Parameter optimization of dual gas flow combined thermal test based on surrogate model

-

摘要:

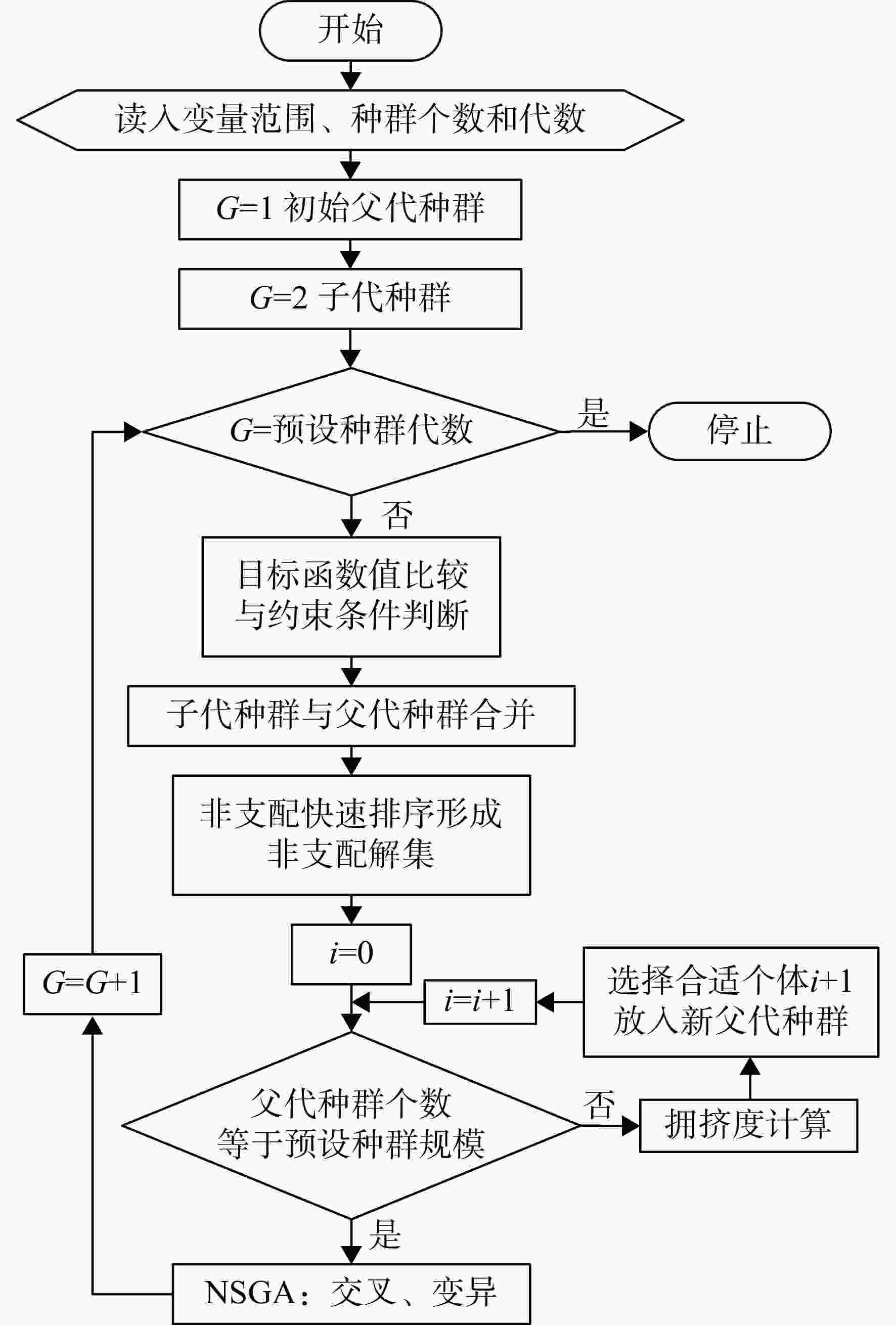

为确保双路燃气组合热试验过程中试件表面热流与高超声速气动热流的吻合性,对试验参数进行了优化设计。针对典型尖楔结构建立了双路燃气组合加热的数值计算模型,通过拉丁超立方采样及基于模糊聚类的加点策略获取了128个样本点,开展了数值模拟,并采用Kriging代理模型以及带精英策略的非支配排序遗传优化算法,以燃气加热热流与气动热流的吻合度为优化目标,完成了多目标优化。结果表明,通过增加样本点,显著减小了代理模型误差;8个测试样本点下试件表面热流密度平均相对误差最大约为7%,大部分区域平均误差不超过5%,方均根误差的均值为1.72%,最大值误差的最大值为13.6%,表明Kriging代理模型具有较高的预测精度;通过优化,试件表面燃气加热热流分布与气动加热热流分布吻合较好,驻点处热流密度相对误差小于1%,平板区域相对误差不超过10%,表明了基于Kriging代理模型的双路燃气组合热试验参数优化方法的有效性。

Abstract:In order to ensure the coincidence between heat flux on the surface of the specimen during the dual gas flow combined thermal test and hypersonic aerodynamic heat flow, the test parameters were optimized. Numerical model of the dual gas flow combined heating for typical tip wedge structure was built, 128 samples were selected via the Latin Hypercube sampling method and the adding-point strategy based on fuzzy clustering, and numerical simulation was carried out. Then, Kriging surrogate model and elitist non-dominated sorting generic algorithm were applied in multi-objective optimization, which aimed at minimizing the difference between gas flow heating and hypersonic aerodynamic heating. The results showed that the error of surrogate model was significantly reduced by increasing samples. The maximum of mean relative errors of surface heat flux of 8 test samples was about 7%, and less than 5% in most areas, while the mean value of root mean square errors and the peak value of maximum errors were 1.72% and 13.6%, respectively, indicating that the Kriging surrogate model had high prediction accuracy. What’s more, through optimization, the distribution of surface heat flux by gas flow heating was in good agreement with that of hypersonic aerodynamic heat flow. The relative error of heat flux at stagnation was less than 1%, and no more than 10% at the flat plate area, which showed the effectiveness of parameters optimization of dual gas flow combined thermal test based on Kriging surrogate model.

-

Key words:

- high temperature gas flow /

- thermal test /

- optimization design /

- surrogate model /

- tip wedge structure

-

表 1 设计变量取值范围

Table 1. Value range of design variables

设计变量 取值范围 下限 上限 Ma1 0.1 0.5 Ma2 0.1 0.5 d/mm 1 8 l/mm 5 20 表 2 NSGA-Ⅱ算法参数设定值

Table 2. Parameter settings of NSGA-Ⅱ algorithm

参数 设定值 种群个数 10 种群代数 100 交叉概率 0.9 实数向量变异概率 1.0 二进制字符串变异概率 1.0 实数交叉分配指数 20 实数变异分配指数 20 表 3 测试样本取值

Table 3. Value of test samples

序号 Ma1 Ma2 d/mm l/mm 1 0.39 0.28 6.16 7.37 2 0.28 0.22 7.88 14.26 3 0.34 0.40 1.73 9.01 4 0.20 0.41 6.58 10.75 5 0.10 0.32 4.00 5.03 6 0.23 0.16 2.70 18.39 7 0.44 0.48 4.56 14.78 8 0.48 0.13 2.99 17.16 表 4 测试样本点下表面热流密度误差

Table 4. Errors of surface heat flux of test samples

序号 $ {e_{{\text{NRMSE}}}} $/% $ {L_\infty } $/% 1 1.47 11.98 2 2.40 13.60 3 2.94 12.94 4 0.89 5.43 5 2.18 11.81 6 1.55 12.53 7 0.91 6.89 8 1.40 7.39 平均值 1.72 最大值 13.60 表 5 Pareto最优解及其相对坐标原点的距离

Table 5. Pareto optimal solution and distance from coordinate origin

编号 Ma1 Ma2 d/mm l/mm δ0/% δ1/% Δ No.966 0.410 0.110 1.73 10.04 13.4 17.0 0.22 No.758 0.413 0.113 2.14 8.87 6.5 21.9 0.23 No.738 0.412 0.113 2.18 10.08 8.9 21.3 0.23 No.920 0.410 0.110 2.15 10.04 9.8 20.9 0.23 No.879 0.410 0.113 2.18 10.04 9.7 21.2 0.23 No.808 0.415 0.105 2.13 8.05 4.3 23.4 0.24 No.946 0.410 0.110 2.16 8.08 6.0 23.0 0.24 No.508 0.403 0.105 1.01 8.69 19.9 14.2 0.25 No.504 0.401 0.109 1.28 8.89 19.0 16.0 0.25 No.882 0.405 0.108 1.01 10.32 22.0 12.0 0.25 No.832 0.405 0.102 1.01 10.70 22.6 11.9 0.26 No.982 0.416 0.102 2.35 8.38 3.0 25.4 0.26 No.452 0.403 0.128 1.02 11.47 25.7 11.3 0.28 No.916 0.424 0.104 2.35 7.96 1.3 31.3 0.31 No.941 0.425 0.102 2.35 7.96 1.3 32.9 0.33 No.267 0.395 0.128 1.02 12.92 32.2 10.1 0.34 No.192 0.393 0.142 1.02 12.90 33.8 9.4 0.35 -

[1] JOYCE P, POMROY J, GRINDLE L. The hyper-X launch vehicle: challenges and design considerations for hypersonic flight testing[R]. AIAA-2005-3333, 2005. [2] RONDEAU C M, JORRIS T R. X-51A scramjet demonstrator program: waverider ground and flight test[R]. Armed Services Technical Information Agency Documents, ADA593742, 2013. [3] GRANT P, SUSAN P. A heating analysis of the nosecap and leading edges of the X-34 vehicle[R]. AIAA 98-0878, 1998. [4] PRABHU D, LOOMIS M, VENKATAPATHY E, et al. X-33 aerothermal environment simulations and aerothermodynamic design[R]. AIAA-1998-0868, 1998. [5] 姚峰,董素君,王浚. 高温燃气热环境模拟方案仿真研究[J]. 航空动力学报,2010,25(4): 768-773.YAO Feng,DONG Sujun,WANG Jun. Numerical analysis of subsonic high-temperature-gas thermal environment simulation[J]. Journal of Aerospace Power,2010,25(4): 768-773. (in Chinese) [6] 董素君,齐玢,李志杰,等. 低速高温燃气流热模拟试验方法和设备[J]. 航空动力学报,2012,27(5): 961-968.DONG Sujun,QI Bin,LI Zhijie,et al. Approach and facility for aerodynamic thermal test by lower speed and high-temperature gas flow[J]. Journal of Aerospace Power,2012,27(5): 961-968. (in Chinese) [7] 董素君,李志杰,王浚. 尖楔结构低速高/中温双路气流组合热试验方法[J]. 航空动力学报,2013,28(2): 290-296.DONG Sujun,LI Zhijie,WANG Jun. Combined heating method of low speed and high/middle temperature gas flow for thermal test of tip wedge structure[J]. Journal of Aerospace Power,2013,28(2): 290-296. (in Chinese) [8] 陈鑫,刘莉,岳振江. 基于代理模型的高超声速气动热模型降阶研究[J]. 北京理工大学学报,2016,36(4): 340-347.CHEN Xin,LIU Li,YUE Zhenjiang. A reduced order modeling for aerothermodynamic of hypersonic vehicles based on surrogate method[J]. Transactions of Beijing Institute of Technology,2016,36(4): 340-347. (in Chinese) [9] 杨丽,佟操,陈闯,等. 基于Kriging模型和遗传算法的齿轮修形减振优化[J]. 航空动力学报,2017,32(6): 1412-1418.YANG Li,TONG Cao,CHEN Chuang,et al. Vibration reduction optimization of gear modification based on Kriging model and genetic algorithm[J]. Journal of Aerospace Power,2017,32(6): 1412-1418. (in Chinese) [10] 夏露,王丹,张阳,等. 基于自适应代理模型的气动优化方法[J]. 空气动力学学报,2016,34(4): 433-440.XIA Lu,WANG Dan,ZHANG Yang,et al. Aerodynamic optimization method based on adaptive surrogate model[J]. Acta Aerodynamica Sinica,2016,34(4): 433-440. (in Chinese) [11] 魏仁敏,杜刚,金捷. 基于Kriging代理模型的单边膨胀喷管尾缘切角优化[J]. 航空动力学报,2018,33(4): 874-881.WEI Renmin,DU Gang,JIN Jie. Optimization of trailing edge angles of single expansion ramp nozzle based on Kriging method[J]. Journal of Aerospace Power,2018,33(4): 874-881. (in Chinese) [12] 衣春轮,刘燕斌,曹瑞,等. 基于代理模型的高超声速飞行器外形参数优化[J]. 航空动力学报,2019,34(11): 2354-2365.YI Chunlun,LIU Yanbin,CAO Rui,et al. Shape parameters optimization of hypersonic vehicle based on surrogate model[J]. Journal of Aerospace Power,2019,34(11): 2354-2365. (in Chinese) [13] DEB K,PRATAP A,AGARWAL S,et al. A fast and elitist multiobjective genetic algorithm: NSGA-Ⅱ[J]. IEEE Transactions on Evolutionary Computation,2002,6(2): 182-197. doi: 10.1109/4235.996017 [14] JOHN J B,RUSSEL M C. Critical hypersonic aerothermodynamic phenomena[J]. Annual Review of Fluid Mechanics,2006(38): 129-157. [15] 齐玢,董素君,石泳,等. 典型尖楔结构燃气流热试验工况确定方法[J]. 航空动力学报,2018,33(4): 911-918.QI Bin,DONG Sujun,SHI Yong,et al. Determination method for thermal test condition of the tip wedge structure heated by high temperature gas flow[J]. Journal of Aerospace Power,2018,33(4): 911-918. (in Chinese) [16] XIONG Kai, LI Yunhua, DONG Sujun. Temperature distribution of a test specimen with high-speed heat air-flow passing through[J]. Thermal Science, 2018, 22(6A): 2527-2538. [17] 吴睿,聂万胜,蔡红华,等. UDMH/NTO火箭发动机尾焰流场特性数值仿真[J]. 航空动力学报,2018,33(4): 952-960.WU Rui,NIE Wansheng,CAI Honghua,et al. Numerical simulation of flow field characteristics of UDMH/NTO rocket engine plume[J]. Journal of Aerospace Power,2018,33(4): 952-960. (in Chinese) [18] CHEN Xin,LIU Li,LONG Teng,et al. A reduced order aerothermodynamic modeling framework for hypersonic vehicles based on surrogate and POD[J]. Chinese Journal of Aeronautics,2015,28(5): 1328-1342. doi: 10.1016/j.cja.2015.06.024 [19] CHEN Xin,CAO Zhanwei,FU Bin,et al. Adding-point strategy for surrogate-based reduced-order hypersonic aerothermodynamic modeling based on fuzzy clustering[J]. Journal of Spacecraft and Rockets,2021,58(1): 244-253. doi: 10.2514/1.A34813 -

下载:

下载: