Experiment on dynamic characteristics of squeeze film damper with different groove

-

摘要:

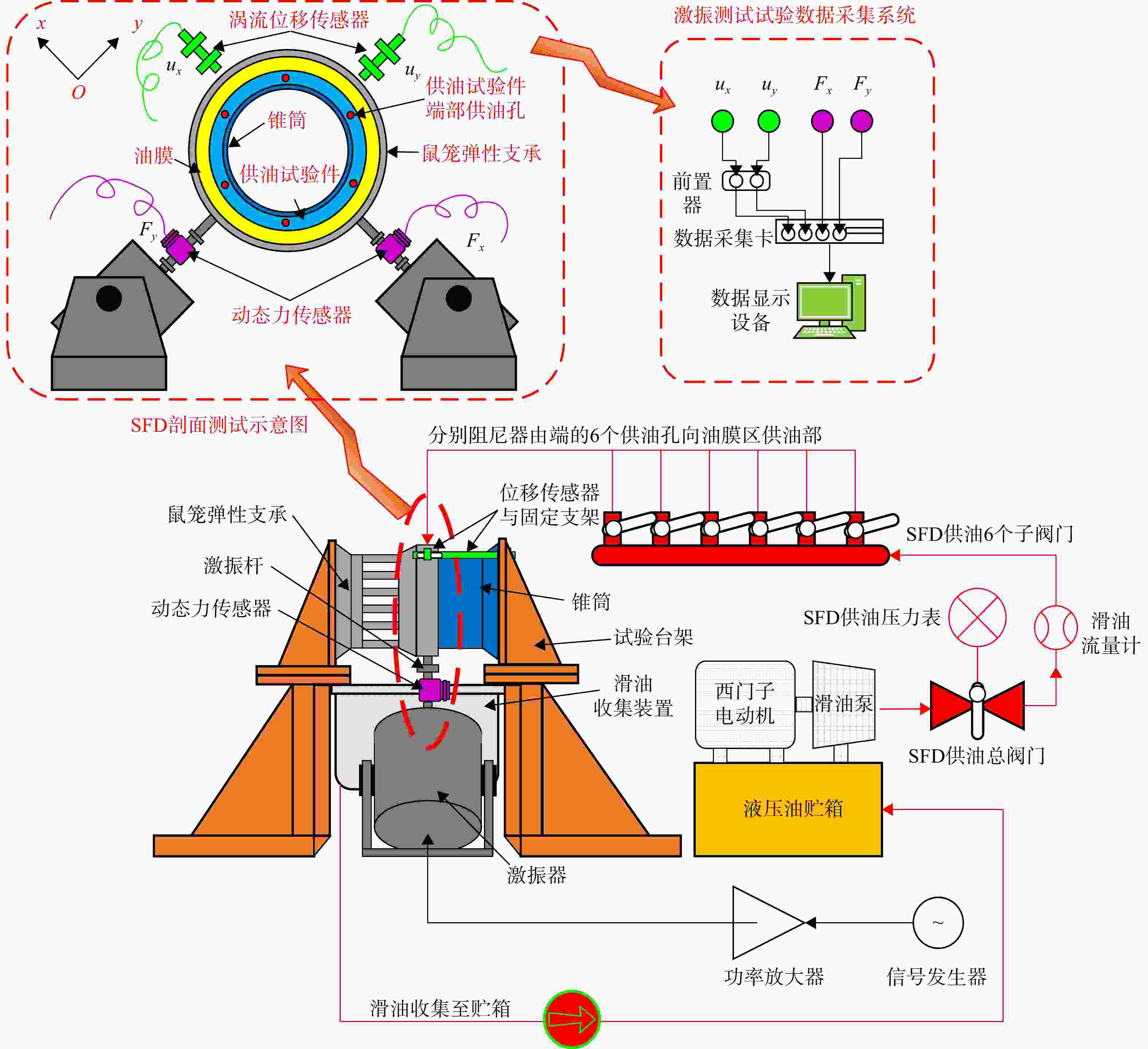

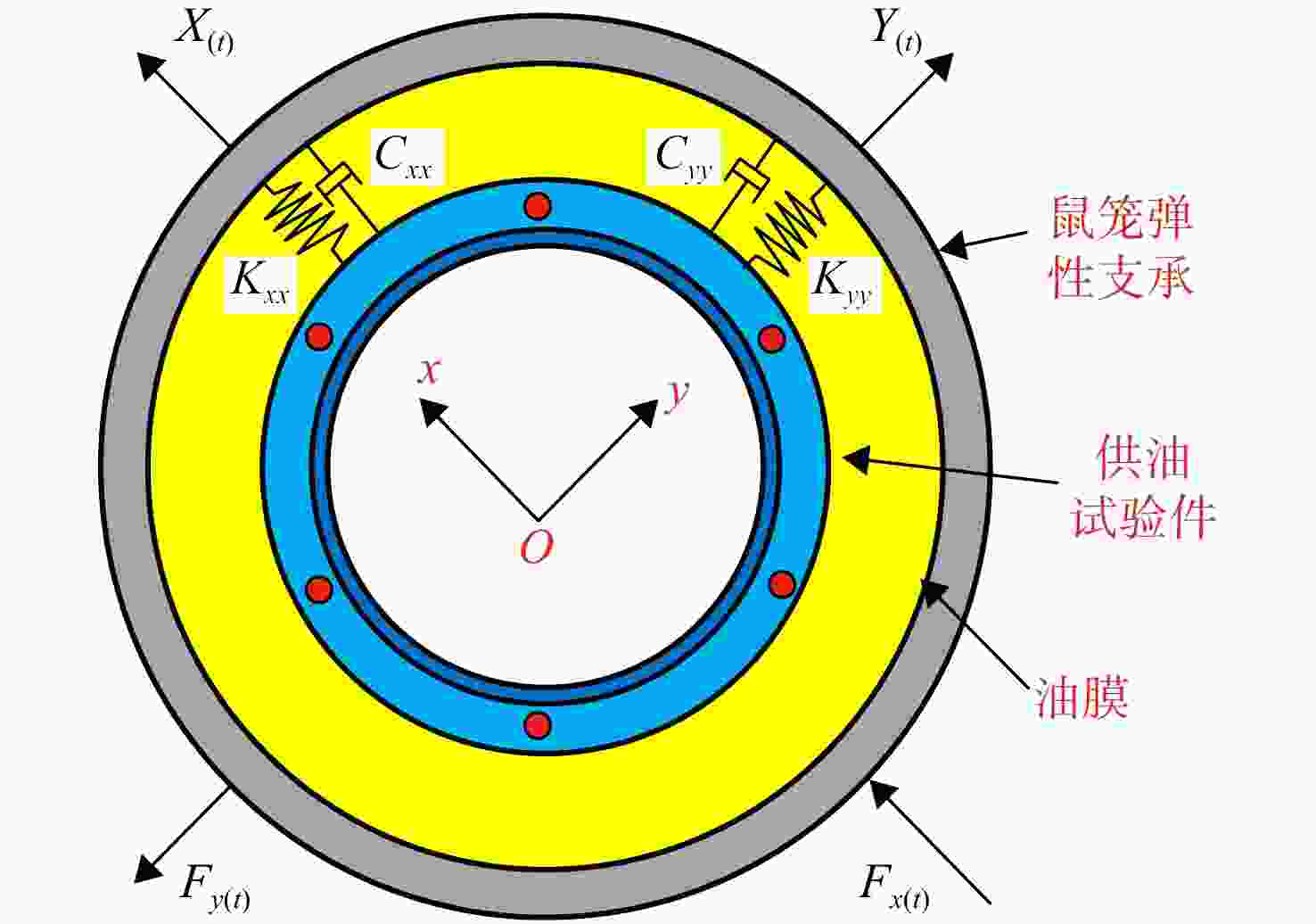

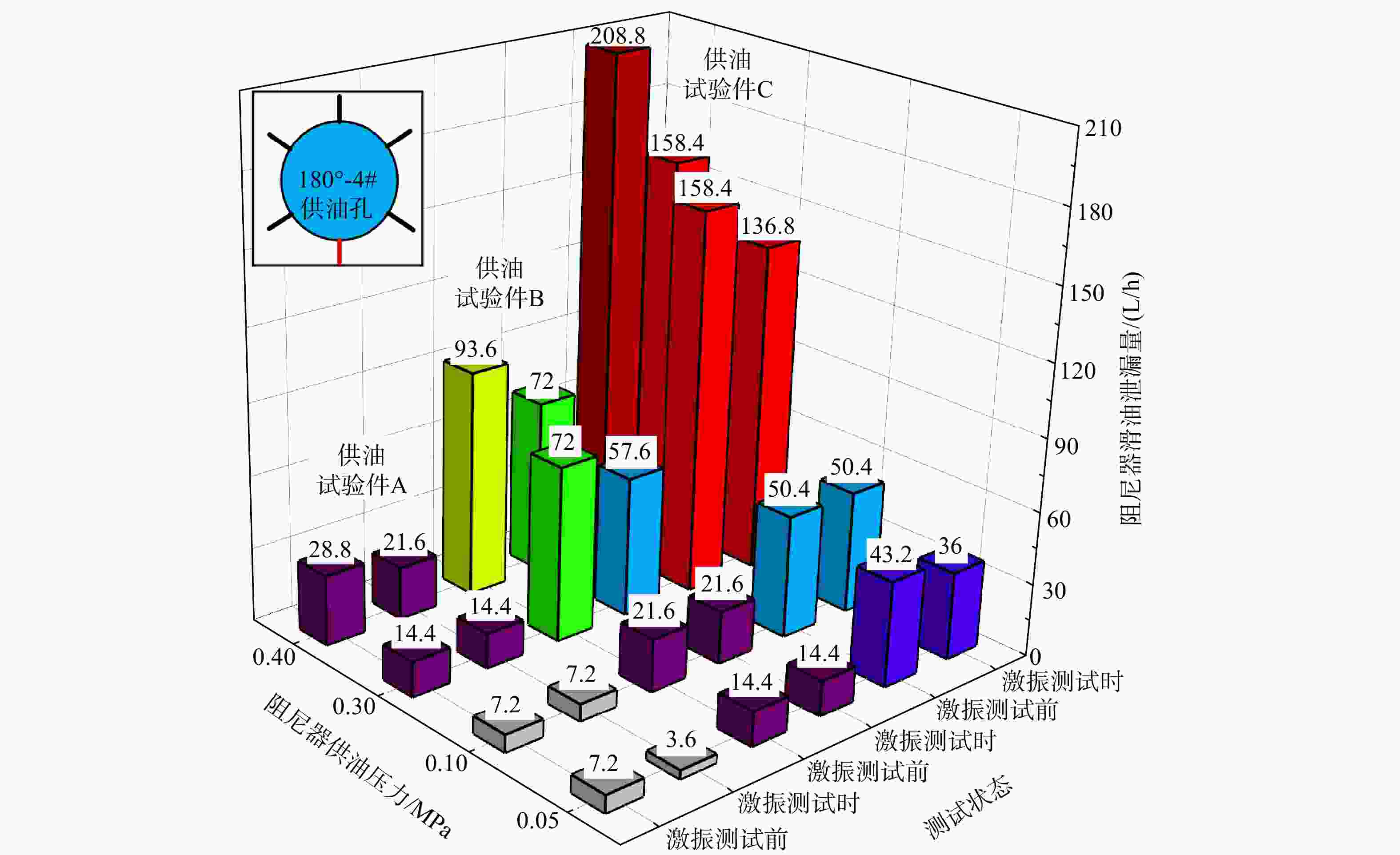

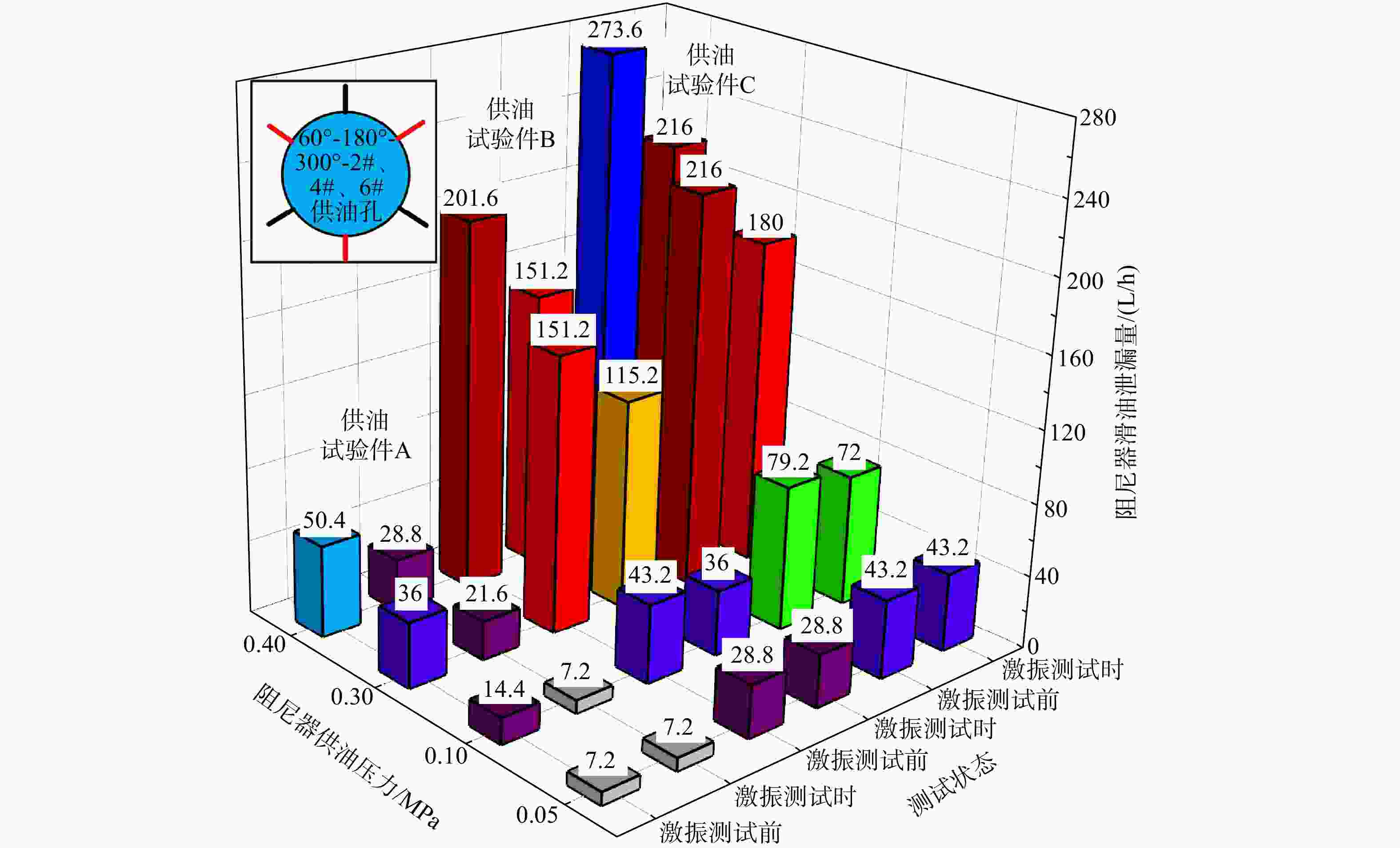

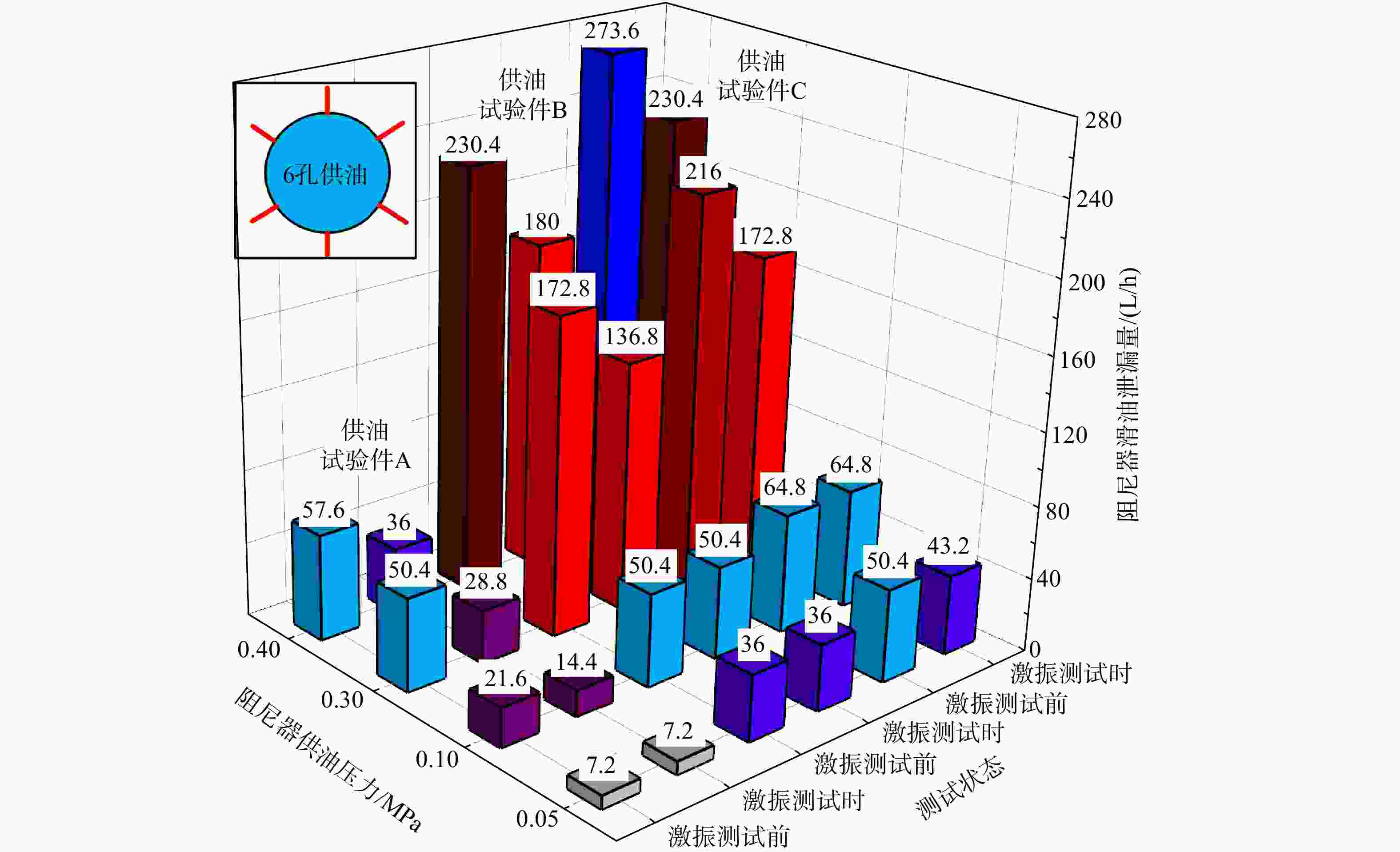

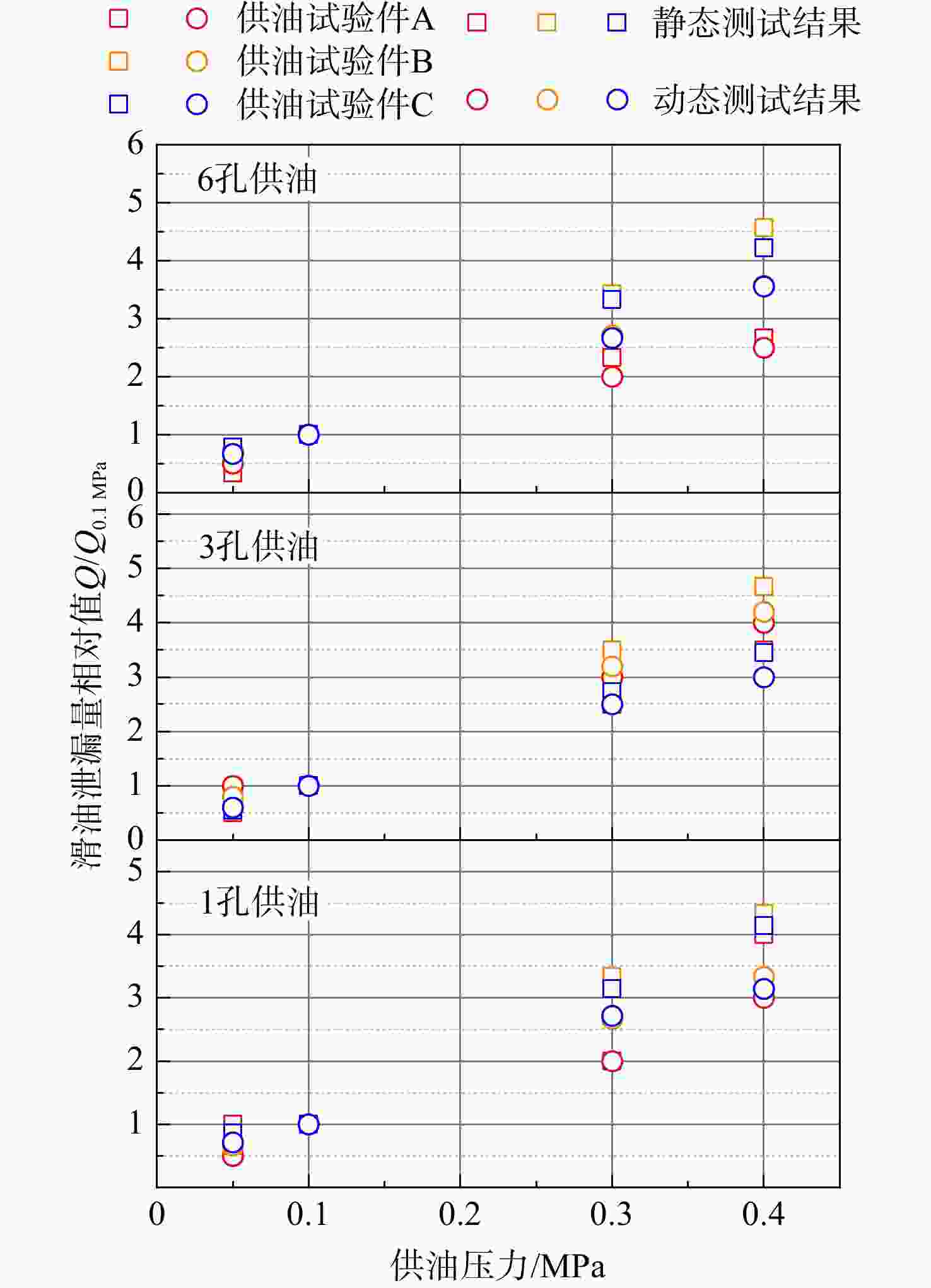

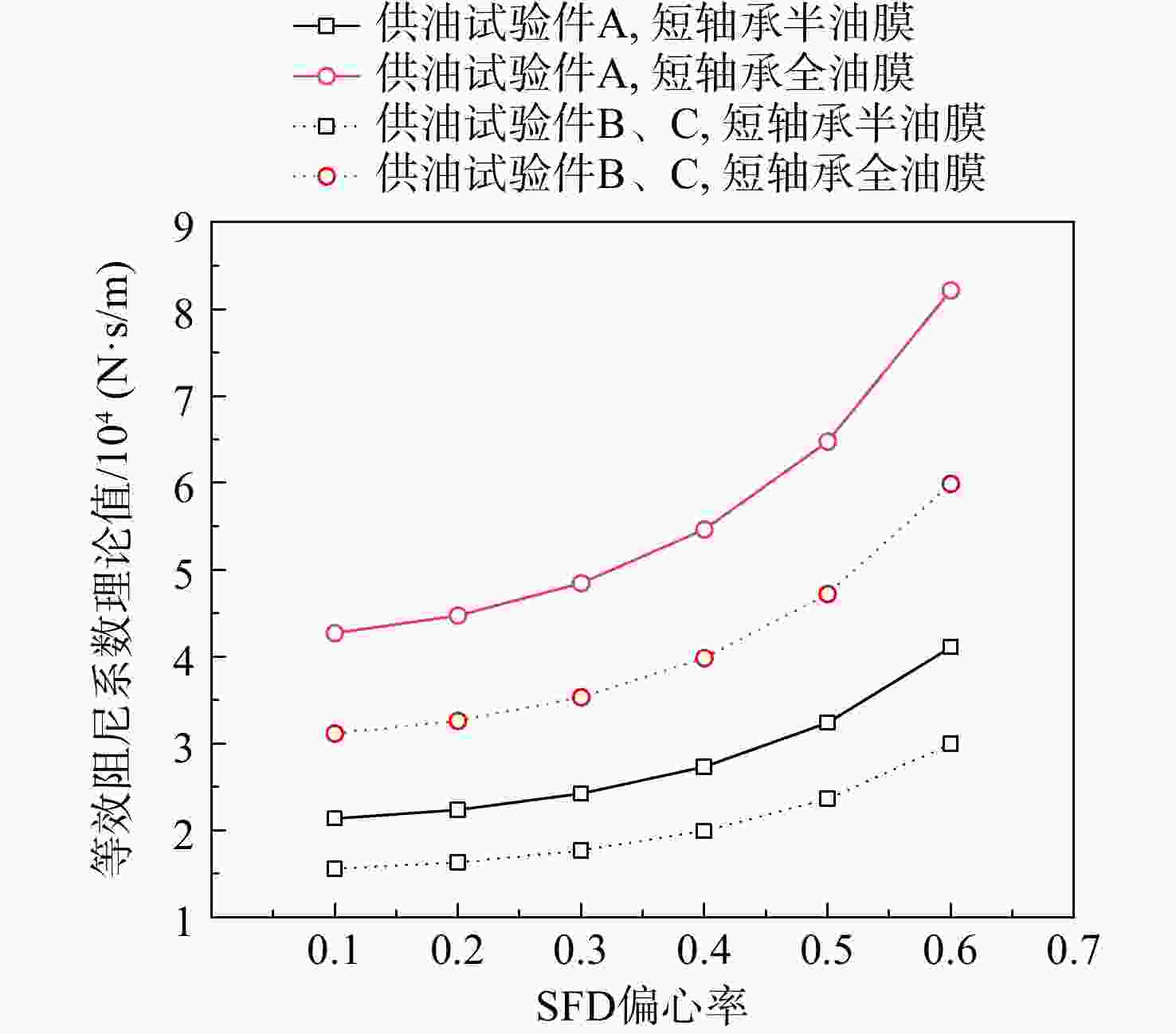

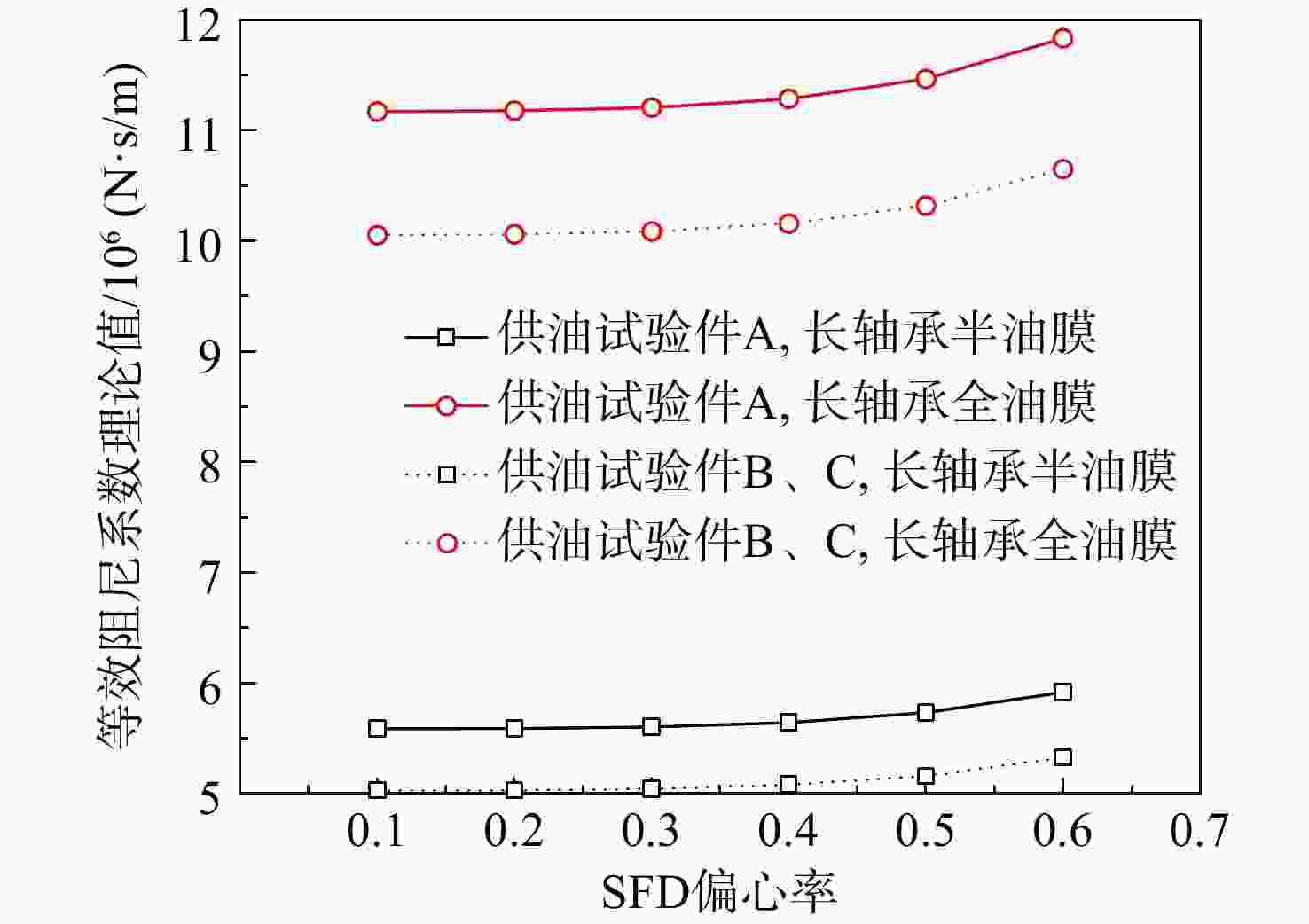

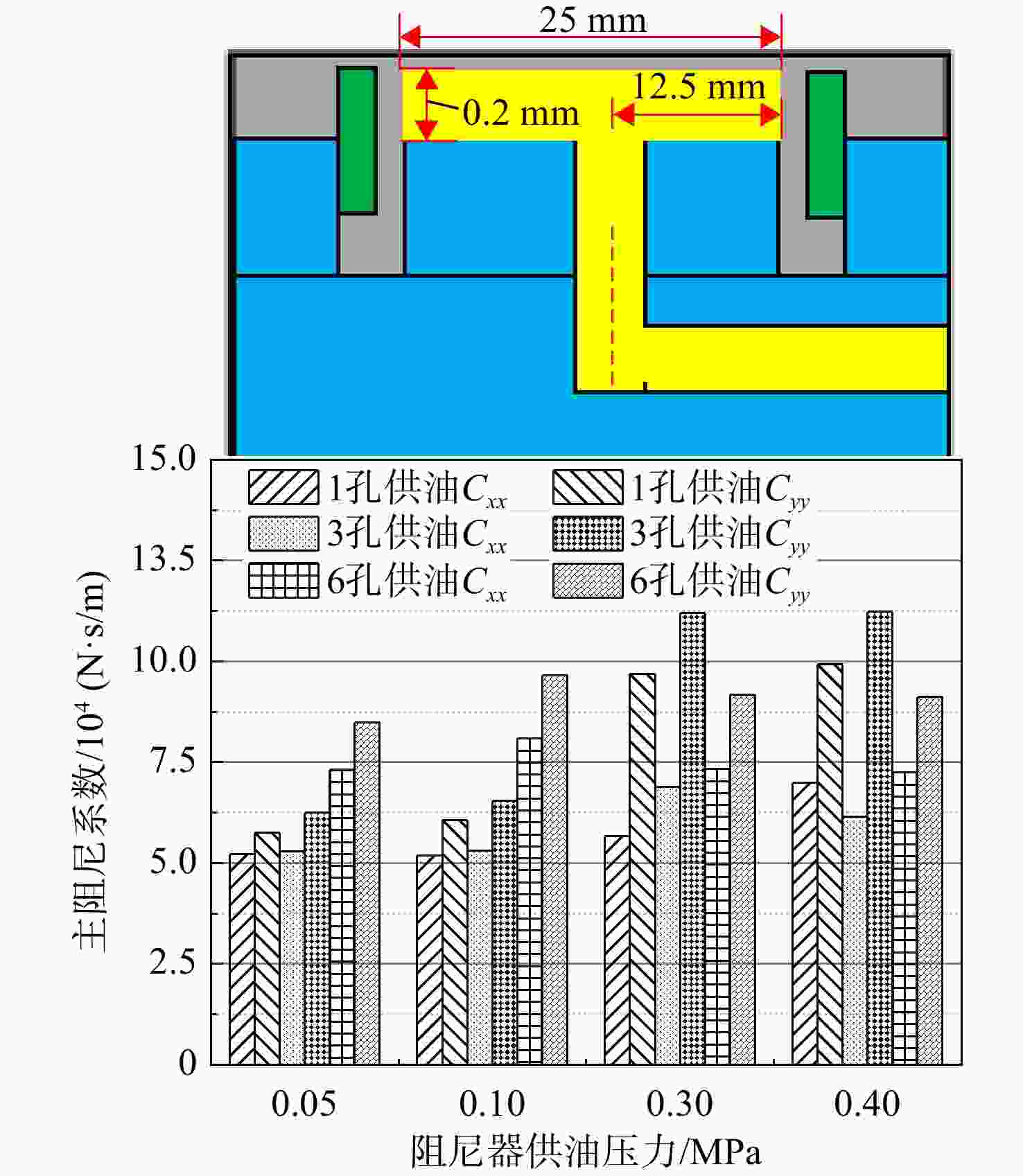

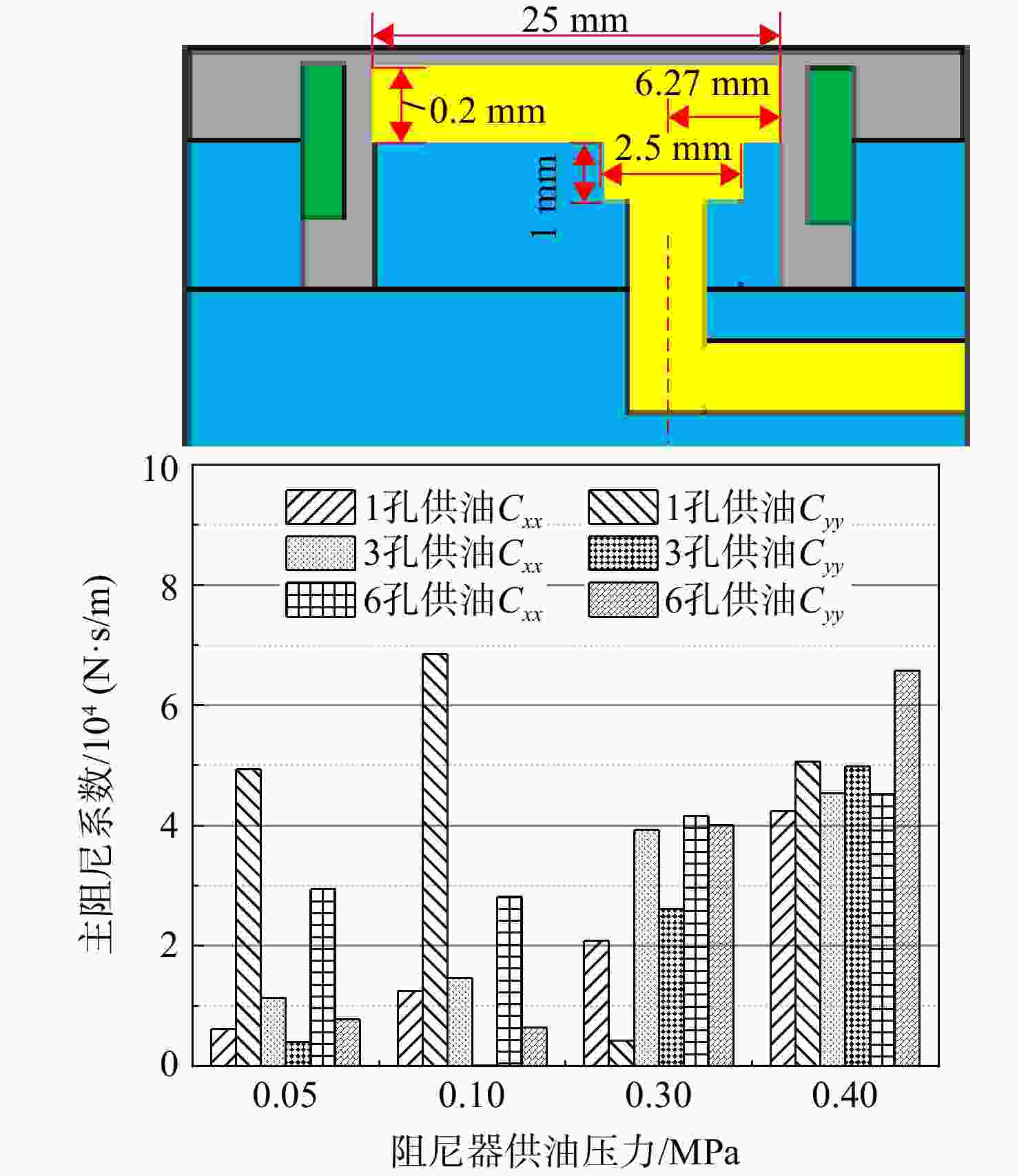

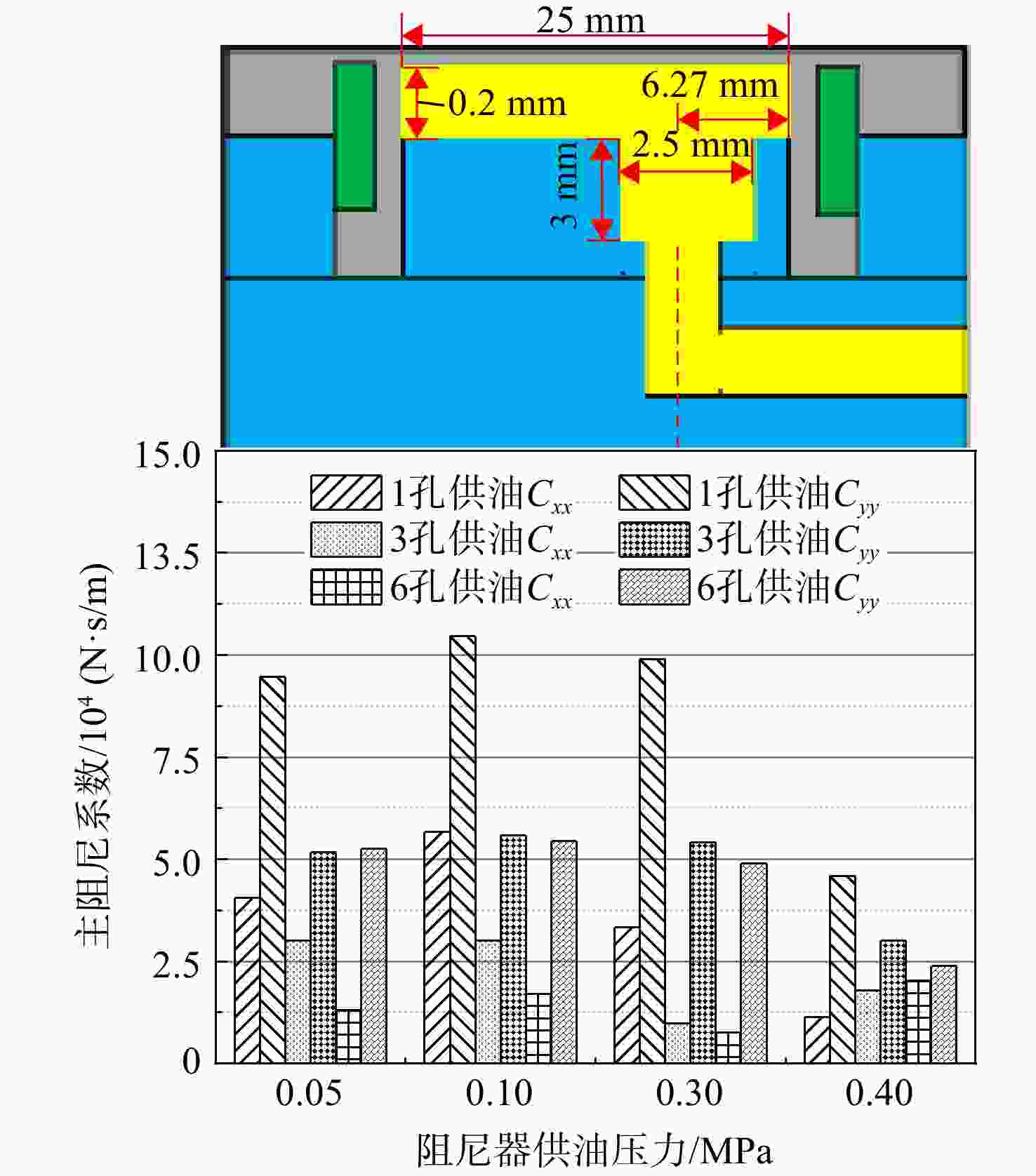

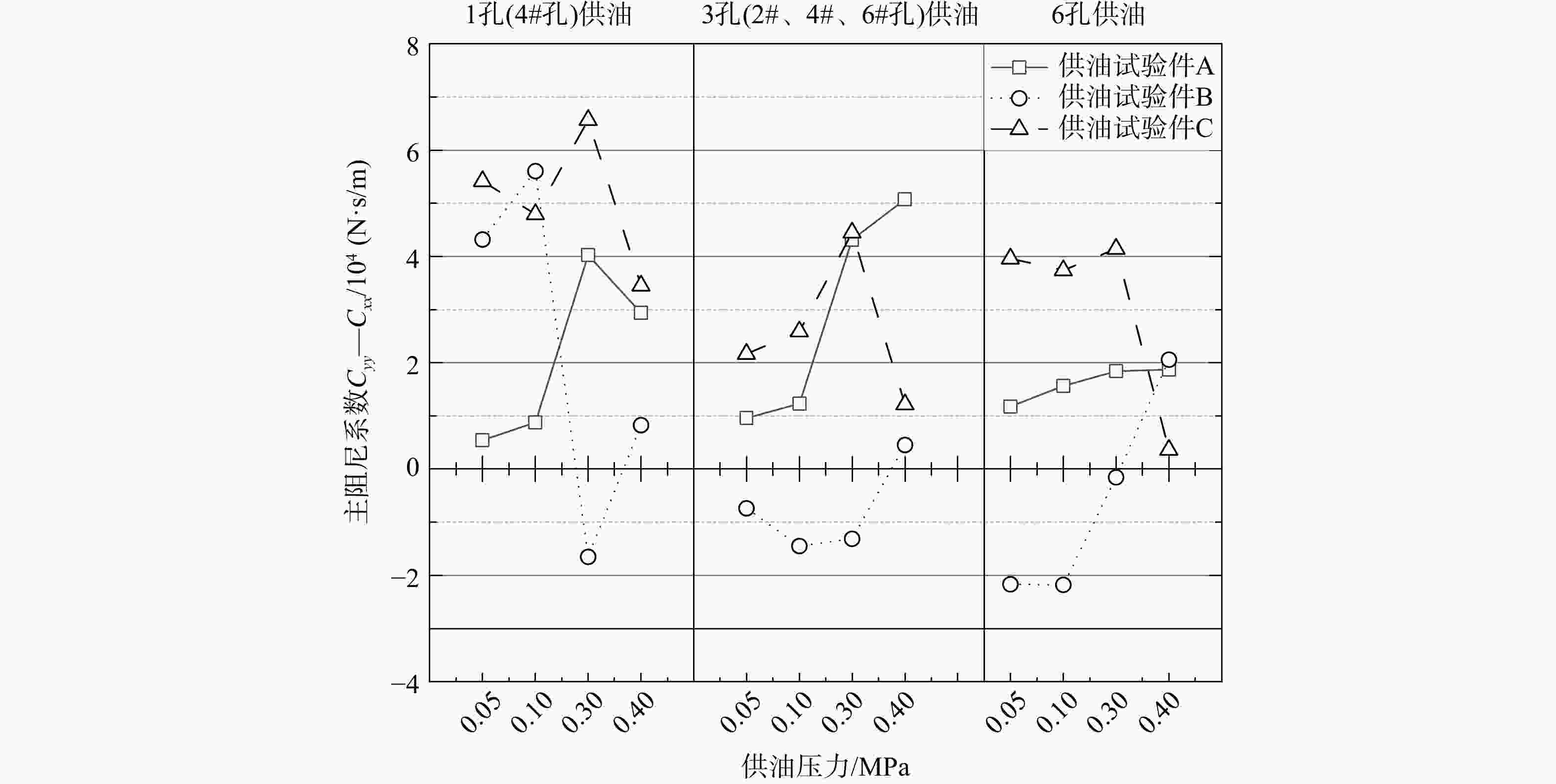

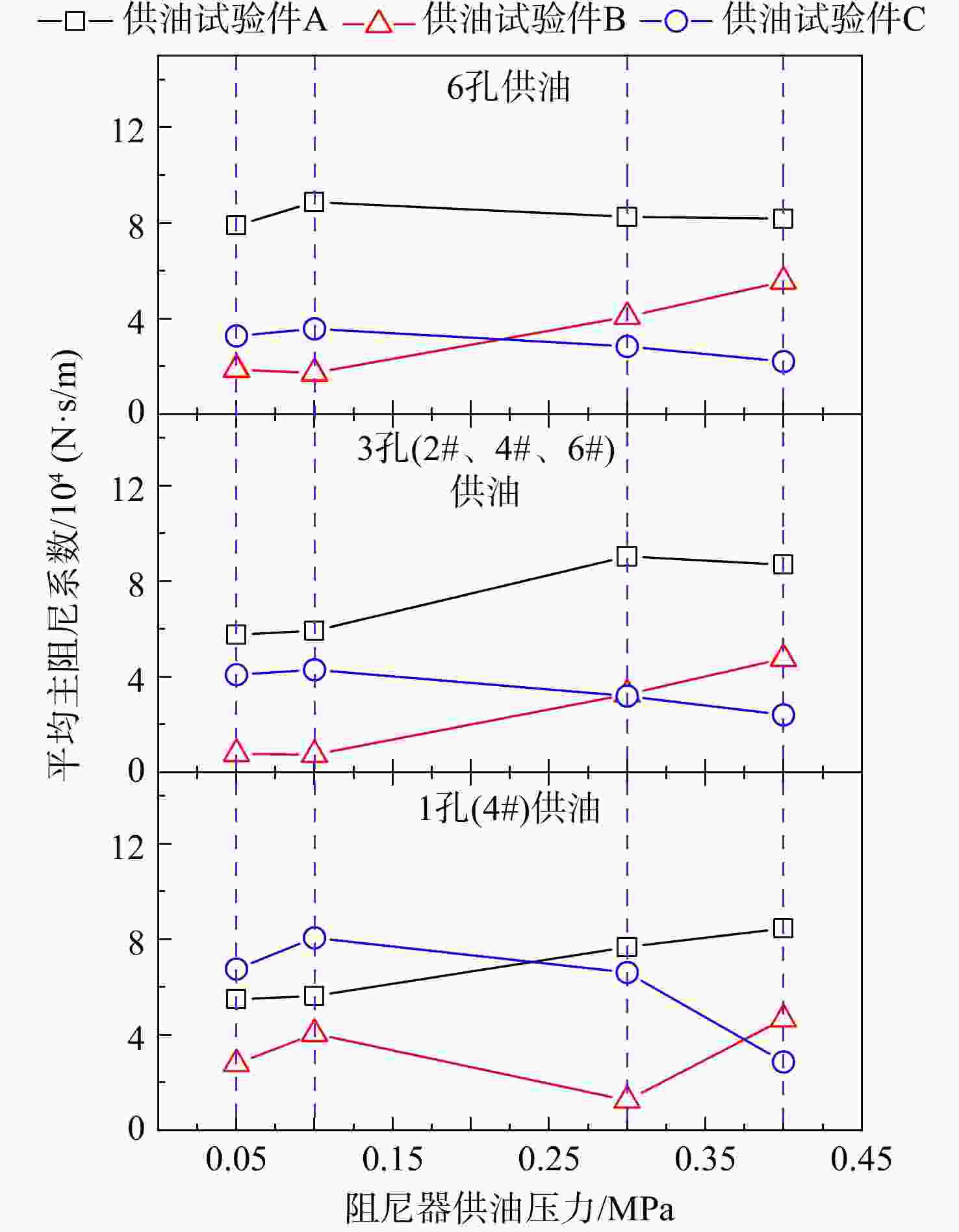

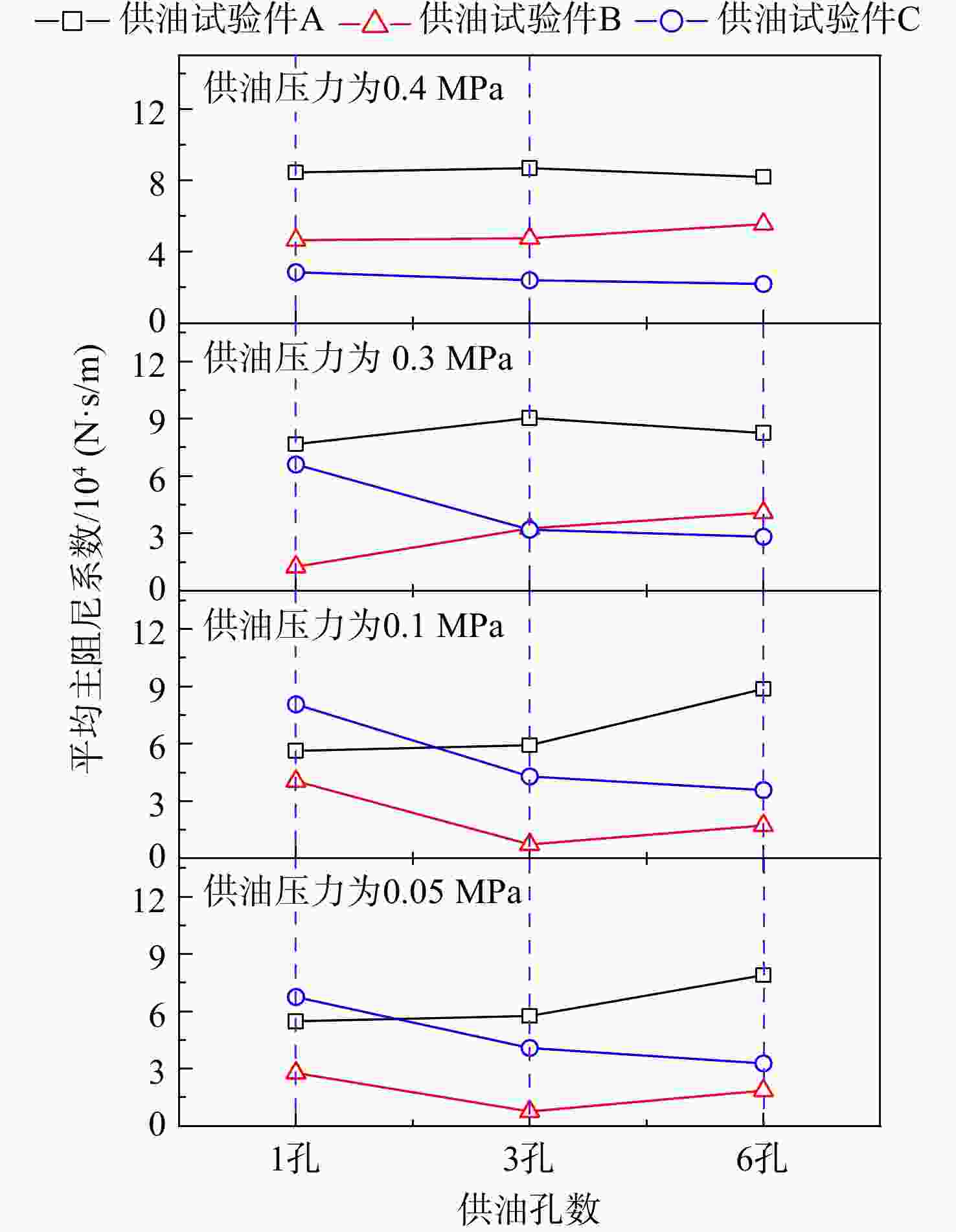

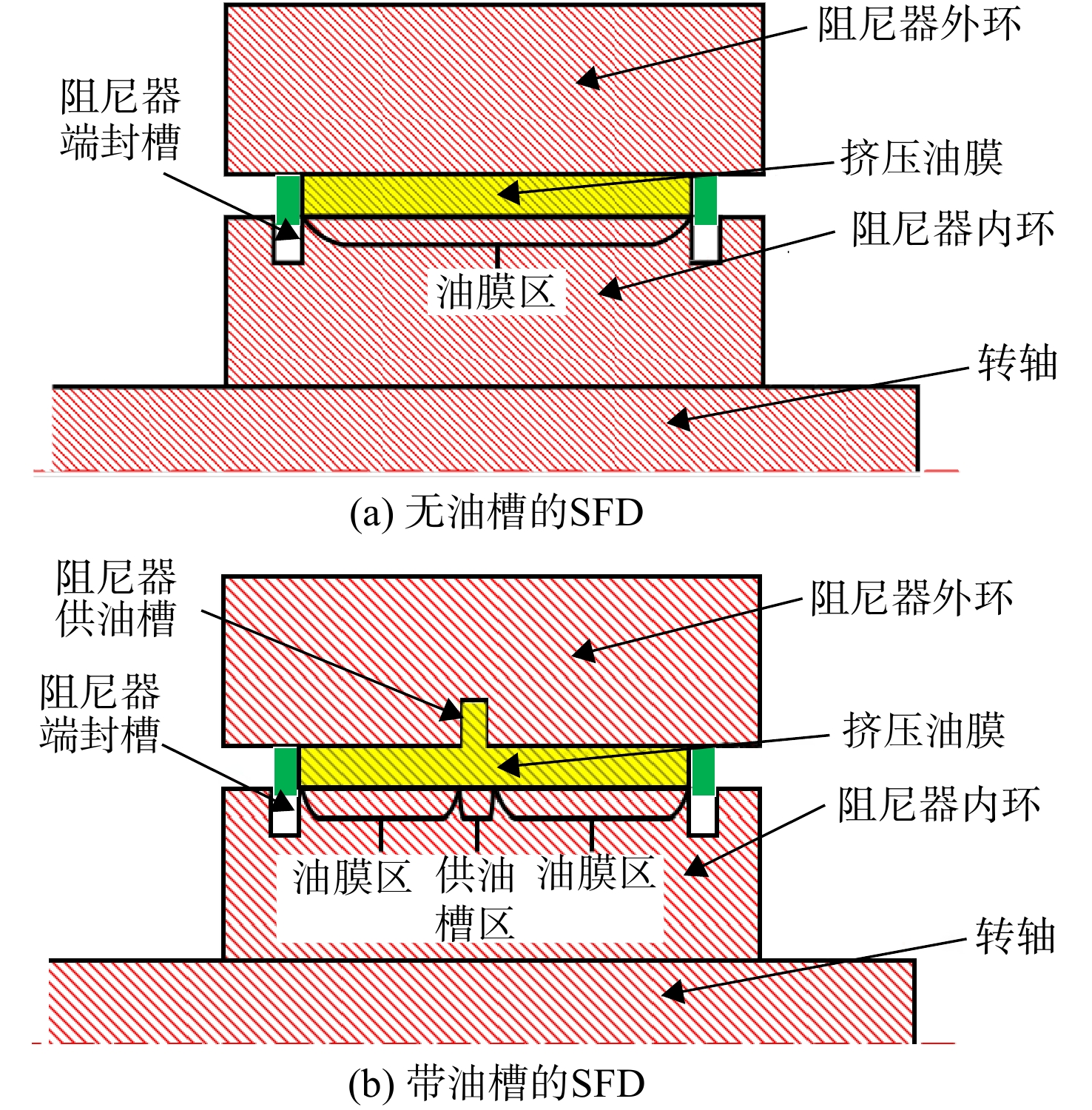

基于挤压油膜阻尼器(squeeze film damper, SFD)动力学特性系数识别试验台研究了油槽深度、供油压力以及供油孔数对活塞环端封SFD泄漏量和阻尼性能的影响。试验结果表明:带油槽结构的SFD滑油泄漏量是无油槽结构的2~7倍,油槽深度增加会增大泄漏量;低油压下阻尼系数的试验结果与短轴承理论解较接近,高油压下阻尼系数的试验结果在短轴承与长轴承理论解之间;对比无油槽结果,带油槽时阻尼性能有所下降,但是0.1 MPa以内两者阻尼系数接近;油槽较浅(深度为5倍油膜半径间隙, 5

c )时,低油压单孔供油与高油压多孔供油平均阻尼系数均能达到4.0×104~5.0×104 N·s/m;油槽较深(深度为15c )时低油压单孔供油平均阻尼系数较大,可达到8.06×104 N·s/m。低油压单孔供油时引入油槽结构显著提高SFD阻尼系数,其可用于提高低供油压下SFD的减振性能。Abstract:The effects of groove depth, oil supply pressure, and the number of oil supply holes on leakage and damping performance of SFD with piston ring end-seals were discussed based on the SFD dynamic coefficients identification experimental device. The experiment results showed that the leakage with the groove was 2—7 times that without the groove of SFD. The test results of the damping coefficient under low oil supply pressure were close to the theoretical solution of short bearing, and the test results under high oil supply pressure were between the theoretical solutions of short bearing and long bearing. Compared with the results of SFD without a groove, the damping performance could decrease with the groove structure, but the damping coefficients were close to each other when the oil supply pressure was less than 0.1 MPa. When the groove was shallow (the depth was 5 times the clearance of oil film radius, 5

c ), the average damping coefficient of single hole & low oil pressure and multiple hole & high oil pressure all can attain 4.0×104—5.0×104 N·s/m, yet when the groove was deep (the depth is 5c ), the average damping coefficient of single hole & low oil pressure was large, up to 8.06×104 N·s/m. As a result, the introduction of a groove can significantly improve the damping coefficients of SFD, which can be used to improve the damping performance of SFD under low oil supply pressure.-

Key words:

- squeeze film damper /

- groove /

- damping coefficient /

- leakage /

- shake test

-

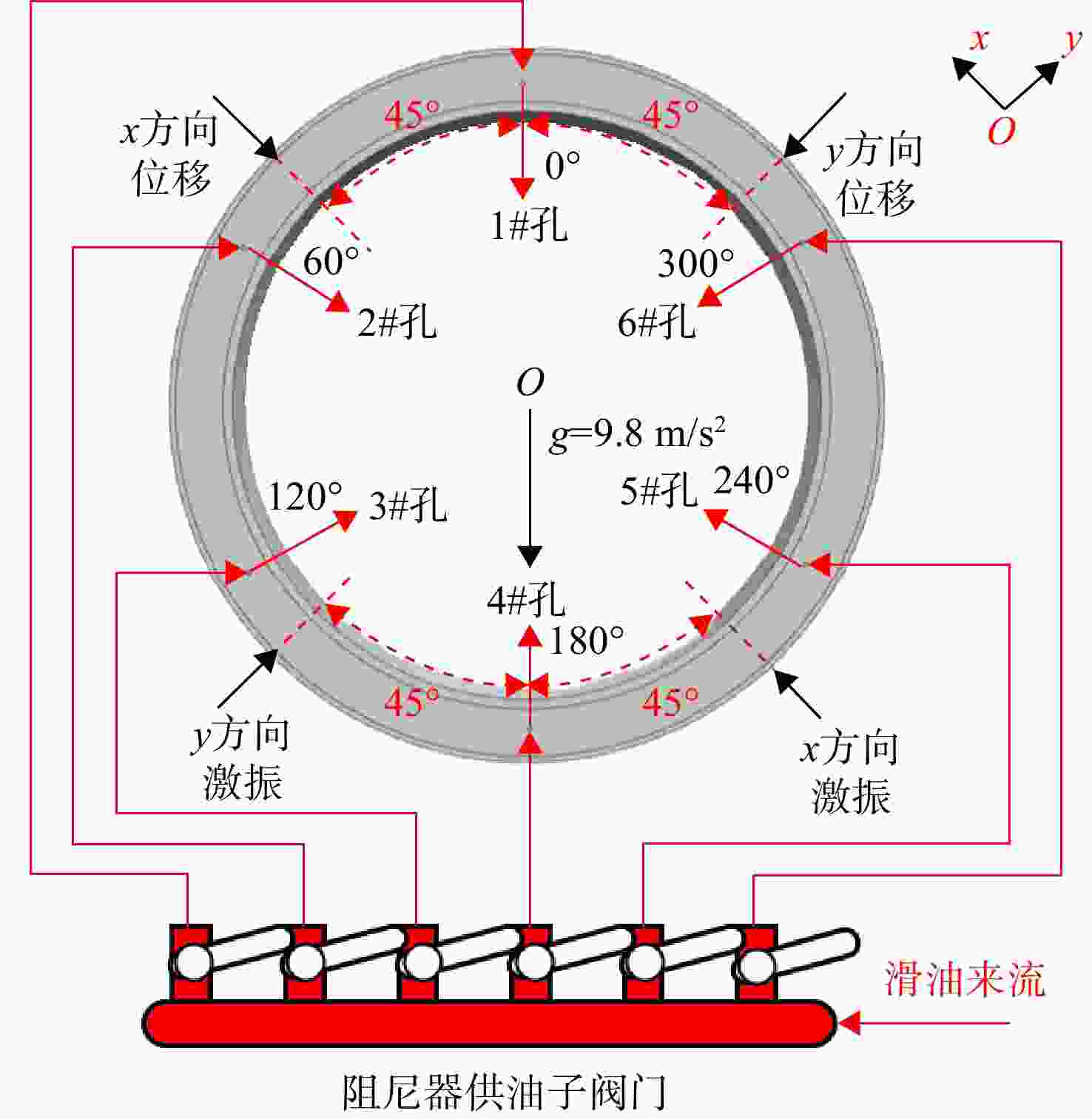

表 1 SFD供油试验件供油孔分布

Table 1. Distribution of oil supply holes on specimens for SFD

供油孔角度/(°) 编号 描述 0(360) 1# 最上方 60 2# 120 3# 180 4# 最下方 240 5# 300 6# 表 2 供油试验件参数汇总

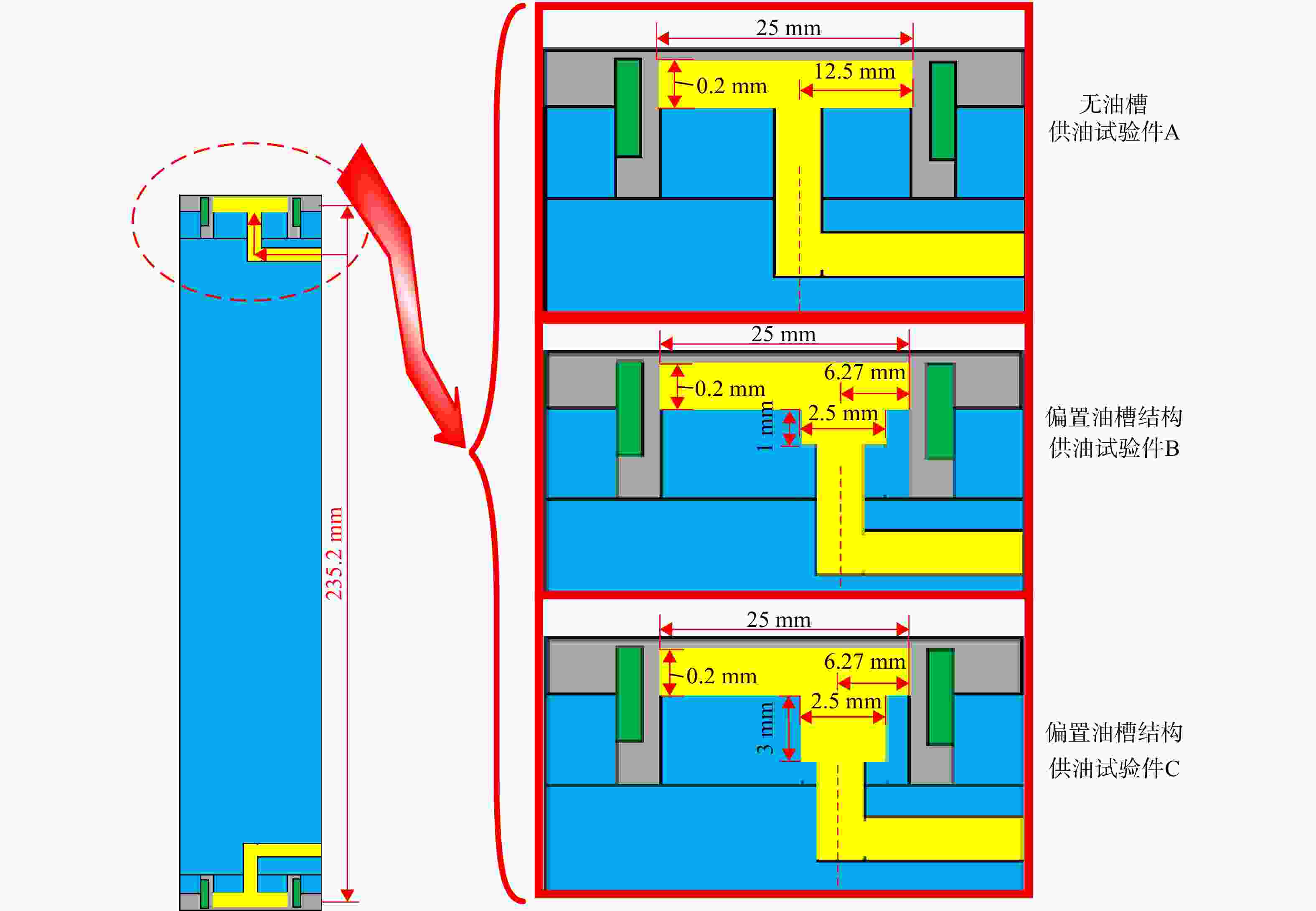

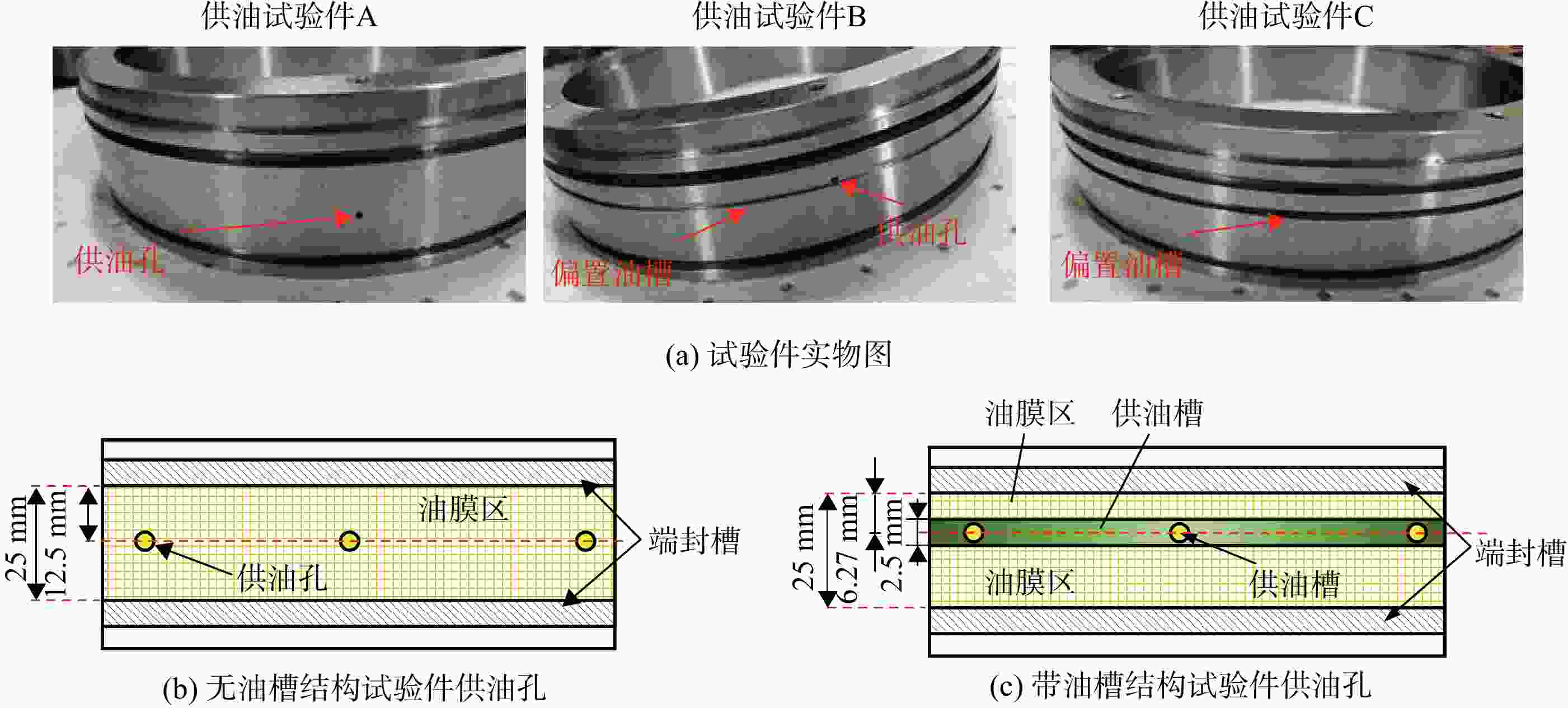

Table 2. Summary parameters of specimens

参数 A B C 参数 A B C 油槽有/无 无 有 有 油槽轴向位置${s_{\text{g}}}$/mm 6.27 6.27 油槽宽度${w_{\text{g}}}$/mm 0 2.5 2.5 有效油膜长度$L$/mm 25 22.5 22.5 油槽深度${d_{\text{g}}}$/mm 0 1 3 -

[1] QUINN R. Experimental study of uncentralized squeeze film dampers[R]. Cleveland,US: Lewis Research Center National Aeronautics and Space Administration,1983. [2] SAN ANDRÉS L. Analysis of short squeeze film dampers with a central groove[J]. Journal of Tribology,1992,114(4): 659-664. [3] ARAUZ G L,SAN ANDRÉS L. Effect of a circumferential feeding groove on the dynamic force response of a short squeeze film damper[J]. Journal of Tribology,1994,116(2): 369-376. [4] ARAUZ G L,ANDRES L S. Experimental force response of a grooved squeeze film damper[J]. Tribology International,1997,30(1): 77-86. [5] ZHANG J X,ROBERTS J B. Force coefficients for a centrally grooved short squeeze film damper[J]. Journal of Tribology,1996,118(3): 608-616. [6] TAN Qingchang,LI Xaohua,ZHAO Dawei. Analytical study of the effect of a circumferential feeding groove on the unbalance response of a rigid rotor in a squeeze film damper[J]. Tribology International,1998,31(5): 265-270. [7] SIEW C C,HILL M,HOLMES R. Evaluation of various fluid-film models for use in the analysis of squeeze film dampers with a central groove[J]. Tribology International,2002,35(8): 533-547. [8] LUND J W,MYLLERUP C M,HARTMANN H. Inertia effects in squeeze-film damper bearings generated by circumferential oil supply groove[J]. Journal of Vibration and Acoustics,2003,125(4): 495-499. [9] DELGADO A,SAN ANDRÉS L. A model for improved prediction of force coefficients in grooved squeeze film dampers and oil seal rings[J]. Journal of Tribology,2010,132(3): 1032202. [10] GROVES K H,BONELLO P. Improved identification of squeeze-film damper models for aeroengine vibration analysis[J]. Tribology International,2010,43(9): 1639-1649. [11] GIBERT C,GUSKOV M,SANCHEZ L,et al. Damping coefficient estimation of a squeeze-film damper operating in a dual shaft test rig[J]. Mécanique & Industries,2010,11(5): 297-308. [12] BOPPA P,SEKARAN A,MORRISON G. Effects of adding a central groove to the squeeze film damper lands[R]. Incline Village,US: ASME,2014. [13] SAN ANDRÉS L,SESHAGIRI S. Damping and inertia coefficients for two end sealed squeeze film dampers with a central groove: measurements and predictions[J]. Journal of Engineering for Gas Turbines and Power,2013,135(11): 112503. [14] SAN ANDRÉS L. Force coefficients for a large clearance open ends squeeze film damper with a central feed groove: experiments and predictions[J]. Tribology International,2014,71: 17-25. [15] SAN ANDRÉS L,JEUNG S H. Experimental performance of an open ends,centrally grooved,squeeze film damper operating with large amplitude orbital motions[J]. Journal of Engineering for Gas Turbines and Power,2015,137(3): 032508. [16] LEE G J,KIM J,STEEN T. Application of computational fluid dynamics simulation to squeeze film damper analysis[J]. Journal of Engineering for Gas Turbines and Power,2017,139(10): 102501. [17] HWANG J S,RYU K,JEUNG S H. Test rig development for identification of rotordynamic force coefficients of squeeze film dampers in automotive turbocharger bearing systems[J]. Journal of the Korean Society of Tribologists and Lubrication Engineers,2018,34(1): 33-41. [18] KANG Xiao,PALAZZOLO A,ZHONG Wan. Auxiliary bearing squeeze film dampers for magnetic bearing supported rotors[J]. Tribology International,2020,146: 106181. [19] FAN Tieshu,BEHDINAN K. An analytical model for open-ended squeeze film damper with a circumferential central groove[J]. Proceedings of the Institution of Mechanical Engineers,Part J: Journal of Engineering Tribology,2021,235(10): 2110-2121. [20] SAN ANDRÉS L,RODRÍGUEZ B. On the experimental dynamic force performance of a squeeze film damper supplied through a check valve and sealed with O-Rings[J]. Journal of Engineering for Gas Turbines and Power,2021,143(11): 111011. [21] SAN ANDRÉS L,JEUNG S H. Response of a squeeze film damper-elastic structure system to multiple and consecutive impact loads[J]. Journal of Engineering for Gas Turbines and Power,2016,138(12): 122504. [22] SAN ANDRÉS L,KOO B,JEUNG S H. Experimental force coefficients for two sealed ends squeeze film dampers (piston rings and O-rings): an assessment of their similarities and differences[J]. Journal of Engineering for Gas Turbines and Power,2019,141(2): 021024. [23] 《航空发动机设计手册》总编委会. 第19册—转子动力学及整机振动[M]. 航空工业出版社,2000: 236-237. -

下载:

下载: