Influence of endwall profiling on purge flow and mainstream flow in the high-pressure turbine

-

摘要:

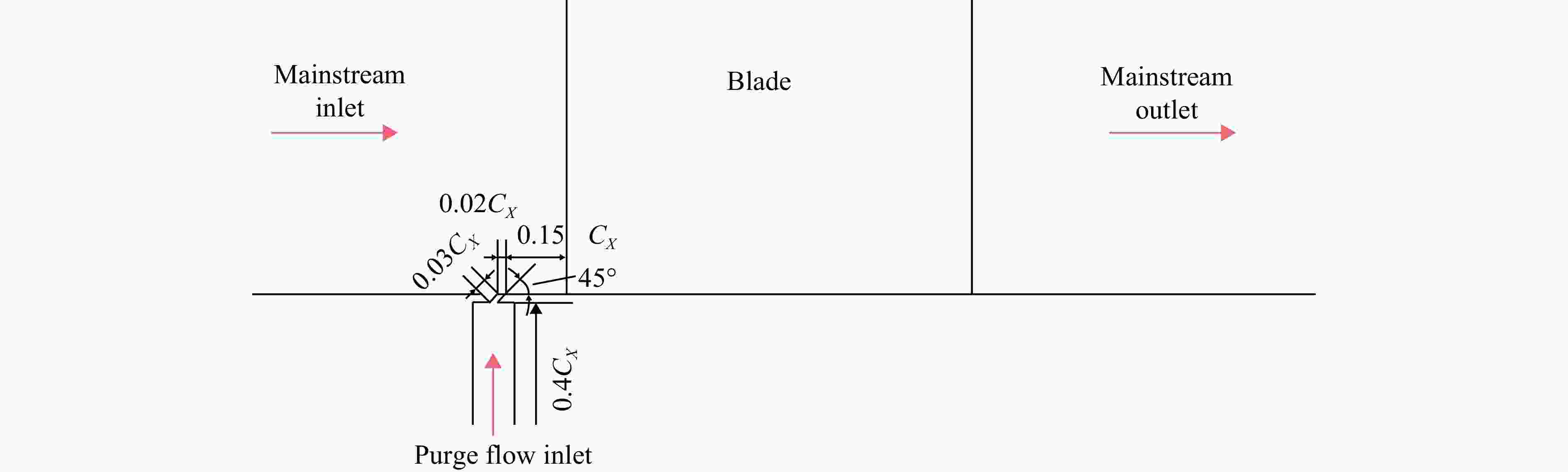

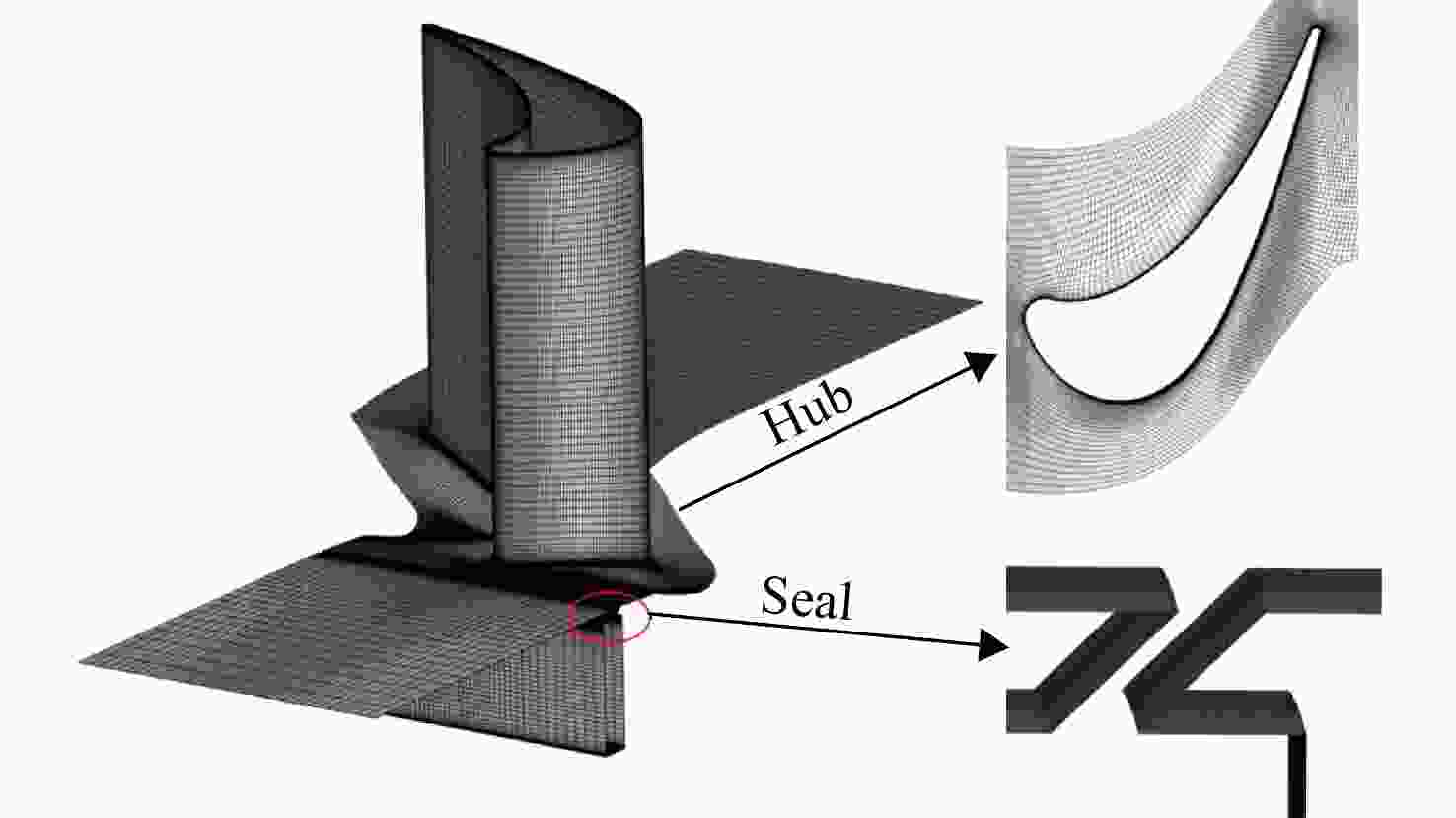

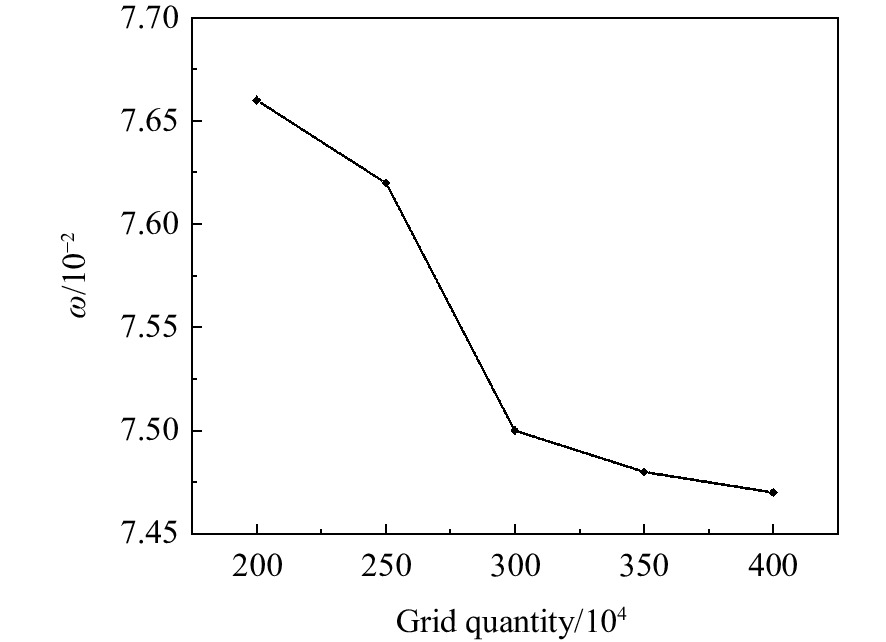

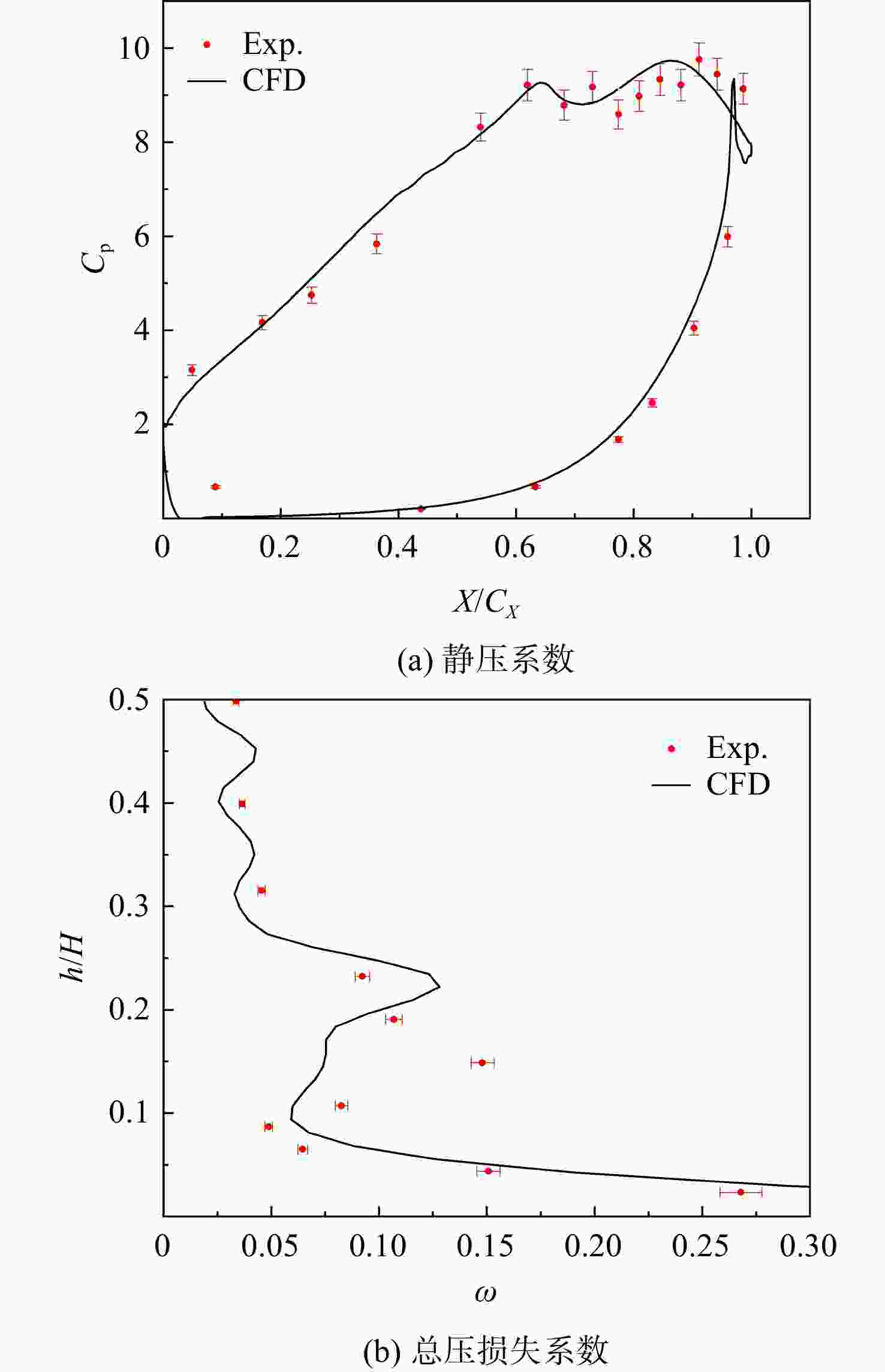

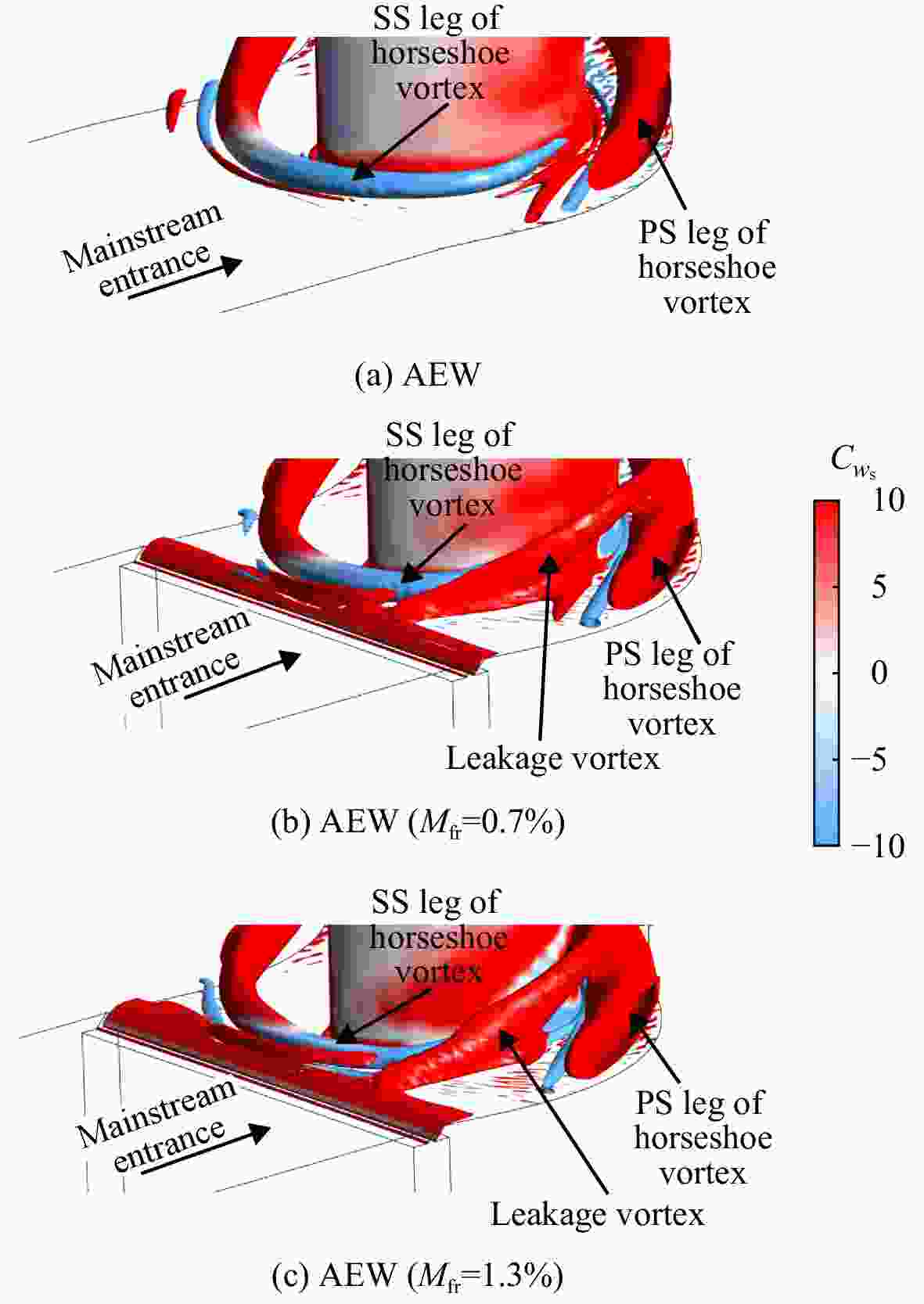

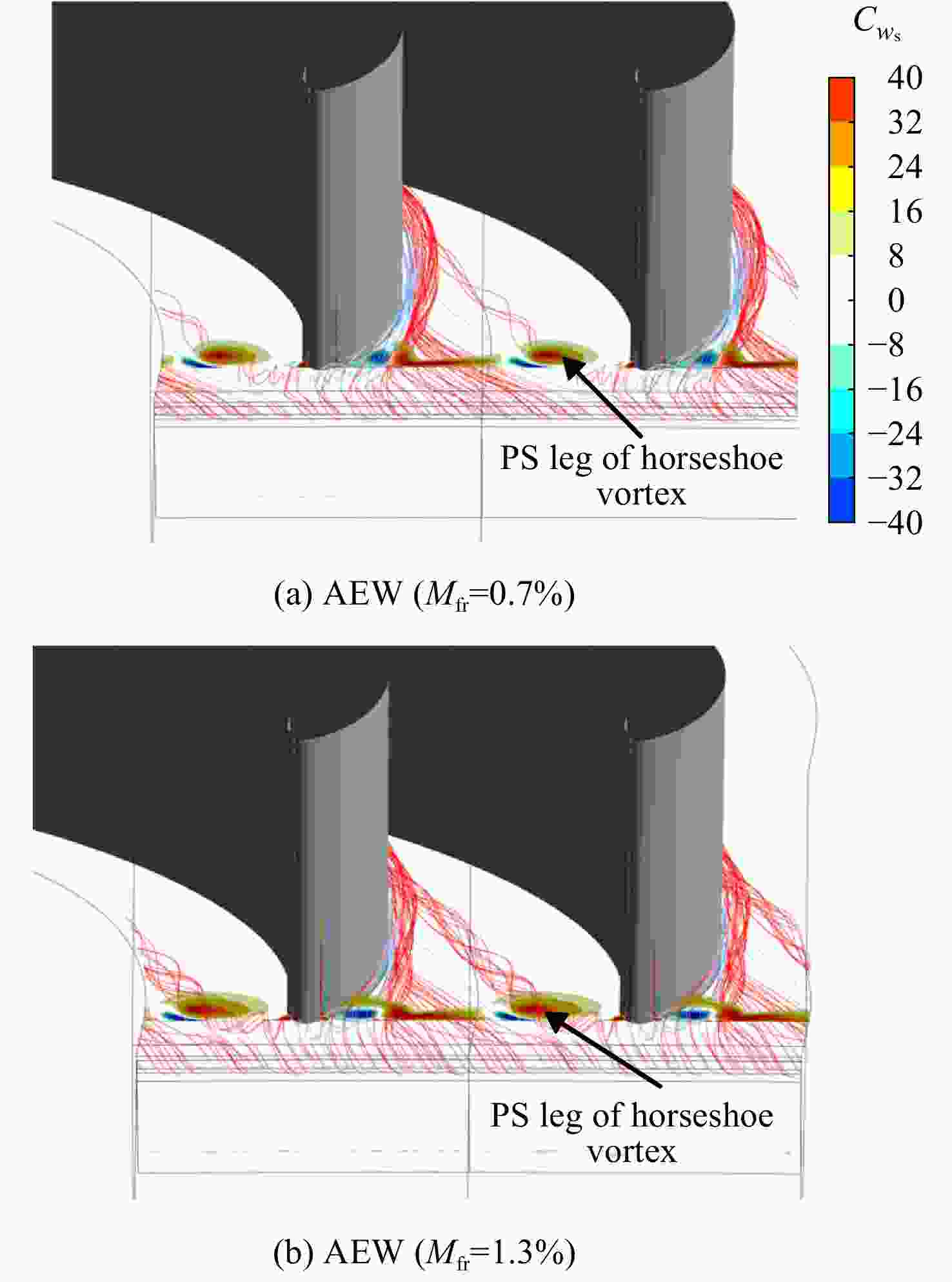

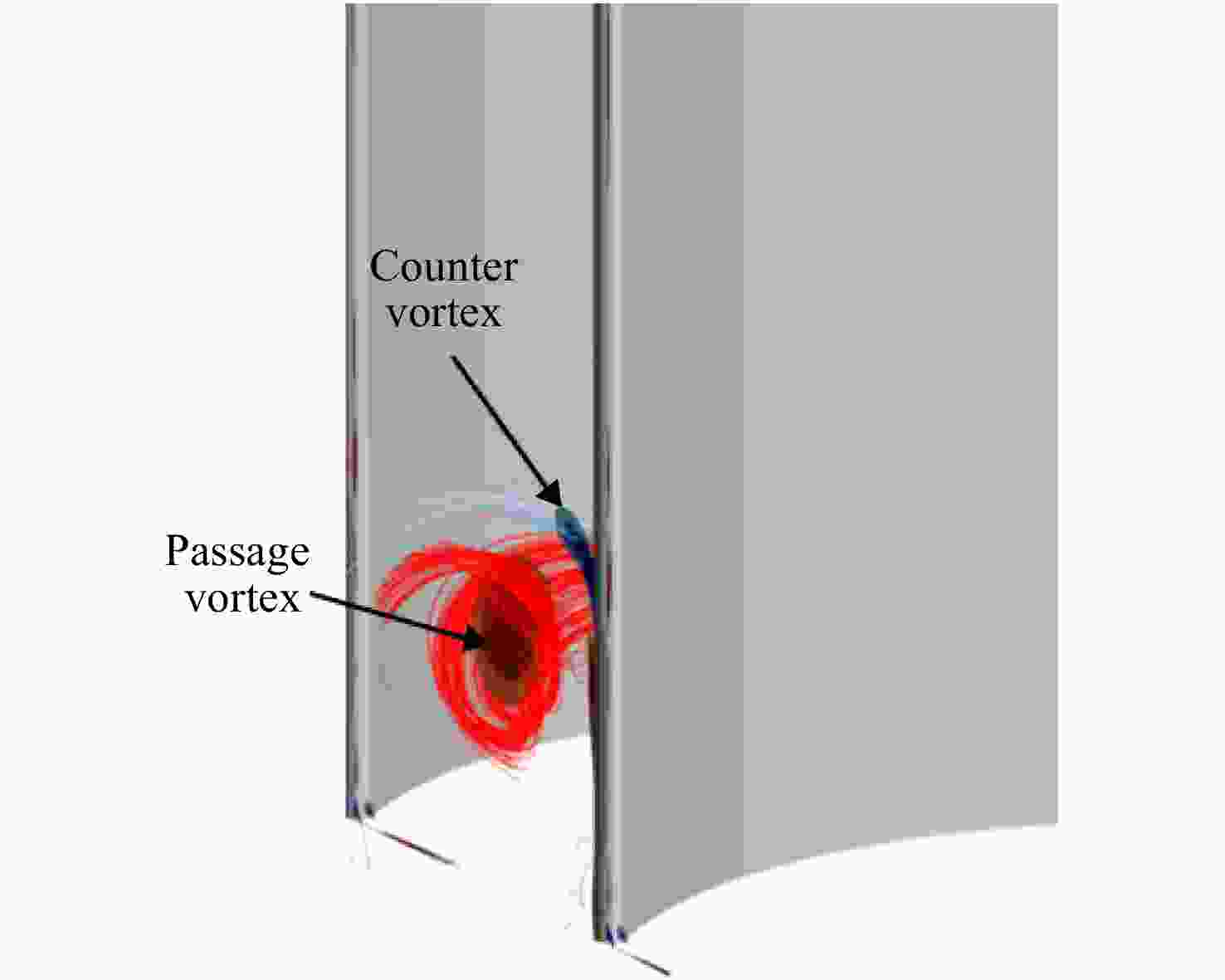

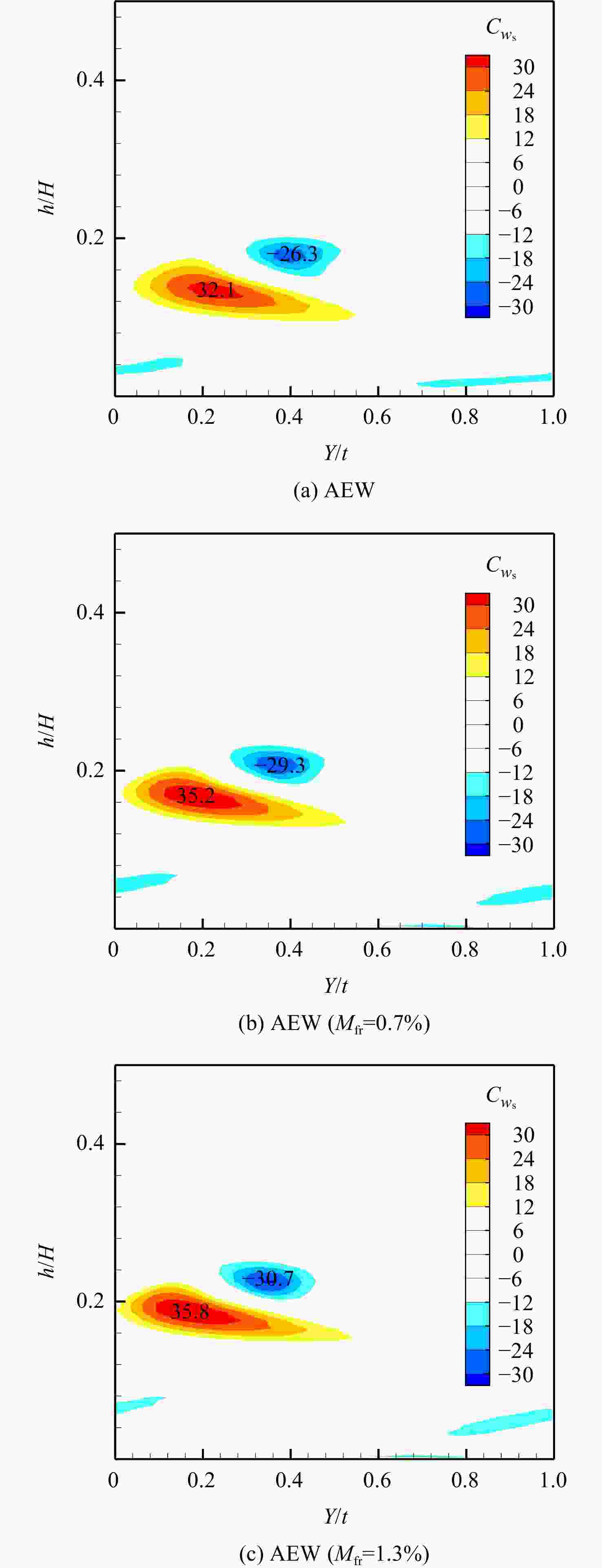

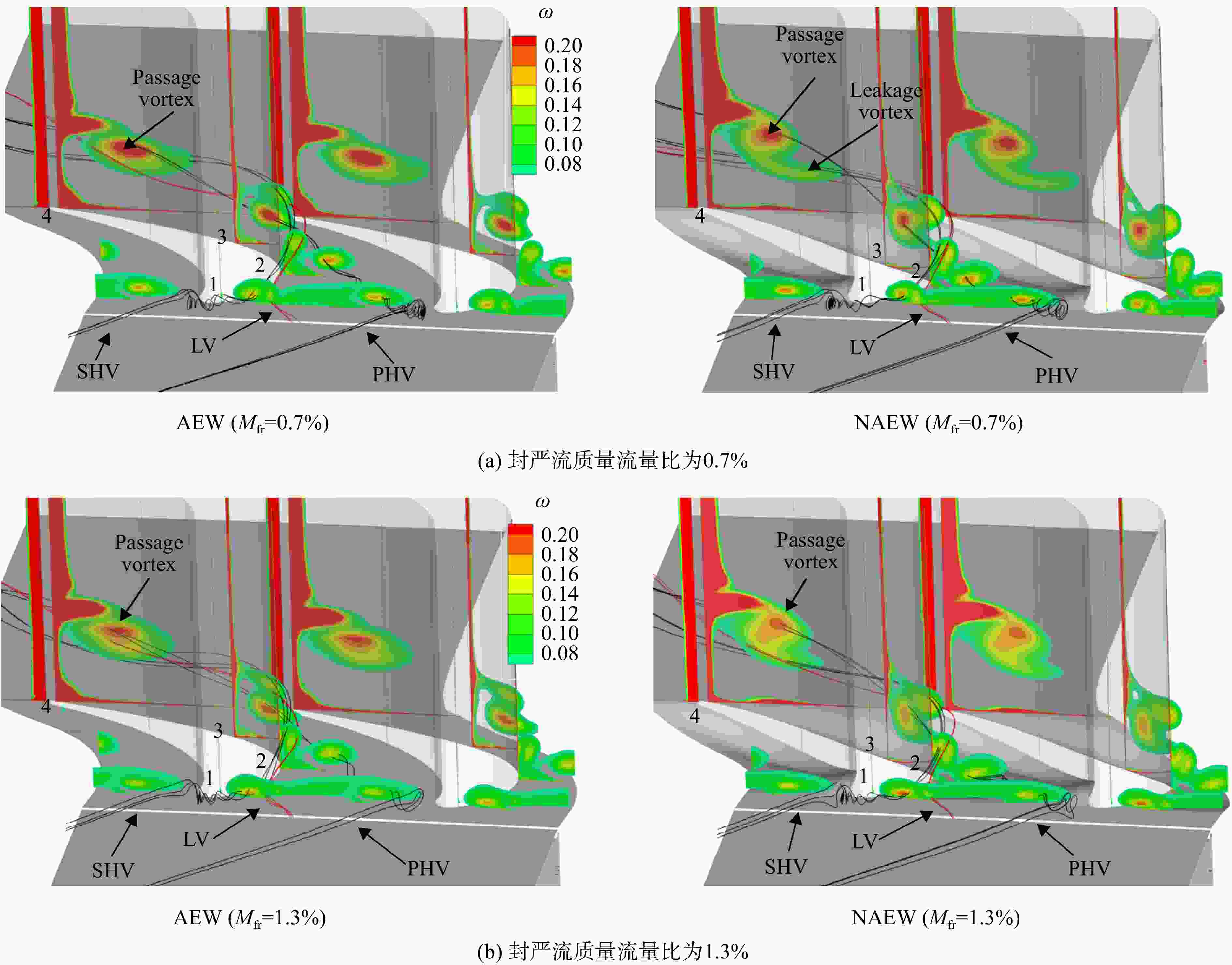

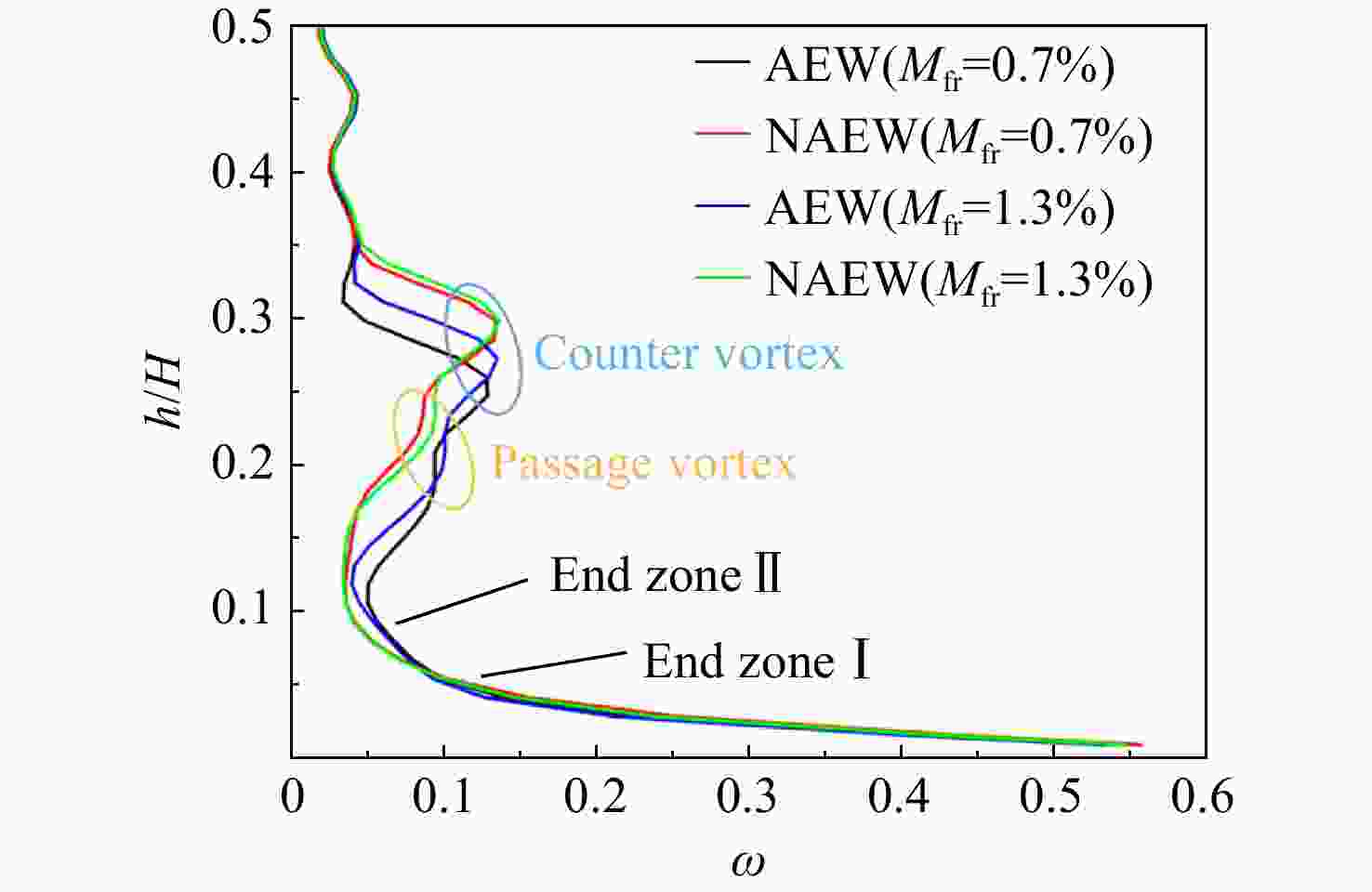

轮缘封严流在保证高压涡轮正常工作的同时也会与通道主流发生相互作用,导致掺混损失增加。以某典型高压涡轮叶栅为研究对象,采用数值模拟的方法,开展了轮缘封严流与主流相互影响机理研究。在此基础之上,探讨了非轴对称端壁对涡轮端区二次流的影响,在不同封严流量下详细分析了涡轮内部损失变化情况。在封严流流量比为0.7%时,非轴对称端壁减弱了端区横向压力梯度,削弱了封严泄漏涡和马蹄涡压力面分支横向迁移的驱动力,延缓了通道涡的形成;当封严流流量比增大到1.3%时,端区二次流的强度更大,非轴对称端壁对端区流动损失仍然具有明显的抑制作用。必须指出的是非轴对称端壁可以削弱叶片吸力面局部的逆压梯度,抑制角区流动分离。

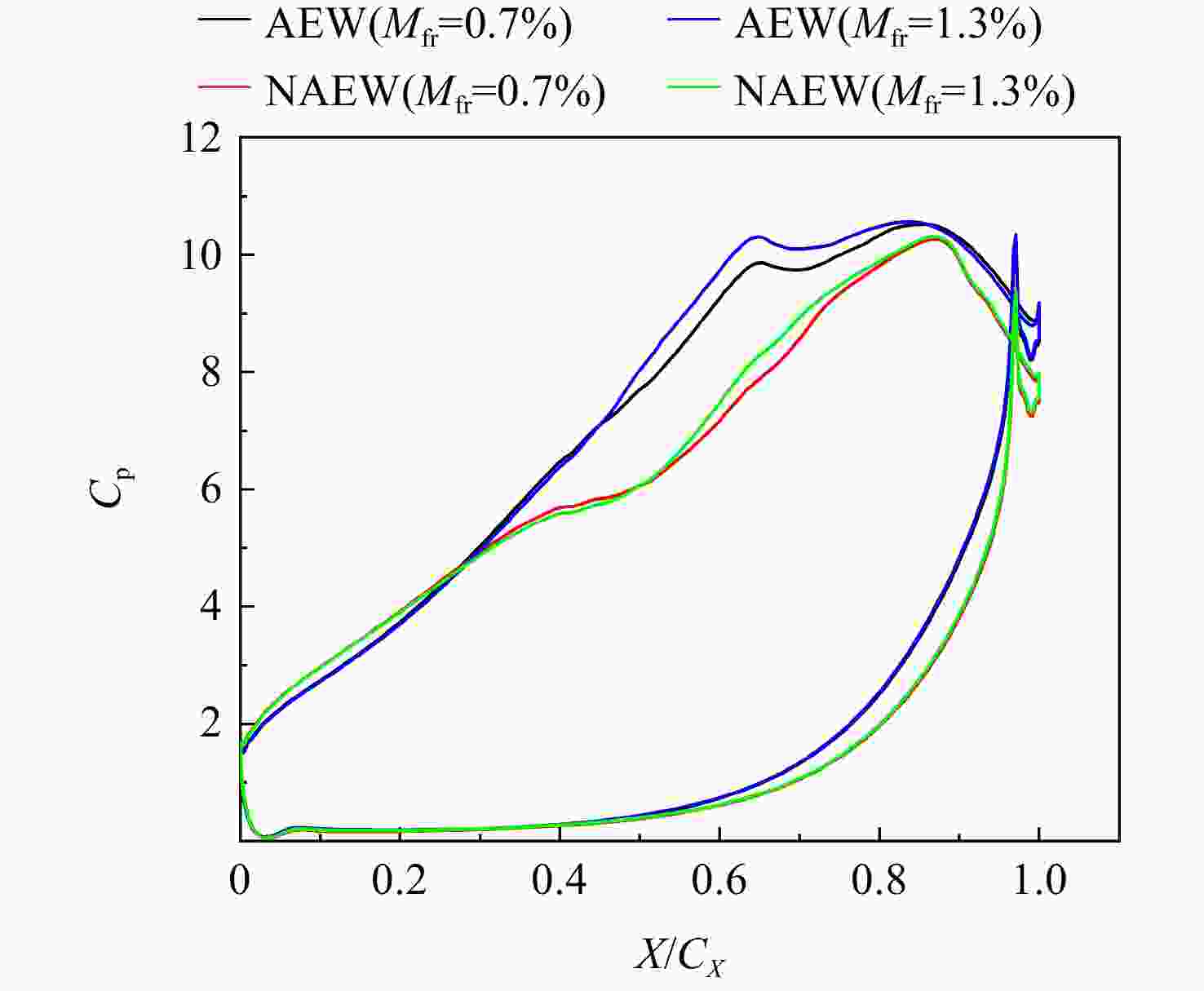

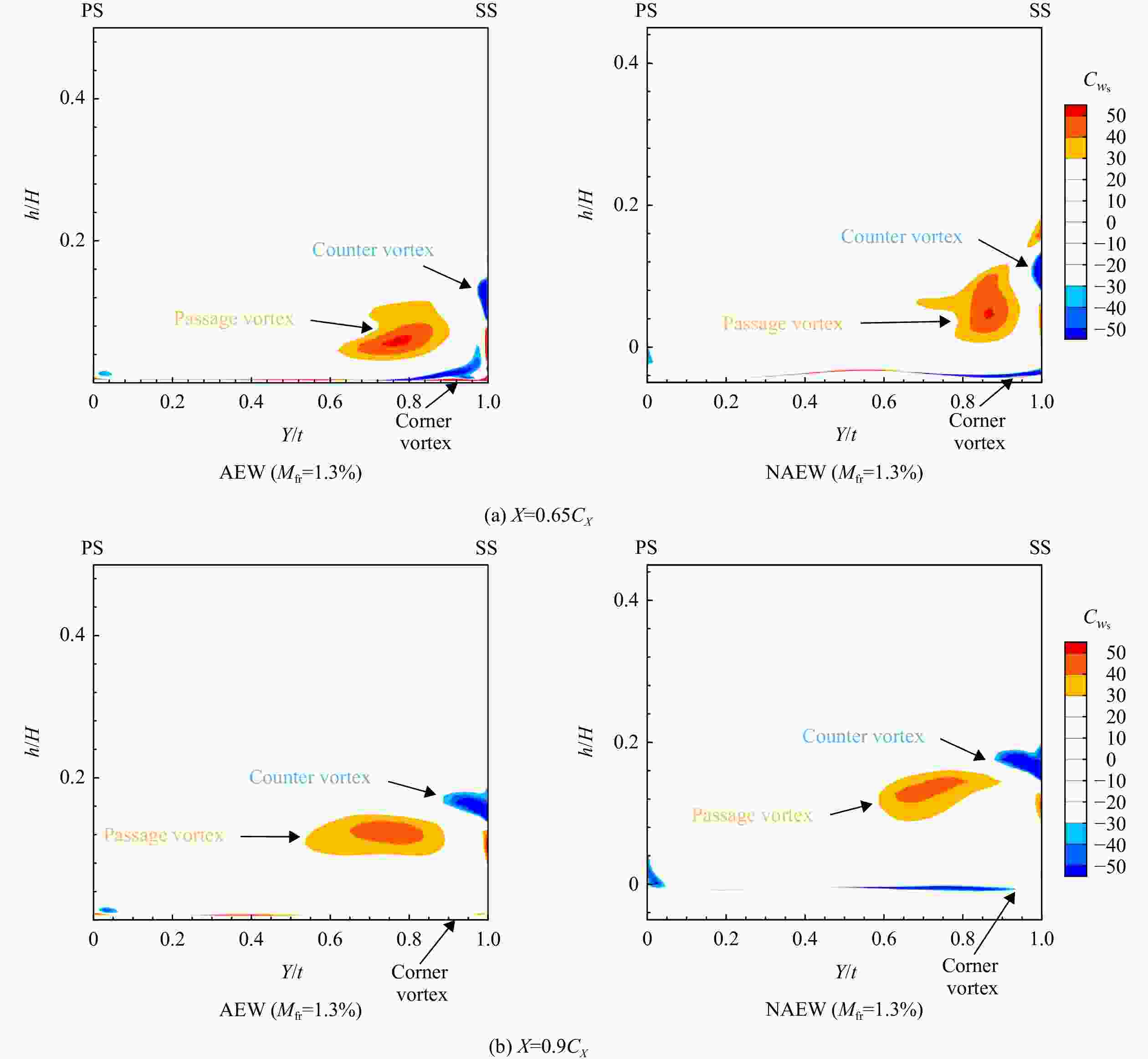

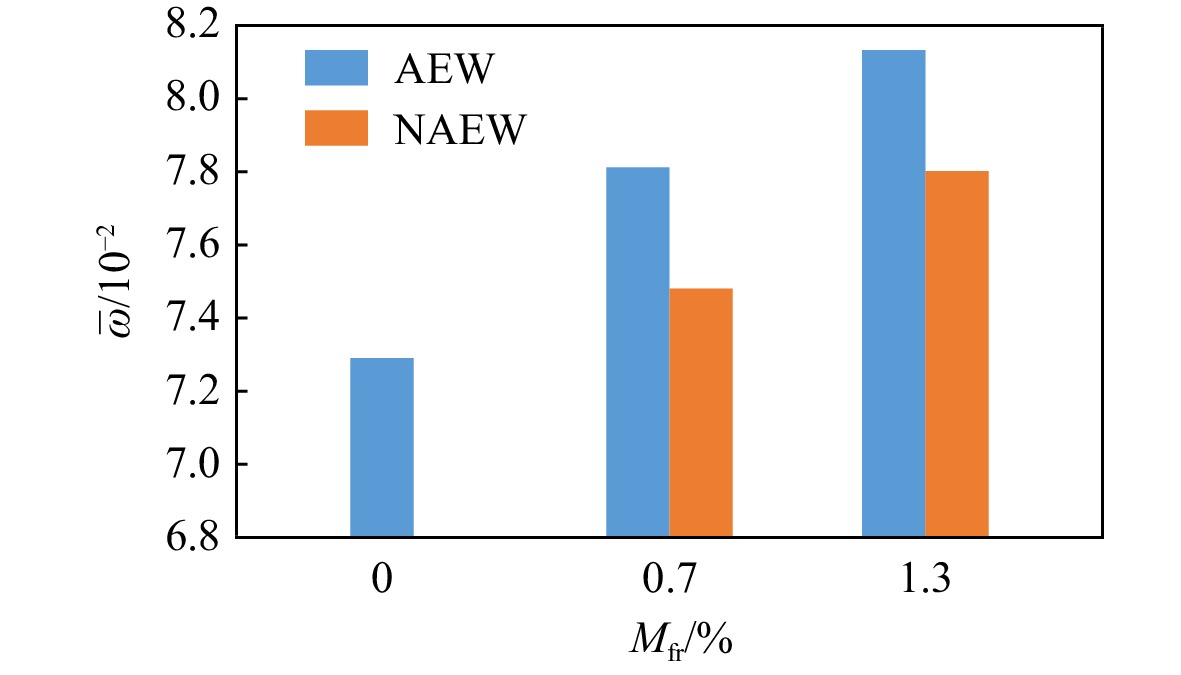

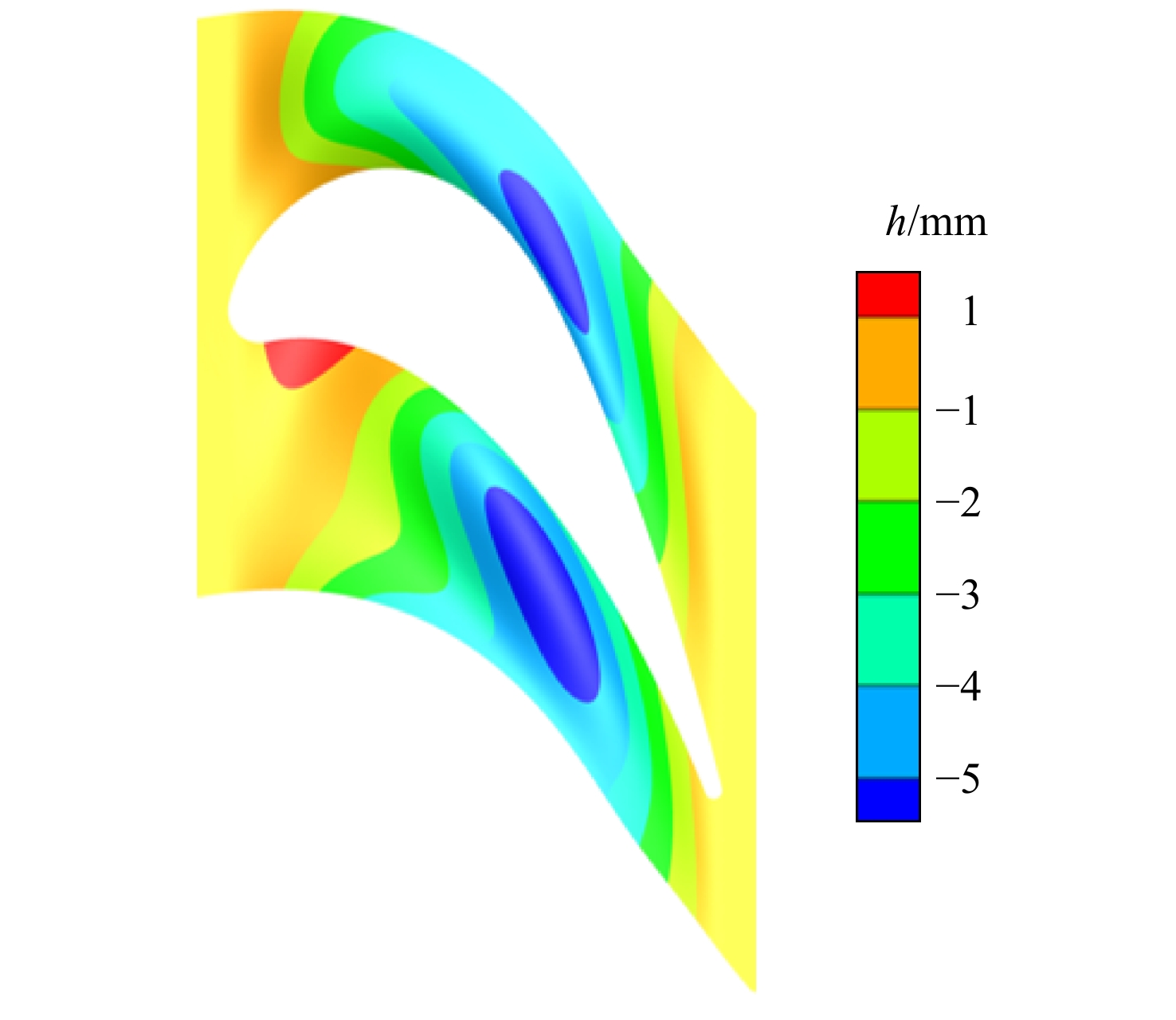

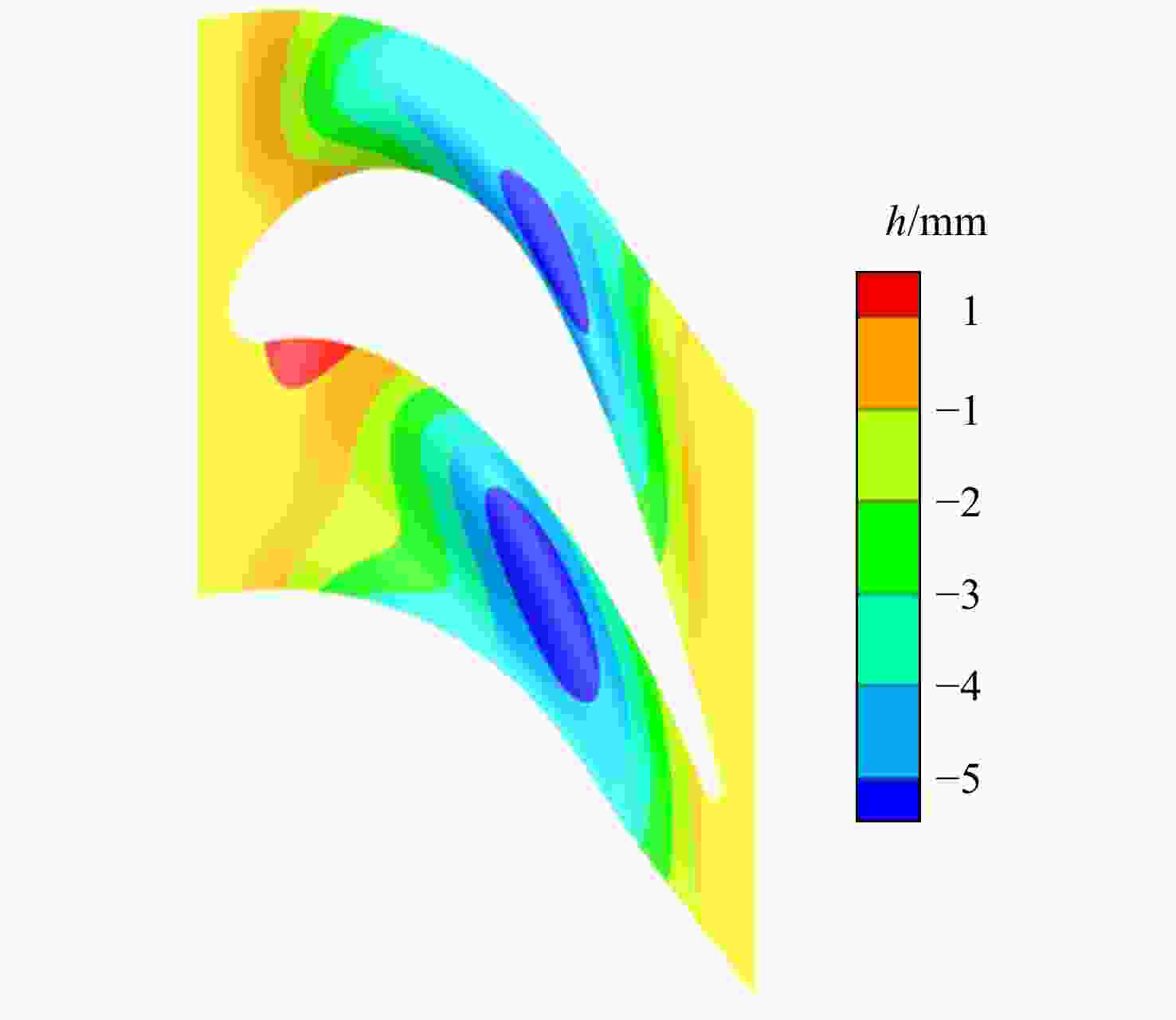

Abstract:Because of the interaction between mainstream flow and the purge flow that can ensure the security of the engine, the flow loss increased accordingly. The typical high-pressure turbine cascade was selected, and the interaction mechanism between the purge flow and mainstream flow in the high-pressure turbine was studied by numerical simulation. On this basis, the influence of non-axisymmetric endwall on secondary flow was deeply discussed and the variation of the flow loss of turbine was analyzed in detail under two different purge flow conditions. When the mass flow ratio of the purge flow was 0.7%, the non-axisymmetrical endwall weakened the transverse pressure gradient near the hub and the driving force of the migration of the pressure side leg of horseshoe vortex and leakage vortex, and delayed the passage vortex formation. When the mass flow ratio of the purge flow increased to 1.3%, the intensity of secondary flow near the hub became stronger, but the non-axisymmetric endwall still had great effect on decreasing the flow loss. It must be noted that the non-axisymmetrical endwall can also weaken the local adverse pressure gradient on the blade suction side and inhibit flow separation in the corner area.

-

Key words:

- high-pressure turbine /

- secondary flow /

- purge flow /

- non-axisymmetric endwall /

- total pressure loss

-

表 1 叶型几何和气动参数

Table 1. Geometry and aerodynamics parameters of the blade

参数 数值 弦长/mm 61.08 轴向弦长/mm 43.92 栅距/mm 50.445 叶高/mm 120 攻角/(°) 1.4 进口气流角/(°) 44 出口气流角/(°) 18.47 进口马赫数 0.26 出口马赫数 0.89 -

[1] SCOBIE J A,SANGAN C M,OWEN J M,et al. Review of ingress in gas turbines[J]. Journal of Engineering for Gas Turbines and Power,2016,138(12): 120801.1-120801.16. [2] ZHANG Ziqing,ZHANG Yingjie,DONG X,et al. Flow mechanism between purge flow and mainstream in different turbine rim seal configurations[J]. Chinese Journal of Aeronautics,2020,33(8): 2162-2175. doi: 10.1016/j.cja.2020.02.016 [3] 杨帆,周莉,王占学. 轮缘封严气流与主流涡系交互作用的非定常数值研究[J]. 推进技术,2019,40(2): 315-323.YANG Fan,ZHOU Li,WANG Zhanxue. Unsteady numerial investigation on vortex interaction between rim seal flow and mainstream[J]. Journal of Propulsion Technology,2019,40(2): 315-323. (in Chinese) [4] SCHREWE S,WERSCHNIK H,SCHIFFER H P. Experimental analysis of the interaction between rim seal and main annulus flow in a low pressure two stage axial turbine[J]. Journal of Turbomachinery,2013,135(5): 1790-1791. [5] HU Jialin,DU Qiang,LIU Jun,et al. Flow development through HP&LP turbines: Part Ⅱ effects of the hub endwall secondary sealing air flow on the turbine’s mainstream flow[J]. Journal of Thermal Science,2017,26(4): 308-315. doi: 10.1007/s11630-017-0943-6 [6] 贾惟. 轮毂封严对涡轮端区流动影响的数值研究[J]. 热能动力工程,2018,33(8): 20-29.JIA Wei. Numerical investigation of influence of rim seal purge flow on turbine endwall flows[J]. Journal of Engineering for Thermal Energy and Power,2018,33(8): 20-29. (in Chinese) [7] 张伸展,温风波,赵志奇,等. 高压涡轮封严冷气对主流气动性能的影响[J]. 航空动力学报,2018,33(5): 1215-1225.ZHANG Shenzhan,WEN Fengbo,ZHAO Zhiqi,et al. Effects of the rim seal coolant gas on aerodynamic performance of mainstream flow in high-pressure turbine[J]. Journal of Aerospace Power,2018,33(5): 1215-1225. (in Chinese) [8] DEVENPORT W J,AGARWAL N K,DEWITZ M B,et al. Effects of a fillet on the flow past a wing-body junction[J]. AIAA Journal,2012,28(12): 2017-2024. [9] RUBECHINI F, GIOVANNINI M, ARNONR A, et al. Reducing secondary flow losses in low-pressure turbines with blade fences: Part I design in an engine-like environment[R]. ASME Paper GT2019-91280, 2019. [10] GIOVANNINI M, RUBECHINI F, AMATO G, et al. Reducing secondary flow losses in low-pressure turbines with blade fences: Part Ⅱ experimental validation on linear cascades[R]. ASME Paper GT2019-91284, 2019. [11] 米攀,李清华,安利平. 多级轴流压气机静子三维造型优化设计[J]. 燃气涡轮试验与研究,2017,30(5): 13-17. doi: 10.3969/j.issn.1672-2620.2017.05.003MI Pan,LI Qinghua,AN Liping. 3D optimization design of multi-stage axial flow compressor stator[J]. Gas Turbine Experiment and Research,2017,30(5): 13-17. (in Chinese) doi: 10.3969/j.issn.1672-2620.2017.05.003 [12] REZASOLTANI M,SCHOBEIRI M T,HAN J C. Experimental investigation of the effect of purge flow on film cooling effectiveness on a rotating turbine with non-axisymmetric endwall contouring[J]. Journal of Turbomachinery,2014,136(9): 91009.1-91009.10. [13] HARVEY N W,ROSE M G,TAYLOR M D,et al. Non-axisymmetric turbine endwall design: Part Ⅰ three-dimensional linear design system[J]. Journal of Turbomachinery,2000,122(2): 278-285. doi: 10.1115/1.555445 [14] HARTLAND J C,GREGORY-SMITH D G,HARVEY N W,et al. Non-axisymmetric turbine endwall design: Part Ⅱ experimental validation[J]. Journal of Turbomachinery,2000,122(2): 286-293. doi: 10.1115/1.555446 [15] ROSE M G. Non-axisymmetric endwall profiling in the HP NGV’s of an axial flow gas turbine[R]. ASME Paper 1994-GT-249, 1994. [16] HARVEY N W. Some effects of non-axisymmetric endwall profiling on axial flow compressor aerodynamics: Part Ⅰ linear cascade investigation[R]. ASME Paper GT-2008-50990, 2008. [17] HARVEY N W, OFFORD T P. Some effects of non-axisymmetric endwall profiling on axial flow compressor aerodynamics: Part Ⅱ multi-stage HPC CFD study[R].ASME Paper GT-2008-50991, 2008. [18] REGINA K, KALFAS A I, ABHARI R S, et al. Aerodynamic robustness of endwall contouring against rim seal purge flow[C]//Proceedings of ASME Turbo Expo 2014: Turbine Technical Conference and Exposition. Dusseldorf, Germany: International Gas Turbine Institute, 2014: 1-14. [19] 朱俊强,屈骁,张燕峰,等. 高负荷低压涡轮内部非定常流动机理及其控制策略研究进展[J]. 推进技术,2017,38(10): 2186-2199.ZHU Junqiang,QU Xiao,ZHANG Yanfeng,et al. Research progress on unsteady flow mechanism and control strategies of high-lift low pressure turbine[J]. Journal of Propulsion Technology,2017,38(10): 2186-2199. (in Chinese) [20] SCHUEPBACH P,ABHARI R S,ROSE M G,et al. Influence of rim seal purge flow on the performance of an endwall-profiled axial turbine[J]. Journal of Turbomachinery,2011,133(2): 021011.1-021011.10. -

下载:

下载: