Experimental study on the effect of cavitation of squeeze film damper under low oil supply pressure

-

摘要:

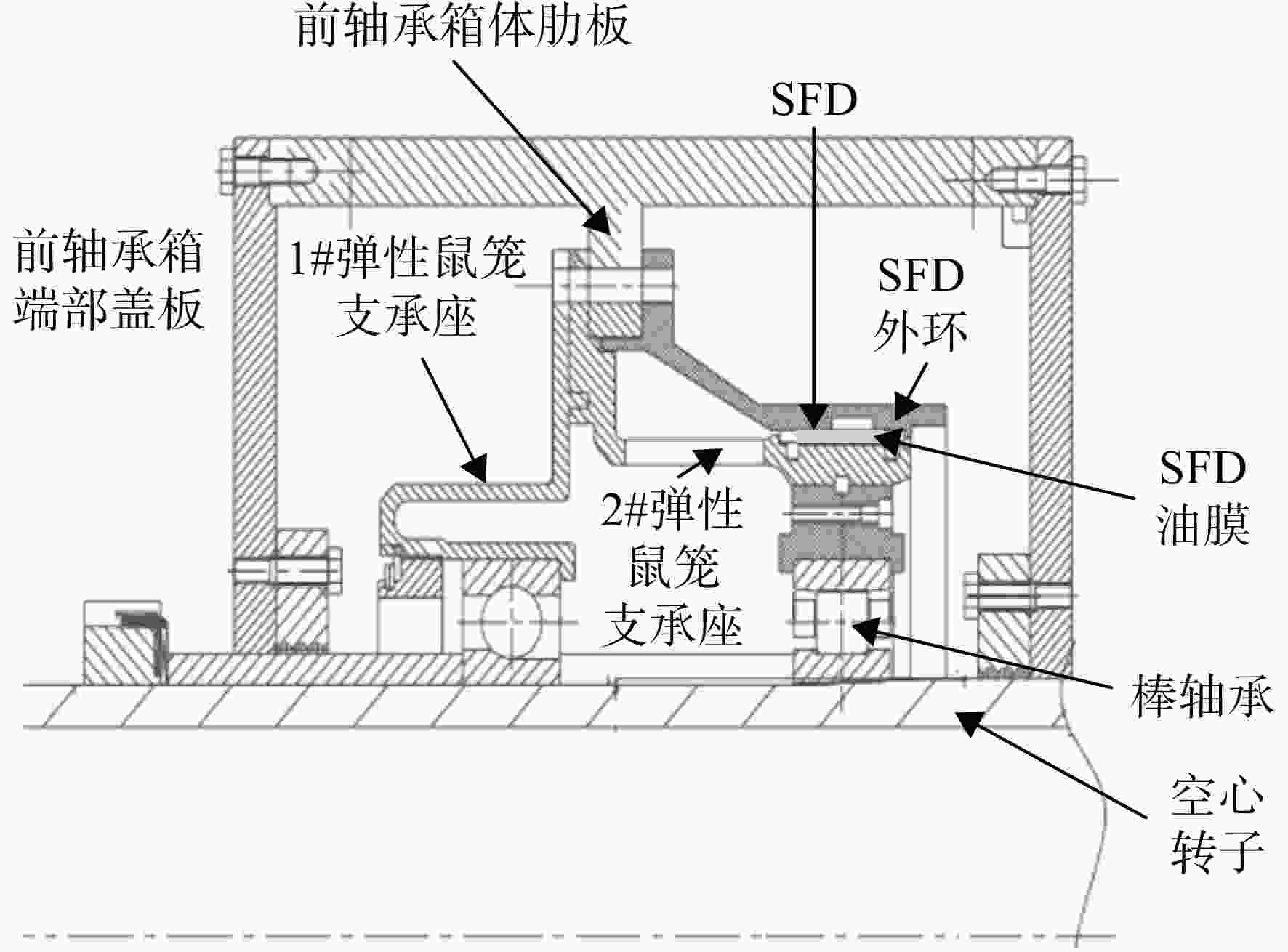

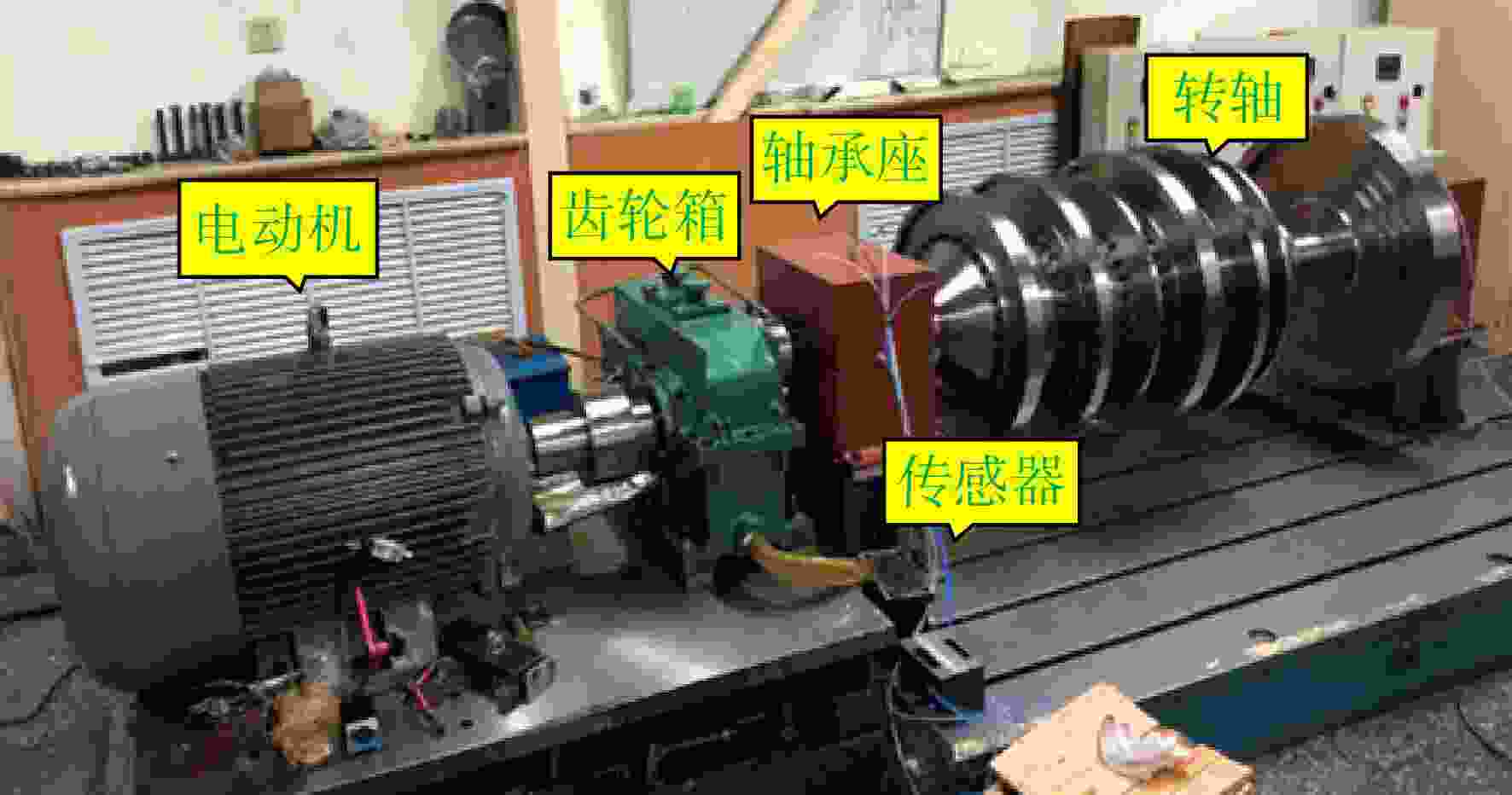

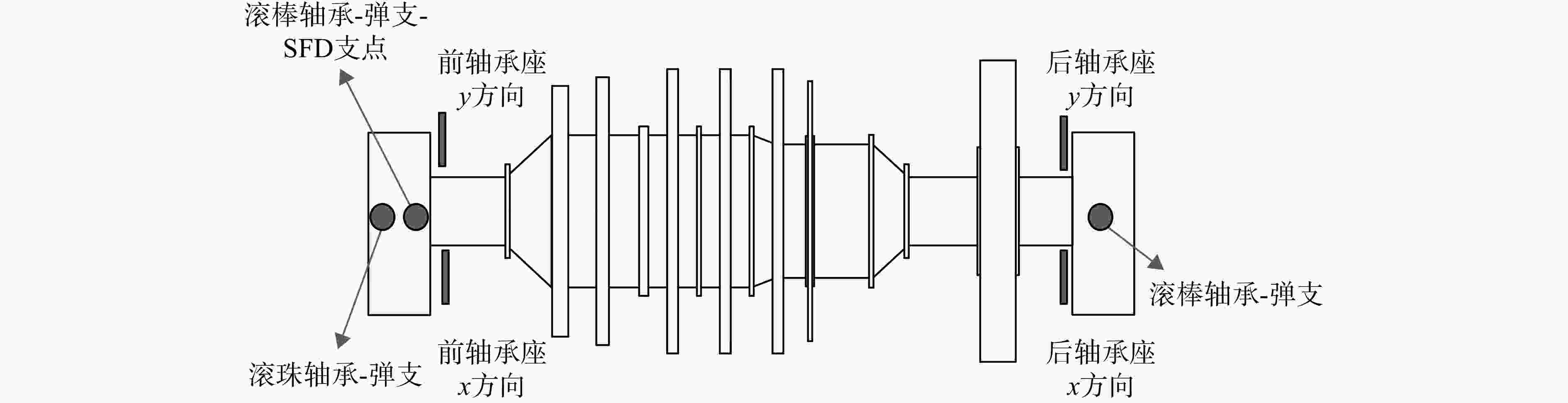

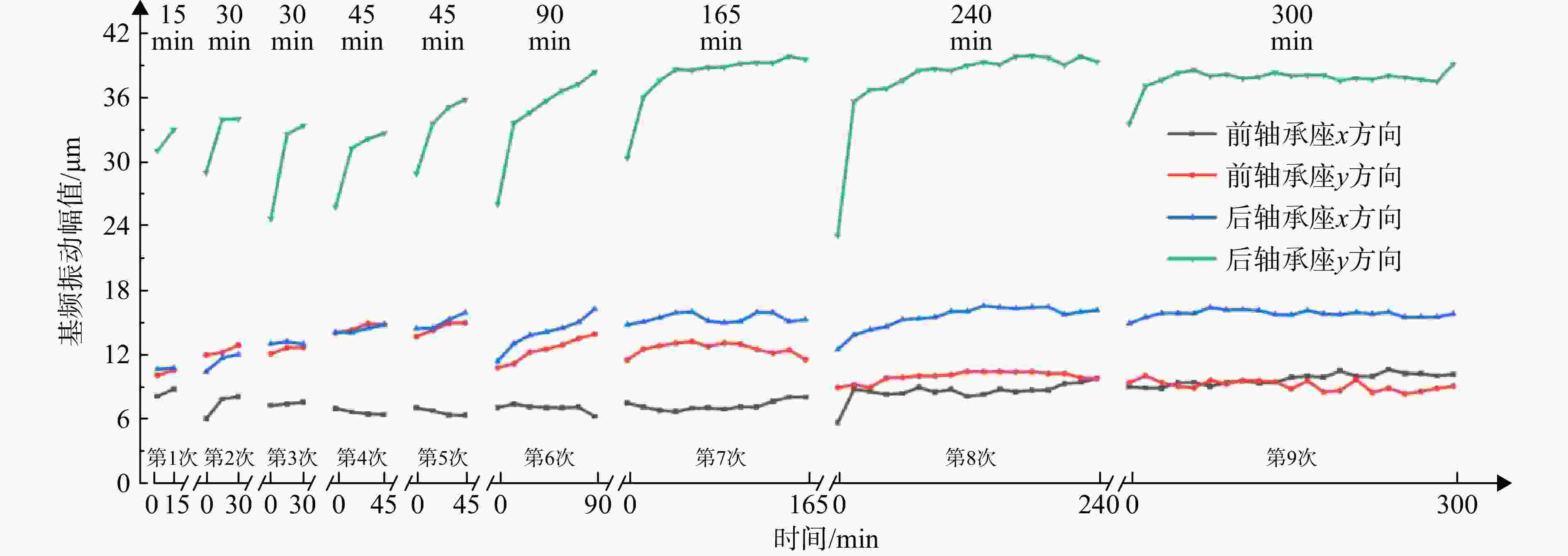

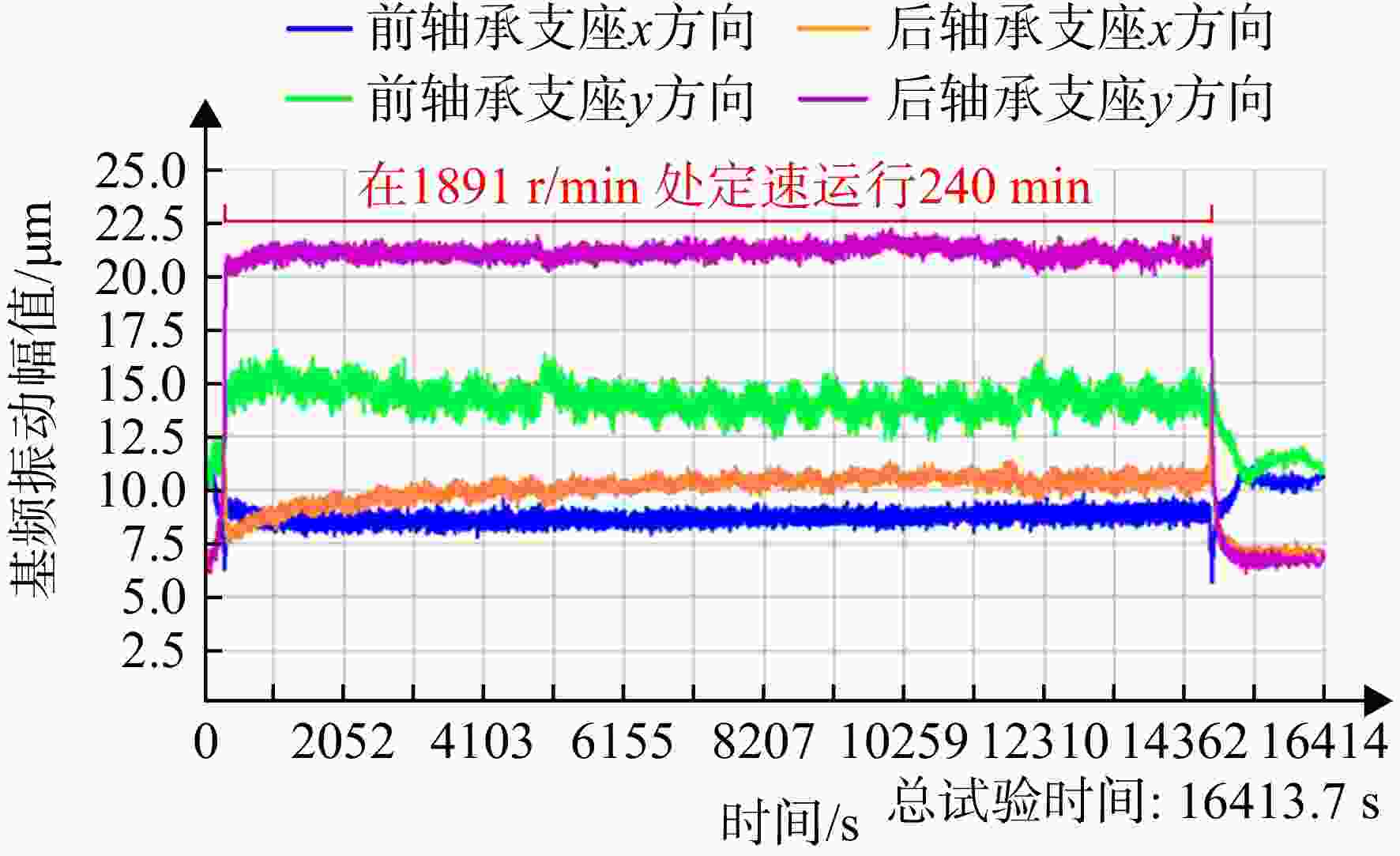

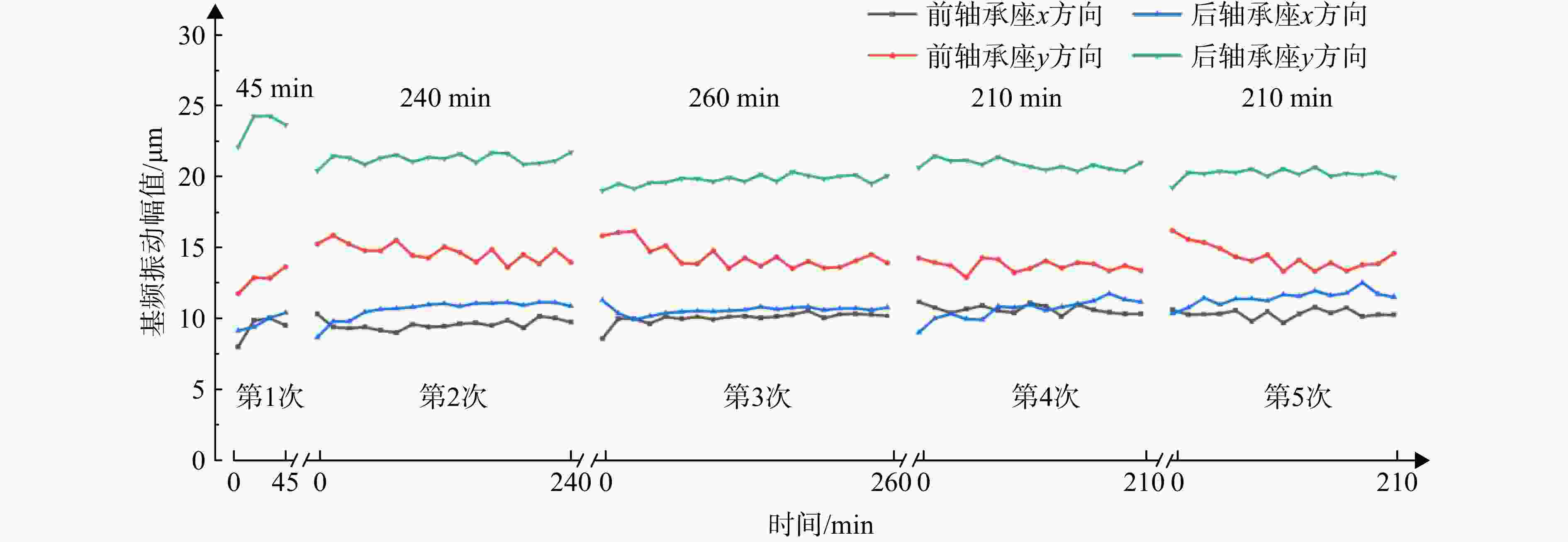

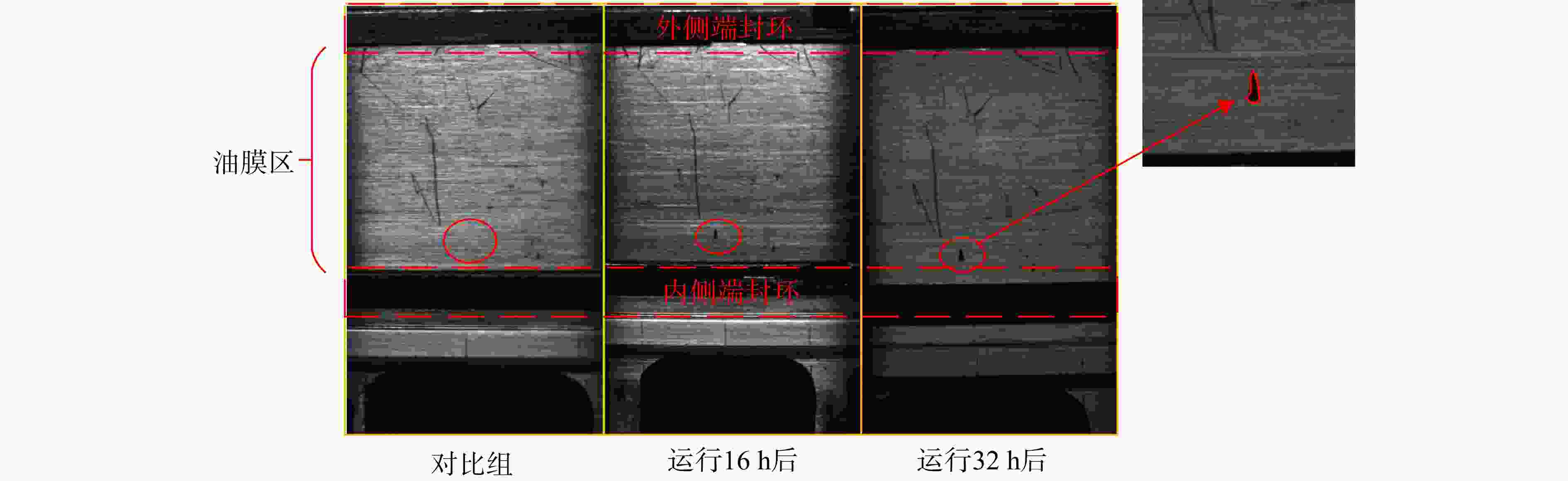

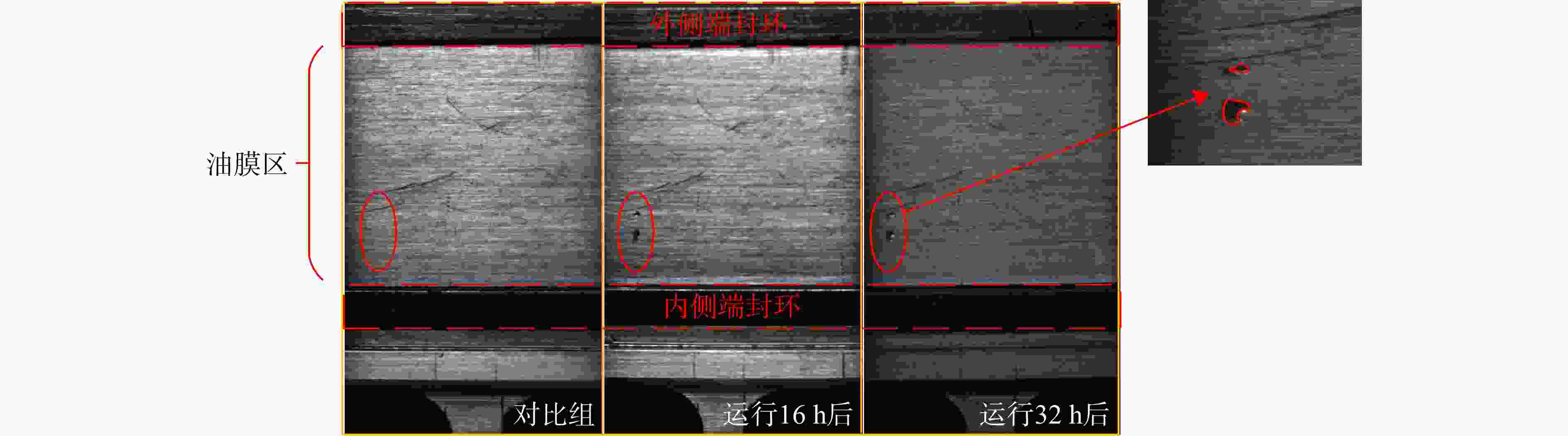

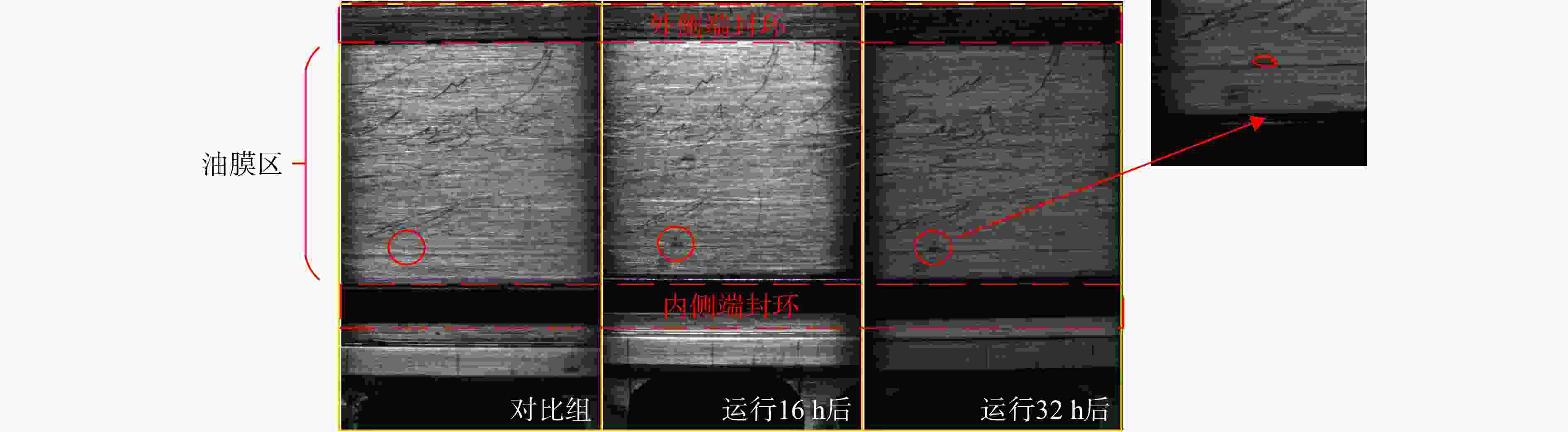

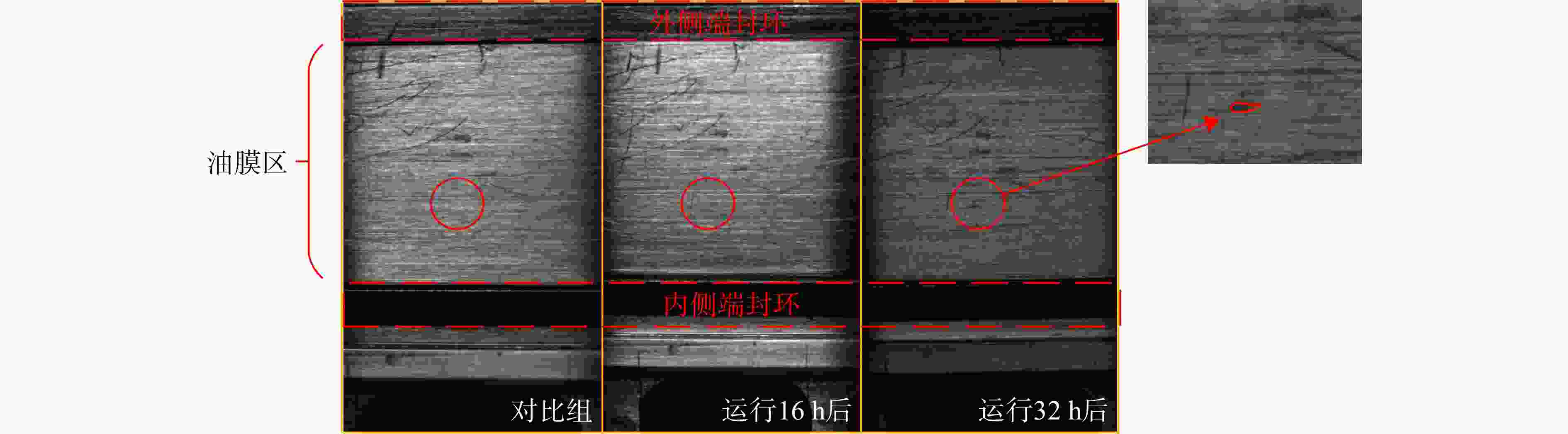

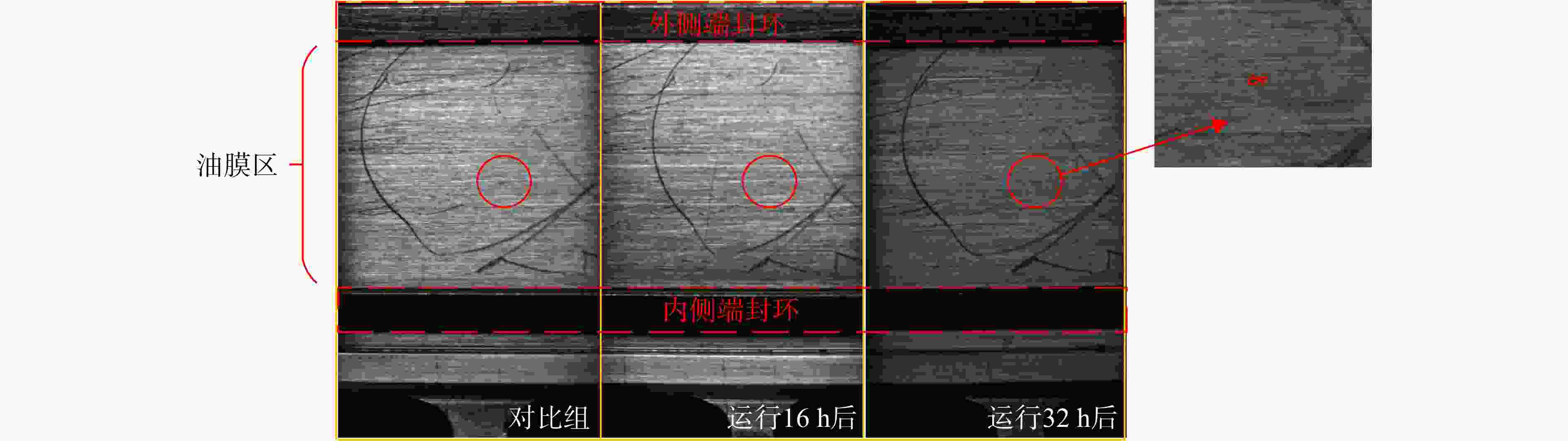

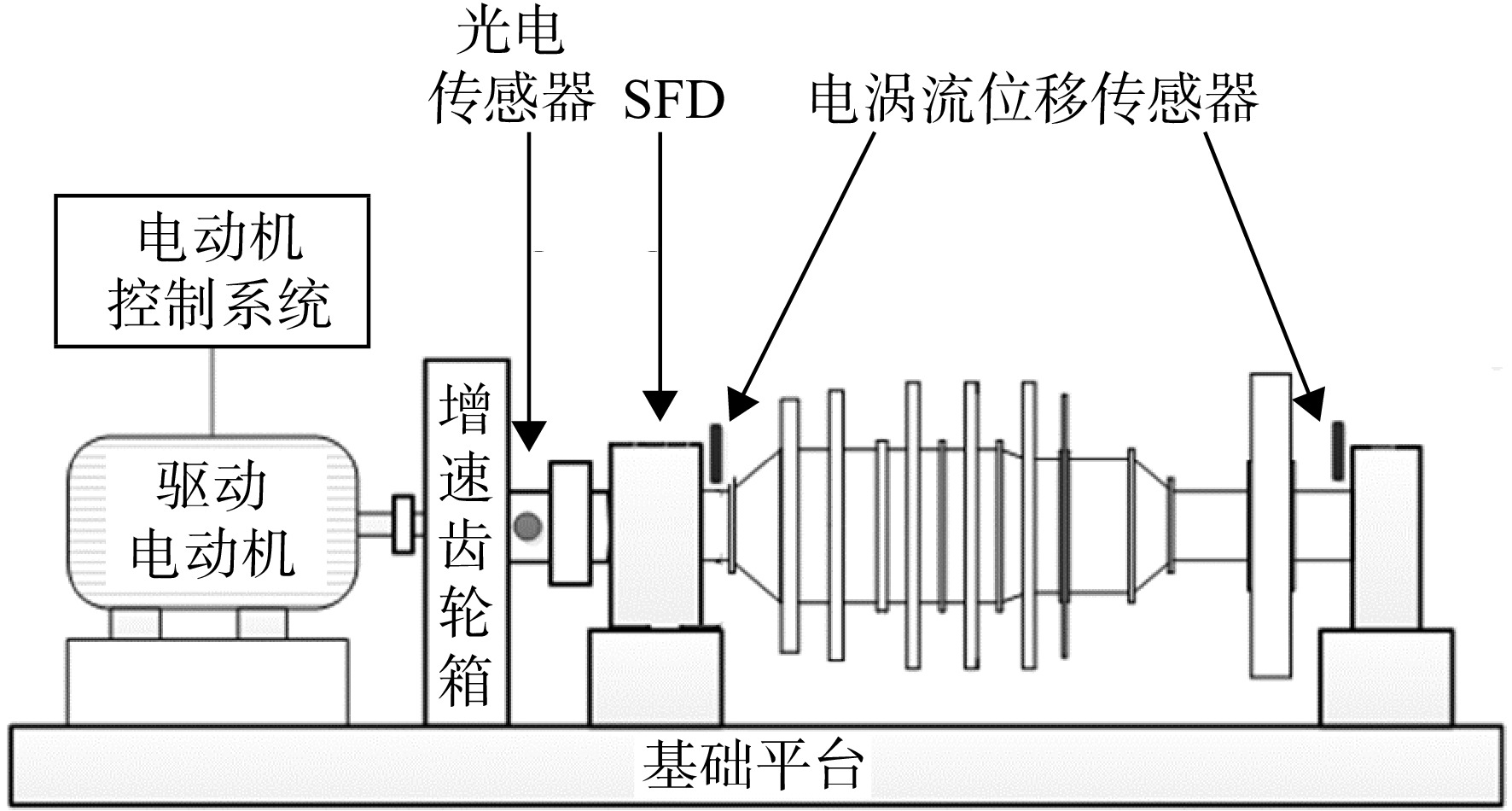

挤压油膜阻尼器(squeeze film damper, SFD)正常工作时避免不了会出现油膜空穴,为了研究SFD长时间运行时转子基频振动变化以及SFD油膜空穴效应对SFD内外环金属表面空化侵蚀情况,基于全尺寸航空发动机高压转子试验台开展了低供油压力(0.02~0.05 MPa)下SFD空穴效应试验研究,考察SFD在临界转速处长时间运行时转子基频振动变化,以及长时间运行后油膜空穴对SFD内外表面形貌的影响,试验结果表明:长时间运行后SFD油膜空穴会对SFD内环表面产生侵蚀作用,形成水滴形、椭圆形以及形状不规则的凹坑群,证明了在临界转速附近考核SFD空穴效应是SFD低供油压力下安全运行必要的试验内容。

Abstract:Oil film cavitation can’t be avoided during normal operation of squeeze film damper (SFD). In order to study the change of rotor fundamental frequency vibration during long-term operation of SFD and the erosion of SFD oil film cavitation effect on the metal surface of inner and outer rings of SFD, experimental study of SFD cavitation effect under low oil supply pressure (0.02—0.05 Mpa) was carried out based on a full-scale aeroengine high-pressure rotor test rig to investigate the change of rotor fundamental frequency vibration during long-term operation of SFD at critical speed, and the effect of oil film cavitation on the internal and external surface morphology of SFD after long-time operation. The experiment results showed that the SFD oil film cavitation could erode the surface of the inner ring of SFD after long-time operation, forming water drop, oval and irregular pit groups, proving that assessing the SFD cavitation effect near the critical speed is a necessary experiment content for the operation safety of SFD under low oil supply pressure.

-

Key words:

- squeeze film damper /

- low oil supply pressure /

- critical speed /

- cavitation erosion /

- surface morphology

-

表 1 工业相机详细参数

Table 1. Detailed parameters of industrial camera

参数 数值及说明 品牌 BASLER 型号 acA2440-75 μm 像素位深/位 12 感光芯片供应商 Sony 感光芯片 IMX250 分辨率/106像素 5 水平/垂直像素尺寸 3.45 μm×3.45 μm 感光芯片尺寸 8.4 mm×7.1 mm 表 2 表面损伤情况汇总

Table 2. Summary of surface damage

区域编号 对比组 运行

16 h后运行

32 h后最终凹坑

深度/mm9~10 × √ √ 0.8 12~13 × √ √ 0.2 18 × √ √ 1 27~28 × √ √ 0.1 29~30 × × √ <0.1 34 × × √ 0.2 注:表中×代表无凹坑,√代表有凹坑。SFD外环经过对比发现油膜区域损伤不严重,第1轮试验后仅发现一处较为明显的凹坑,第2轮试验后没有新增凹坑,最终凹坑深度远远小于0.1 mm。 表 3 评估空气是否进入SFD所需必要参数

Table 3. Necessary parameters to evaluate whether air enters SFD

参数 数值 转子工作时的滑油流量$ {Q_{{\mathrm{oil}}}} $ 36 L/h(0.01 L/s) SFD直径D/mm 235 油膜区长度L/mm 25 转子涡动半径$ e $/mm 0.015~0.02 转子工作转速$ \varOmega $/(r/min) 1891 -

[1] KU C P,TICHY J A. An experimental and theoretical study of cavitation in a finite submerged squeeze film damper[J]. Journal of Tribology,1990,112(4): 725-732. doi: 10.1115/1.2920321 [2] DIAZ S E,SAN ANDRES L A. Measurements of pressure in a squeeze film damper with an air/oil bubbly mixture[J]. Tribology Transactions,1998,41(2): 282-288. doi: 10.1080/10402009808983749 [3] ZEIDAN F Y,VANCE J M. Cavitation leading to a two phase fluid in a squeeze film damper[J]. Tribology Transactions,1989,32(1): 100-104. doi: 10.1080/10402008908981868 [4] WANG Zhenlin,ZHANG Guanghui,WEN Jianquan,et al. Numerical modeling of the flow in the squeeze film dampers with oil feed groove by computational fluid dynamic analysis[J]. Proceedings of the Institution of Mechanical Engineers,Part J: Journal of Engineering Tribology,2017,231(6): 693-707. [5] SAN ANDRÉS L,DELGADO A. Identification of force coefficients in a squeeze film damper with a mechanical end seal—centered circular orbit tests[J]. Journal of Tribology,2007,129(3): 660-668. doi: 10.1115/1.2736708 [6] LAURENTIU M. A brief discussion regarding types of cavitation in squeeze film dampers and cavitation effects[J]. INCAS BULLETIN,2017,9(1): 71-76. doi: 10.13111/2066-8201.2017.9.1.7 [7] FAN Tieshu,HAMZEHLOUIA S,BEHDINAN K. The effect of lubricant inertia on fluid cavitation for high-speed squeeze film dampers[J]. Journal of Vibroengineering,2017,19(8): 6122-6134. doi: 10.21595/jve.2017.19314 [8] 崔颖,李婷,江齐,等. 基于两相流模型的挤压油膜阻尼器空化流场特性数值模拟[J]. 航空动力学报,2019,34(8): 1781-1787. CUI Ying,LI Ting,JIANG Qi,et al. Numerical simulation on cavitation flow field characteristics of squeeze film damper based on two-phase flow model[J]. Journal of Aerospace Power,2019,34(8): 1781-1787. (in Chinese CUI Ying, LI Ting, JIANG Qi, et al . Numerical simulation on cavitation flow field characteristics of squeeze film damper based on two-phase flow model[J]. Journal of Aerospace Power,2019 ,34 (8 ):1781 -1787 . (in Chinese)[9] YAN W,LI X,LI Y. CFD simulation of air ingestion in a squeeze film damper: GT2019-91285 [R]. Phoenix,US: ASME ,2019. [10] IACOBELLIS V,BEHDINAN K,CHAN D,et al. Effect of hole feed system on the response of a squeeze film damper supported rotor[J]. Tribology International,2020,151: 106450. doi: 10.1016/j.triboint.2020.106450 [11] TUL’CHINSKII G A,PANKRATOV G A. Experience of on-site investigations of the cavitation erosion of hydraulic turbines[J]. Hydrotechnical Construction,1988,22(2): 120-123. doi: 10.1007/BF01428977 [12] OKADA T,IWAI Y,AWAZU K. A study of cavitation bubble collapse pressures and erosion part 1: a method for measurement of collapse pressures[J]. Wear,1989,133(2): 219-232. doi: 10.1016/0043-1648(89)90037-9 [13] CHEN Haosheng,LI Jiang,CHEN Darong,et al. Damages on steel surface at the incubation stage of the vibration cavitation erosion in water[J]. Wear,2008,265(5/6): 692-698. [14] OKA Y I,HAYASHI H. Evaluation of erosion resistance for metal–ceramic composites and cermets using a water-jet testing apparatus[J]. Wear,2011,271(9/10): 1397-1403. [15] KAZAMA T,KUMAGAI K,OSAFUNE Y,et al. Erosion of grooved surfaces by cavitating jet with hydraulic oil[J]. Journal of Flow Control,Measurement & Visualization,2015,3(2): 41-50. [16] DULAR M,PETKOVŠEK M. On the mechanisms of cavitation erosion–coupling high speed videos to damage patterns[J]. Experimental Thermal and Fluid Science,2015,68: 359-370. doi: 10.1016/j.expthermflusci.2015.06.001 [17] ROMANOV A,EVDOKIMOV S,SELIVERSTOV V. Cavitation research results of hydroturbine impeller blades and their analysis[J]. MATEC Web of Conferences,2018,196: 02006. doi: 10.1051/matecconf/201819602006 [18] ABOUEL-KASEM A,OSMAN O O,KARRAB S A,et al. The limited role of pit formed by microjet in evolution of cavitation erosion in the incubation period[J]. Journal of Tribology,2022,144(4): 041702. doi: 10.1115/1.4051653 [19] ZAKRZEWSKA D E,BUSZKO M H,KRELLA A K,et al. Damage development on the surface of nickel coating in the initial period of erosion[J]. Materials,2021,14(11): 3123.1-3123.14. doi: 10.3390/ma14113123 [20] ZEIDAN F,VANCE J. Cavitation and air entrainment effects on the response of squeeze film supported rotors[J]. Journal of Tribology,1990,112(2): 347-353. doi: 10.1115/1.2920263 [21] DIAZ S,SAN ANDRE´S L. A model for squeeze film dampers operating with air entrainment and validation with experiments[J]. Journal of Tribology,2001,123(1): 125-133. doi: 10.1115/1.1330742 [22] 张微,王浩洁,丁千,等. 极低压下两相流挤压油膜阻尼器油膜参数特性[J]. 航空动力学报,2020,35(3): 560-568. ZHANG Wei,WANG Haojie,DING Qian,et al. Oil film characteristic of two-phase flow squeeze film damper under extremely low oil supply pressure[J]. Journal of Aerospace Power,2020,35(3): 560-568. (in Chinese ZHANG Wei, WANG Haojie, DING Qian, et al . Oil film characteristic of two-phase flow squeeze film damper under extremely low oil supply pressure[J]. Journal of Aerospace Power,2020 ,35 (3 ):560 -568 . (in Chinese) -

下载:

下载: