Investigation of temperature uniformity of profiled CBN grinding wheel under high frequency induction brazing based on response surface methodology

-

摘要:

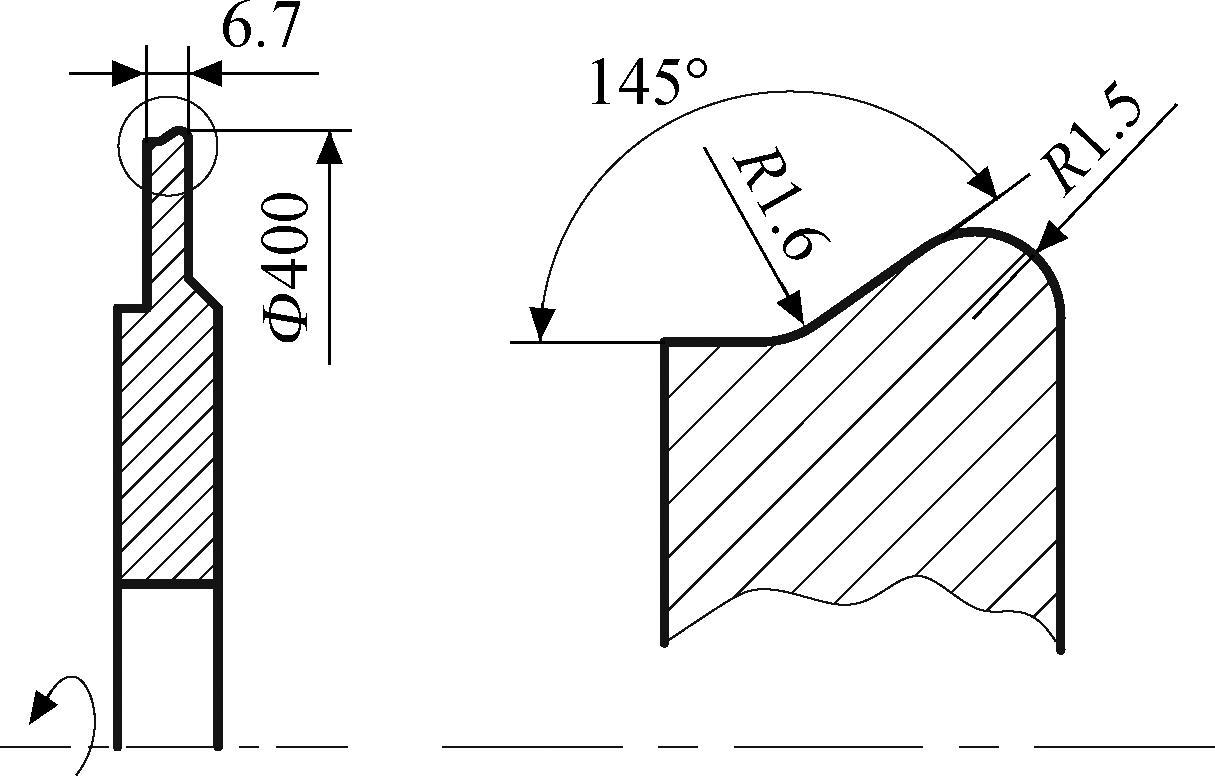

成型砂轮在高频感应钎焊过程中存在温度分布不均匀导致钎焊质量无法满足使用要求,这是长期困扰超硬磨料砂轮高频感应钎焊技术的难题。针对该问题,提出温度均匀性的表征方法,以温度均匀度和平均温度为响应值,基于有限元仿真数据获得了响应曲面法模型。基于该模型,采用方差分析成型砂轮感应钎焊温度均匀性的影响因素显著程度由大到小依次为加热间隙、感应电流、导磁体长度。以平均温度值和温度均匀度为优化目标,基于响应曲面法优化线圈结构和工艺参数,开展了感应加热试验,证明响应曲面法模型优化结果的误差在6.94%以内。高频感应钎焊的成型立方氮化硼(cubic boron nitride,CBN)砂轮宏观形貌显示,钎料在成型面各处铺展的一致性好,表明钎焊过程中在成型面的温度分布具有较好的均匀性。

Abstract:During high frequency induction brazing of super abrasive grinding wheels,it was difficult to get a uniform temperature distribution on the grinding wheel surface,especially the profiled grinding wheel.For this problem,a characterization method of temperature uniformity was proposed.Response surface methodology model of temperature uniformity and average temperature was established based on the finite element method results.Based on this model,analysis of variance was conducted to investigate the influence factors on the temperature uniformity of profiled grinding wheel.It was found that the degrees of the influence on the temperature uniformity and average temperature from maximum to minimum were heating gap,induction current and length of magnetizer respectively.With the target of average temperature and temperature uniformity,the optimal parameters were obtained based on response surface methodology method.The experimental results verified that the error of the response surface methodology models was below 6.94%.Finally,high frequency induction brazing of profiled cubic boron nitride(CBN)grinding wheel was carried out with the optimal parameters.A consistent brazing surface with good spread ability was observed,indicating that good temperature uniformity on the profiled surface was obtained during induction brazing.

-

表 1 响应曲面法各因素与水平

Table 1. Factor and level values of RSM

水平 因素 电流I/A 导磁体长度L/mm 加热间隙h/mm -1 80 1 1 0 120 3.6 3 1 160 6.2 5 表 2 各因素设计方案与仿真结果

Table 2. Design and simulation results of each factors

序号 I/A L/mm h/mm /°C U/% 1 80 1 3 226.847 94.02 2 120 6.2 5 450.8 90.18 3 120 1 5 350 91.57 4 160 3.6 5 584.6 93.24 5 120 3.6 3 538.8 96.61 6 160 6.2 3 829.5 90.84 7 120 1 1 1 406.4 81.56 8 120 6.2 1 1 359.6 82.27 9 80 3.6 1 851 93.35 10 80 3.6 5 227.6 96.02 11 80 6.2 3 238.3 94.65 12 160 1 3 806.1 85.52 13 160 3.6 1 2 124.1 80.71 表 3 平均温度的ANOVA结果

Table 3. ANOVA results of average temperature

项目 平方和 自由度 均方差 F值 P值 模型 3.95×106 5 7.91×105 200.84 <0.000 1 I 9.80×105 1 9.80×105 248.99 <0.000 1 L 986.86 1 986.86 0.250 6 0.626 5 h 2.13×106 1 2.13×106 540.99 <0.000 1 2.10×105 1 2.10×105 53.29 <0.000 1 h² 6.33×105 1 6.33×105 160.69 <0.000 1 残差 43 312.39 11 3 937.49 失拟 43 312.39 7 6 187.48 纯误差 0 4 0 总计 4.00×106 16 R²=0.982 9 Radj²=0.984 2 表 4 温度均匀度的ANOVA结果

Table 4. ANOVA results of temperature uniformity

项目 平方和 自由度 均方差 F值 P值 模型 497.462 9 7 71.066 95.951 <0.000 1 I 110.038 6 1 110.038 148.57 <0.000 1 L 3.591 2 1 3.591 4.848 0.055 1 h 137.697 1 137.697 185.914 <0.000 1 4.730 6 1 4.73 6.387 0.032 3 24.900 1 1 24.9 33.619 0.000 26 L² 93.797 1 93.797 126.641 <0.000 1 h² 110.717 1 1 110.717 149.486 <0.000 1 残差 6.665 8 9 0.741 失拟 6.665 8 5 1.333 纯误差 0 4 0 总计 504.128 8 16 R²=0.986 8 Radj²=0.976 5 -

[1] 丁文锋,奚欣欣,占京华,等.航空发动机钛材料磨削技术研究现状及展望[J].航空学报,2019,40(6):6⁃41.DING Wenfeng,XI Xinxin,ZHAN Jinghua,et al.Research status and future development of grinding technology of titanium materials for aero⁃engines[J].Acta Aeronauticaet Astronautica Sinica,2019,40(6):6⁃41.(in Chinese) [2] XIAO Haozhong,XIAO Bing,WU Hengheng,et al.Microstructure and mechanical properties of vacuum brazed CBN abrasive segments with tungsten carbide reinforced Cu⁃Sn⁃Ti alloys[J].Ceramics International,2019,45(9):12469⁃12475. [3] SIMHAN D R,GHOSH A.Vacuum brazing of cubic boron nitride to medium carbon steel with Zr added passive and Ti activated eutectic Ag⁃Cu alloys[J].Ceramics International,2018,44(5):4891⁃4899. [4] 卢金斌,穆云超,孟普.钛基钎料真空钎焊立方氮化硼的分析[J].焊接学报,2010,31(5):57⁃60.LU Jinbin,MU Yunchao,MENG Pu.Analysis on vacuum brazing of CBN with Ti⁃base filler[J].Transactions of the China Welding Institution,2010,31(5):57⁃60.(in Chinese) [5] 任慧中,李奇林,雷卫宁,等.感应钎焊温度对CBN砂轮磨削性能的影响[J].中国机械工程,2018,29(7):829⁃834.REN Huizhong,LI Qilin,LEI Weining,et al.Effects of induction brazing temperature on grinding performances of CBN grinding wheels[J].China Mechanical Engineering,2018,29(7):829⁃834.(in Chinese) [6] ROMMEL D,SCHERM F,KUTTNER C,et al.Laser cladding of diamond tools:interfacial reactions of diamond and molten metal[J].Surface and Coatings Technology,2016,291:62⁃69. [7] CHEN Jiajia,FU Yucan,LI Qilin,et al.Investigation on induction brazing of revolving heat pipe grinding wheel[J].Materials and Design,2017,116:21⁃30. [8] VALERY R,DON L,RAYMOND C,et al.Handbook of induction heat[M].New York,US:Marcel Dekker Incorporated,2003. [9] BARKA N,CHEBAK A,OUAFI A E,et al.A new approach in optimizing the induction heating process using flux concentrators:application to 4340 steel spur gear[J].Journal of Materials Engineering and Performance,2014,23(9):3092⁃3099. [10] GAO Kai,QIN Xunpeng,WANG Zhou,et al.Effect of magnetizer geometry on the spot induction heating process[J].Journal of Materials Processing Technology,2016,231:125‑136. [11] 童欣,苏宏华,徐九华,等.成形砂轮超高频感应加热温度分布均匀性分析[J],焊接学报,2015,36(2):51⁃54.TONG Xin,SU Honghua,XU Jiuhua,et al.Uniformity of ultra⁃high frequency induction heating temperature distribution of grinding wheel[J].Transactions of the China Welding Institution,2015,36(2):51⁃54.(in Chinese) [12] MONTGOMERY D C.Design and analysis of experiments[M].New York,US:John Wiley,1984. [13] 邵佳丰,罗晨,周怡君,等.基于自由变形技术的分流叶片形状优化设计[J].航空动力学报,2021,36(6):1315⁃1323.SHAO Jiafeng,LUO Chen,ZHOU Yijun,et al.Optimization design of splitter blade shape based on free form deformation technology[J].Journal of Aerospace Power,2021,36(6):1315⁃1323.(in Chinese) [14] 李峰,李学崑,朱天行,等.基于响应曲面法的强化感应加热数值仿真[J].清华大学学报(自然科学版),2013,53(4):469⁃475.LI Feng,LI Xuekun,ZHU Tianxing,et al.Numerical simulations of strengthen induction heating with response surface methodology[J].Journal of Tsinghua University (Science and Technology),2013,53(4):469⁃475.(in Chinese) [15] KHALIFA M,BARKA N,BROUSSEAU J,et al.Reduction of edge effect using response surface methodology and artificial neural network modeling of a spur gear treated by induction with flux concentrators[J].International Journal of Advanced Manufacturing Technology,2019,104(1/2/3/4):103⁃117. [16] LI Qilin,XU Jiuhua,SU Honghua.Simulation of temperature field in ultra⁃high frequency induction heating and verification[J].Transactions of Nanjing University of Aeronautics and Astronautics,2013,30(2):155⁃161. [17] JIANG Zhaoneng,HUANG Shichun,WANG Zhixin,et al.Efficient analysis of coated object using fast algorithm with surface impedance boundary condition[J].International Journal of Applied Electromagnetics and Mechanics,2020,63(3):521⁃528. [18] FERROUILLAT P,GUERIN C,MEUNIER G,et al.Computations of source for non⁃meshed coils with A⁃V formulation using edge elements[J].IEEE Transactions on Magnetics,2015,51(3):1⁃4. [19] SHIH S,NIAN S,HUANG M,et al.Nonplanar mold surface heating using external inductive coil and magnetic shielding materials[J].International Communications in Heat and Mass Transfer,2016,71:44⁃55. -

下载:

下载: