Combustion flow field structure and performance in hydrogen-fueled scramjet

-

摘要:

基于氢燃料单凹腔矩形截面超燃冲压发动机,在发动机入口马赫数为2的条件下,采用RANS(Reynolds-averaged Navier Stokes)方法求解包含10组分21步化学反应机理模型,并结合有限速率燃烧模型进行了数值模拟研究,并与试验数据进行对比。分析了无化学反应和化学反应流动条件下的燃烧室流场结构,研究了不同当量比对燃烧室燃烧性能的影响,考察了不同喷注位喷注氢气时的流场燃烧特性。结果表明:当量比的提高会使燃烧产物分布扩大并后移,发动机燃烧模态由超燃转为亚燃,发动机总压损失上升,燃烧效率降低,推力增加。在当量比为0.1~0.3时,在凹腔前端喷注燃料的发动机燃烧性能优于凹腔内喷注,当量比为0.4~0.5则相反。

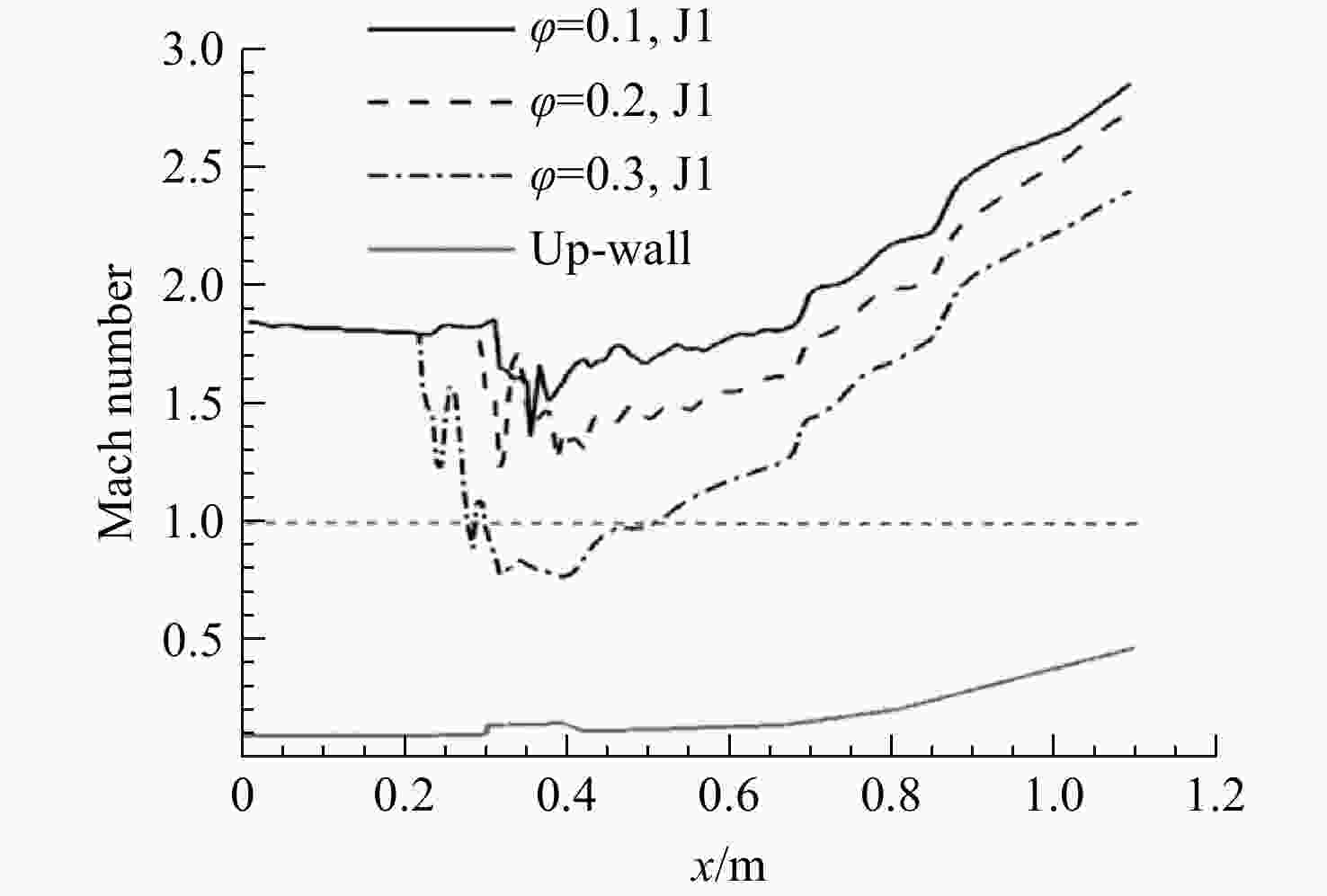

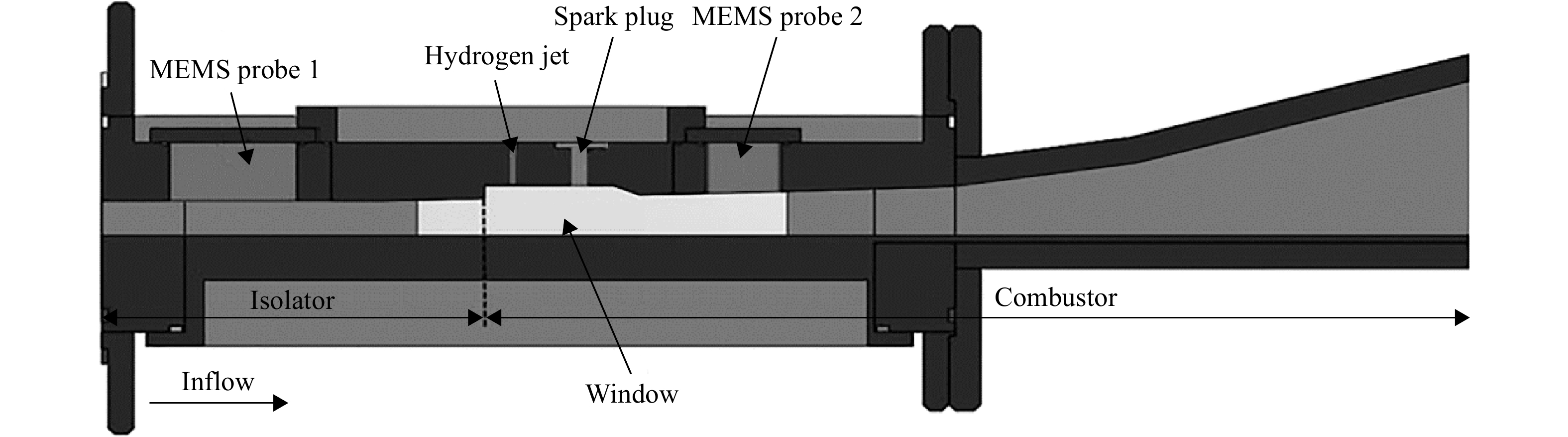

Abstract:Based on the hydrogen-fueled single cavity rectangular cross-section scramjet, under the inflow condition of Mach number 2, the RANS (Reynolds-averaged Navier Stokes) method was used to solve the chemical mechanism model (10 species and 21 reactions), while the finite-rate combustion model was used to finish numerical simulation, and compared with the experimental data. The flow field structure of the combustor under nonreacting and reacting flow conditions was analyzed, then the effects of different equivalence ratios on the combustion performance of the combustor were discussed, and the combustion flow field characteristics of hydrogen injection at different injection positions were investigated. Results demonstrated that the distribution of combustion products was expanded and also moved back with the increase of equivalence ratio, changed the engine combustion mode from supersonic combustion to subsonic combustion, increased the total pressure loss, decreased the combustion efficiency and augment the thrust. At 0.1 to 0.3 equivalent ratios, the scramjet combustion performance of fuel injected at the front of the cavity was better than that injected in the cavity, which was contrary to 0.4 to 0.5 equivalent ratios.

-

Key words:

- scramjet /

- hydrogen /

- combustion efficiency /

- equivalence ratio /

- total pressure loss

-

表 1 无化学反应流动数值计算结果与试验值比较

Table 1. Comparison between experimental values and numerical simulation

参数 试验值 计算值 相对误差/% 监测点1壁面压力/MPa 0.103 0.109 5.83 监测点2壁面压力/MPa 0.101 0.103 1.98 监测点1壁面切应力/Pa 825 770 −6.67 监测点2壁面切应力/Pa 401 382 −4.74 表 2 出口处燃烧效率

Table 2. Combustion efficiency of outlet

φ J1 J2 0.1 0.888 0.899 0.2 0.689 0.844 0.3 0.784 0.791 0.4 0.721 0.715 0.5 0.626 0.605 -

[1] 杨事民, 张建良. 超燃冲压发动机燃烧室流场数值模拟[J]. 航空发动机, 2009, 35(4): 25-28.YANG Shiming, ZHANG Jianliang. Numerical simulation of flow field of a scramjet combustor[J]. Aeroengine, 2009, 35(4): 25-28. (in Chinese) [2] 王靛,宋文艳,李建平,等. 超燃冲压发动机燃烧室冷态流场研究[J]. 航空动力学报,2008,23(6): 1135-1140.WANG Dian,SONG Wenyan,LI Jianping,et al. Cold flow research in scramjet combustor[J]. Journal of Aerospace Power,2008,23(6): 1135-1140. (in Chinese) [3] 鲁阳. 超燃冲压发动机燃烧室内流动与燃烧的数值模拟[D]. 杭州: 浙江大学, 2014.LU Yang. Numerical simulation of flow and combustion in a scramjet combustor[D]. Hangzhou: Zhejiang University, 2014. (in Chinese) [4] SETTLES G S,WILLIAMS D R,BACA B K,et al. Reattachment of a compressible turbulent free shear layer[J]. AIAA Journal,1982,20(1): 60-67. doi: 10.2514/3.51047 [5] HORSTMAN C C,SETTLES G S,WILLIAMS D R,et al. A reattaching free shear layer in compressible turbulent flow[J]. AIAA Journal,1982,20(1): 79-85. doi: 10.2514/3.51049 [6] 李建平,宋文艳,肖隐利. 超燃冲压发动机/机体一体化优化设计[J]. 航空动力学报,2011,26(4): 874-879.LI Jianping,SONG Wenyang,XIAO Yinli. Research on the optimization design of integrated scramjet/airframe[J]. Journal of Aerospace Power,2011,26(4): 874-879. (in Chinese) [7] TIAN Y,HAN Y,YANG S,et al. Investigation of fluctuating characteristics of wall shear stress in supersonic flow[J]. Physics of Fluids,2019,31(12): 125110.1-125110.10. [8] 鲍文,郭林春,崔涛,等. 超燃冲压发动机燃烧室传感器最佳位置选择[J]. 航空动力学报,2007,22(3): 475-479. doi: 10.3969/j.issn.1000-8055.2007.03.026BAO Wen,GUO Linchun,CUI Tao,et al. Optimal sensor location of scramjet combustor[J]. Journal of Aerospace Power,2007,22(3): 475-479. (in Chinese) doi: 10.3969/j.issn.1000-8055.2007.03.026 [9] 王林森,涂晓波,王宇航,等. 基于acetone-PLIF技术的超燃冲压发动机燃烧室燃料/空气掺混特性[J]. 航空动力学报,2021,36(8): 1614-1620.WANG Linsen,TU Xiaobo,WANG Yuhang,et al. Fuel/air mixing characteristics of scramjet combustor based on acetone-PLIF technology[J]. Journal of Aerospace Power,2021,36(8): 1614-1620. (in Chinese) [10] MA G,SUN M,ZHAO G,et al. Numerical investigation of an axisymmetric model scramjet assisted with cavity of different aft wall angles[J]. International Journal of Aerospace Engineering,2021,2021: 1-17. [11] ALI M,FUJIWARA T,LEBLANC J E. Influence of main flow inlet configuration on mixing and flameholding in transverse injection into supersonic airstream[J]. International Journal of Engineering Science,2000,38(11): 1161-1180. doi: 10.1016/S0020-7225(99)00074-9 [12] CHOUBEY G,YUVARAJAN D,HUANG W,et al. Hydrogen fuel in scramjet engines: a brief review[J]. International Journal of Hydrogen Energy,2020,45(33): 16799-16815. doi: 10.1016/j.ijhydene.2020.04.086 [13] PECNIK R,TERRAPON V E,HAM F,et al. Reynolds-averaged Navier-Stokes simulations of the HyShot Ⅱ scramjet[J]. AIAA Journal,2012,50(8): 1717-1732. doi: 10.2514/1.J051473 [14] CHOUBEY G,PANDEY K M. Effect of different strut+wall injection techniques on the performance of two-strut scramjet combustor[J]. International Journal of Hydrogen Energy,2017,42(18): 13259-13275. doi: 10.1016/j.ijhydene.2017.04.024 [15] 田野,乐嘉陵,杨顺华,等. 氢燃料超燃燃烧室流场结构和火焰传播规律试验研究[J]. 实验流体力学,2019,33(1): 72-78. doi: 10.11729/syltlx20180027TIAN Ye,LE Jialing,YANG Shunhua,et al. Experimental study on flow structure and flame development in a hydrogen-fueled supersonic combustor[J]. Journal of Experiments in Fluid Mechanics,2019,33(1): 72-78. (in Chinese) doi: 10.11729/syltlx20180027 [16] 钟富宇,乐嘉陵,韩亦宇,等. 当量比对氢燃料超燃燃烧室流场结构和燃烧模态影响研究[J]. 推进技术,2019,40(2): 324-330.ZHONG Fuyu,LE Jialing,HAN Yiyu,et al. Investigation for effects of equivalence ratio on flow structure and combustion mode in a hydrogen fueled scramjet combustor[J]. Journal of Propulsion Technology,2019,40(2): 324-330. (in Chinese) [17] UKAI T,ZARE-BEHTASH H,ERDEM E,et al. Effectiveness of jet location on mixing characteristics inside a cavity in supersonic flow[J]. Experimental Thermal and Fluid Science,2014,52: 59-67. doi: 10.1016/j.expthermflusci.2013.08.022 [18] LUETKE N, MOHIELDIN T, TIWARI S. Unsteady numerical analysis of hydrogen combustion in a dual mode engine[R]. AIAA-2007-5425, 2007. [19] 乐嘉陵,田野,杨顺华,等. 脉冲燃烧风洞中空气节流对煤油燃料超燃冲压发动机火焰稳定影响研究[J]. 推进技术,2018,39(10): 2160-2170.LE Jialing,TIAN Ye,YANG Shunhua,et al. Study on flame stabilization in a kerosene fueled scramjet combustor with air throttling in a pulse combustion wind tunnel[J]. Journal of Propulsion Technology,2018,39(10): 2160-2170. (in Chinese) [20] 田野,杨顺华,乐嘉陵,等. 空气节流对乙烯燃料超燃冲压发动机流场结构影响研究[J]. 推进技术,2015,36(4): 481-487.TIAN Ye,YANG Shunhua,LE Jialing,et al. Study on flow structure of an ethylene-fueled scramjet combustor with air throttling[J]. Journal of Propulsion Technology,2015,36(4): 481-487. (in Chinese) [21] BERGLUND M,FEDINA E,FUREBY C,et al. Finite rate chemistry large-eddy simulation of self-ignition in supersonic combustion ramjet[J]. AIAA Journal,2010,48(3): 540-550. doi: 10.2514/1.43746 [22] SANTANA E R,WEIGAND B. Effect of the reaction mechanism on the numerical prediction of the performance of a scramjet combustor at cruise flight 8 Mach number[J]. Aerospace Science and Technology,2021,112(4): 106595.1-106595.20. [23] Ó CONAIRE M,CURRAN H J,SIMMIE J M,et al. A comprehensive modeling study of hydrogen oxidation[J]. International Journal of Chemical Kinetics,2004,36(11): 603-622. doi: 10.1002/kin.20036 [24] TIAN Y,YANG S,LE J,et al. Investigation of combustion and flame stabilization modes in a hydrogen fueled scramjet combustor[J]. International Journal of Hydrogen Energy,2016,41(42): 19218-19230. doi: 10.1016/j.ijhydene.2016.07.219 [25] CHOI J Y, NOH J, BYUN J R, et al. Numerical investigation of combustion/shock-train interactions in a dual-mode scramjet engine[R]. AIAA-2011-2395, 2011. [26] NOH J, CHOI J Y, BYUN J R, et al. Numerical study of the auto-ignition of ethylene in an scramjet combustor with air throttling[R]. AIAA-2010-7063, 2010. -

下载:

下载: