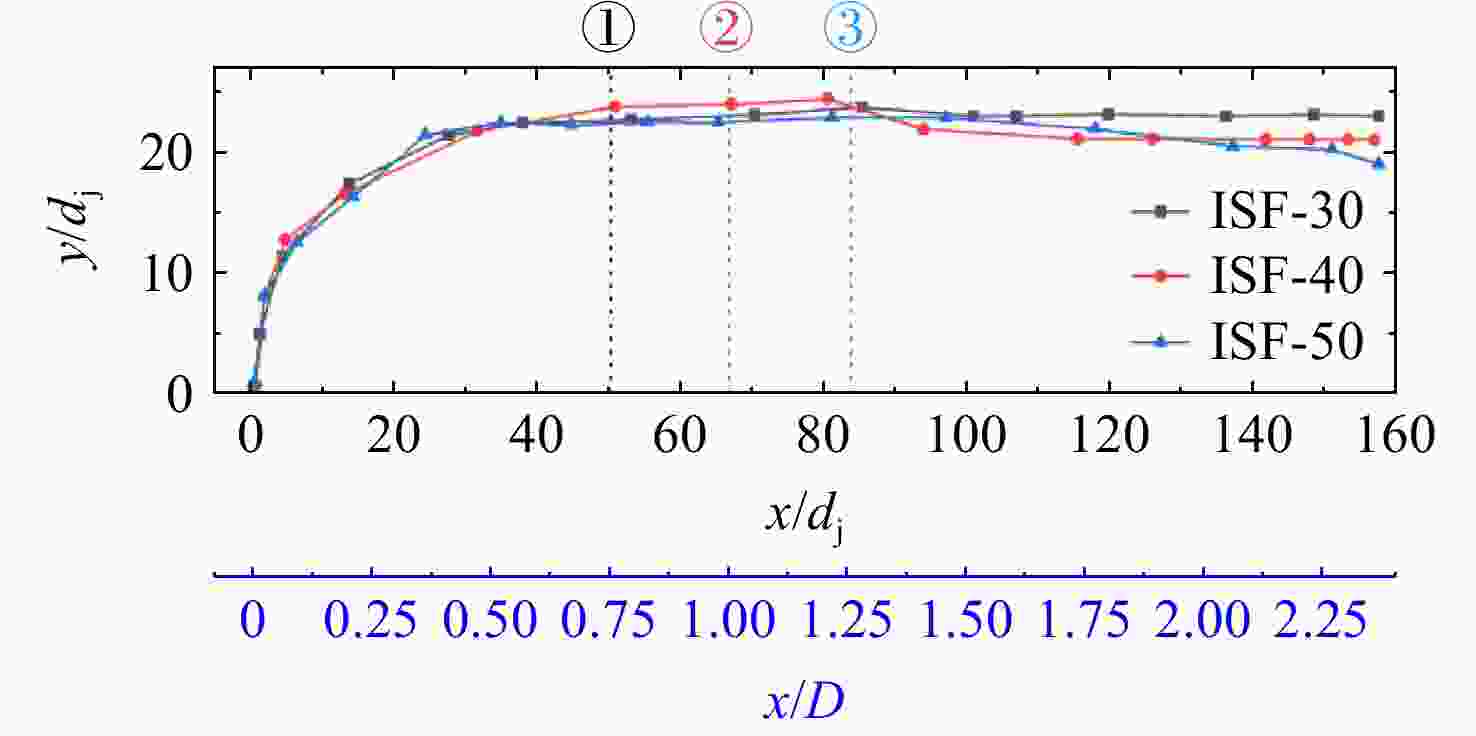

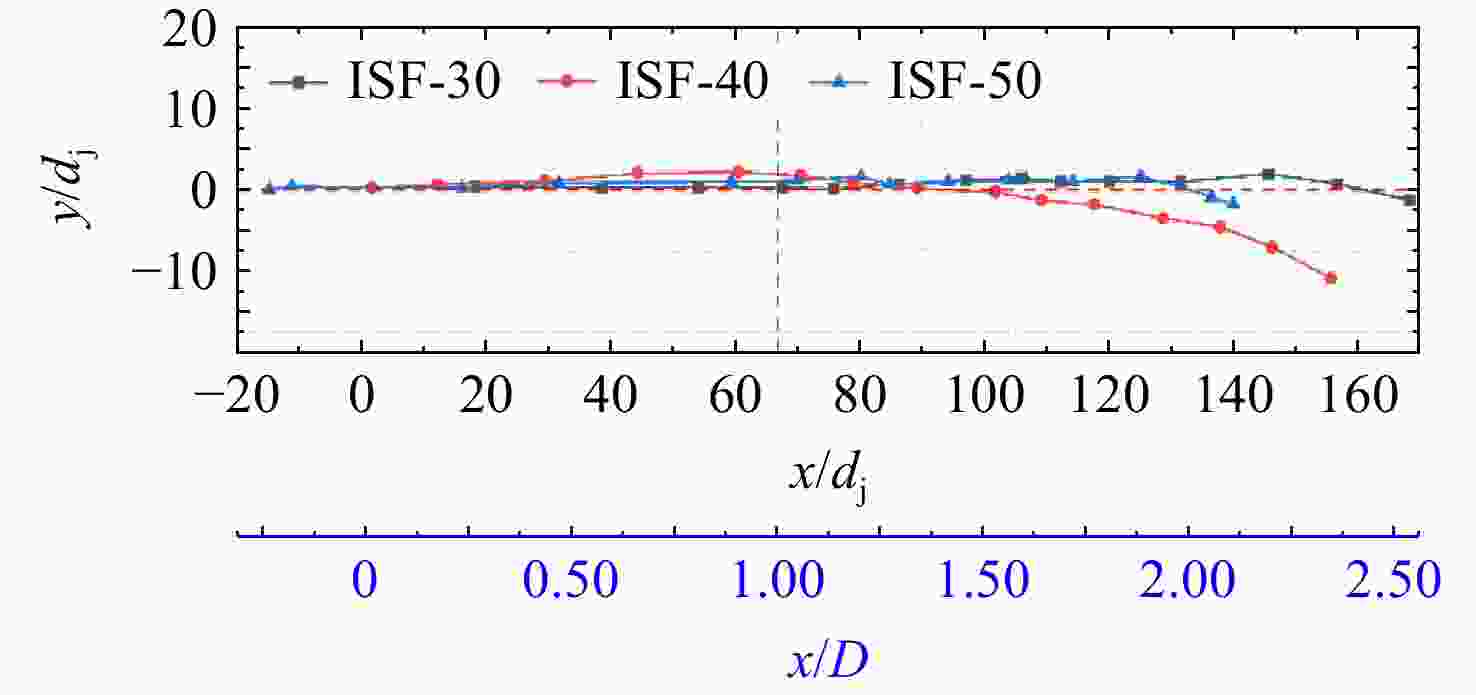

Abstract:The liquid spray distribution characteristics of a kind of integrated strut flameholder (ISF) with cross injection were studied with water, under the conditions of ambient temperature and pressure, incoming flow Mach number 0.182 and liquid-air momentum ratio range from 10 to 70, using laser sheet/photography. The effect of liquid-air momentum ratio and injection position on the distribution trajectory of liquid spray was discussed. The results showed that the outer trajectory of the liquid spray of ISF was similar to that of the crossflow, and the inner trajectory was bent back to the recirculation zone owing to the entrainments of the recirculation zone, which was more significant for low liquid-air momentum ratio condition. The liquid-air momentum ratio served as an important factor for inner and outer trajectory of the spray; the penetration depth of the liquid spray of ISF increased with the increase of liquid-air momentum ratio. The injection position of ISF had little influence on the outer trajectory of the liquid spray, but had a significant influence on the inner trajectory. It was not good for the entrainments of spray into recirculation zone when the injection distance was too far or too close, which was related to the closely coupling of the liquid injection and the flameholder.

-

-

[1] LOVETT J, BROGAN T, PHILIPPONA D, et al. Development needs for advanced after-burner designs[R]. AIAA 2004-4192, 2004. [2] 胡晓煜. 美国全面实施下一代军用航空发动机技术发展计划[J]. 国际航空,2007(12): 40-42.HU Xiaoyu. US’ new advanced turbine engine technology development program[J]. International Aviation,2007(12): 40-42. (in Chinese) [3] EBRAHIMI H B. Overview of gas turbine augmentor design, operation and combustion oscillation[R]. Toronto, Canada: 19th Annual Conference on Liquid Atomization and Spray Systems, 2006. [4] 张孝春,孙雨超,刘涛. 先进加力燃烧室设计技术综述[J]. 航空发动机,2014,40(2): 24-30,60. doi: 10.13477/j.cnki.aeroengine.2014.02.006ZHANG Xiaochun,SUN Yuchao,LIU Tao. Summary of advanced afterburner design technology[J]. Aeroengine,2014,40(2): 24-30,60. (in Chinese) doi: 10.13477/j.cnki.aeroengine.2014.02.006 [5] 孙雨超,张志学,李江宁,等. 一体化加力燃烧室方案设计及数值研究[J]. 航空科学技术,2011(4): 71-74. doi: 10.3969/j.issn.1007-5453.2011.04.021SUN Yuchao,ZHANG Zhixue,LI Jiangning,et al. Design and numerical research of integrated rear frame and afterburner[J]. Aeronautical Science and Technology,2011(4): 71-74. (in Chinese) doi: 10.3969/j.issn.1007-5453.2011.04.021 [6] 季鹤鸣, 樊于军, 杨茂林. 新型内突扩加力燃烧室方案可行性分析[J]. 航空发动机, 2006, 32(1); 35-37.JI Heming, FAN Yujun, YANG Maolin. Feasibility analysis of a new inner dumped afterburner concept[J]. Aeroengine, 2006, 32(1): 35-37. (in Chinese) [7] CLEMENTS T R, GRAVES C B. Augmentor burner: US5385015A[P]. 1995-01-31. [8] CLEMENTS T R. Method for distributing fuel within an augmentor: US5685140[P]. 1997-11-11. [9] KOSHOFFER J M. Method and apparatus for gas turbine engine: US6983601[P]. 2006-01-10. [10] ZINN B T, VAKILI A D, YU F M. Stability limits and fuel placement in carbureted fuel injection system (CFIS) flameholder[R]. AIAA 86-0280, 1986. [11] LOVETT J A, CROSS C, LUBARSKY E, et al. A review of mechanisms controlling bluff-body stabilized flames with closely-coupled fuel injection[R]. ASME GT2011-46676, 2011. [12] 刘广海,刘玉英,谢奕. 凹腔对一体化支板火焰稳定器燃烧性能的影响[J]. 航空动力学报,2018,33(8): 1838-1844. doi: 10.13224/j.cnki.jasp.2018.08.006LIU Guanghai,LIU Yuying,XIE Yi. Effect of cavity on combustion characteristics of integrated strut flame stabilizer[J]. Journal of Aerospace Power,2018,33(8): 1838-1844. (in Chinese) doi: 10.13224/j.cnki.jasp.2018.08.006 [13] 刘玉英,周春阳,谢奕,等. 一体化凹腔支板稳定器贫油熄火性能初步试验[J]. 航空动力学报,2020,35(1): 75-80. doi: 10.13224/j.cnki.jasp.2020.01.009LIU Yuying,ZHOU Chunyang,XIE Yi,et al. Preliminary experiment on the lean blow-off of an integrated cavity-based struct flameholder[J]. Journal of Aerospace Power,2020,35(1): 75-80. (in Chinese) doi: 10.13224/j.cnki.jasp.2020.01.009 [14] 刘广海,刘玉英. 翼型支板火焰稳定器结构参数的研究[J]. 航空动力学报,2015,30(6): 1350-1356. doi: 10.13224/j.cnki.jasp.2015.06.009LIU Guanghai,LIU Yuying. Investigation on structural parameters of airfoil shaped strut flame stabilizer[J]. Journal of Aerospace Power,2015,30(6): 1350-1356. (in Chinese) doi: 10.13224/j.cnki.jasp.2015.06.009 [15] 罗莲军,刘玉英,张文龙,等. 喷油杆与凹腔支板稳定器近距匹配雾化特性[J]. 航空动力学报,2013,28(11): 2462-2467. doi: 10.13224/j.cnki.jasp.2013.11.011LUO Lianjun,LIU Yuying,ZHANG Wenlong,et al. Atomization characteristics of fuel injector and cavity-based strut flame stabilizer under close-range matching condition[J]. Journal of Aerospace Power,2013,28(11): 2462-2467. (in Chinese) doi: 10.13224/j.cnki.jasp.2013.11.011 [16] 刘玉英,周弘毅,谢奕,等. 喷油杆和凹腔支板稳定器近距匹配的液雾分布可视化[J]. 航空动力学报,2018,33(3): 549-556. doi: 10.13224/j.cnki.jasp.2018.03.005LIU Yuying,ZHOU Hongyi,XIE Yi,et al. Visualization on spray distribution of close-coupled fuel injector and struct with cavity flameholder system[J]. Journal of Aerospace Power,2018,33(3): 549-556. (in Chinese) doi: 10.13224/j.cnki.jasp.2018.03.005 [17] 黄勇, 林宇震, 樊未军. 燃烧与燃烧室[M]. 北京: 北京航空航天大学出版社, 2009. [18] 林宇震,李林,张弛,等. 液体射流喷入横向气流混合特性研究进展[J]. 航空学报,2014,35(1): 46-57.LIN Yuzhen,LI Lin,ZHANG Chi,et al. Progress on the mixing of liquid jet injected into a crossflow[J]. Acta Aeronautica Sinica,2014,35(1): 46-57. (in Chinese) [19] ELSHAMY O M. Experimental investigations of steady and dynamic behavior of transverse liquid jets[D]. Cincinnati, US: University of Cincinnati, 2007. [20] 金仁瀚,张铮,刘勇,等. 横向加热气流中直射式喷嘴侧喷雾化特性研究[J]. 推进技术,2013,34(5): 658-663. doi: 10.13675/j.cnki.tjjs.2013.05.014JIN Renhan,ZHANG Zheng,LIU Yong,et al. Experimental study on atomization characteristics of simple nozzle in heating cross flow[J]. Journal of Propulsion Technology,2013,34(5): 658-663. (in Chinese) doi: 10.13675/j.cnki.tjjs.2013.05.014 [21] LEFEBVRE A H. Atomization and spray[M]. New York, US: Hemisphere Publishing Corporation, 1989. [22] AMIRREZA A,NASSER A. Global droplet size in liquid jet in a high-temperature and high-pressure crossflow[J]. AIAA Journal,2019,57(3): 1260-1273. doi: 10.2514/1.J056496 [23] 李晨阳,吴里银,李春,等. 超声速气流中凹腔对液体射流穿透深度的影响[J]. 航空动力学报,2018,33(1): 232-238. doi: 10.13224/j.cnki.jasp.2018.01.028LI Chenyang,WU Liyin,LI Chun,et al. Efffect of cavity on liquid jet penetration in supersonic crossflow[J]. Journal of Aerospace Power,2018,33(1): 232-238. (in Chinese) doi: 10.13224/j.cnki.jasp.2018.01.028 [24] 谢凤英. 数字图像处理及应用[M]. 北京: 电子工业出版社, 2016. [25] AMIGHI A,ESLAMIAN M. Atomization of liquid jet in high-pressure and high-temperature subsonic crossflow[J]. AIAA Journal,2014,52(7): 1374-1385. doi: 10.2514/1.J052548 [26] WU P K,KIRKENDALL K A,FULLER R P,et al. Spray structures of liquid fuel jets atomized in subsonic crossflows[J]. Journal of Propulsion and Power,1988,14(2): 173-182. [27] YOON H J,HONG J G,LEE C. Correlations for penetration height of single and double liquid jets in cross flow under high-temperature conditions[J]. Atomization and Sprays,2011,21(8): 673-686. doi: 10.1615/AtomizSpr.2012004212 -

下载:

下载: