Numerical simulation and experimental validation for erosion wear of TC4 plates

-

摘要:

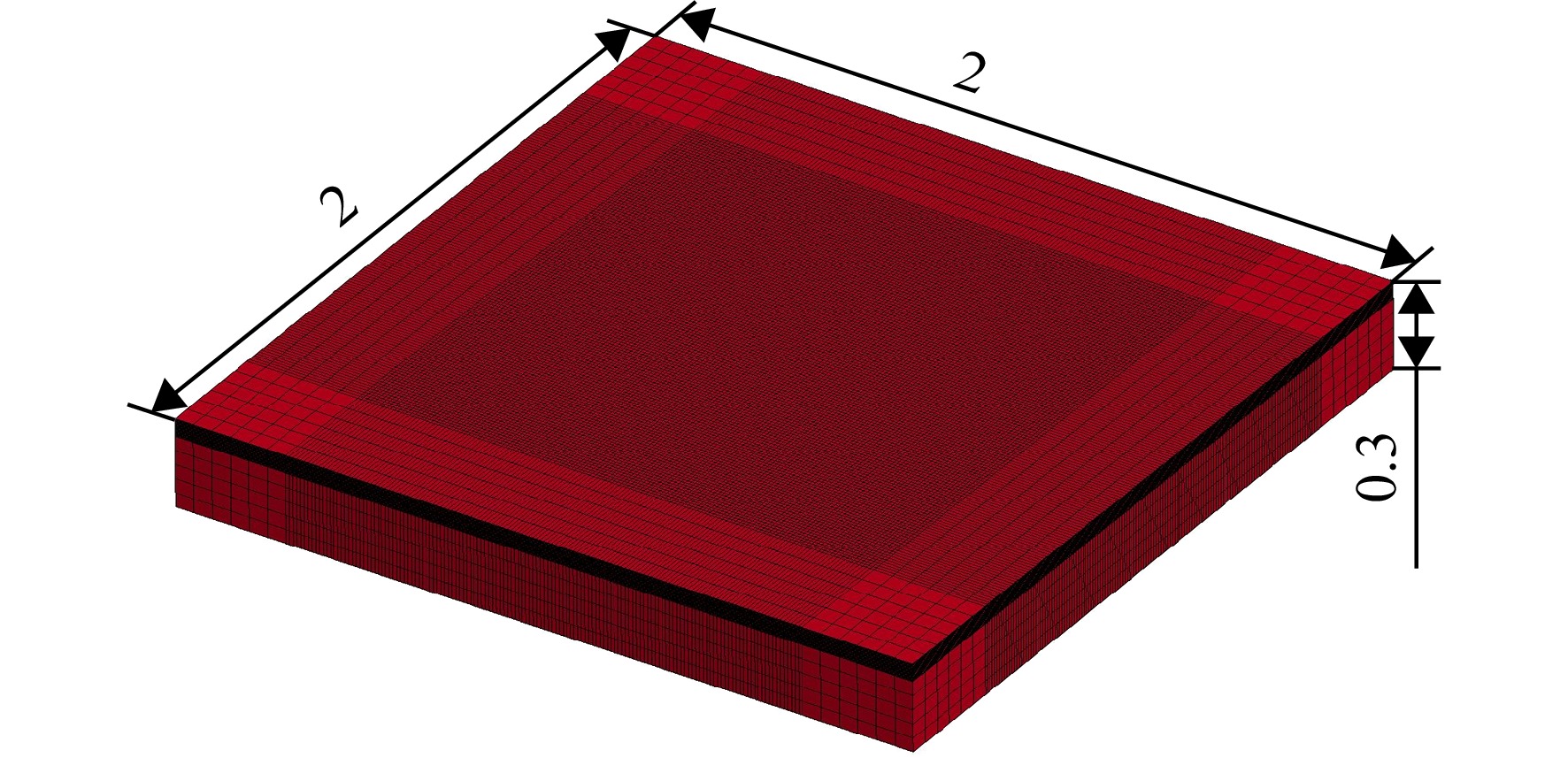

为了准确地预测不同冲蚀机制下TC4材料的冲蚀率,通过有限元法建立多颗粒随机冲蚀模型,研究在不同颗粒形状、冲击角与冲击速度的Al2O3颗粒冲蚀下TC4平板的冲蚀机理和冲蚀率。通过与相同条件下的冲蚀试验获得的冲蚀率进行对比,验证了数值仿真模型的合理性与真实性。结果表明:30°的低角度冲蚀仿真应使用正方体颗粒,其棱角与材料的相对运动更符合刀具切削的过程;90°的高角度冲蚀仿真应使用球形颗粒,能体现冲蚀过程中对凹坑接触面造成的剪切和挤压作用;相同条件下颗粒冲击速度越大,冲蚀率增长越快,30°的冲蚀率增长较为迅速,90°的冲蚀率增长较为平缓。

Abstract:In order to accurately predict the erosion rate of TC4 material under different erosion mechanisms, a multi-particle random erosion model was established by finite element method, and the erosion mechanism and erosion rate of TC4 plate under the erosion of Al2O3 particles with different particle shapes, impact angles and impact velocities were studied. Compared with the erosion rate obtained by erosion test under the same conditions, the rationality and authenticity of the numerical simulation model were verified. Results showed that cubic particles should be used in the simulation of low-angle erosion at 30 degrees, and the relative movement between edges and materials was more in line with the cutting process. Spherical particles should be used in the simulation of 90 degrees high-angle erosion, which can reflect the shearing and squeezing effects on the contact surface of pits during erosion. Under the same conditions, the greater the impact velocity of particles was, the faster the erosion rate increased, the faster the erosion rate increased at 30 degrees, and the more gentle the erosion rate increased at 90 degrees.

-

Key words:

- TC4 plate /

- erosion rate /

- finite element method /

- particle shape /

- impingement angle

-

表 1 TC4平板的材料参数

Table 1. Material parameter of TC4 plate

材料参数 Ti-6Al-4V 密度ρ/(kg/m3) 4430 弹性模量E/GPa 110 泊松比υ 0.33 J-C屈服强度A/MPa 1098 J-C硬化系数B/MPa 1092 应变硬化系数n 0.93 应变率硬化常数C 0.014 热熔化系数m 1.1 熔点Tm/K 1903 比热容cp/(J/(kg·K)) 670 J-C失效参数d1 −0.09 J-C失效参数d2 0.27 J-C失效参数d3 0.48 J-C失效参数d4 0.014 J-C失效参数d5 3.87 C0/(km/s) 5130 S 1.028 Grüneisen系数γ 1.23 表 2 Al2O3颗粒材料参数

Table 2. Material parameters of Al2O3 particles

材料参数 数值 密度ρ/(kg/m3) 4000 弹性模量E/GPa 310 泊松比υ 0.22 表 3 数值仿真模型条件设置

Table 3. Condition setting of numerical simulation model

编号 形状 冲击角/(°) 冲击速度/(m/s) 1 球 90 90 2 球 90 107 3 球 90 122 4 球 90 132 5 球 30 90 6 球 30 107 7 球 30 122 8 球 30 132 9 正方体 90 90 10 正方体 90 107 11 正方体 90 122 12 正方体 90 132 13 正方体 30 90 14 正方体 30 107 15 正方体 30 122 16 正方体 30 132 表 4 试验条件设置

Table 4. Test condition setting

编号 粒径/µm 冲击角/(°) 冲击速度/(m/s) 1 180 90 90 2 180 90 107 3 180 90 122 4 180 90 132 5 180 30 90 6 180 30 107 7 180 30 122 8 180 30 132 表 5 全角度范围仿真与试验条件设置

Table 5. Full angle range simulation and test condition setting

冲击角/(°) 试验 仿真 编号 形状 编号 形状 15 9 球、正方体 17 球 18 正方体 45 10 球、正方体 19 球 20 正方体 60 11 球、正方体 21 球 22 正方体 75 12 球、正方体 23 球 24 正方体 -

[1] HAMED A,TABAKOFF W C,WENGLARZ R V. Erosion and deposition in turbomachinery[J]. Journal of Propulsion and Power,2006,22(2): 350-360. doi: 10.2514/1.18462 [2] FINNIE I,MCFADDEN D H. On the velocity dependence of the erosion of ductile metals by solid particles at low angles of incidence[J]. Wear,1978,48(1): 181-190. doi: 10.1016/0043-1648(78)90147-3 [3] BITTER J G A. A study of erosion phenomena: Part Ⅰ[J]. Wear,1963,6(1): 5-21. doi: 10.1016/0043-1648(63)90003-6 [4] BITTER J G A. A study of erosion phenomena: Part Ⅱ[J]. Wear,1963,6(1): 169-190. doi: 10.1016/0043-1648(63)90073-5 [5] ELTOBGY M S,NG E,ELBESTAWI M A. Finite element modeling of erosive wear[J]. International Journal of Machine Tools and Manufacture,2005,45(11): 1337-1346. doi: 10.1016/j.ijmachtools.2005.01.007 [6] WANG Yufei,YANG Zhenguo. Finite element model of erosive wear on ductile and brittle materials[J]. Wear,2008,265(5/6): 871-878. doi: 10.1016/j.wear.2008.01.014 [7] AZIMIAN M,SCHMITT P,BART H J. Numerical investigation of single and multi-impacts of angular particles on ductile surfaces[J]. Wear,2015,342/343: 252-261. doi: 10.1016/j.wear.2015.08.022 [8] 马松林,赵振华,颜诚,等. 不同形状砂尘高速冲蚀TC4平板的数值仿真[J]. 航空动力学报,2019,34(2): 321-330. doi: 10.13224/j.cnki.jasp.2019.02.008MA Songlin,ZHAO Zhenhua,YAN Cheng,et al. Numerical simulation of TC4 plates with high speed erosion of sand dust with different shapes[J]. Journal of Aerospace Power,2019,34(2): 321-330. (in Chinese) doi: 10.13224/j.cnki.jasp.2019.02.008 [9] 杜明超,李增亮,董祥伟,等. 菱形颗粒冲击材料表面冲蚀磨损特性分析[J]. 摩擦学学报,2020,40(1): 1-11. doi: 10.16078/j.tribology.2019066DU Mingchao,LI Zengliang,DONG Xiangwei,et al. Analysis of material surface erosion characteristics due to rhomboid-shaped particle impact[J]. Tribology,2020,40(1): 1-11. (in Chinese) doi: 10.16078/j.tribology.2019066 [10] 王光存. 离心压缩机叶轮冲蚀磨损机理和规律的研究[D]. 济南: 山东大学, 2015.WANG Guangcun. Study on erosion wear mechanism and law of impeller in centrifugal compressor[D]. Jinan: Shandong University, 2015. (in Chinese) [11] JOHNSON G R,COOK W H. A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures[J]. Engineering Fracture Mechanics,1983,21: 541-548. [12] GREGORY K. Failure modeling of titanium 6Al-4V and aluminum 2024-T3 with the Johnson-cook material model[R]. Washington DC: Department of Transportation Federal Aviation Administration, 2003. [13] ZHANG Yancheng,OUTEIRO J C,MABROUKI T. On the selection of Johnson-Cook constitutive model parameters for Ti-6Al-4 V using three types of numerical models of orthogonal cutting[J]. Procedia CIRP,2015,31: 112-117. doi: 10.1016/j.procir.2015.03.052 [14] 唐长刚. LS-DYNA有限元分析及仿真[M]. 北京: 电子工业出版社, 2014. [15] WOYTOWITZ P J,RICHMAN R H. Modeling of damage from multiple impacts by spherical particles[J]. Wear,1999,233/234/235: 120-133. [16] YERRAMAREDDY S,BAHADUR S. Effect of operational variables, microstructure and mechanical properties on the erosion of Ti-6Al-4V[J]. Wear,1991,142(2): 253-263. doi: 10.1016/0043-1648(91)90168-T [17] PEPI M,SQUILLACIOTI R,PFLEDDERER L,et al. Solid particle erosion testing of helicopter rotor blade materials[J]. Journal of Failure Analysis and Prevention,2012,12(1): 96-108. doi: 10.1007/s11668-011-9531-3 [18] EVSTIFEEV A,KAZARINOV N,PETROV Y,et al. Experimental and theoretical analysis of solid particle erosion of a steel compressor blade based on incubation time concept[J]. Engineering Failure Analysis,2018,87: 15-21. doi: 10.1016/j.engfailanal.2018.01.006 [19] 董刚. 材料冲蚀行为及机理研究[D]. 杭州: 浙江工业大学, 2004.DONG Gang. Study on the erosion wear behaviors and mechanisms of several materials[D]. Hangzhou: Zhejiang University of Technology, 2004. (in Chinese) [20] American Society of Testing Materials (ASTM). Standard test method for conducting erosion tests by solid particle impingement using gas jets: ASTM G76-13 [S]. West Conshohocken: ASTM, 2013: 1-6. -

下载:

下载: