Fault diagnosis method of rolling bearing using MFMD and Transformer-CNN

-

摘要:

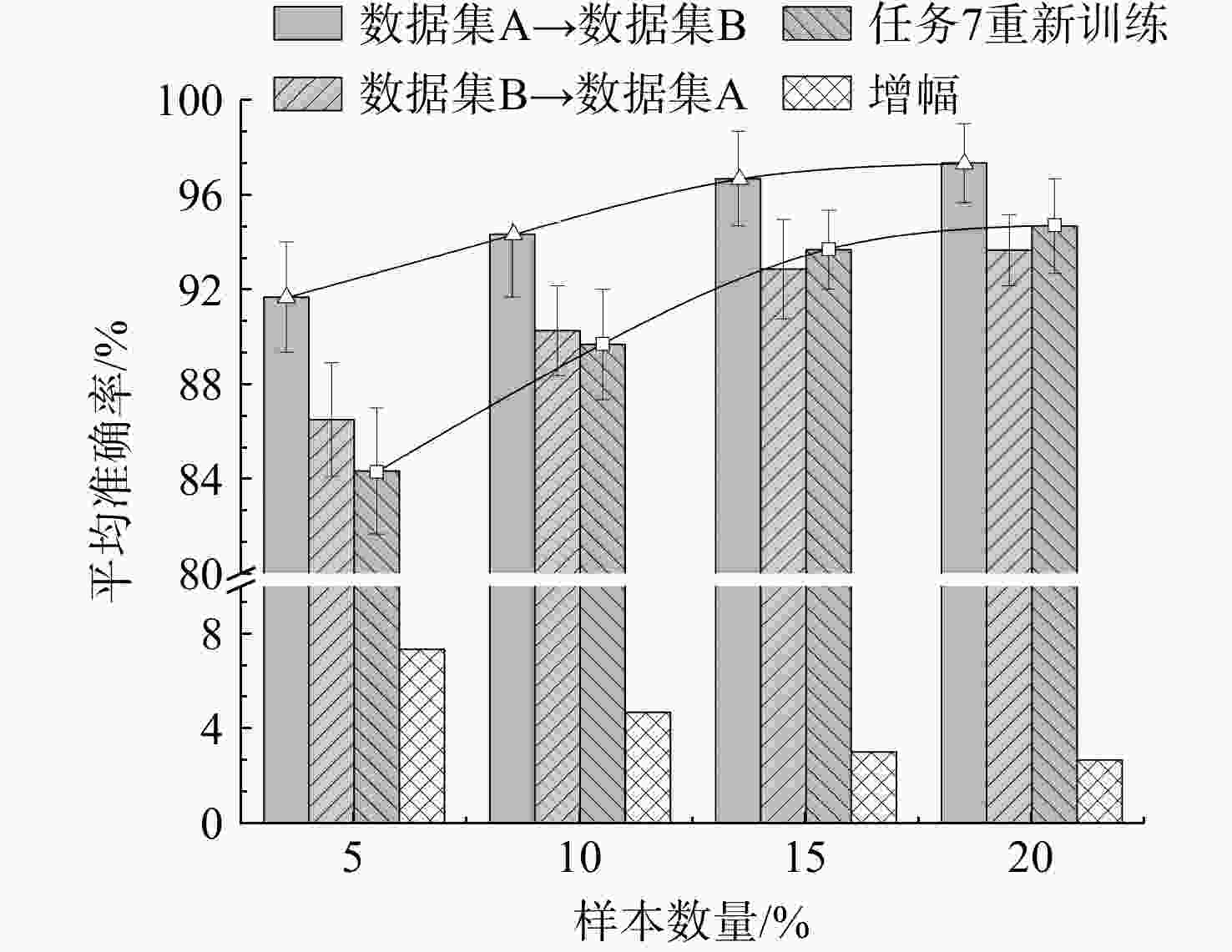

针对滚动轴承在变工况和跨型号下故障诊断效果不佳、泛化能力较差,同时在实际训练中样本数量严重不足的问题,从振动信号序列特性出发,提出了一种基于改进傅里叶模态分解(MFMD)和Transformer convolutional neural network(Transformer-CNN)的故障诊断方法。设计了振动数据预处理模块,利用MFMD和位置编码对数据样本进行预处理并标记序列位置关系,随后设计了基于注意力机制的Transformer-CNN序列建模单元,利用最大值池化优化了缩放点积注意力机制的循环堆叠结构,减少了网络的待训练参数并提升了网络序列建模能力。采用预训练-微调的迁移学习方法,将预训练模型参数迁移至目标域并进行模型微调,可以避免数据不足导致的过拟合现象。实验结果表明:相较于基准算法,Transformer-CNN可以降低50%以上的故障诊断错误率。在变工况和跨型号的小样本迁移学习实验中,该算法可以提升8.75%的诊断准确率,同时可以提升收敛速度。

-

关键词:

- 滚动轴承 /

- 故障诊断 /

- Transformer-CNN /

- 小样本 /

- 迁移学习

Abstract:Considering the worse effect and generalization ability of rolling bearing fault diagnosis under variable working conditions and cross-type conditions as well as the shortage of serious samples in practice, a fault diagnosis method using modified Fourier mode decomposition (MFMD) and Transformer convolutional neural network (Transformer-CNN) was proposed based on the sequence characteristics of vibration signal. The vibration data preprocessing module was designed, in which MFMD and position encoding were adopted to preprocess the samples and mark the sequence position relationships. The Transformer-CNN sequence modeling unit with the scaled dot-product attention mechanism was then designed, and the cyclic stack structure was optimized by the max-pooling, which reduced the network parameters and improved the sequence modeling capability. The pre-training-fine-tuning transfer learning method was adopted to transfer the trained mode parameters to the target domain and fine-tune, which avoided the over-fitting caused by insufficient data. The results showed that Transformer-CNN can reduce the fault diagnosis error by more than 50% compared with the benchmark algorithms. In the case of cross-working and cross-type conditions with small samples, the algorithm enables to achieve 8.75% diagnosis accuracy improvement and faster convergence.

-

Key words:

- rolling bearing /

- fault diagnosis /

- Transformer-CNN /

- small sample /

- transfer learning

-

表 1 Transformer-CNN网络参数

Table 1. Network parameters of Transformer-CNN

顺序 网络层 输出尺寸 核大小 标准化 1 输入层 64×800×1 2 嵌入层 64×800×64 3 位置编码层 64×800×64 4 编码器层 64×800×64 是 5 池化层 64×800×8 8×1 6 编码器层 64×800×8 是 7 编码器层 64×800×8 是 8 编码器层 64×800×8 是 9 池化层 64×800×1 8×1 10 线性层 64×10×1 11 Softmax 64×10 表 2 网络基本参数设置

Table 2. Basic parameter setting of networks

项目 设置 优化器 Adam学习率为0.0001 损失函数 交叉熵损失 批处理大小 64 表 3 轴承样本统计

Table 3. Bearing sample statistics

数据集 负载 转速/(r/min) 故障尺寸/mm 故障类型 训练样本数量 测试样本数量 A 0.7 kW 1772 0.1778,

0.3556,

0.5334正常/内圈/

外圈/滚动体800 200 1.4 kW 1750 2.1 kW 1730 B 11 kN 2250 正常 400 100 内圈 外圈 表 4 不同编码器设置结果

Table 4. Results of different encoder settings

参数 方案 1+3 2+2 3+1 准确率/% 99.15±2.15 97.15±2.60 90.55±2.10 平均耗时/s 14.73 15.56 16.16 参数总量 132 259 17 7563 212 867 表 5 对比算法结构参数设置

Table 5. Contrast algorithm structure parameter settings

算法 设置 Transformer 实体嵌入(800,64)→

位置编码(800,64)→

编码器×4(800,64)→线性层(10,1)→SoftmaxCNN 实体嵌入(800,64)→

卷积块(800,64)→

最大值池化(400,64)→

卷积&池化→线性层(10,1)→SoftmaxLSTM 实体嵌入(800,64)→

LSTM(隐层节点个数为1024,层数为2)→

池化层(2114,1)→

线性层(10,1)→Softmax表 6 不同算法的效果对比

Table 6. Effect comparison of different algorithms

网络类型 Transformer-CNN Transformer CNN LSTM 准确率/% 99.15±2.15 98.15±2.20 97.45±3.10 97.20±3.15 平均耗时/s 14.73 16.77 21.04 16.23 参数量 132259 241415 229927 255687 表 7 迁移任务的总结

Table 7. Summary of transfer tasks

编号 场景 迁移任务 迁移条件 1 变工况 工况1→工况2 0.7→1.4 kW 2 工况1→工况3 0.7→2.1 kW 3 工况2→工况3 1.4→2.1 kW 4 工况3→工况1 2.1→0.7 kW 5 工况3→工况2 2.1→1.4 kW 6 工况2→工况1 1.4→0.7 kW 7 跨型号 轴承A→轴承B A→B 8 轴承B→轴承A B→A 表 8 变工况迁移学习故障分类结果

Table 8. Fault classification results of transfer learning under variable working conditions

迁移场景 准确率/% 5%样本 10%样本 15%样本 20%样本 1 90.00±1.50 97.25±1.75 98.65±1.60 99.00±1.25 2 90.50±1.50 97.50±1.30 98.30±1.25 99.05±1.15 3 90.25±1.35 97.15±1.50 98.55±1.30 98.95±1.40 4 89.75±1.35 97.10±1.75 98.50±1.40 99.15±1.50 5 91.50±1.50 97.55±1.75 98.05±1.65 99.05±1.20 6 90.20±1.35 97.25±1.65 98.35±1.80 99.10±1.65 场景1重新训练 81.25±2.25 92.50±2.35 94.75±1.75 95.65±1.50 迁移学习准确率增幅 8.75 4.75 3.90 3.35 -

[1] 张向阳, 陈果, 郝腾飞, 等. 基于机匣信号的滚动轴承故障卷积神经网络诊断方法[J]. 航空动力学报, 2019, 34(12): 2729-2737.ZHANG Xiangyang, CHEN Guo, HAO Tengfei, et al. Rolling bearing fault convolution neural network diagnosis method based on gearbox signal[J]. Journal of Aerospace Power, 2019, 34 (12): 2729-2737. (in Chinese) [2] SINGH P,JOSHI S D,PATNEY R K,et al. The Fourier decomposition method for nonlinear and nonstationary time series analysis[J]. Proceedings Mathematical Physical and Engineering Sciences,2015,473(2199): 871-0897. [3] 郑近德, 潘海洋, 程军圣, 等. 基于自适应经验傅里叶分解的机械故障诊断方法[J]. 机械工程学报, 2020, 56(9): 125-136.ZHENG Jinde, PAN Haiyang , CHENG Junsheng , et al. Mechanical fault diagnosis method based on adaptive empirical Fourier decomposition[J]. Journal of Mechanical Engineering, 2020, 56(9): 125-136. (in Chinese) [4] CHENG Yiwei,LIN Manxi,WU Jun,et al. Intelligent fault diagnosis of rotating machinery based on continuous wavelet transform-local binary convolutional neural network[J]. Knowledge-Based Systems,2021,216: 106796.1-106796.12. [5] LI Jimeng,CHENG Xing,LI Qiang,et al. Adaptive energy-constrained variational mode decomposition based on spectrum segmentation and its application in fault detection of rolling bearing[J]. Signal Processing,2021,183: 108025.1-108025.17. [6] 雷亚国,贾峰,孔德同,等. 大数据下机械智能故障诊断的机遇与挑战[J]. 机械工程学报,2018,54(5): 94-104. doi: 10.3901/JME.2018.05.094LEI Yaguo,JIA Feng,KONG Detong,et al. Opportunity and challenge of mechanical intelligent fault diagnosis under big data[J]. Journal of Mechanical Engineering,2018,54(5): 94-104. (in Chinese) doi: 10.3901/JME.2018.05.094 [7] 张西宁,郭清林,刘书语. 深度学习技术及其故障诊断应用分析与展望[J]. 西安交通大学学报,2020,54(12): 1-13.ZHANG Xining,GUO Qinglin,LIU Shuyu. Deep learning technology and its application analysis and prospect of fault diagnosis[J]. Journal of Xi’an Jiaotong University,2020,54(12): 1-13. (in Chinese) [8] WEISS K,KHOSHGOFTAAR T M,WANG D D. A survey of transfer learning[J]. Journal of Big Data,2016,3(1): 1-40. doi: 10.1186/s40537-015-0036-x [9] NITISH S,GEOFFREY E. HINTON, et al. Dropout: a simple way to prevent neural networks from overfitting.[J]. Journal of Machine Learning Research,2014,15(1): 1929-1958. [10] LI Xiang,ZHANG Wei,DING Qian. Cross-domain fault diagnosis of rolling element bearings using deep generative neural networks[J]. IEEE Transactions on Industrial Electronics,2019,66(7): 5525-5534. doi: 10.1109/TIE.2018.2868023 [11] 张西宁,余迪,刘书语. 基于迁移学习的小样本轴承故障诊断方法研究[J]. 西安交通大学学报,2021,55(10): 30-37.ZHANG Xining,YU Di,LIU Shuyu. Research on small sample bearing fault diagnosis method based on transfer learning[J]. Journal of Xi’an Jiaotong University,2021,55(10): 30-37. (in Chinese) [12] ZHANG Kaiyu,CHEN Jinglong,ZHANG Tianci,et al. A compact convolutional neural network augmented with multiscale feature extraction of acquired monitoring data for mechanical intelligent fault diagnosis[J]. Journal of Manufacturing Systems,2020,55: 273-284. doi: 10.1016/j.jmsy.2020.04.016 [13] ZHU J,CHEN N,SHEN C. A new deep transfer learning method for bearing fault diagnosis under different working conditions[J]. IEEE Sensors Journal,2019,20(15): 8394-8402. [14] 何强,唐向红,李传江,等. 负载不平衡下小样本数据的轴承故障诊断[J]. 中国机械工程,2021,32(10): 1164-1171,1180.HE Qiang,TANG Xianghong,LI Chuanjiang,et al. Bearing fault diagnosis of small sample data under unbalanced load[J]. China Mechanical Engineering,2021,32(10): 1164-1171,1180. (in Chinese) [15] HOCHREITER S,SCHMIDHUBER J. Long short-term memory[J]. Neural Computation,1997,9(8): 1735-1780. doi: 10.1162/neco.1997.9.8.1735 [16] CHUNG J, GULCEHRE C, CHO K H, et al. Empirical evaluation of gated recurrent neural networks on sequence modeling[EB/OL]. [2021-08-20].https: //arxiv.org/abs/1412.3555. [17] 周奇才,沈鹤鸿,赵炯,等. 基于改进堆叠式循环神经网络的轴承故障诊断[J]. 同济大学学报(自然科学版),2019,47(10): 1500-1507. doi: 10.11908/j.issn.0253-374x.2019.10.016ZHOU Qicai,SHEN Hehong,ZHAO Jiong,et al. Bearing fault diagnosis based on improved stackable cyclic neural network[J]. Journal of Tongji University (Natural Science Edition),2019,47(10): 1500-1507. (in Chinese) doi: 10.11908/j.issn.0253-374x.2019.10.016 [18] ASHISH V, NOAM S, NIKI P, et al. Attention is all you need[EB/OL]. [2021-06-20].https: //arxiv.org/abs/1706.03762. [19] LIU Junfeng,YU Xiang. Rolling element bearing fault diagnosis for complex equipment based on MFMD and BP neural network[J]. Journal of Physics Conference Series,2021,1948(1): 012113.1-012113.10. [20] LIU Tao,CHEN Jin,DONG Guangming,et al. The fault detection and diagnosis in rolling element bearings using frequency band entropy[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science,2013,227(1): 87-99. doi: 10.1177/0954406212441886 [21] KIM Y, DENTON C, HOANG L, et al. Structured attention networks[EB/OL]. [2021-06-20].https: //arxiv.org/abs/1702.00887. [22] WANG Biao,LEI Yagup,LI Naipeng,et al. A hybrid prognostics approach for estimating remaining useful life of rolling element bearings[J]. IEEE Transactions on Reliability,2018,69(1): 401-412. [23] JOHNSON R, ZHANG T. Convolutional neural networks for text categorization: shallow word-level vs. deep character-level[EB/OL]. [2021-06-20].https: // arxiv.org/abs/1609.00718. [24] LA S W, XU L H, LIU K, et al. Recurrent convolutional neural networks for text classification[C]// Twenty-ninth AAAI conference on Artificial Intelligence. Menlo Park, US: AIAA, 2015: 2267-2273. [25] 赵海峰,杨国斌. 基于振动信号的深沟球轴承滚动体故障诊断研究[J]. 化工机械,2014,41(3): 291-295. doi: 10.3969/j.issn.0254-6094.2014.03.006ZHAO Haifeng,YANG Guobin. Research on rolling body fault diagnosis of deep groove ball bearing based on vibration signal[J]. Chemical Machinery,2014,41(3): 291-295. (in Chinese) doi: 10.3969/j.issn.0254-6094.2014.03.006 -

下载:

下载: